Pipeline welding process

A welding process and pipeline technology, applied in welding equipment, manufacturing tools, tubular objects, etc., can solve the problems of slow construction progress, chaotic management, and high personnel turnover, and achieve lower labor costs, lower quality costs, and operability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

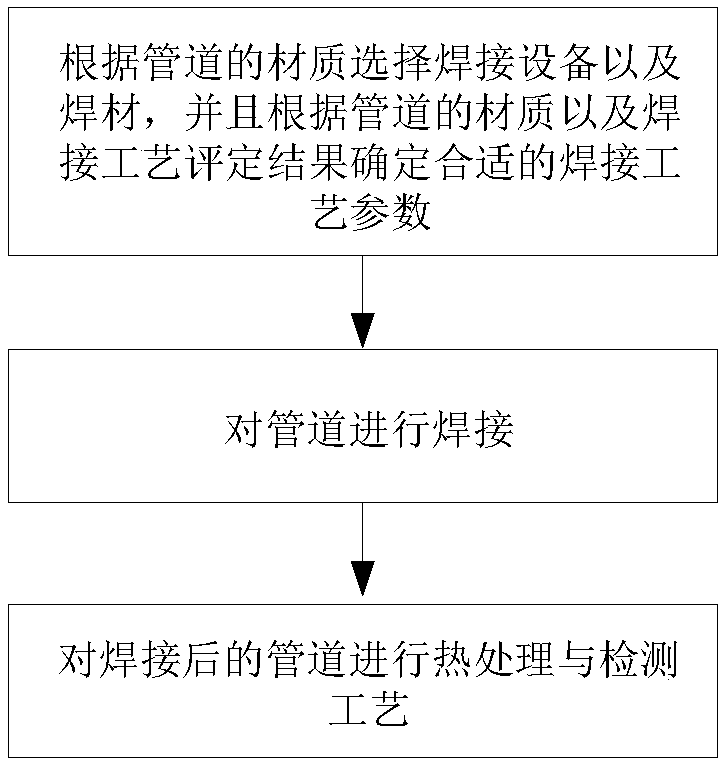

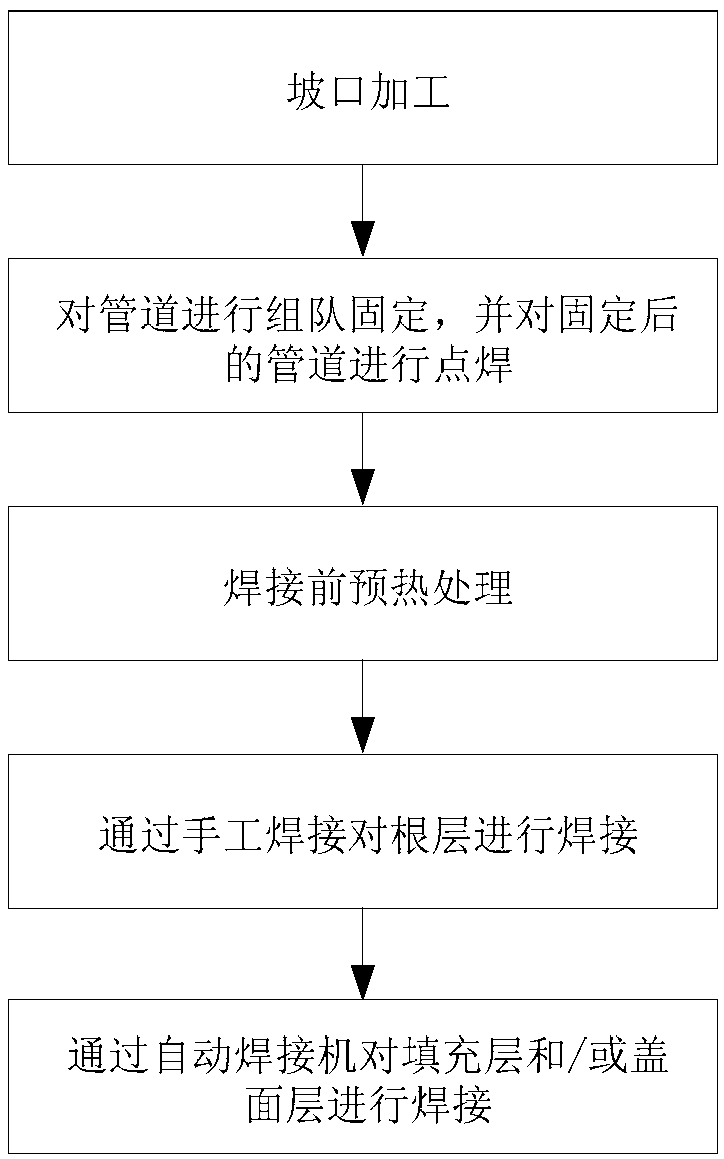

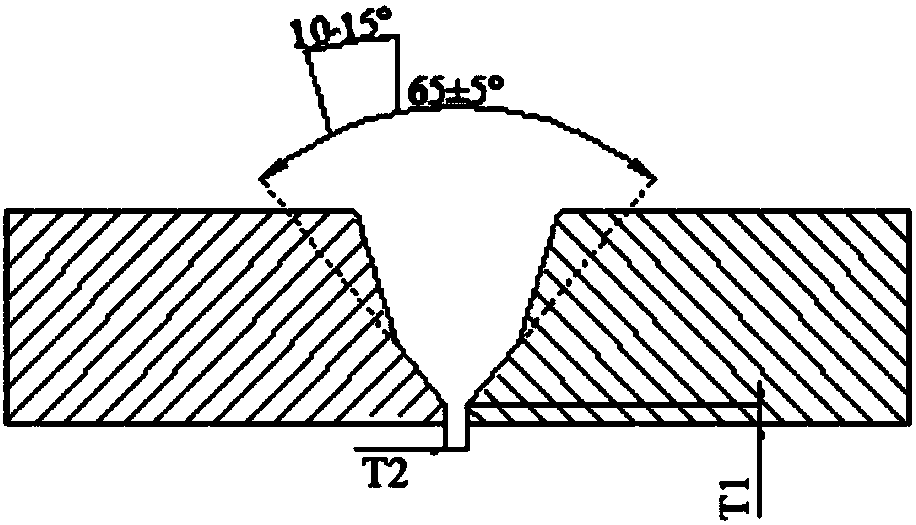

[0023] According to the present invention, a pipeline welding process that can effectively solve the construction quality and speed of large-diameter thick-walled pipelines, ensure the on-site construction quality, construction progress and construction cost, and effectively solve the construction problems of large-diameter thick-walled pipelines is provided. The diameter of said large-diameter pipe is greater than or equal to 500mm. According to an embodiment of the present invention, the pipeline welding process includes: welding the root layer, the filling layer and the cover layer; wherein, the root layer is welded by manual welding, especially by manual argon tungsten arc welding; and Wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com