Spraying-free polyolefin composition with special aesthetic effect and a preparation method and application thereof

A special effect powder and polyolefin technology, applied in the field of polymer materials, can solve the problems of uneven distribution of special effect powder, unstable flow rate, poor compatibility, etc. compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

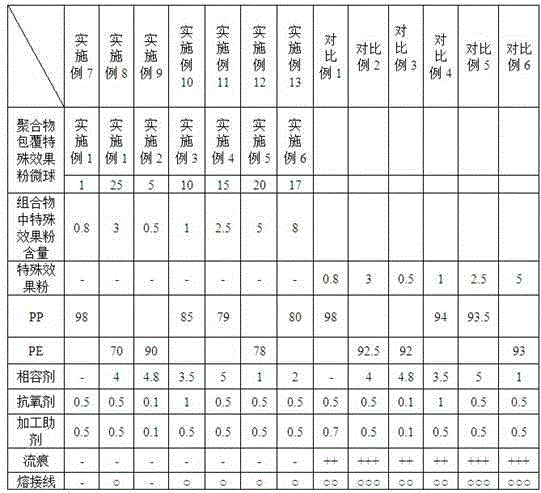

Examples

Embodiment 1-6

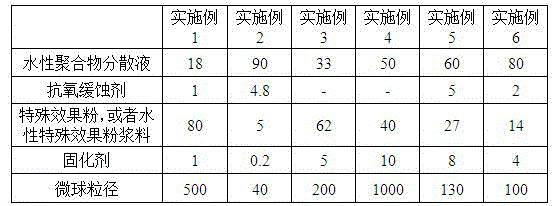

[0045] Example 1-6 Preparation of polymer-coated special effect powder microspheres:

[0046]According to the formula in Table 1, firstly, add anti-oxidation and corrosion inhibitor to the water-based polymer dispersion at room temperature, stir and disperse for 15 minutes to obtain a dispersion; while stirring, slowly add special effect powder, or water-based Special effect powder slurry, then add curing agent while stirring, and continue to stir for 30-120 minutes, so that the special effect powder is fully dispersed and covered by the dispersion liquid, and finally a composite dispersion liquid of polymer-coated special effect powder is obtained; The composite dispersion liquid is spray-dried to obtain polymer-coated special-effect powder microspheres. The temperature of the air inlet during the spray-drying process is 150-300° C., and the temperature of the air outlet is 50-130° C.

Embodiment 1

[0049] In embodiment 1: the aqueous polymer dispersion liquid is modified ethylene-vinyl acetate emulsion, and its solid content is 10wt%; Metal powder is the flake aluminum powder through surface treatment, and the content of Al element in the aluminum powder is 60wt%, Contains Zn and Sn at the same time; its particle size is 100μm; the anti-oxidation and corrosion inhibitor is pyrogallic acid; the curing agent is polyisocyanate.

Embodiment 2

[0050] In embodiment 2: aqueous polymer dispersion liquid is modified ethylene-vinyl acetate emulsion, and its solid content is 30wt%; Metal powder is the flaky copper powder through surface treatment, and the content of Cu element is 70wt% in the copper powder, Contains Zn and Sn at the same time; its particle size is 5μm; the anti-oxidation and corrosion inhibitor is benzotriazole; the curing agent is polycarbodiimide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com