Novel automatic tolerance adjusting device

An automatic adjustment device and tolerance technology, applied in the direction of hand-held tools, manufacturing tools, etc., can solve the problems of high technical difficulty, low work efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

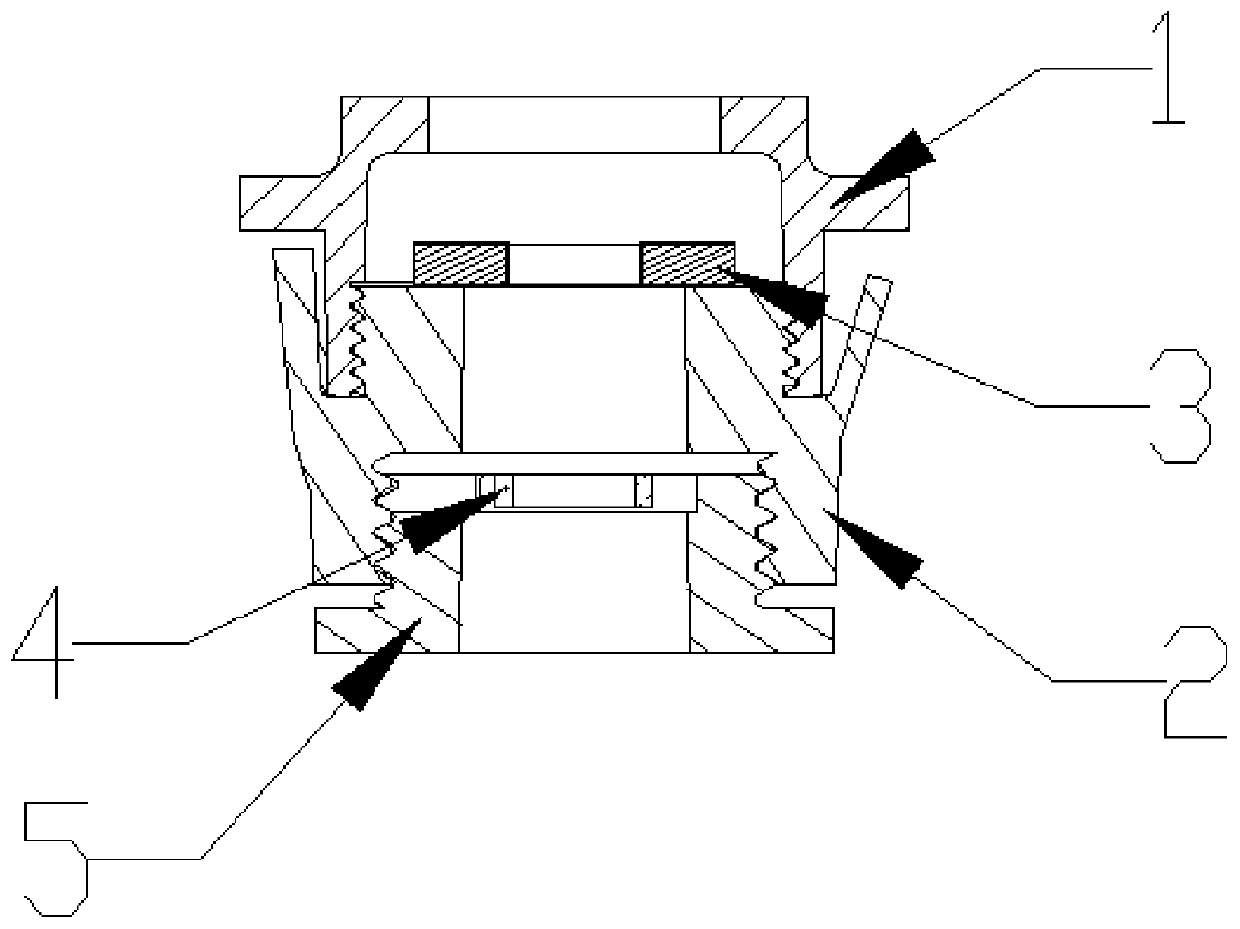

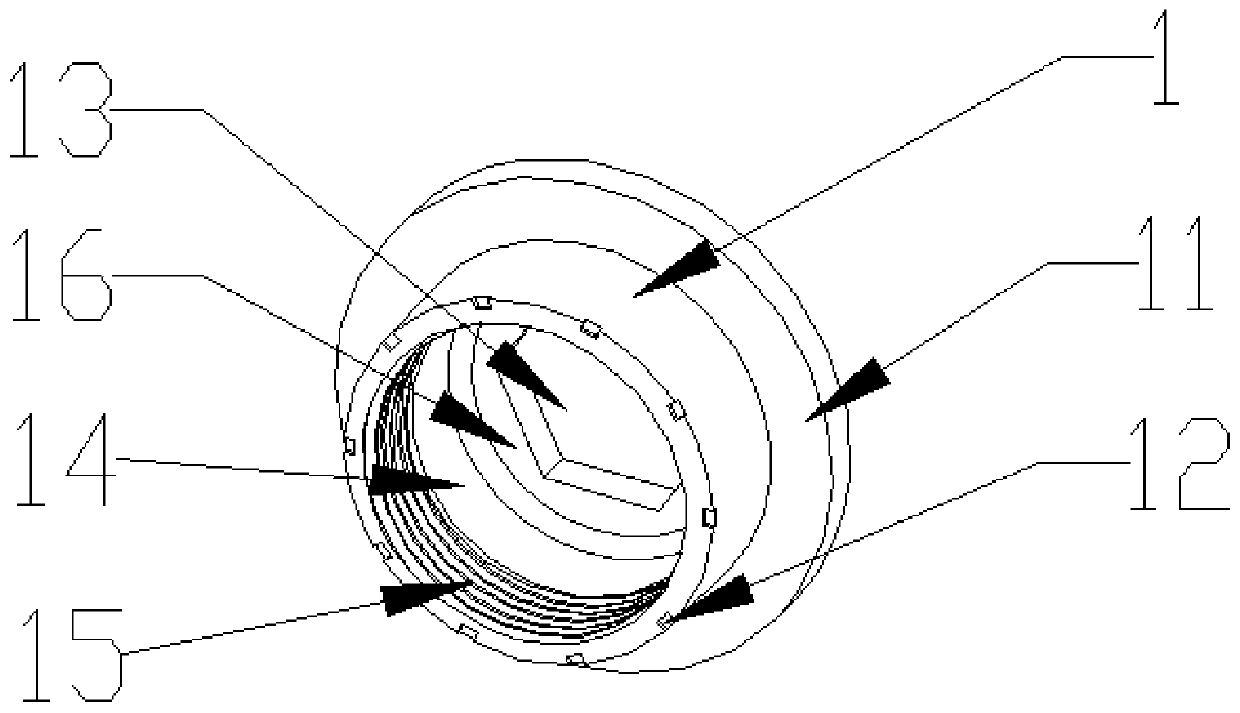

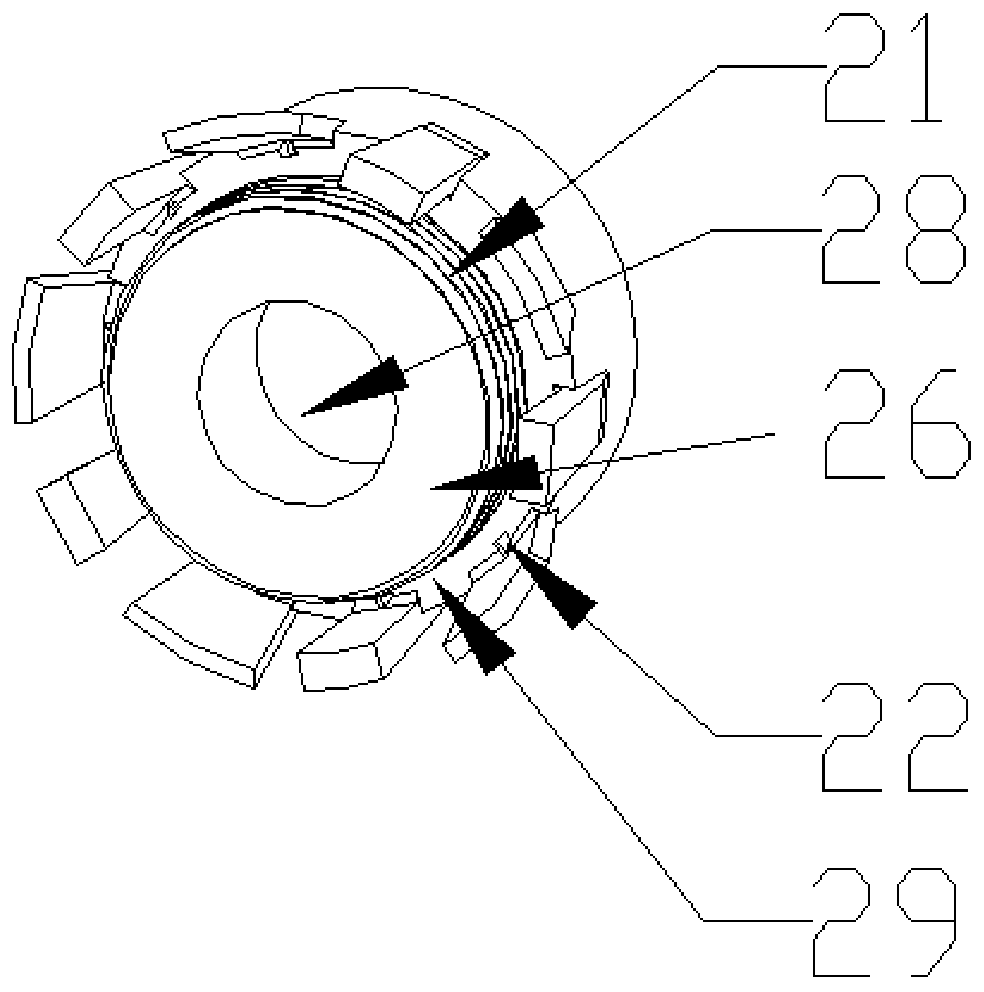

[0045] This embodiment provides a new type of tolerance automatic adjustment device, its structure is detailed in the attached Figure 1-8 As shown: it includes an upper shell 1, a positioning stud 2 and a locking washer 3; the upper shell 1 is a hollow cavity structure, and its inner cavity is divided into a mounting hole 13 and a first inner cavity 14 by a baffle plate 16; One end of the positioning stud 2 is provided with a boss 26 that matches the first inner cavity 14, the boss 26 is inserted into the first inner cavity 14, and forms a shaft hole gap with the baffle plate 16; the locking pad The piece 3 is set in the first inner cavity 14 and can move freely in the gap of the shaft hole; it also includes a star piece 4 and an adjusting nut 5, and the upper and lower ends of the positioning stud 2 are threaded with the upper shell 1 and the upper shell 1 respectively. The adjusting nut 5 is connected and fixed, and the other end of the positioning stud 2 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com