Vibration wear-resistant coating and preparation method and spraying process thereof

A wear-resistant paint and primer technology, applied in the field of paint, can solve the problems of paint film peeling performance, instability, poor vibration wear resistance of paint film, etc., to improve vibration wear resistance and durability, simple processing, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

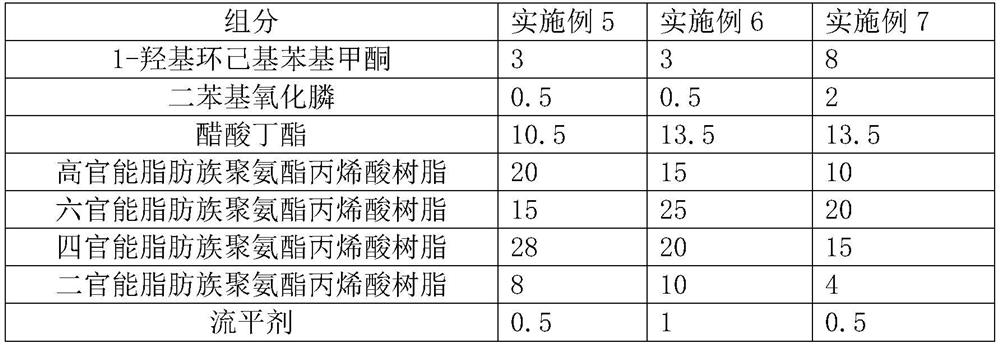

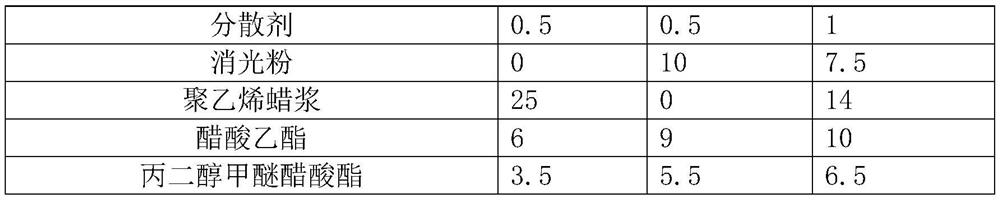

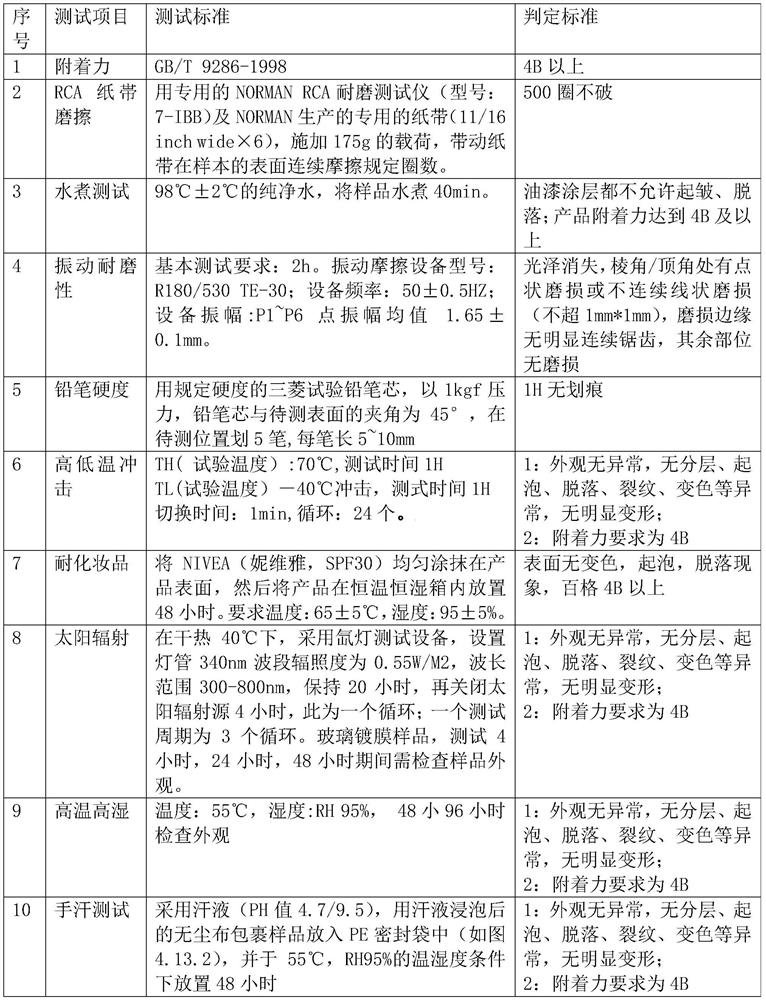

Examples

Embodiment 1

[0039] A preparation method of a special PU type primer for vibration and wear resistance, comprising the following steps:

[0040] Weigh each component according to the weight ratio in Table 1, weigh the solid thermoplastic acrylic resin and 9 / 24 mixed solvent according to the formula, mix and disperse evenly, and obtain the first mixture; mix the hydroxyl acrylic resin, cellulose acetate butyrate and the first The mixture is uniformly dispersed to obtain the second mixture; respectively, the silver powder and the mixed solvent are stirred evenly at a ratio of 1:1, and then soaked for 4 hours to obtain the silver paste of the mixture; under the condition of low-speed stirring, then in the second mixture, add them in sequence according to the mass ratio Adhesion promoter, auxiliary agent, mixed silver paste, mixed solvent, dispersed and stirred evenly. That is, the PU type primer is obtained.

[0041] A spraying process of a special PU type primer for vibration and wear resis...

Embodiment 2

[0044] A preparation method of a special PU type primer for vibration and wear resistance, comprising the following steps:

[0045] Weigh each component according to the weight ratio in Table 1, weigh the solid thermoplastic acrylic resin and 5 / 24 mixed solvent according to the formula, mix and disperse evenly, and obtain the first mixture; mix the hydroxyl acrylic resin, cellulose acetate butyrate and the first The mixture is uniformly dispersed to obtain the second mixture; the nano-color paste and the mixed solvent are stirred evenly at a ratio of 1:1, and filtered through 300 mesh to obtain the mixture nano-color paste; under low-speed stirring conditions, then in the second mixture, by mass Then add adhesion promoter, auxiliary agent, mixture nano-color paste, and mixed solvent in sequence, disperse and stir evenly, and obtain the PU-type primer.

[0046] A spraying process of a special PU type primer for vibration and wear resistance, comprising the following steps:

[...

Embodiment 3

[0049] A preparation method of a special PU type primer for vibration and wear resistance, comprising the following steps:

[0050] Weigh each component according to the weight ratio in Table 1, weigh the solid thermoplastic acrylic resin and solvent according to the formula, mix and disperse evenly, and obtain the first mixture; , to obtain the second mixture; the nano-color paste and the mixed solvent were stirred evenly at a ratio of 2:1, and filtered through 300 mesh to obtain the mixture nano-color paste; under the condition of low-speed stirring, then in the second mixture, respectively added according to the mass ratio Adhesion promoter, auxiliary agent, mixture of nano-color paste, mixed solvent, dispersed and stirred evenly to obtain the PU-type primer.

[0051] A spraying process of a special PU type primer for vibration and wear resistance, comprising the following steps:

[0052] Before spraying, add HDI curing agent and open oil water to the mixed ink according t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com