Manufacturing method of metalline shell and shell manufactured by same

A technology of metal texture and production method, which can be used in chemical instruments and methods, lamination auxiliary operations, electrical equipment shells/cabinets/drawers, etc., and can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

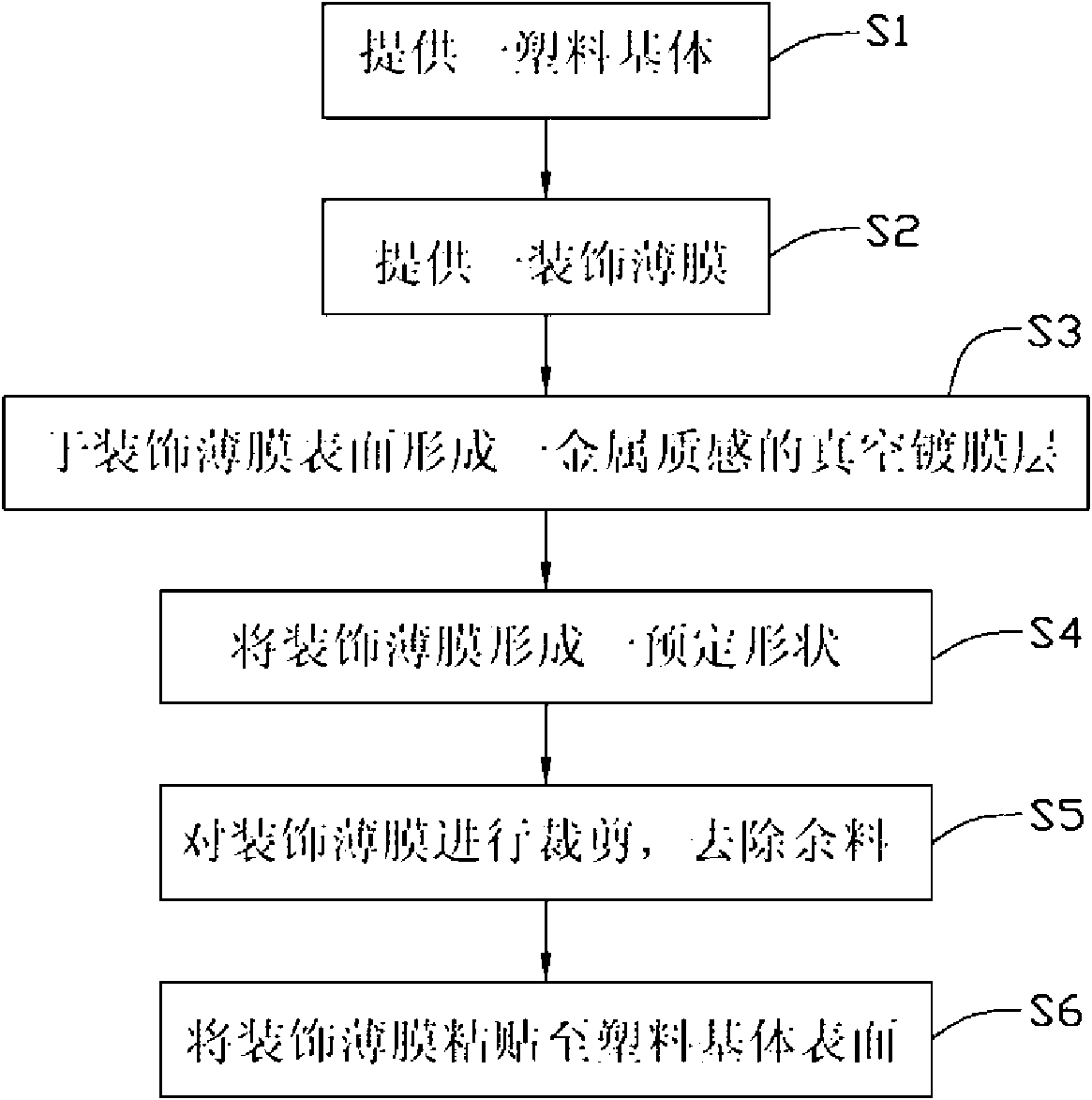

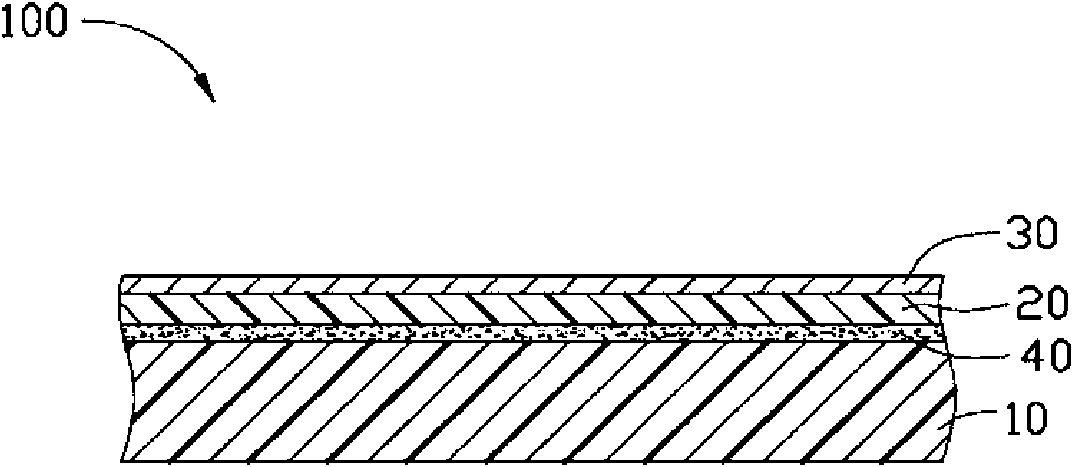

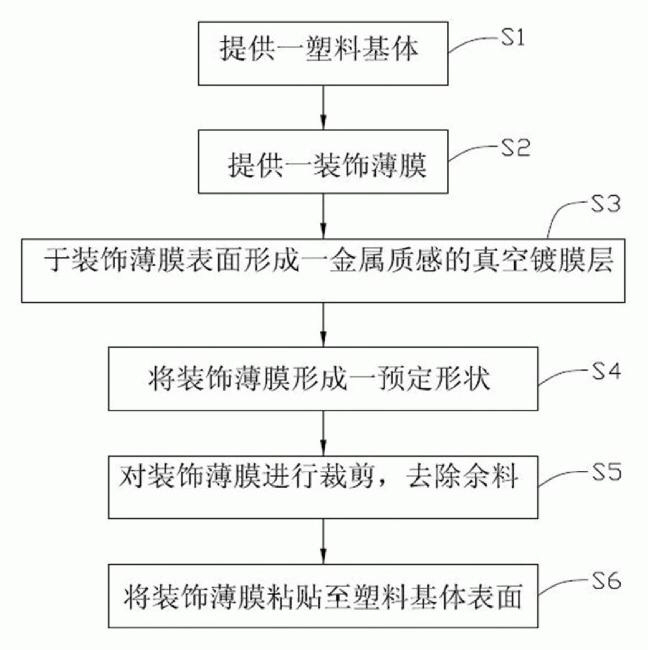

[0017] see figure 1 and figure 2 , a preferred embodiment of the manufacturing method of the metal shell of the present invention comprises the following steps:

[0018] Step S1: Provide a plastic base 10, which can be formed by injection molding, and the plastic base 10 has the structure of the shell to be manufactured.

[0019] Step S2: providing a decorative film 20 . The material of this decorative film 20 can be plastic, also can be leather, fabric etc., wherein plastic can be selected from polymethyl methacrylate (Polymethyl Methacrylate, PMMA), polyvinyl chloride (Polyvinly Chloride, PVC), polyethylene terephthalic acid One or a combination of vinyl ester (Polyethylene Terephthalate, PET), polycarbonate (Polycarbonate, PC), polyethylene (Polyethylene, PE), etc.

[0020] Step S3: Form a non-conductive coating layer 30 with metallic texture on the surface of the decorative film 20 by vacuum evaporation or sputtering. The material forming the non-conductive coating la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com