Continuous production line for sizing material

A production line and compound technology, applied in the field of compound continuous production line, can solve the problem of reducing the work intensity of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order for those skilled in the art to better understand the technical solutions provided by the present invention, the following will be described in conjunction with specific embodiments.

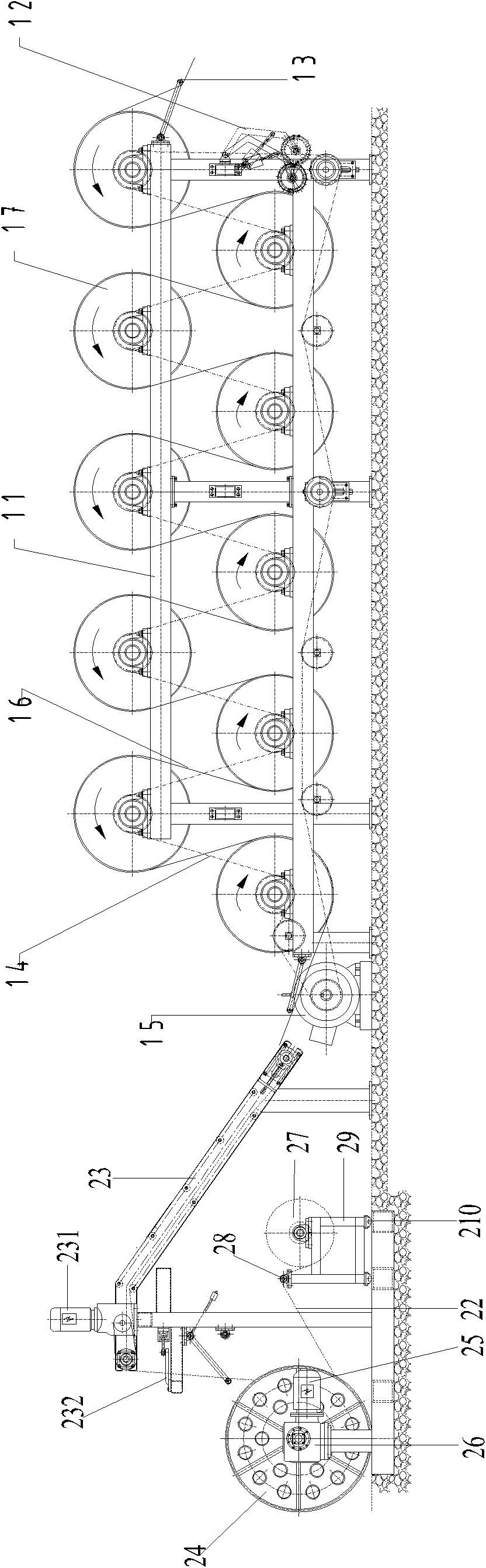

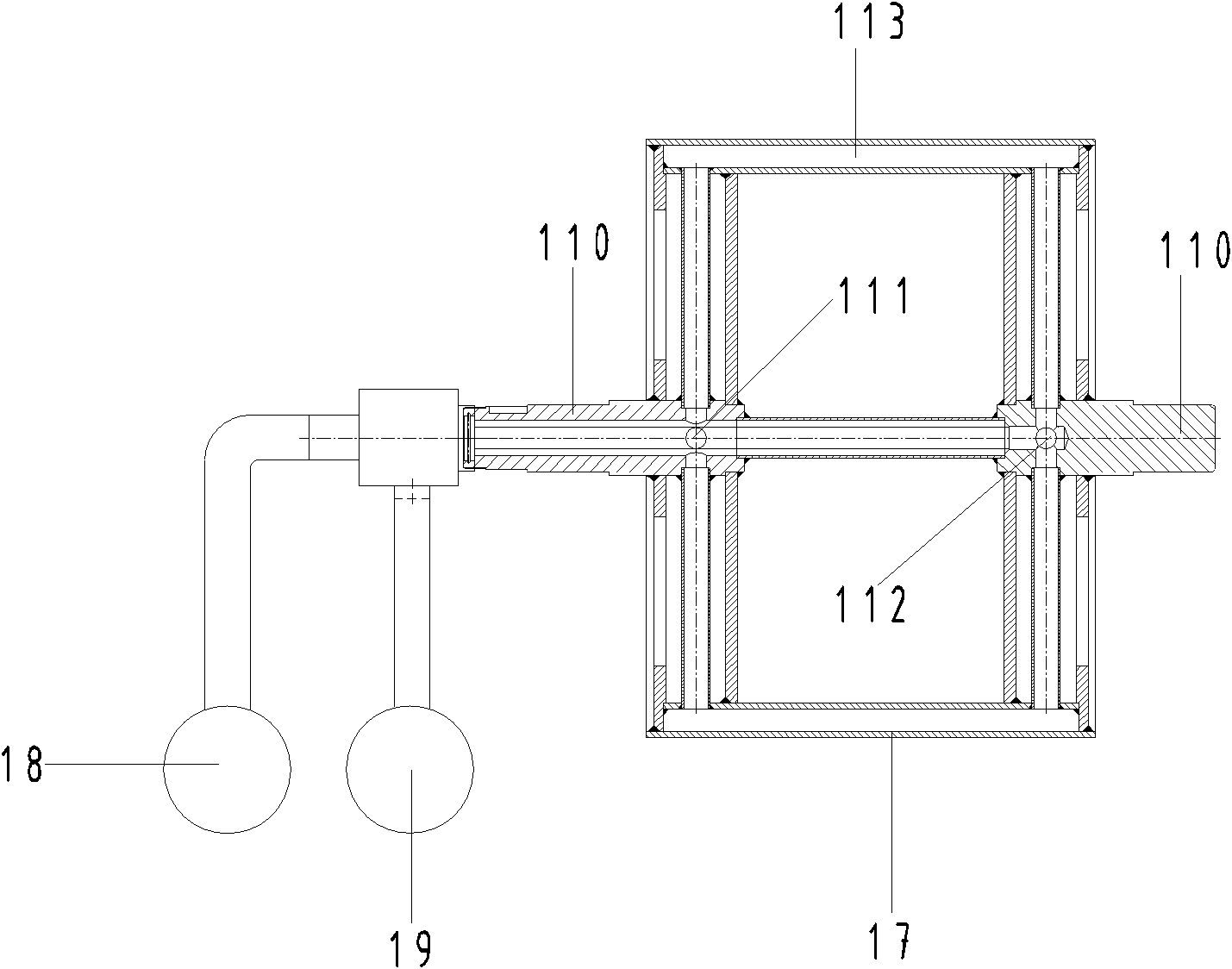

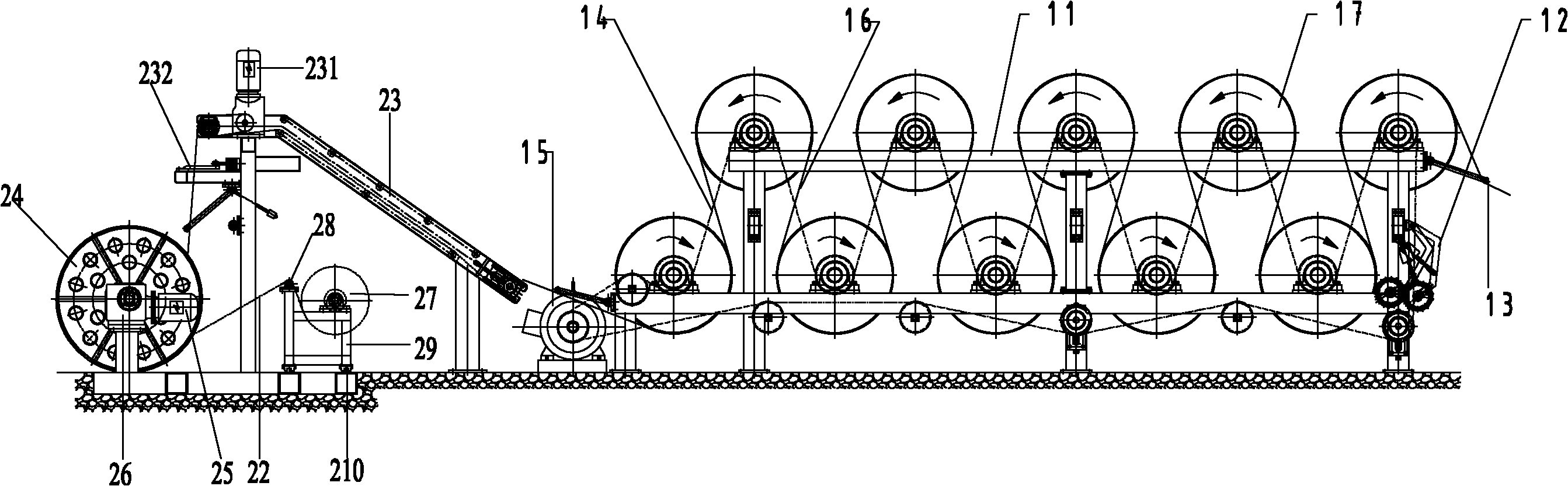

[0016] See figure 1 and figure 2 , figure 1 It is a structural schematic diagram of the film cooling device and the curling device in the continuous production line of the rubber compound of the present invention; figure 2 for figure 1 Schematic diagram of the connection between the middle cooling roll and the water inlet and outlet pipes.

[0017] The continuous production line of the rubber material provided by the invention comprises a rubber cutting machine, a belt scale, a kneader, an open mill, a sheet press machine, a film cooling device and a curling device. After weighting, it is sent to the kneader through the feeding conveyor belt, and the rubber material is kneaded by the kneader and then transported to the open mill through the bucket conveyor. To the tablet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com