Engine camshaft and preparation method thereof

A camshaft and engine technology, which is applied to engine components, machines/engines, mechanical equipment, etc., can solve the problems of single material of engine camshafts, cumbersome manufacturing process and high economic cost, and achieve guaranteed service life, low quality cost, guaranteed the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

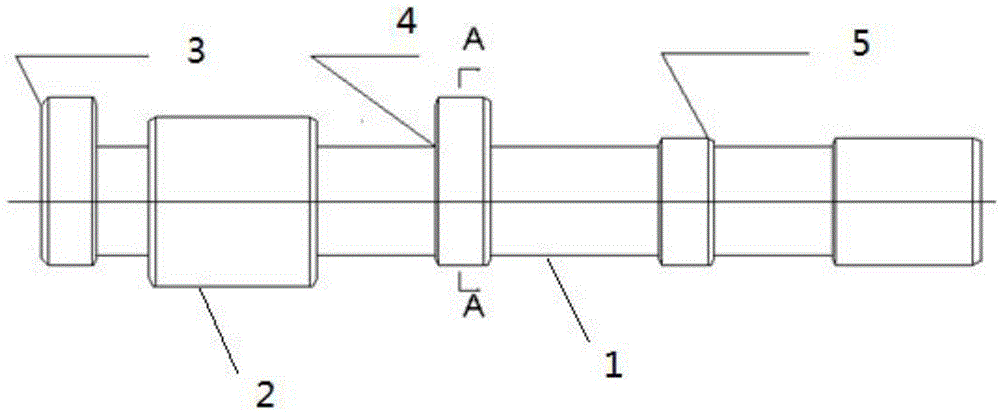

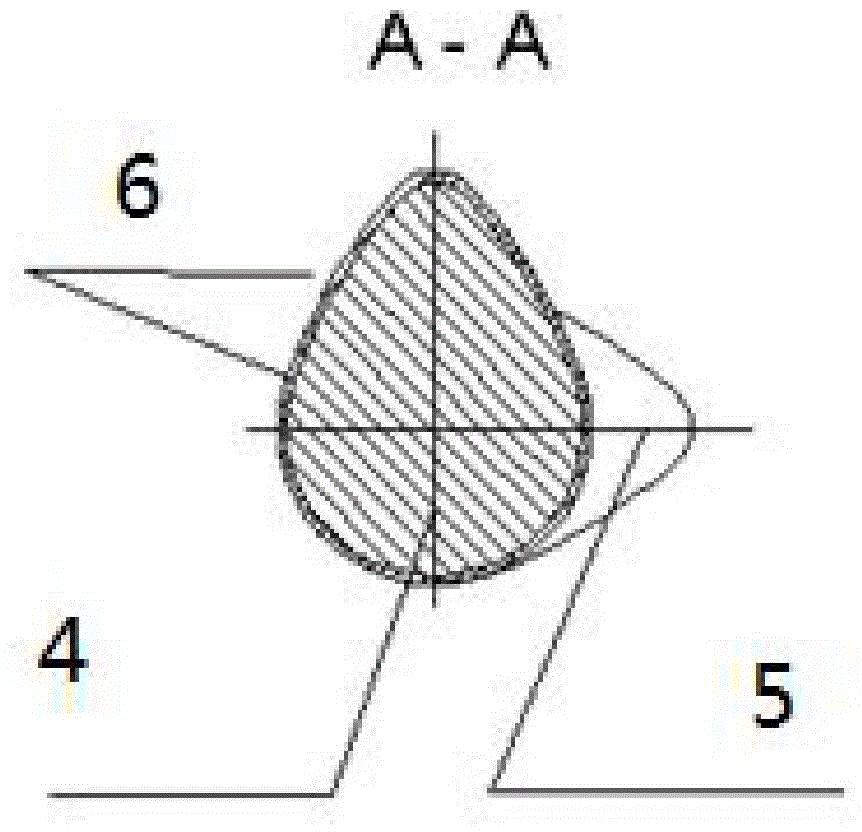

[0032] This embodiment provides an engine camshaft, such as figure 1 and figure 2 As shown, it includes a main shaft 1, a plurality of cams and bearings 2, and a bearing 2 is fixedly installed between each of the cams and at both ends of the main shaft 1 through a bearing fixing plate. The cams include an oil pump cam 3, an air intake The cam 4 and the exhaust cam 5 are fitted and installed on the main shaft 1, wherein each of the cams includes a wear-resistant layer 6, and the wear-resistant layer 6 is made of composite materials.

[0033] Preferably, the composite material of the wear-resistant layer 6 is hard alloy material. The hard alloy material is made of high-hardness tungsten carbide, titanium carbide, etc. as a matrix, and bonded metal cobalt, nickel, etc. by powder metallurgy. There are a large number of carbides in cemented carbide, which has a high melting point, high hardness, and high wear resistance.

[0034] Preferably, the composite material of the wear-r...

Embodiment 2

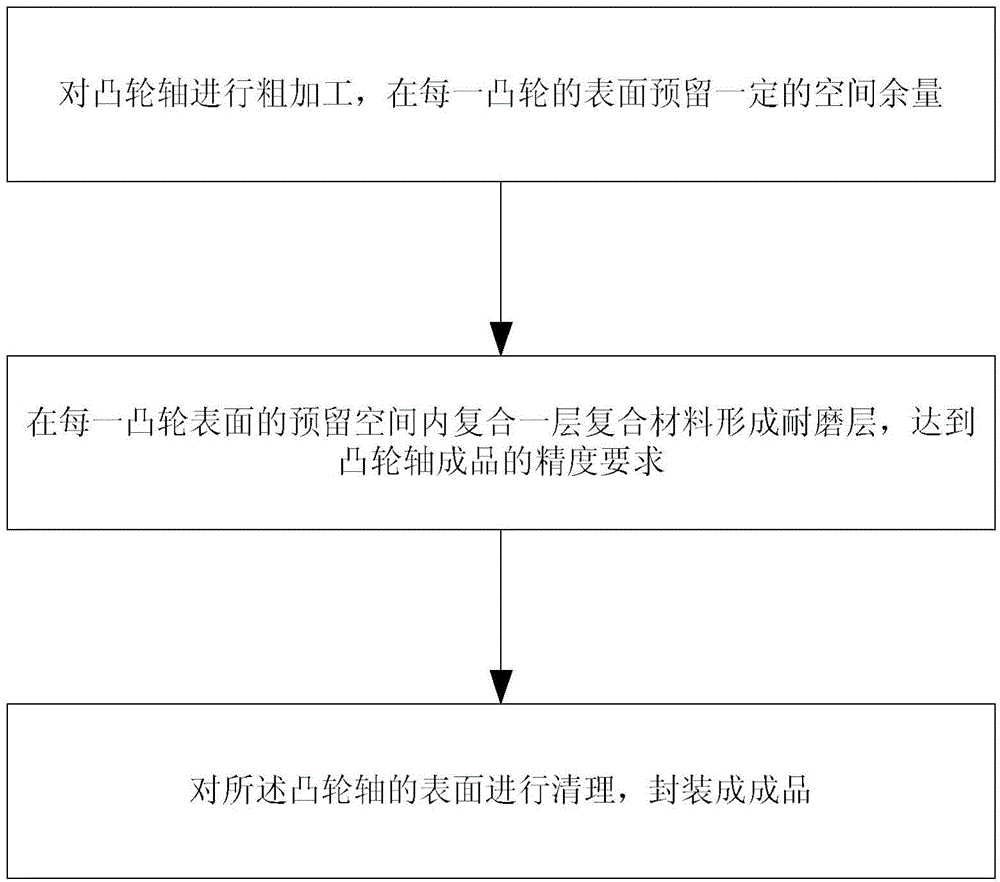

[0039] The present embodiment provides a kind of preparation method of engine camshaft, as image 3 shown, including the following steps:

[0040] S1: Carry out rough machining on the camshaft, and reserve a certain space margin on the surface of each cam;

[0041] S2: Composite a layer of composite material in the reserved space on each cam surface to form a wear-resistant layer to meet the precision requirements of the finished camshaft;

[0042] S3: cleaning the surface of the camshaft and packaging it into a finished product.

[0043] The rough machining of the camshaft in the step S1 is the same as the prior art, mainly including casting / forging blank-milling end face drilling center hole-drilling oil hole, deburring-rough and finish turning journal-rough grinding journal and shoulder -Cleaning the root oil groove, chamfering -finishing the journal, shoulder and end face -milling the keyway and other processes. Through the rough and finish machining of the camshaft, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com