Patents

Literature

55results about How to "Improve positioning strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

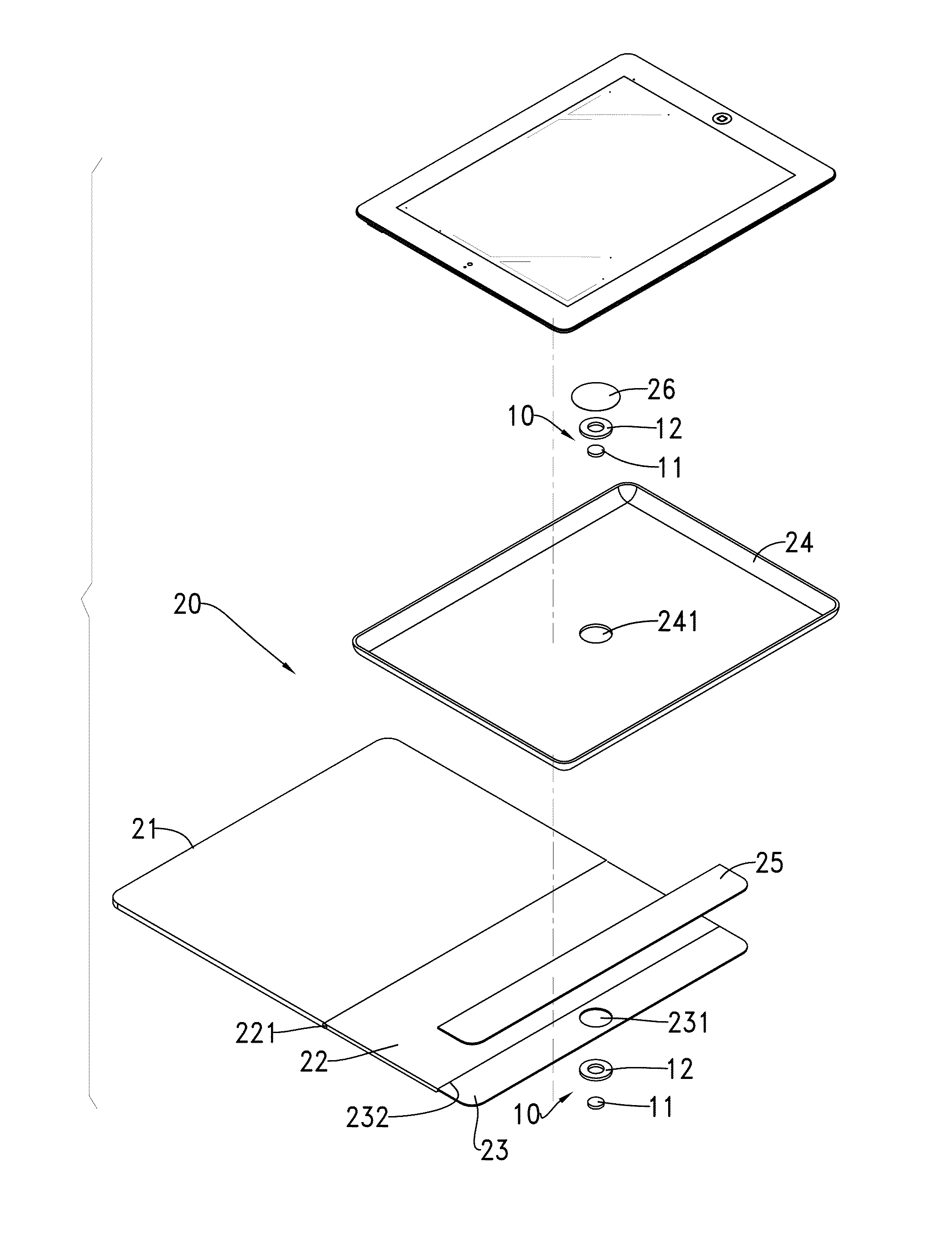

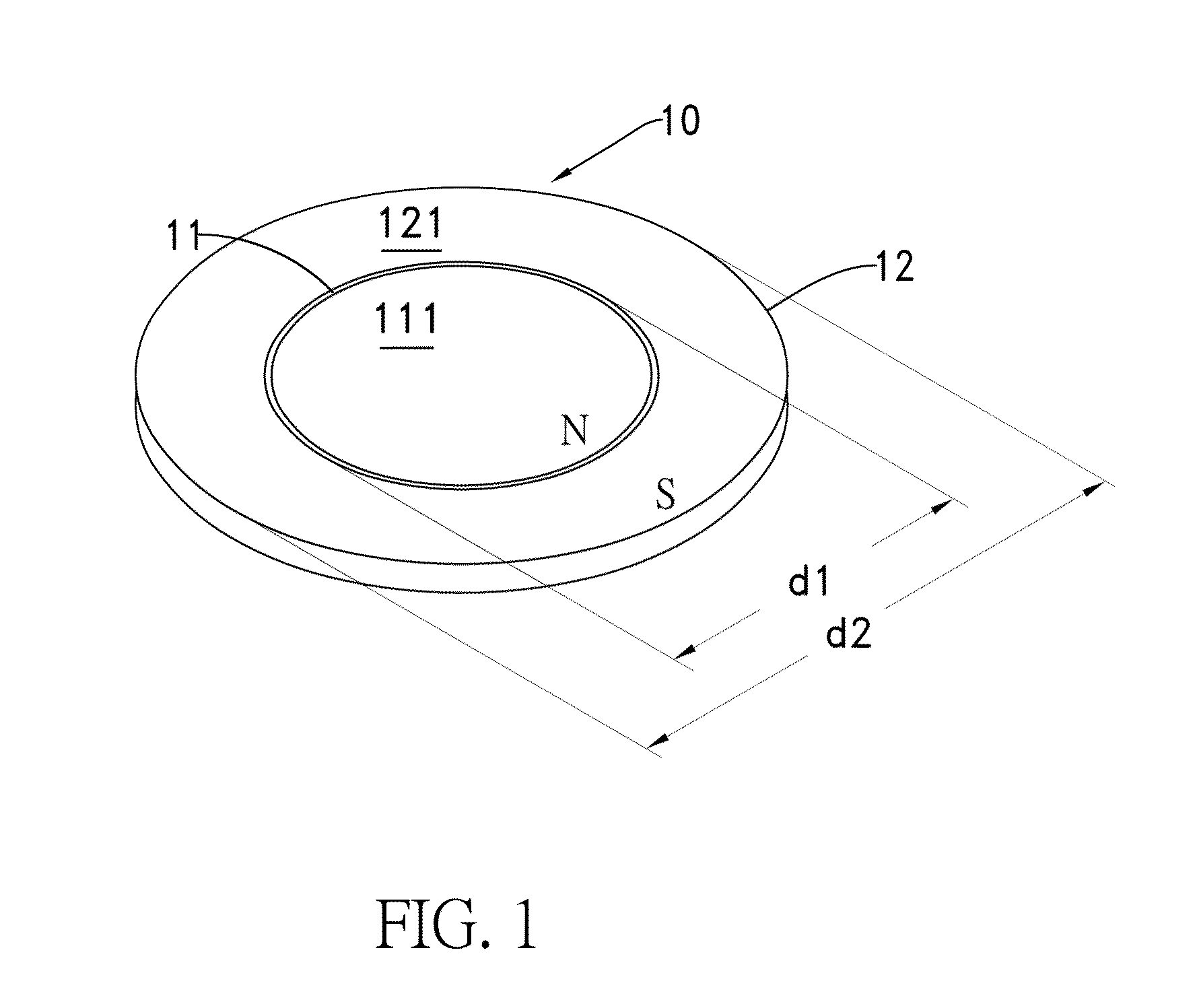

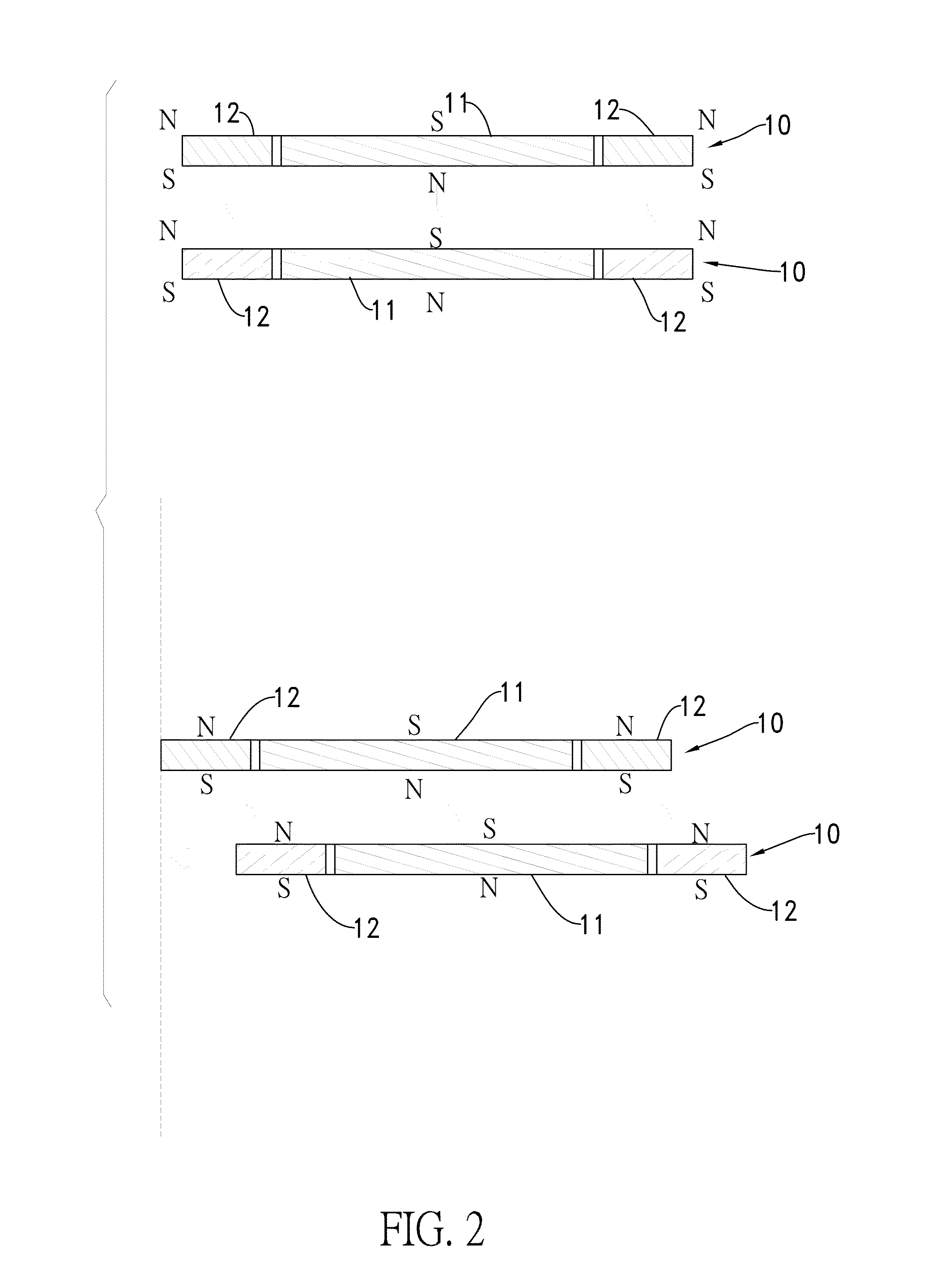

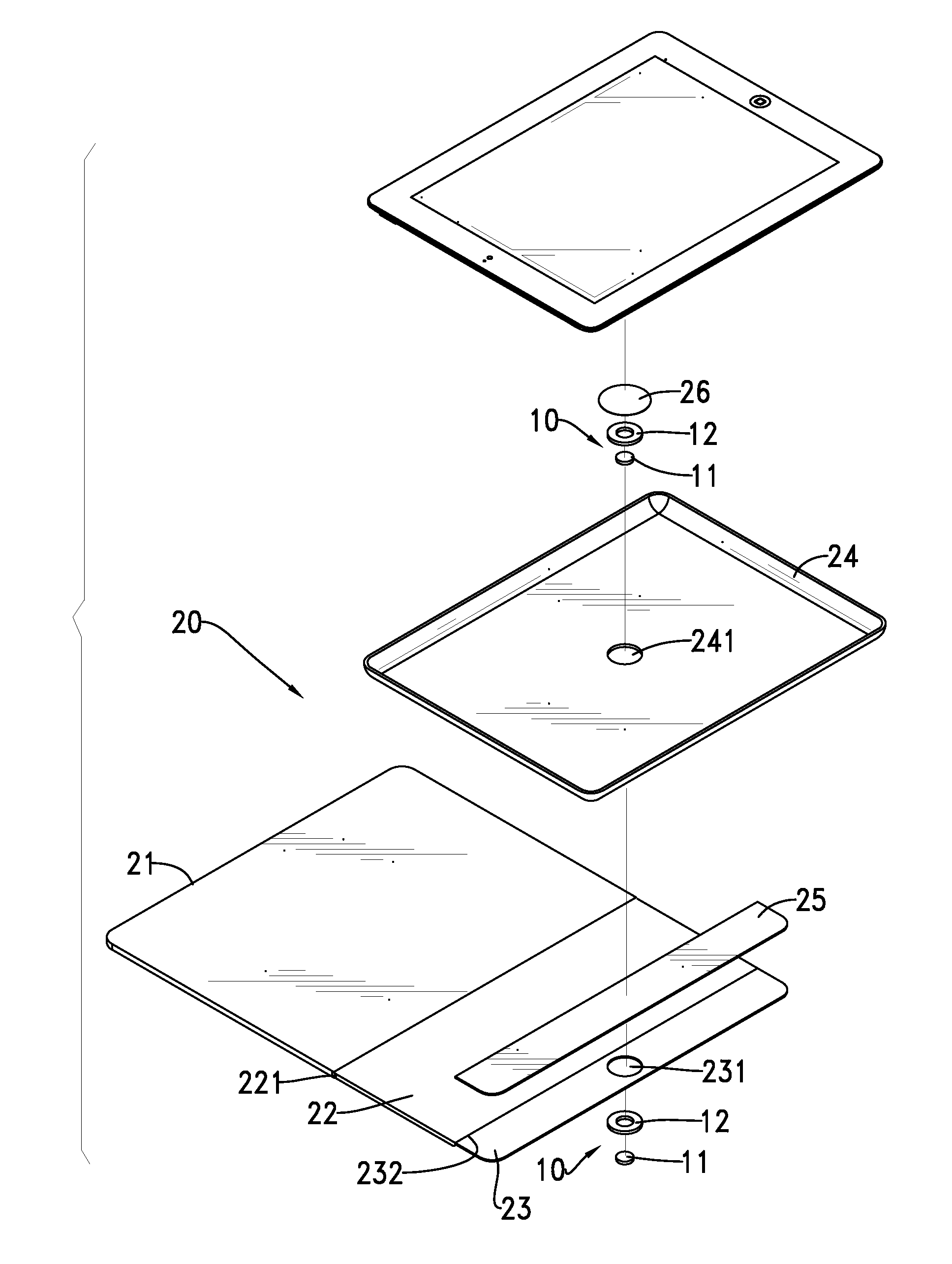

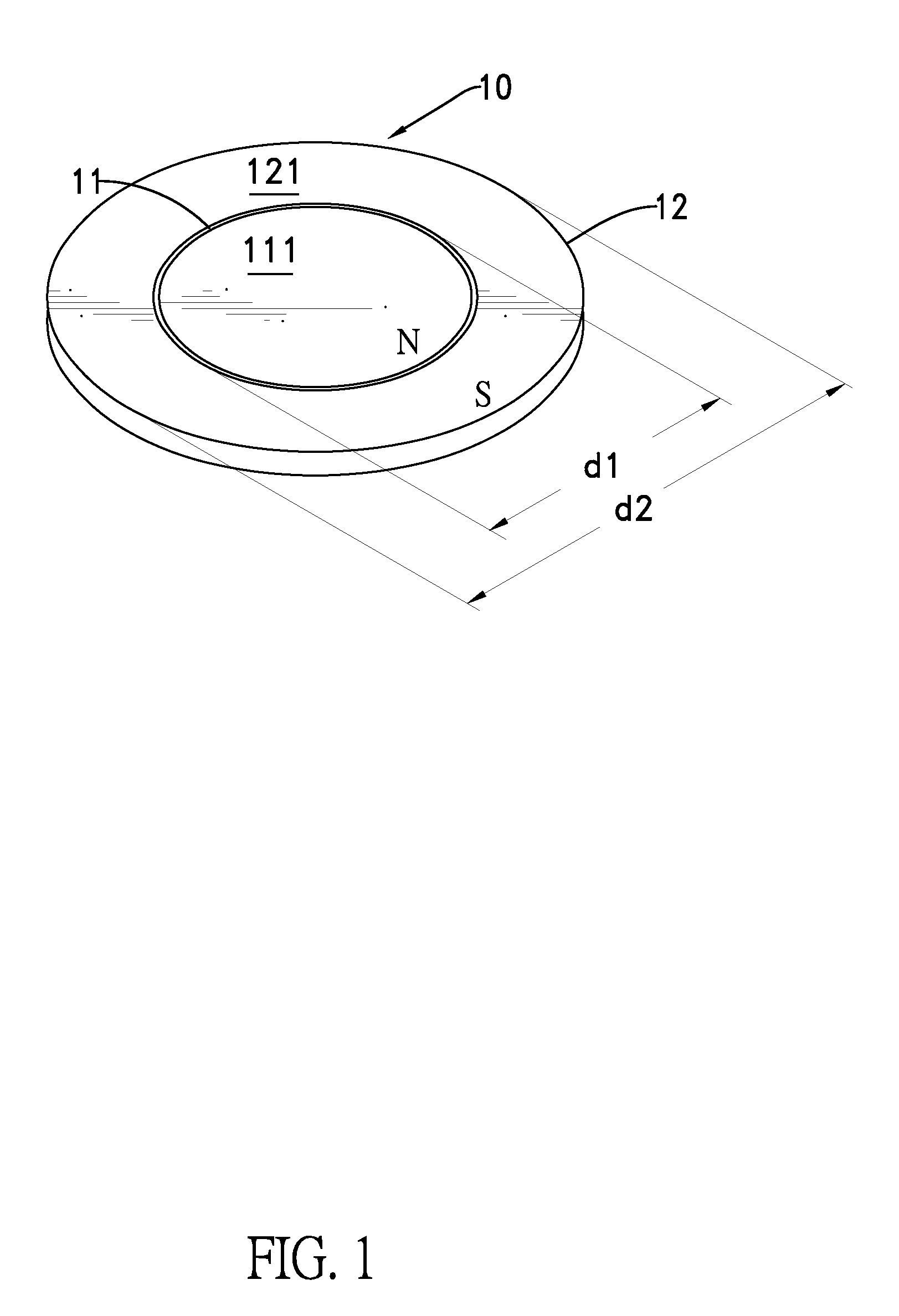

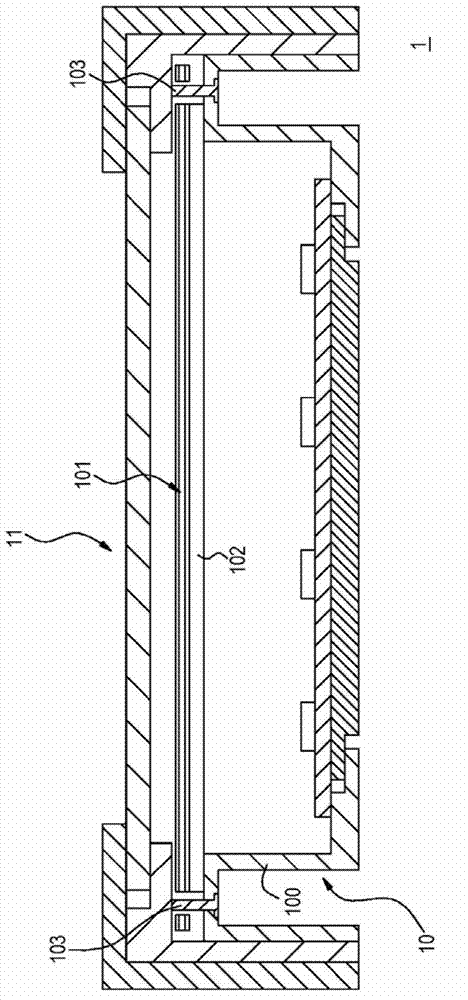

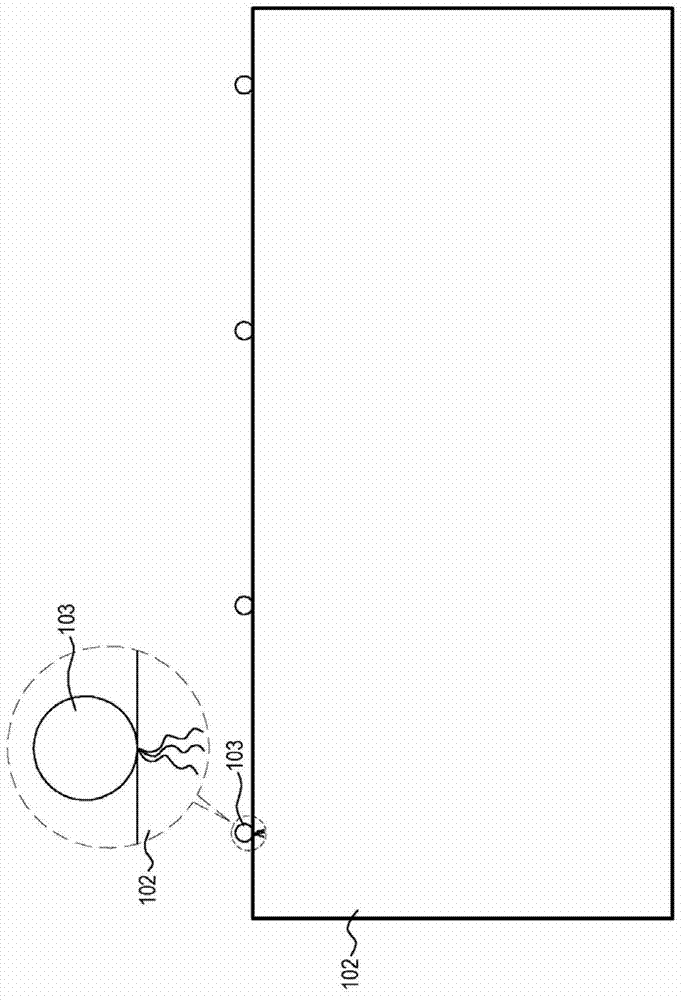

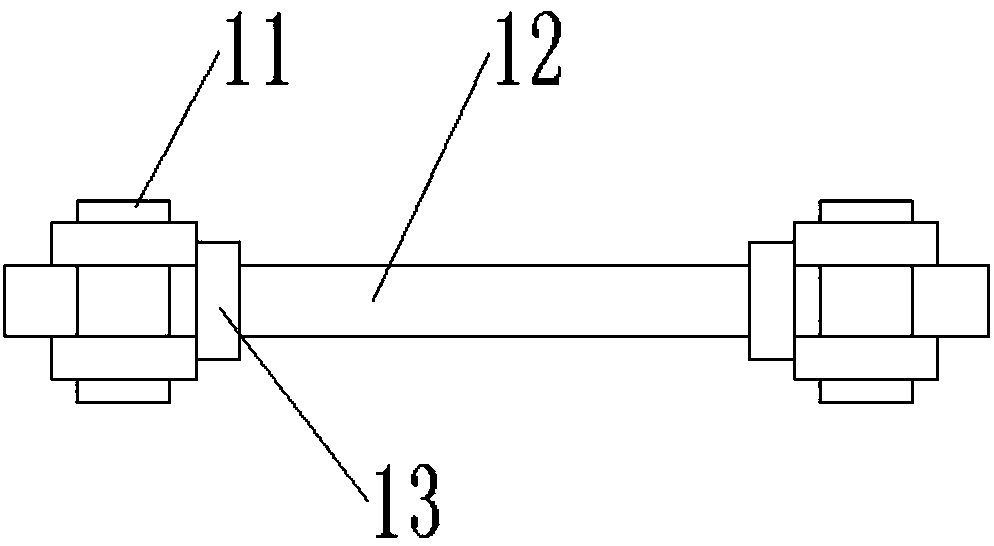

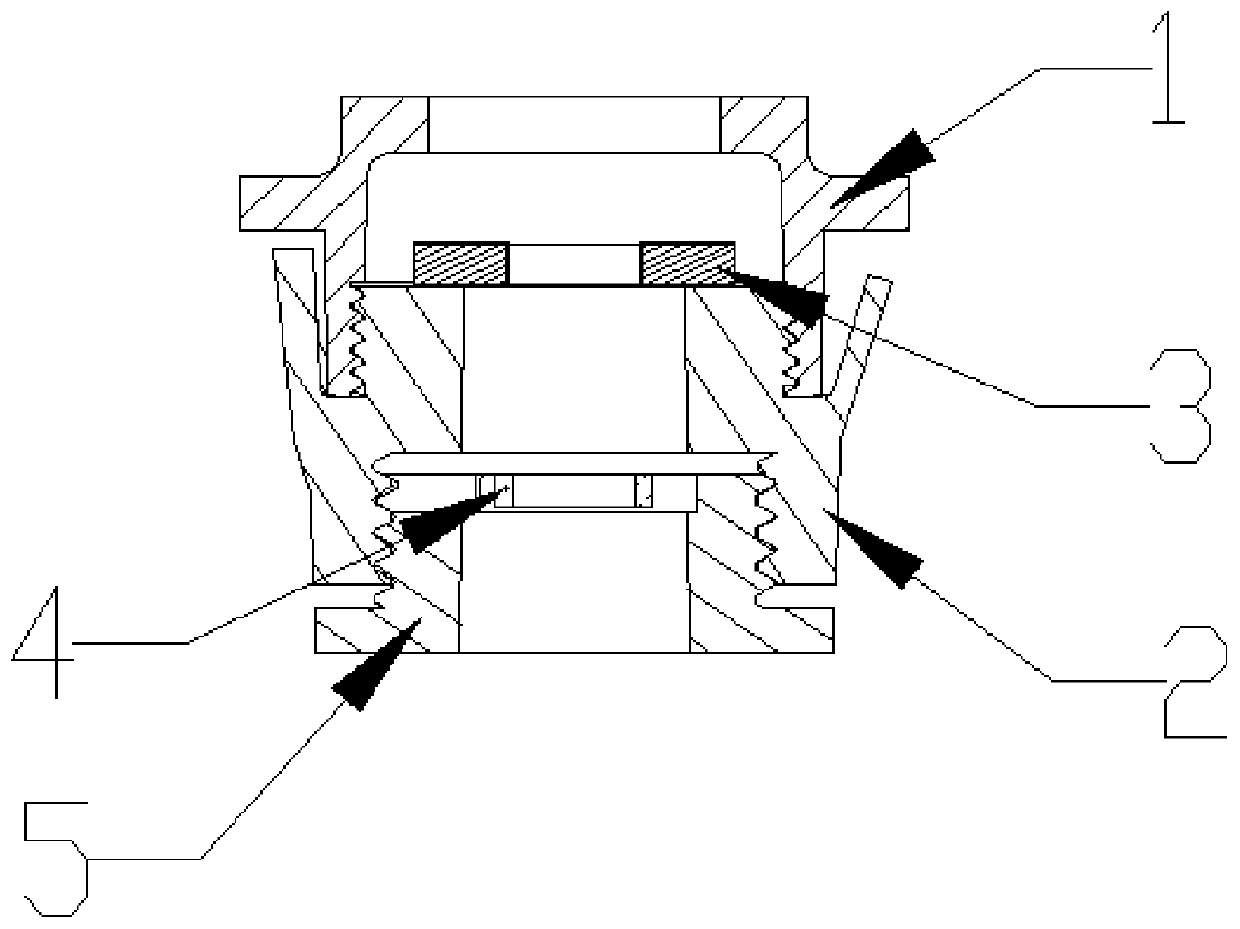

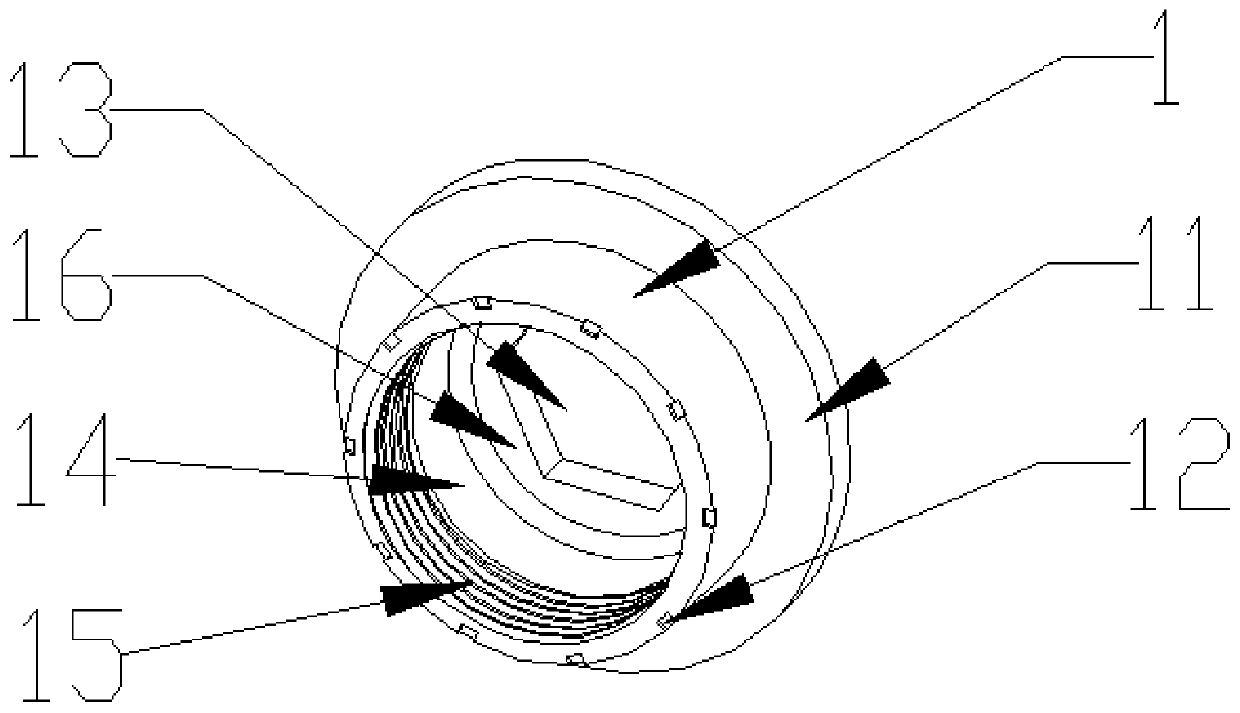

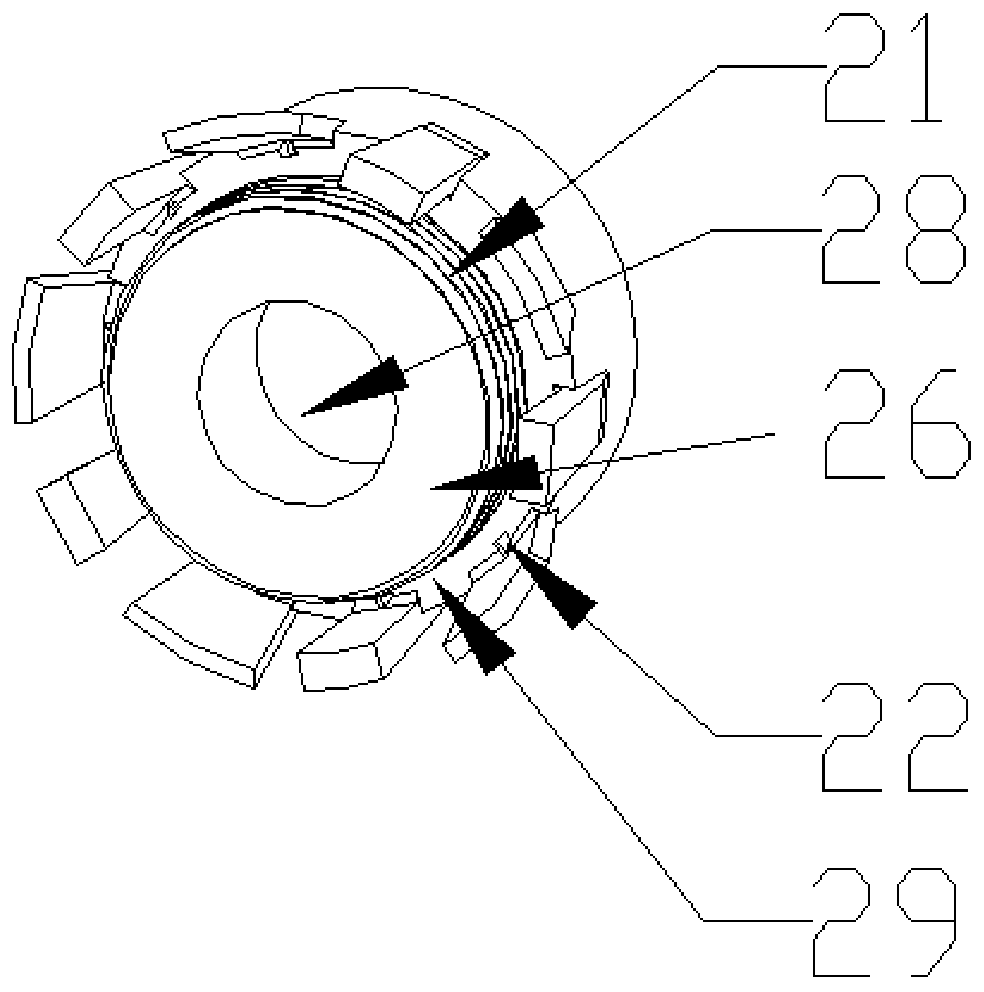

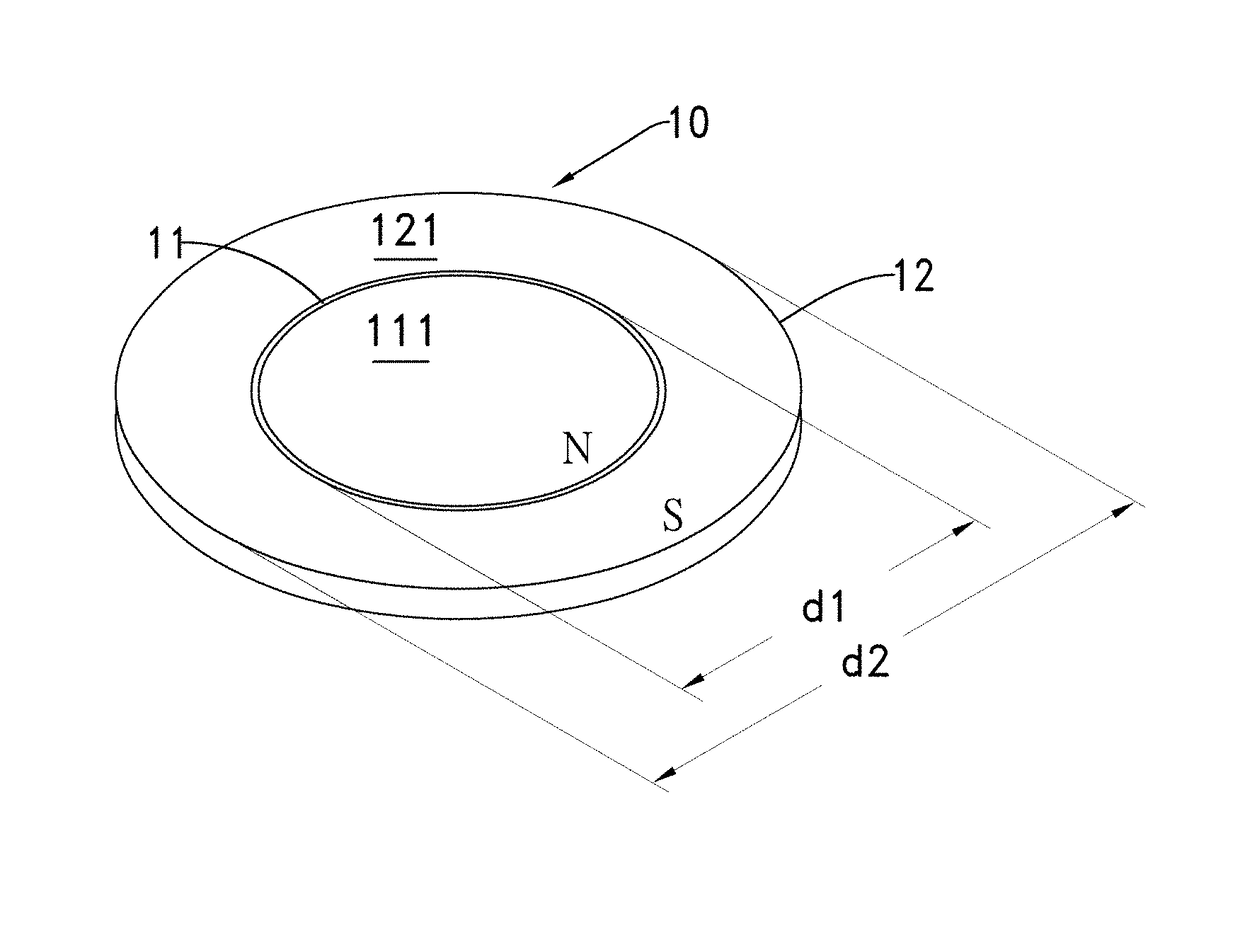

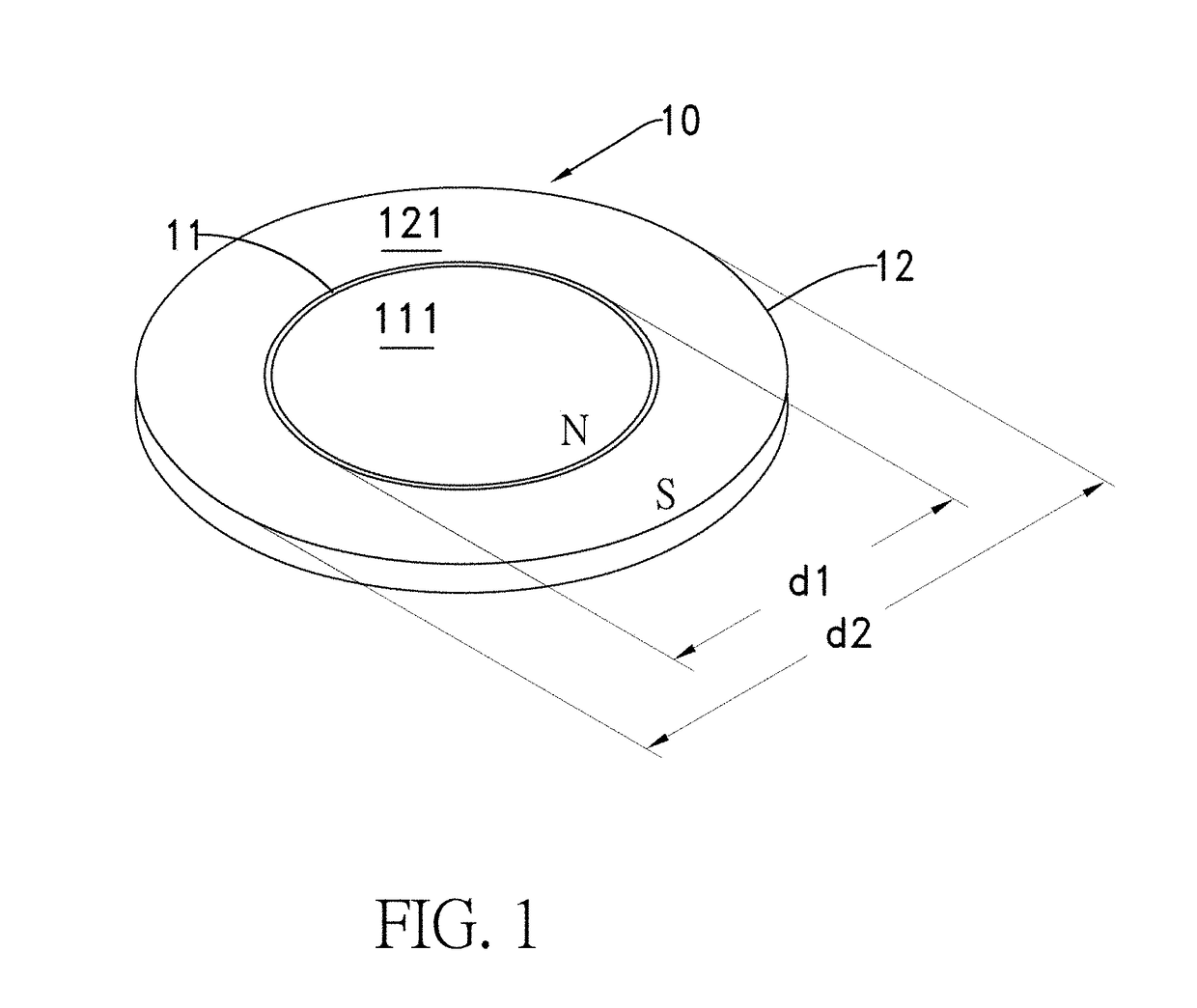

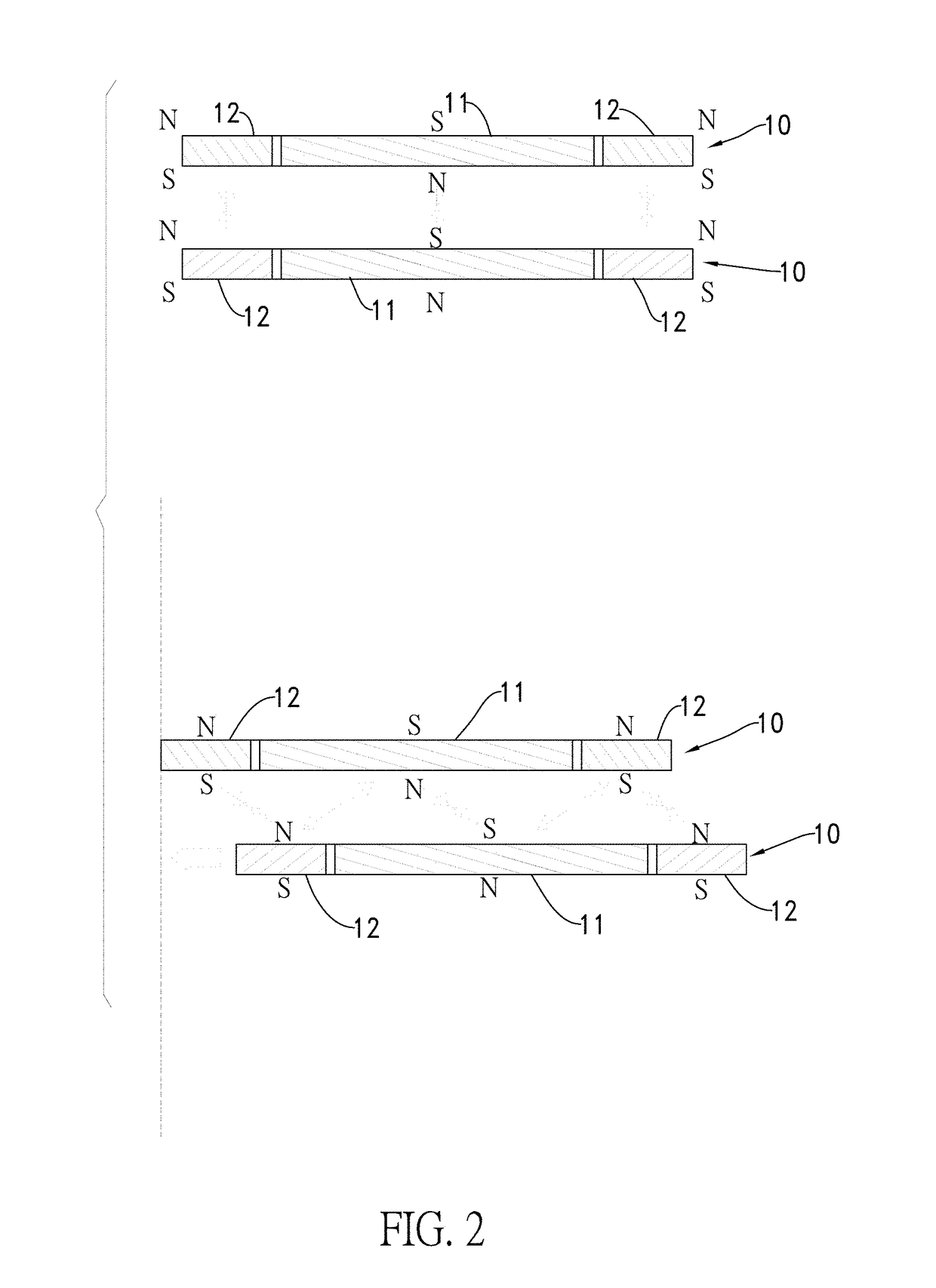

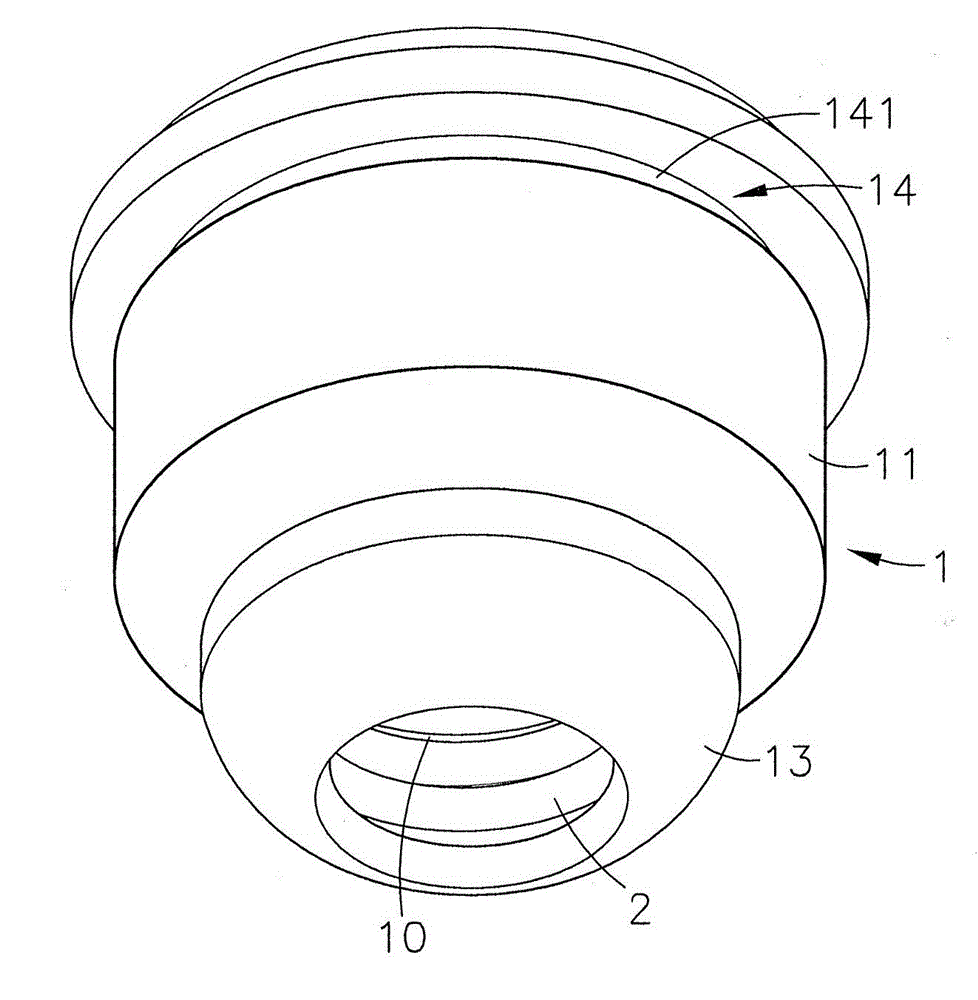

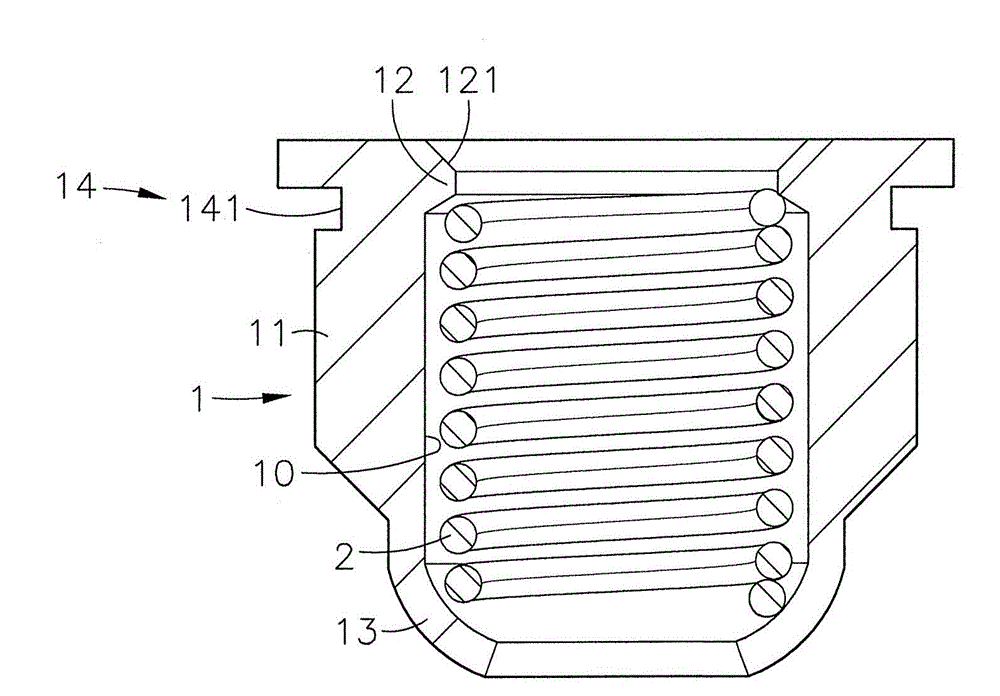

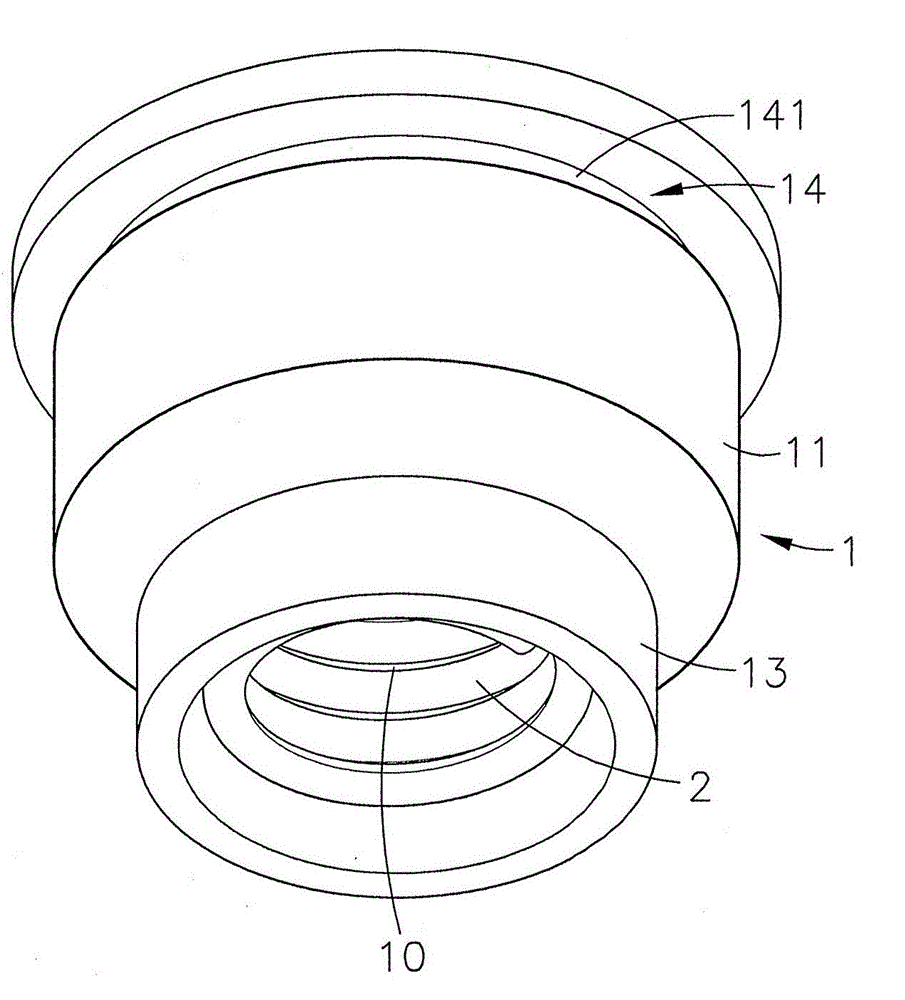

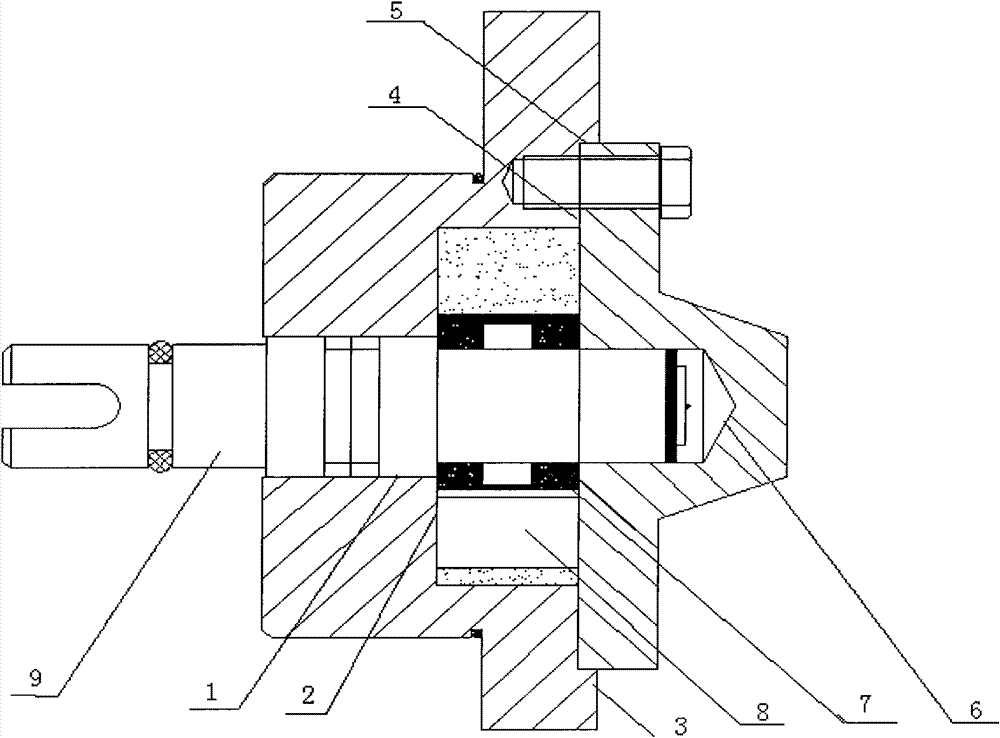

Magnetic attraction-fixing assembly, two-piece apparatus, and rotating support structure for a portable device having the magnetic attraction-fixing assembly

ActiveUS20160125988A1Improve positioning strengthHigh strengthCasings/cabinets/drawers detailsPermanent magnetsMagnetic polesEngineering

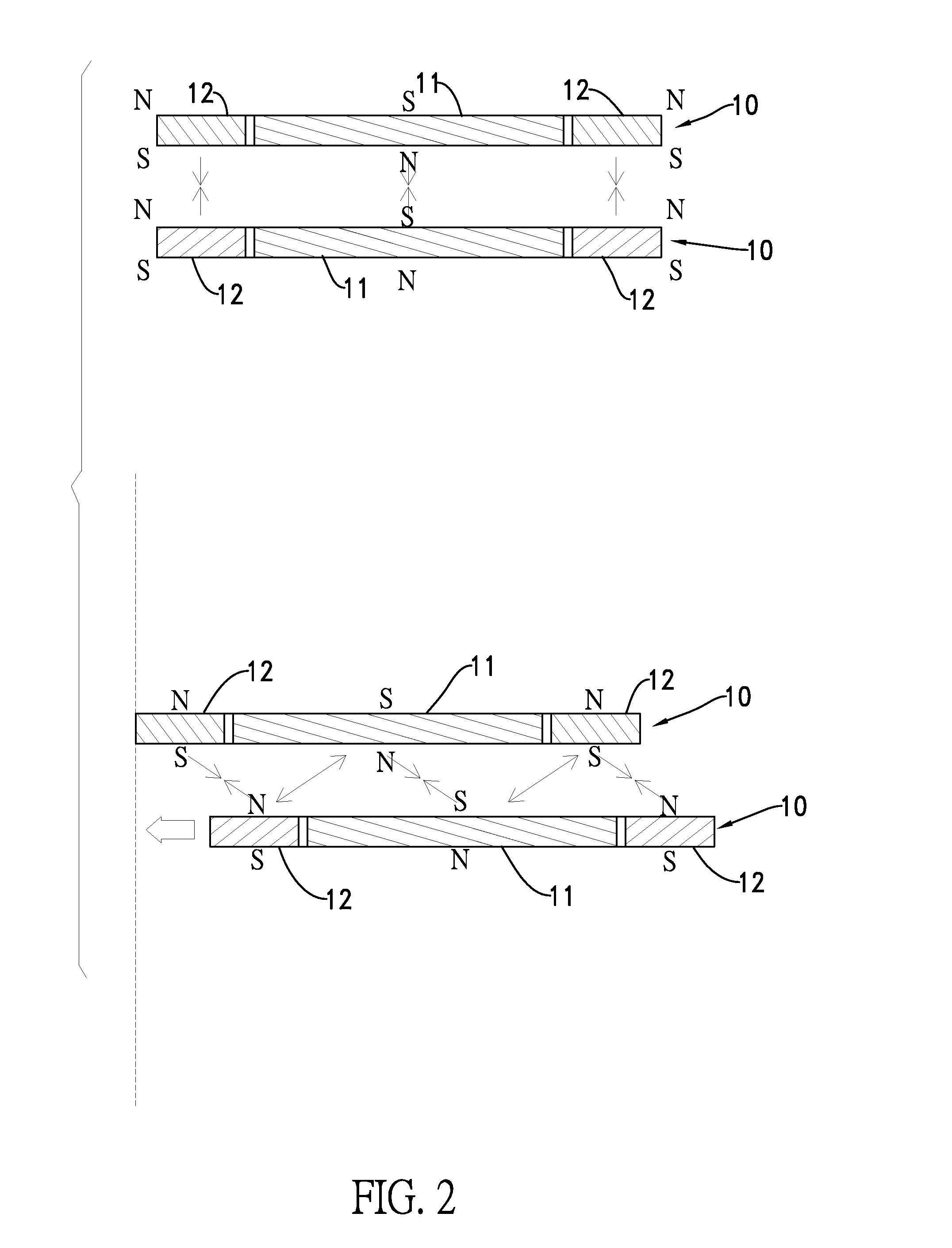

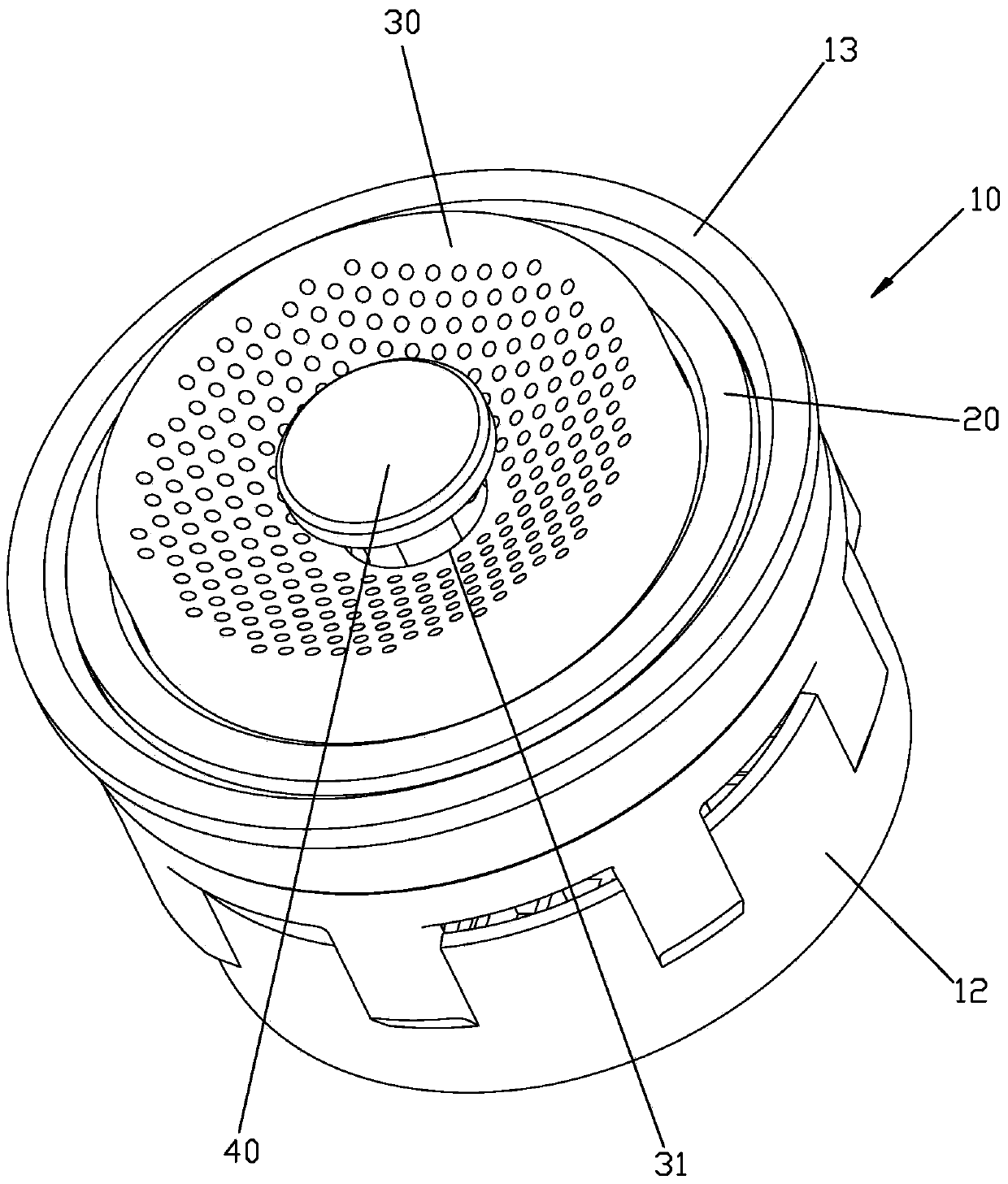

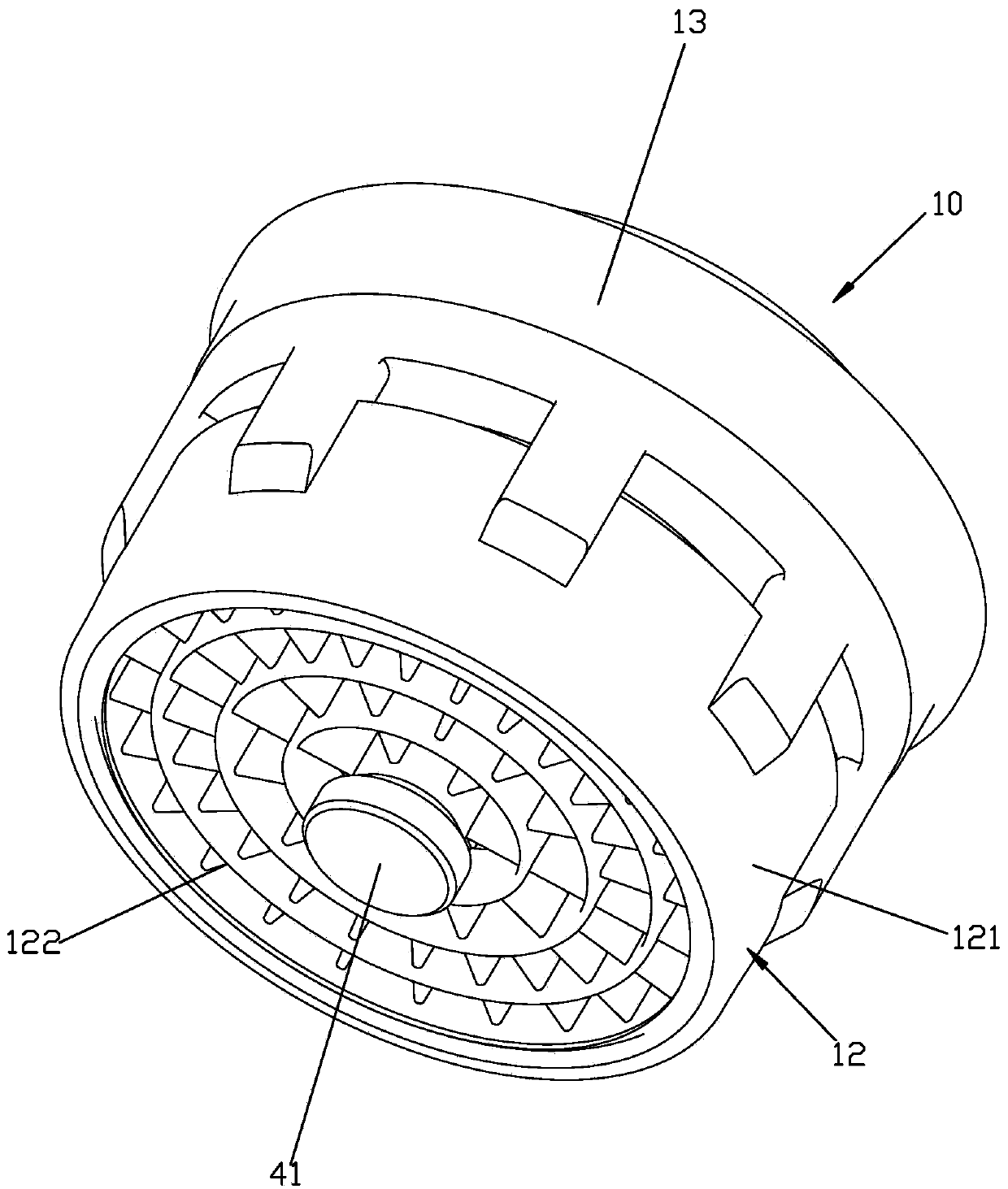

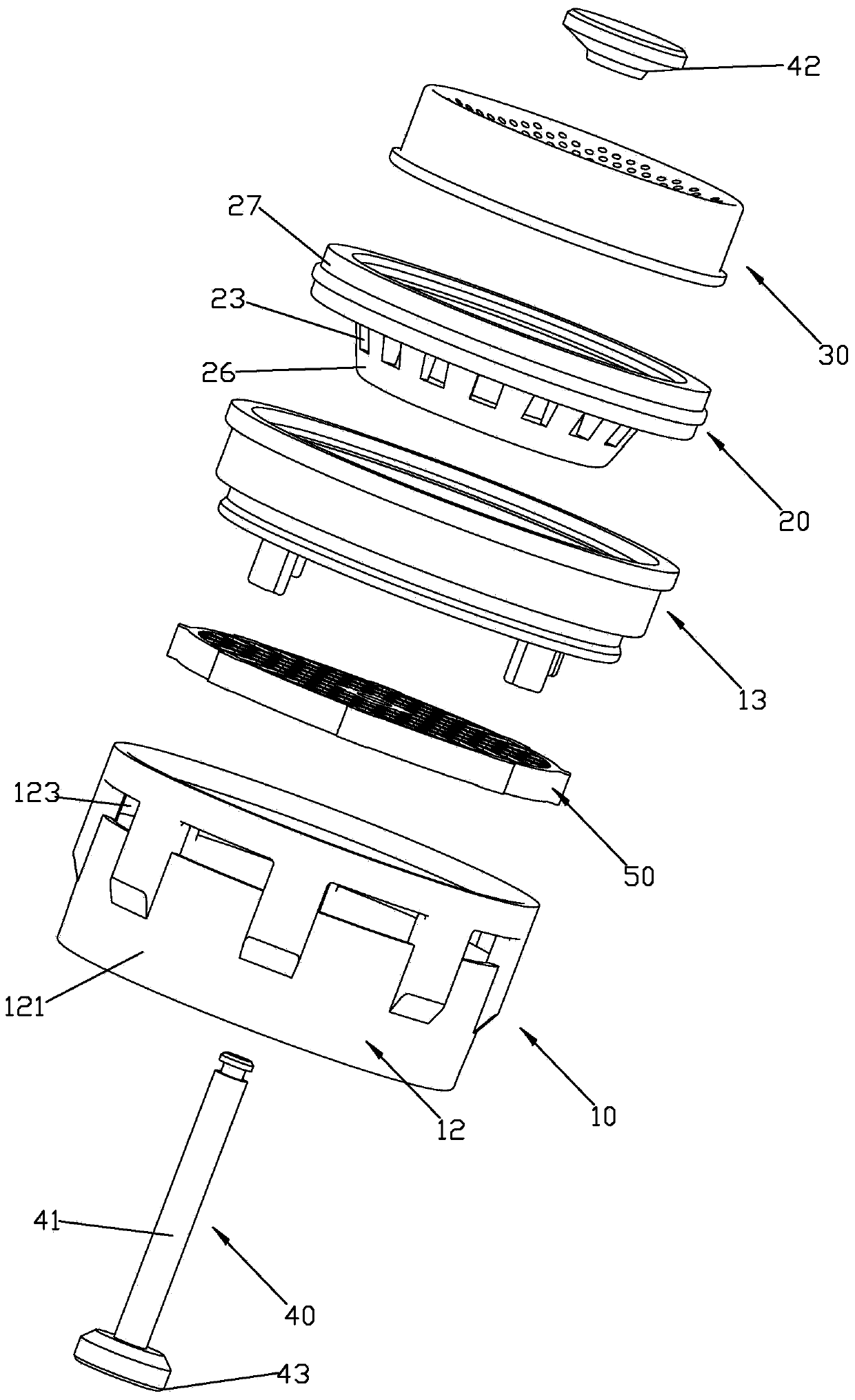

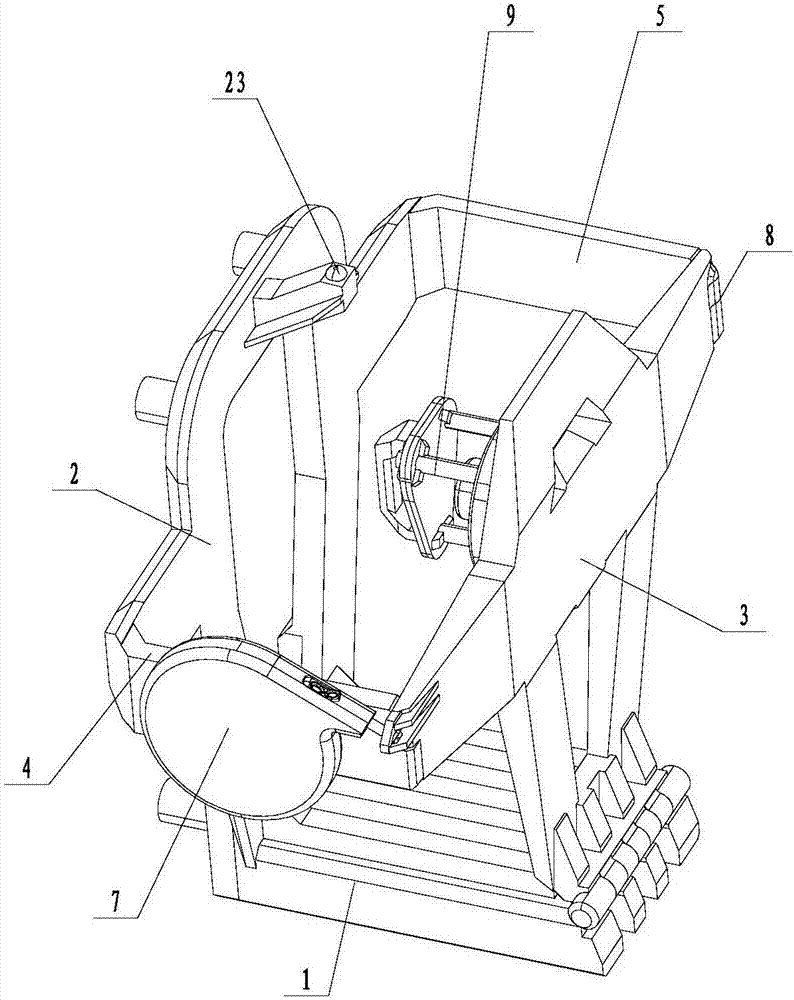

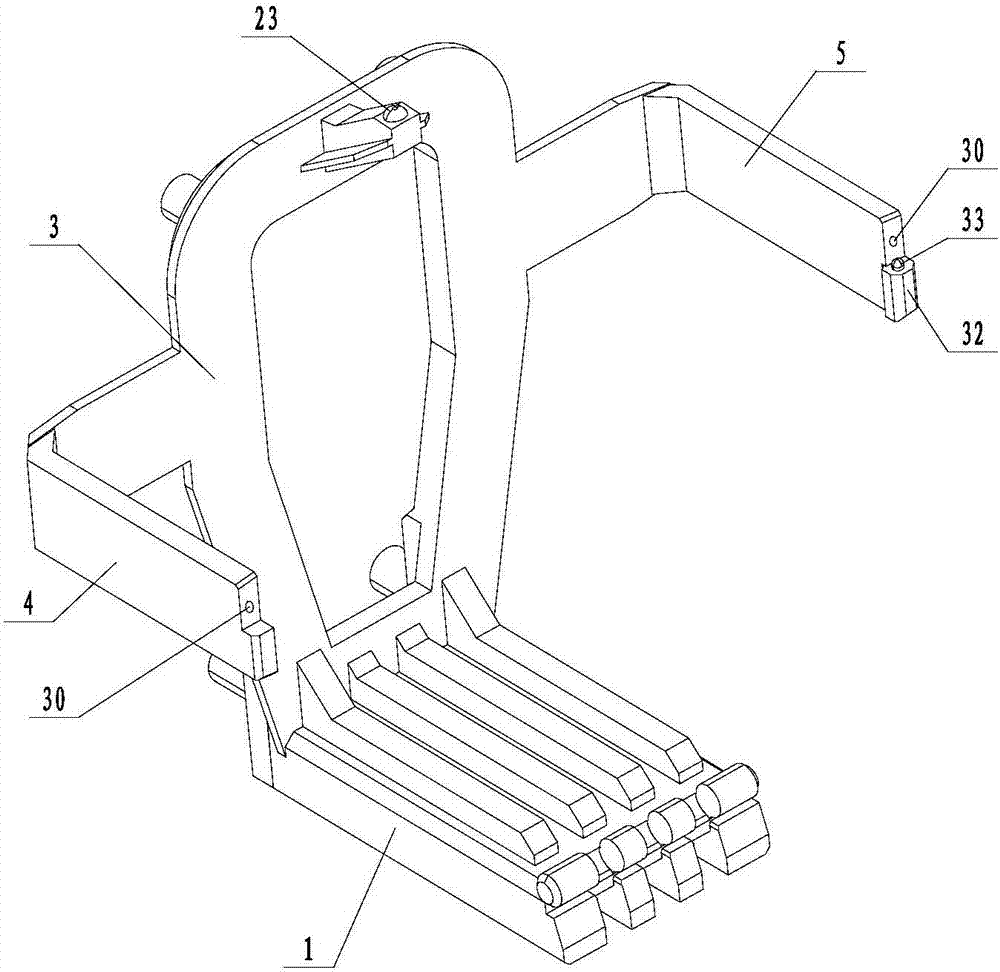

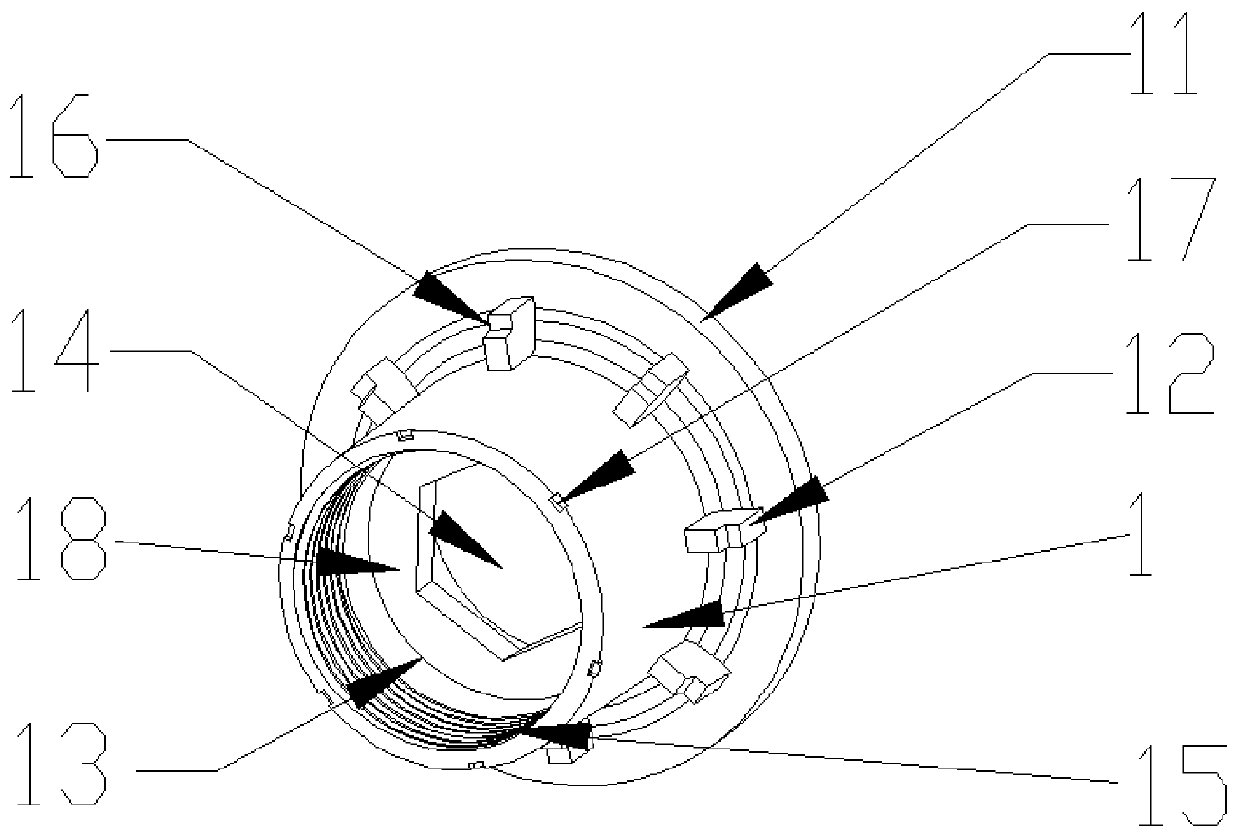

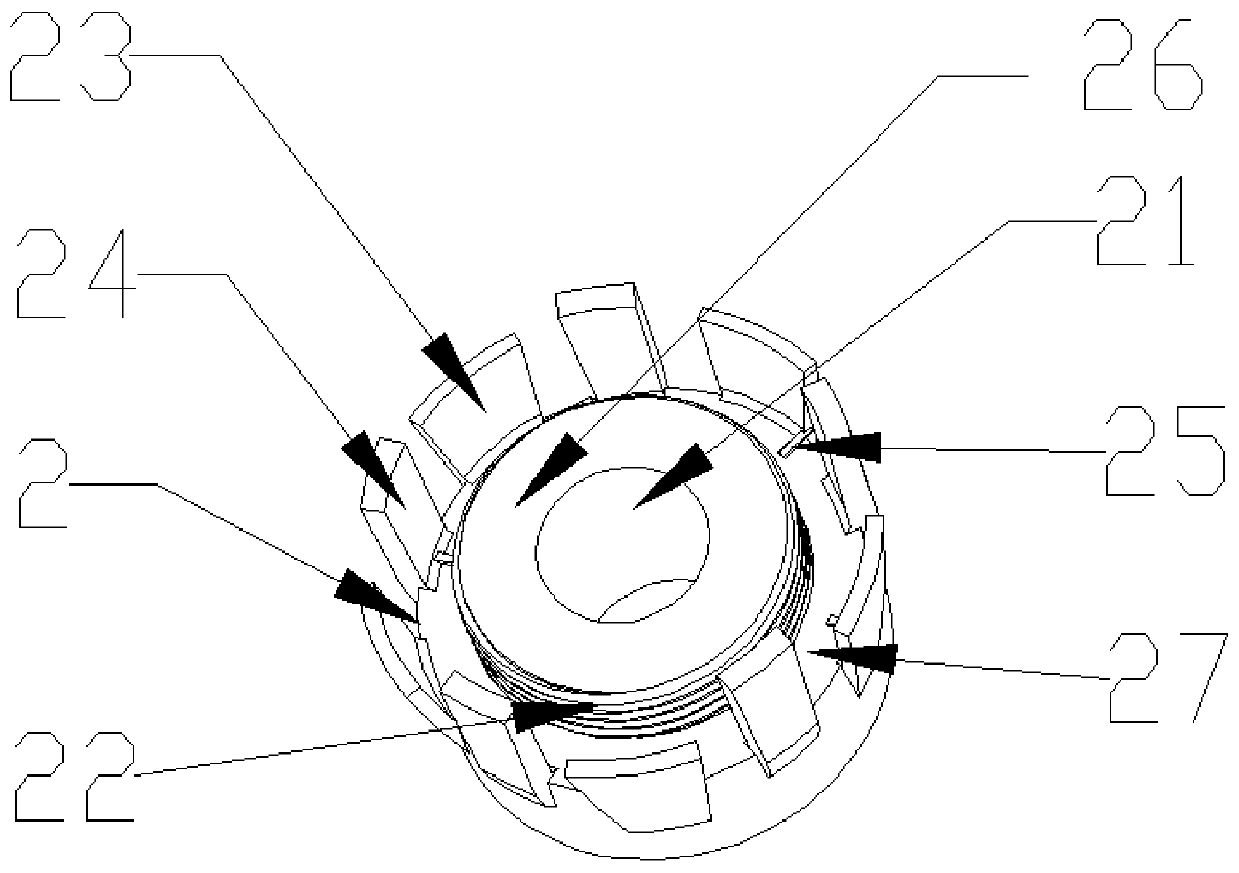

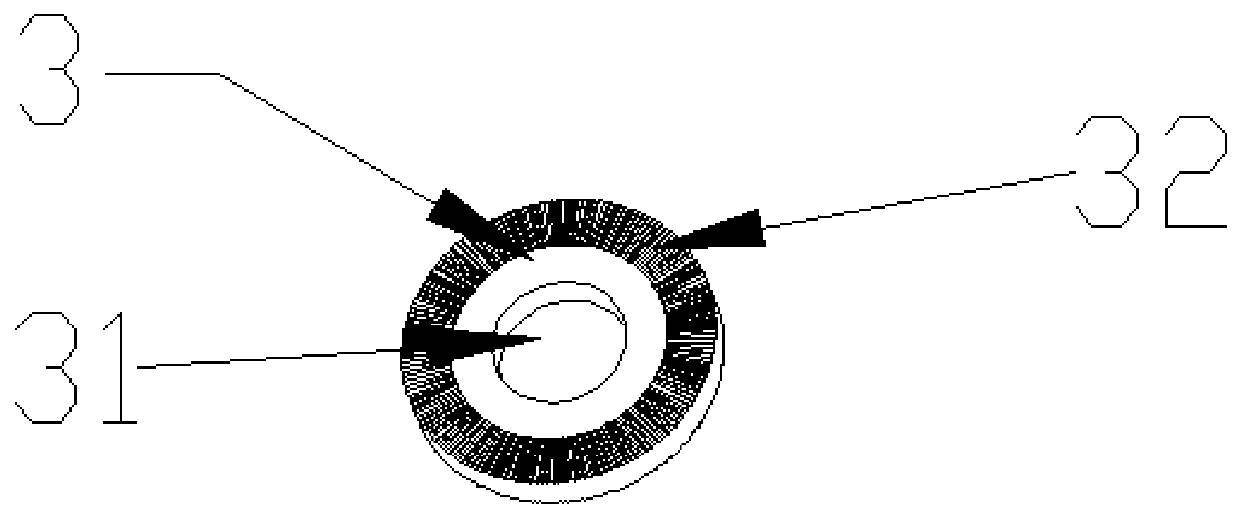

A magnetic attraction-fixing assembly and a rotating support structure for a portable device are provided. The magnetic attraction-fixing assembly includes two magnetic units, the two magnetic units stacked with and attracting each other; wherein each of the magnetic units respectively comprises a circular magnetic component and at least one annular magnetic component around the circular magnetic component, a magnetic pole of the circular plane of the circular magnetic component is an unlike pole to a magnetic pole of an annular plane of the annular magnetic component that is adjacent to the circular magnetic component. The rotating support structure comprises two magnetic units and a body. Magnetic attractions in both radial and axial directions are enhanced.

Owner:LEE BING ZHANG

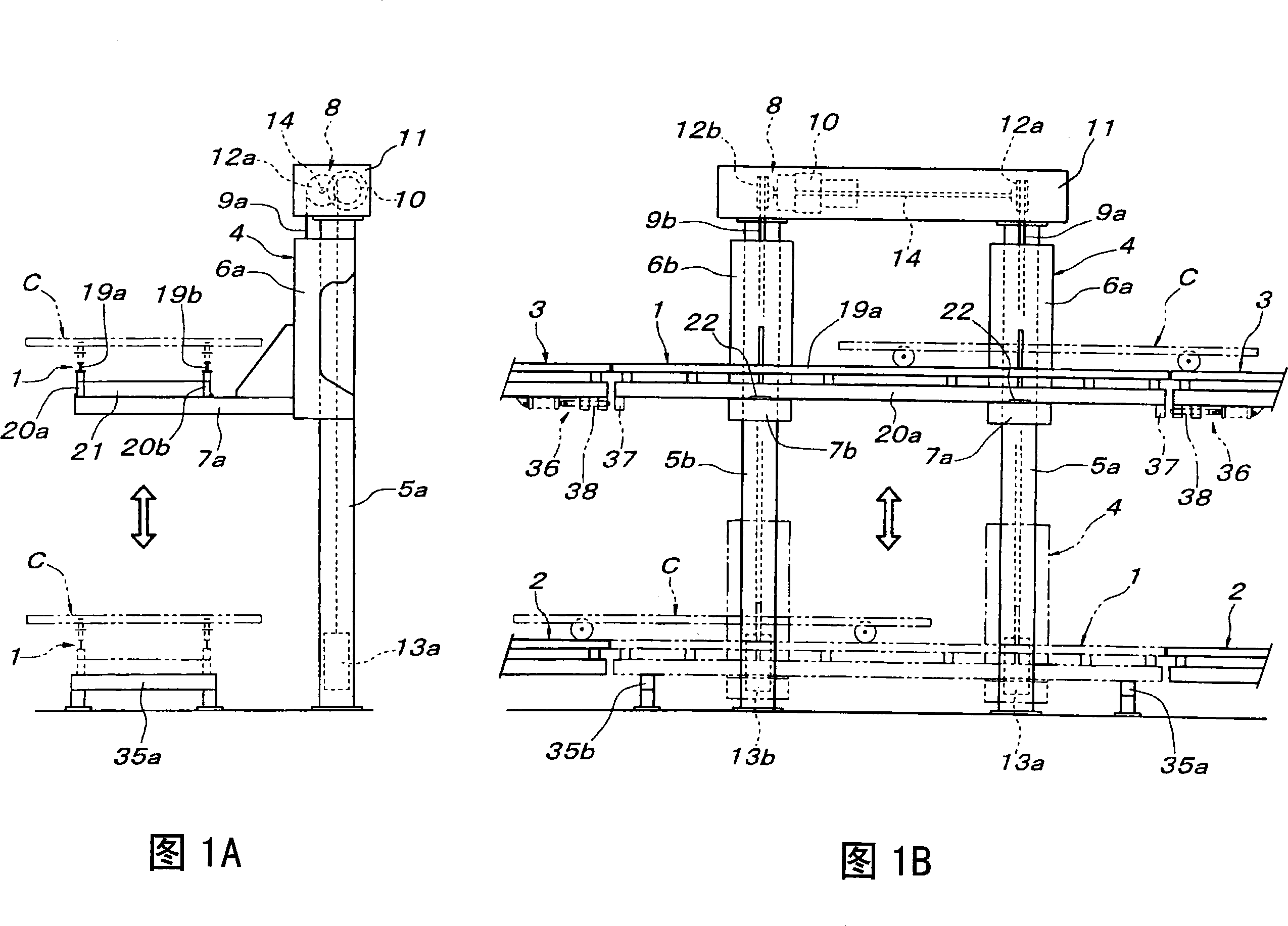

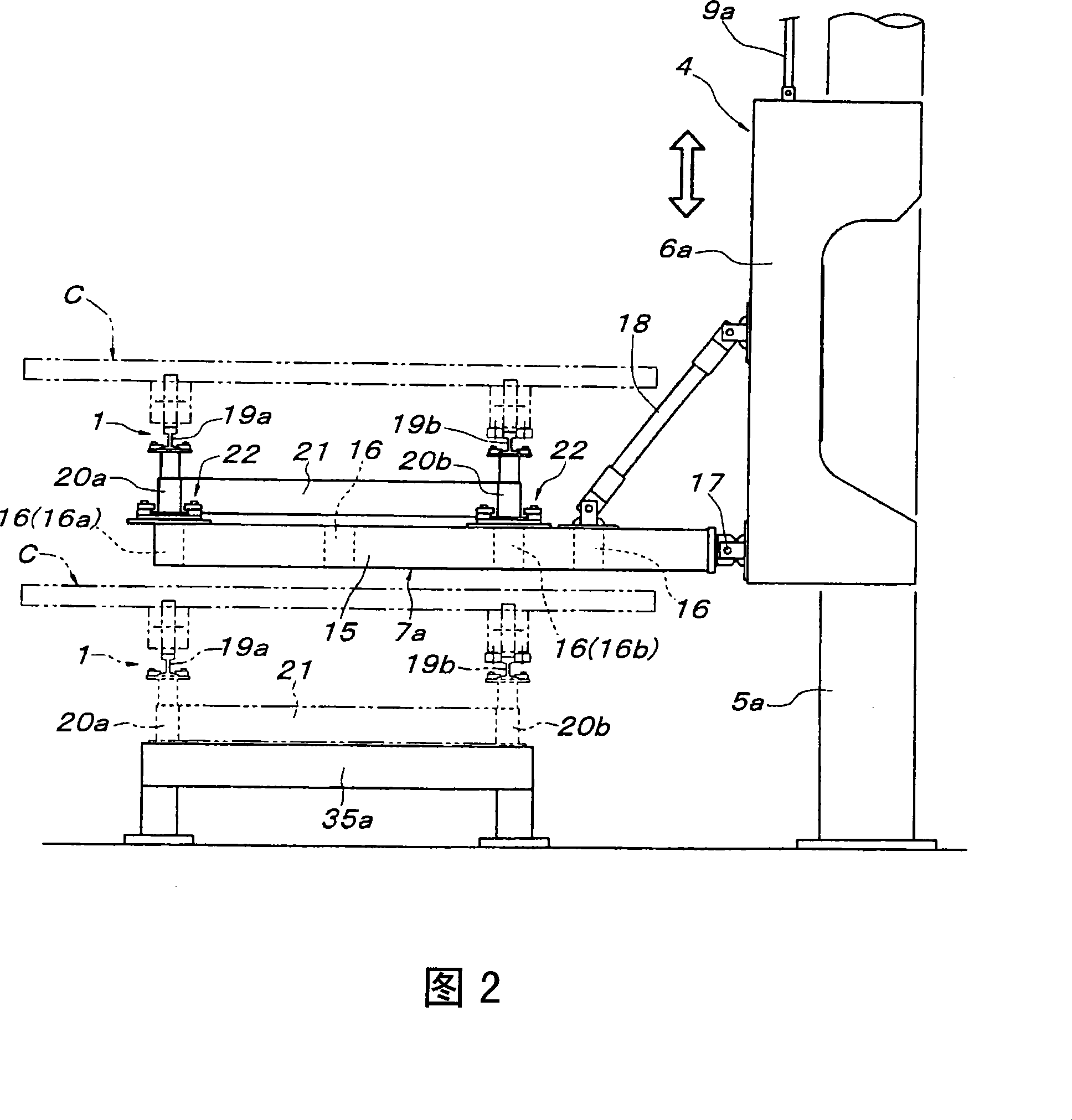

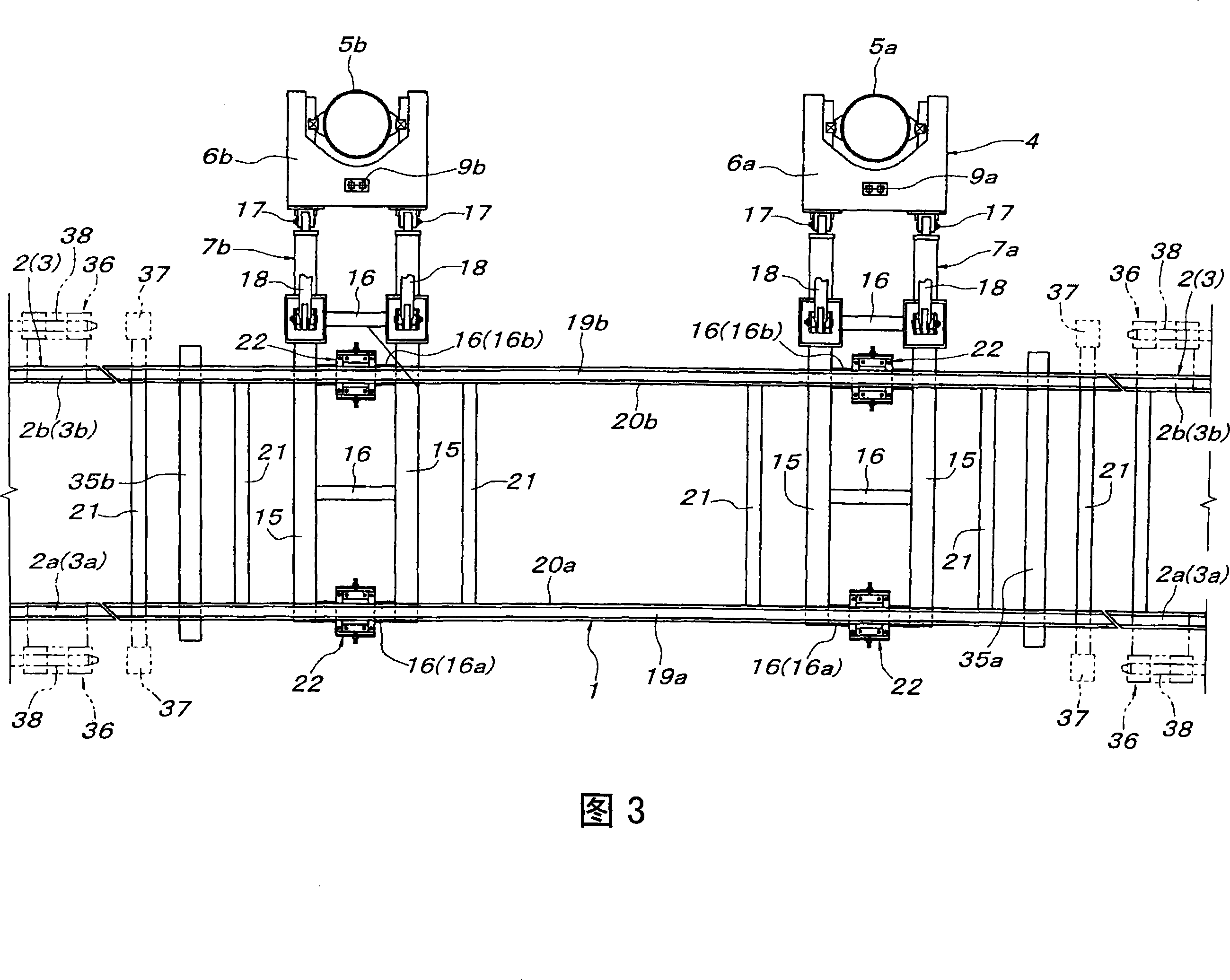

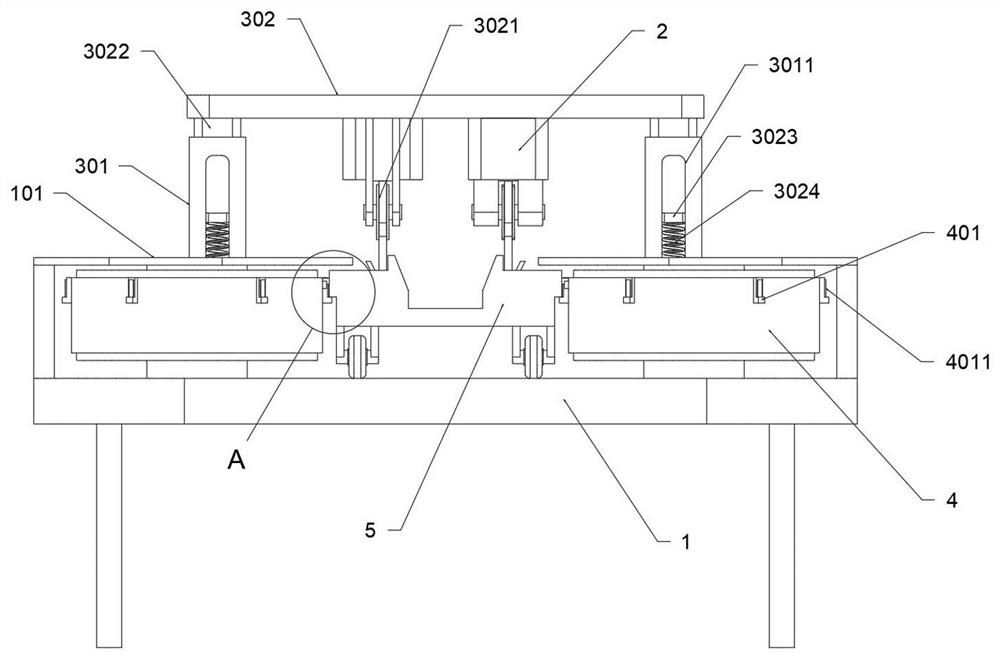

Upper and lower path switching device for traveling body for transportation

ActiveCN101229880AReduced load resistanceSafe and smooth transfer movementRailway componentsLifting framesLower limitPath switching

The present invention easily improves the accuracy of connection level alignment between an elevating guide rail and a fixed side guide rail in a path switching device which switches vertically a traveling path of a conveyance carriage or the like via an elevating guide rail, and in an upper and lower path switching device for a traveling body for transportation, including an elevating guide rail supported horizontally by an elevating body, upper fixed guide rails to be connected to the elevating guide rail at a lifted position of the elevating body, and lower fixed guide rails which are connected to the elevating guide rail at a lowered position of the elevating body, the elevating guide rail is supported movably vertically in a predetermined range with respect to the elevating body, and receiving members for receiving the elevating guide rail at a level at which the elevating guide rail is connected to the lower fixed guide rails before the elevating body reaches a lower limit thereof are provided.

Owner:DAIFUKU CO LTD

Magnetic attraction-fixing assembly and a rotating support structure for a portable device having the magnetic attraction-fixing assembly

InactiveUS20160128210A1Improve positioning strengthHigh strengthPicture framesCasings/cabinets/drawers detailsMagnetic polesEngineering

Provided is a magnetic attraction-fixing assembly and a rotating support structure for a portable device. The magnetic attraction-fixing assembly comprises two magnetic units, the two magnetic units stacked with and attracting each other; wherein each of the magnetic units respectively comprises a circular magnetic component and at least one annular magnetic component around the circular magnetic component, a magnetic pole of the circular plane of the circular magnetic component is an unlike pole to a magnetic pole of an annular plane of the annular magnetic component that is adjacent to the circular magnetic component. The rotating support structure comprises two magnetic units and a body. Magnetic attractions in both radial and axial directions are enhanced.

Owner:LEE BING ZHANG

Water discharging device with cleaning function

ActiveCN103821201AAvoid cloggingSimple structureDiaphragm valvesEngine diaphragmsHigh rateWater discharge

The invention discloses a water discharging device with a cleaning function. The water discharging device comprises a body part, a flow divider, a filter screen and a sealed part, wherein the flow divider is arranged in a mounting through hole of the body part and is provided with a bottom wall and a surrounding part which surrounds outside the bottom wall and is provided with a plurality of communicated flow dividing holes; the filter screen is arranged at the front end of the flow divider; one opening of a drain channel is a drain through hole formed in the center of the filter screen, and the other opening of the drain channel is communicated with the flow dividing holes; the sealed part is connected to the flow divider and can be changed between a clean state and a sealed state, and the connection or disconnection of the drain channel is controlled by controlling the sealed part to be in the clean or sealed state. The water discharging device has the advantages that capability of preventing impurity particles from blocking a water outlet nozzle, cleaning the filtered impurity particles and sharing the flow dividing holes, simple and compact structure, relatively small occupied space, low mould opening cost and relatively high rate of finished products.

Owner:XIAMEN SOLEX HIGH TECH IND CO LTD

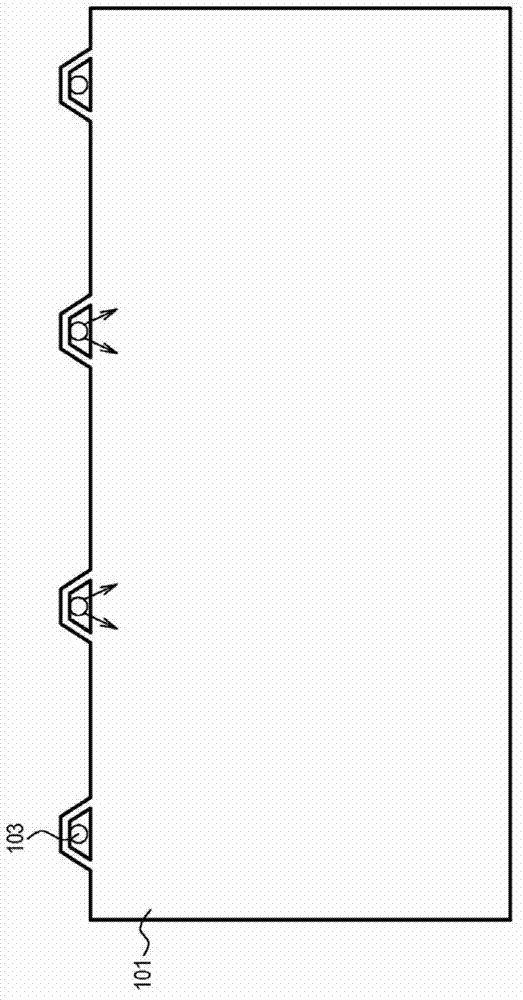

Backlight module and LCD including same

InactiveCN102767758AImprove positioning strengthLight fasteningsNon-linear opticsLiquid-crystal displayEngineering

A backlight module includes a back panel provided with at least one side, and is provided with a backlight unit including an optical plate and an optical film, wherein the at least one side is provided with a surface. The backlight module is characterized in that the surfaces are equipped with brackets; the brackets include horizontal parts and vertical parts extending from the horizontal parts; the vertical parts include planes and convexes; the planes are used for supporting the optical plate; and the convexes are used for positioning the optical film. The invention further provides an LCD including the backlight module.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Novel combined type building formwork fixing structure

InactiveCN109838092AReduce axial forceNot easy to stretch and deformForms/shuttering/falseworksArchitectural engineeringUltimate tensile strength

The invention discloses a novel combined type building formwork fixing structure. The fixing structure includes first fixing rods; the outer walls on the two ends of each first fixing rod are providedwith grooves; the outer walls on one sides of the two grooves are in clamp connection with tenons; the outer walls on one sides of the tenons are welded with second fixing rods; the outer walls on one ends of the second fixing rods are provided with pulling grooves; the outer walls on the other sides of the second fixing rods are welded with telescoping rods; the telescoping rods are inserted inthe inner walls of the pulling grooves; the outer walls of the two sides on the top of each second fixing rod are welded with connecting blocks; the outer walls on the opposite sides of the connectingblocks are provided with pre-tightening rods; and the outer walls on one sides of the second fixing rods are welded with second pins. A threaded rod is not easy to stretch and deform, so that the axial strain capabilities of the threaded rod can be enhanced, the fixing effects of a building formwork positioning structure can be improved, the integral intensity of the fixing structure can be enhanced, and the fixing structure has strong protection effects on internal concrete.

Owner:TIANJIN XINFUSHENG NEW BUILDING TEMPLATE CO LTD

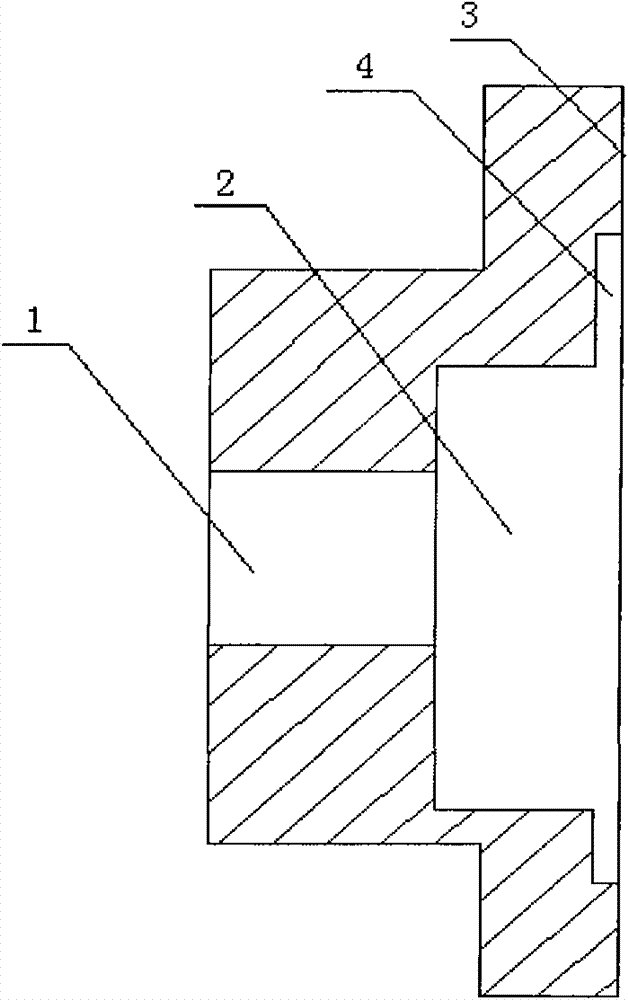

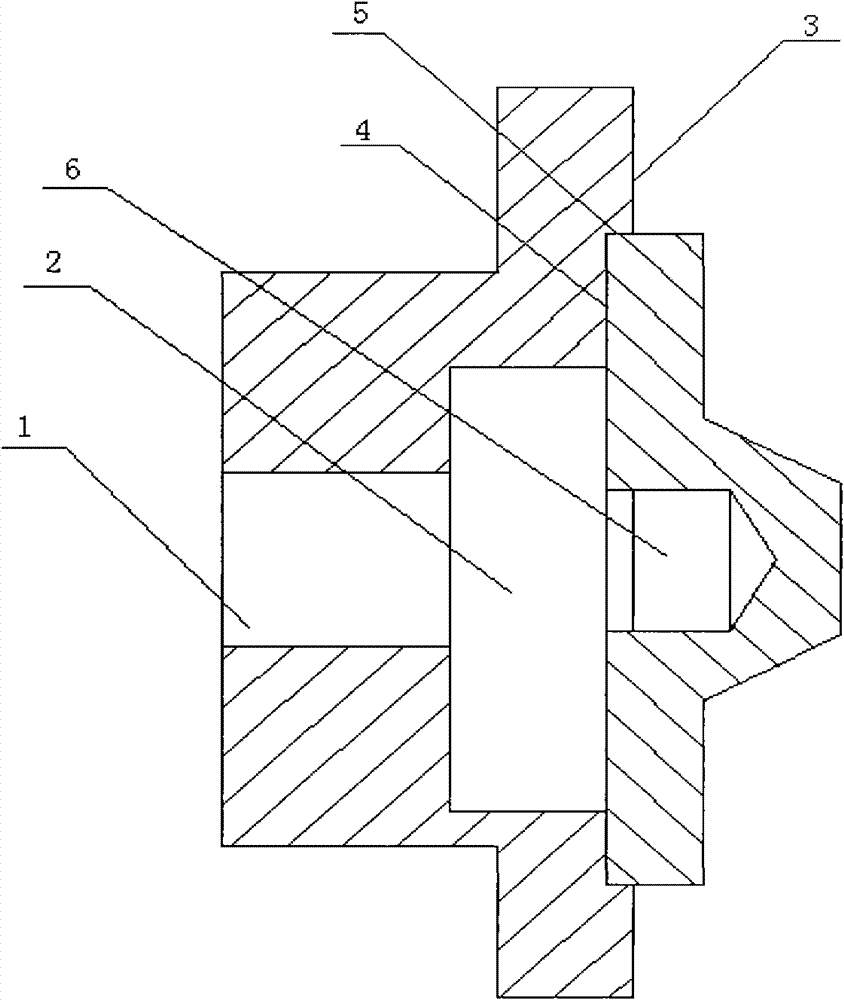

Novel automatic tolerance adjusting device

PendingCN110153948AAchieve lockingRealization of automatic tolerance adjustmentMetal-working hand toolsEngineeringKinetic energy

The invention provides a novel automatic tolerance adjusting device which comprises an upper shell, a positioning stud, a locking gasket, a star-like piece and an adjusting nut. The upper and lower ends of the positioning stud are fixedly connected with the upper shell and the adjusting nut through threads, and the locking gasket is arranged in a first inner cavity of the upper shell and freely moves in an axial hole gap; and the outer wall of the star-like piece is provided with a pusher dog, the star-like piece is arranged in a second inner cavity of the positioning stud and freely moves ina star-like hole gap, and the pusher dog pushes and adjusts a star-like boss of the adjusting nut and drives the adjusting nut to rotate. The novel automatic tolerance adjusting device fully utilizeskinetic energy generated by rotation and advancement of bolts, can achieve automatic rigid supporting to eliminate tolerance accumulation, realizes rapid and effective precise positioning and assembling, and solves the problems that in the prior art, the steps are many, the cost is high, the operation technical difficulty is high, and the work efficiency is low; and meanwhile, the overall structure is fixed in rigidness and suitable for application to special conditions with higher strength.

Owner:SHANGHAI JIAMU AUTO PARTS CO LTD

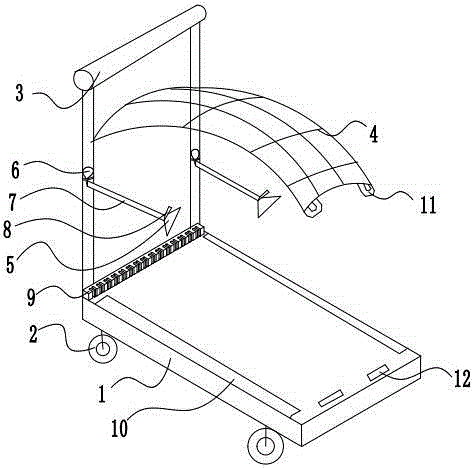

Glass conveyor

InactiveCN105173725ASimple structureEasy to manufactureCharge manipulationConveyor partsEngineeringPulley

The invention relates to a glass conveying device, in particular to a glass conveyor. The glass conveyor comprises a bottom board, sliding wheels and a handle, wherein the sliding wheels and the handle are arranged on the bottom board. The handle is located at one end of the bottom board. The handle is provided with an elastic net cover used for binding glass. The net cover is provided with clamping pieces. Buckles in which the clamping pieces are inserted are arranged at the other end, away from the handle, of the bottom board. The handle is further provided with suction cups and air bags capable of being manually squeezed. Air pipes for communication are arranged between the air bags and the suction cups. The suction cups are provided with squeezing blocks used for closing the air pipes and exhausting air. The bottom board is detachably connected with a clamping groove where glass is clamped and located. The glass conveyor can be used for conveying glass of various sizes.

Owner:深圳市光华中空玻璃工程有限公司

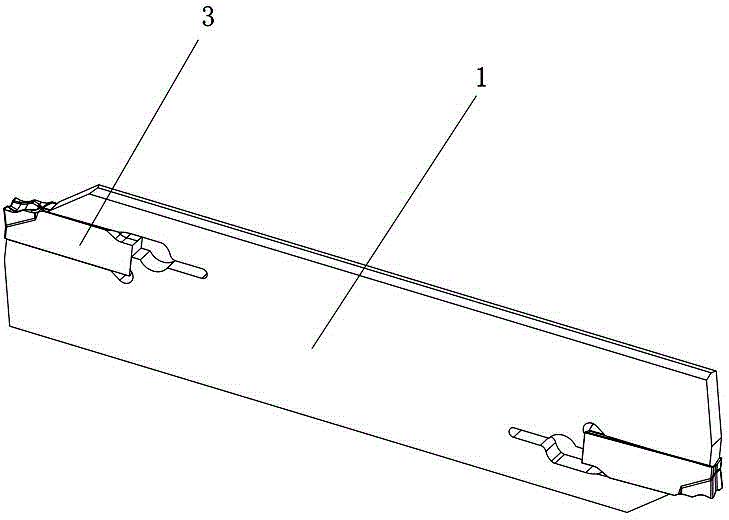

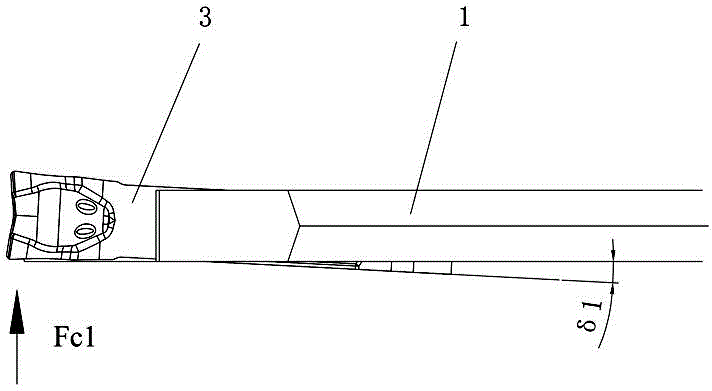

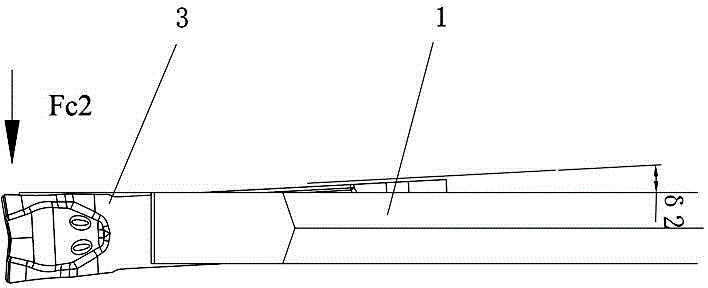

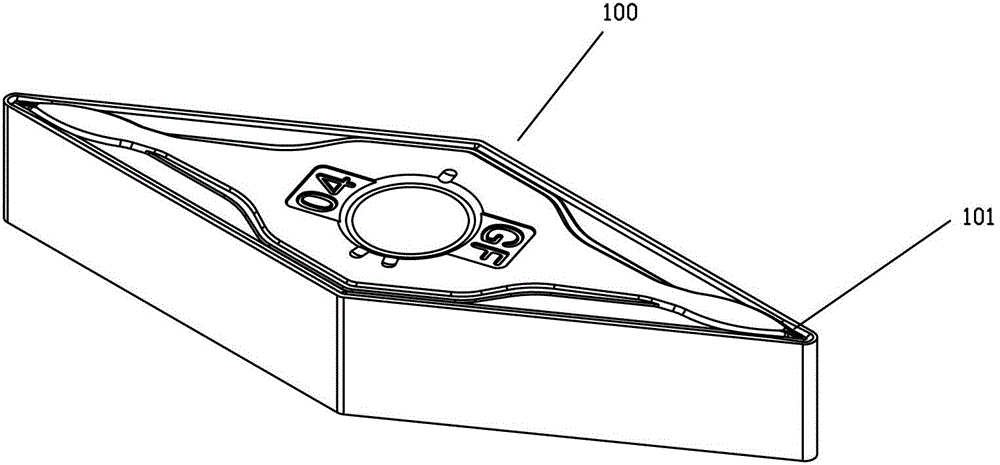

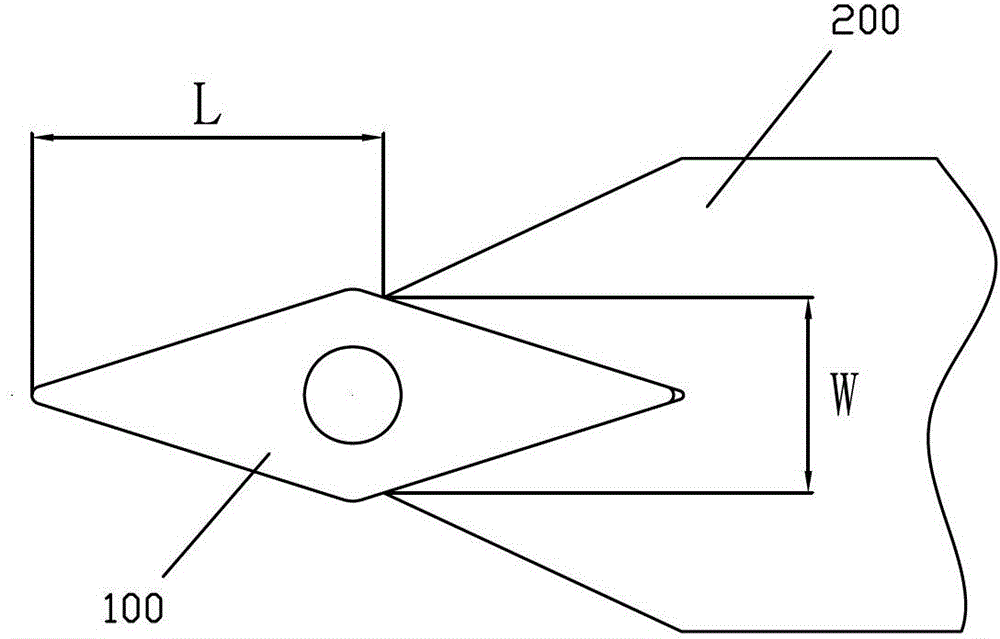

Grooving cutter

ActiveCN104858456AImproved resistance to lateral impactsImprove positioning strengthCutting insertsTurning toolsEngineeringCutting force

The invention discloses a grooving cutter which comprises a tool rest body and a blade, wherein a blade groove is formed in the front end of the tool rest body; the blade groove comprises a blade clamping section and an extension section; the blade is mounted in the blade clamping section; a first lower part positioning surface, a second lower part positioning surface, a lower part front end side positioning surface and a lower part rear end side positioning surface are arranged at the lower part of the blade; the lower part front end side positioning surface and the lower part rear end side positioning surface are opposite in positioning direction; the first lower part positioning surface and the second lower part positioning surface form an included angle beta in the length direction of the blade; a first bearing surface, a second bearing surface, a lower part front end side bearing surface and a lower part rear end side bearing surface which are respectively corresponding to the first lower part positioning surface, the second lower part positioning surface, the lower part front end side positioning surface and the lower part rear end side positioning surface are arranged at the lower part of the blade clamping section. The groove cutter has the advantages of being high in positioning intensity and accuracy, and capable of bearing a lateral cutting force.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Magnetic attraction-fixing assembly, two-piece apparatus, and rotating support structure for a portable device having the magnetic attraction-fixing assembly

ActiveUS9799436B2Improve positioning strengthHigh strengthPermanent magnetsStands/trestlesMagnetic polesEngineering

A magnetic attraction-fixing assembly and a rotating support structure for a portable device are provided. The magnetic attraction-fixing assembly includes two magnetic units, the two magnetic units stacked with and attracting each other; wherein each of the magnetic units respectively comprises a circular magnetic component and at least one annular magnetic component around the circular magnetic component, a magnetic pole of the circular plane of the circular magnetic component is an unlike pole to a magnetic pole of an annular plane of the annular magnetic component that is adjacent to the circular magnetic component. The rotating support structure comprises two magnetic units and a body. Magnetic attractions in both radial and axial directions are enhanced.

Owner:LEE BING ZHANG

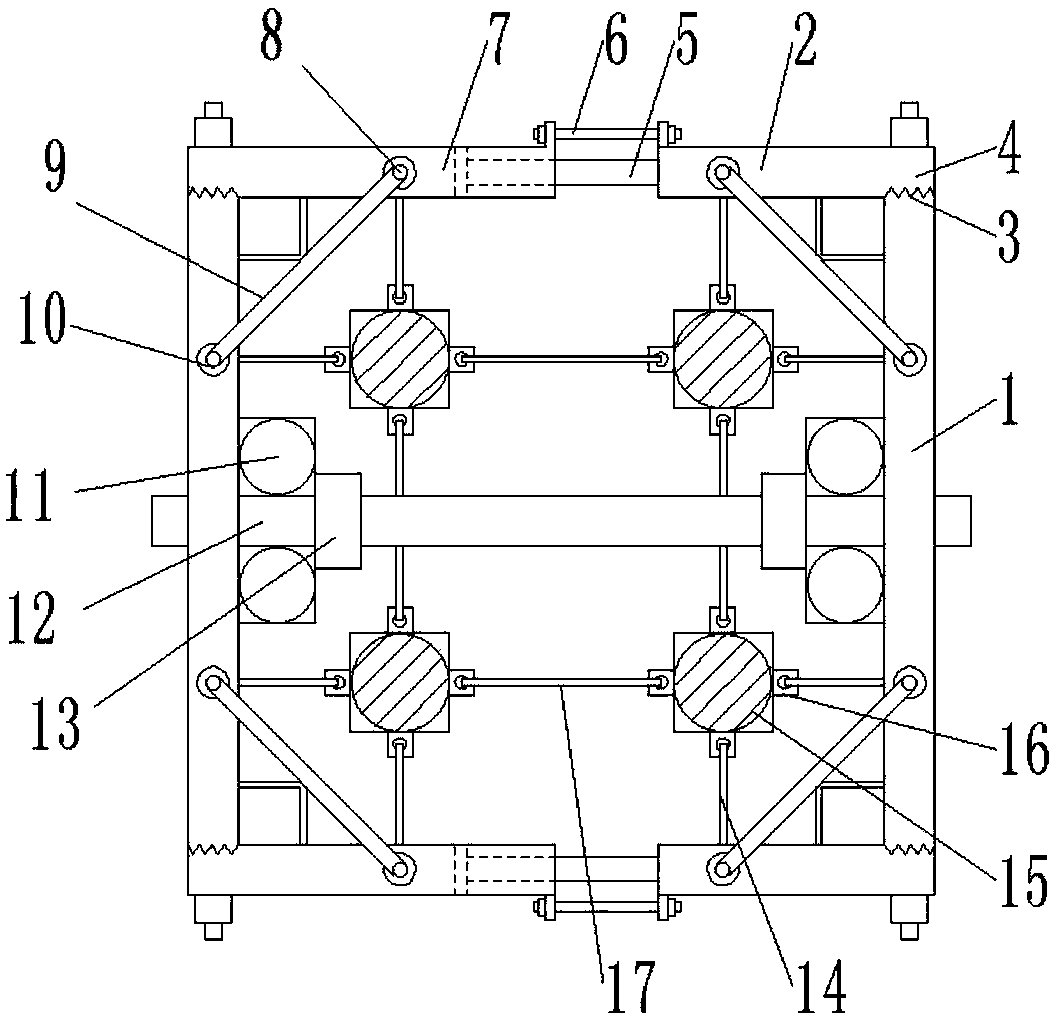

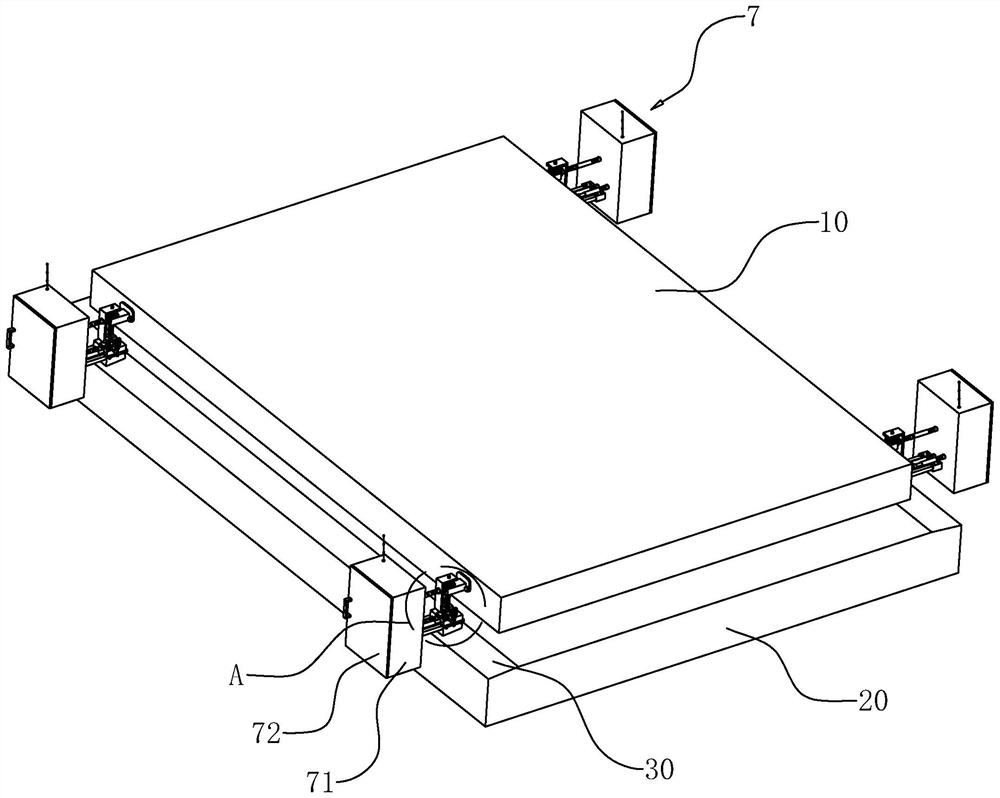

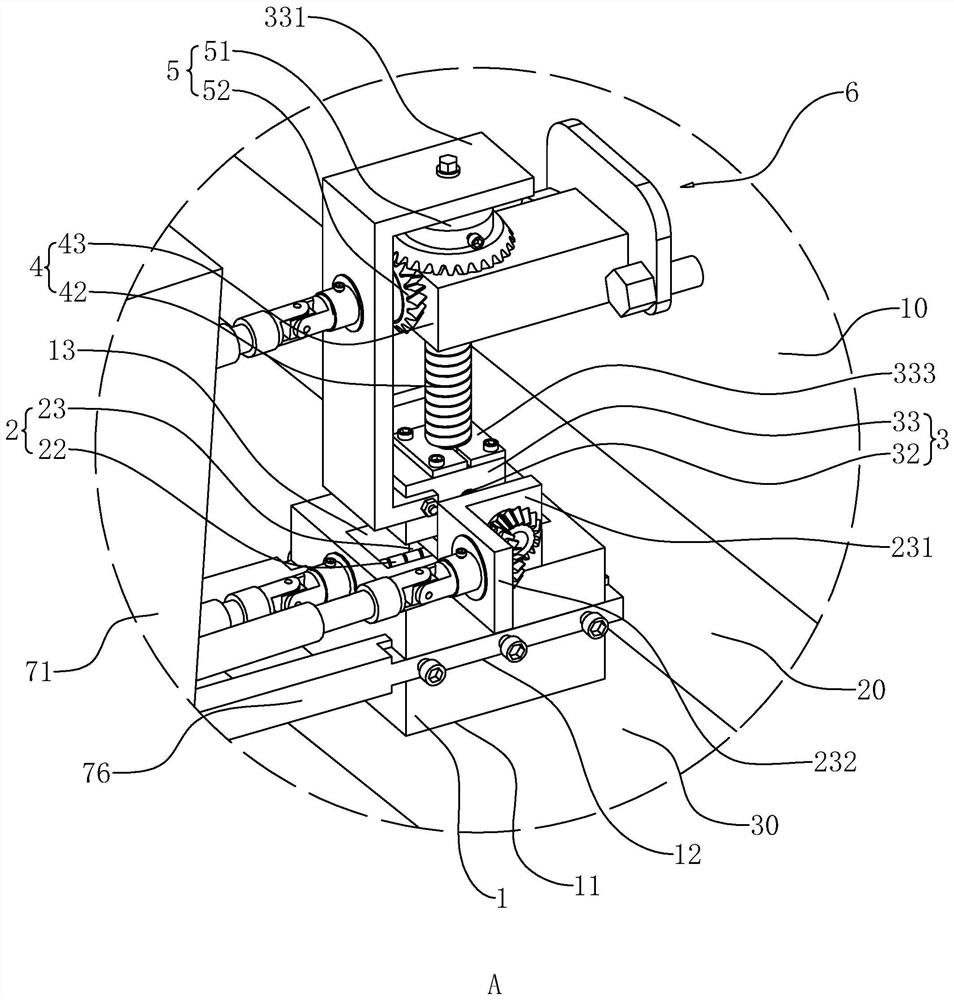

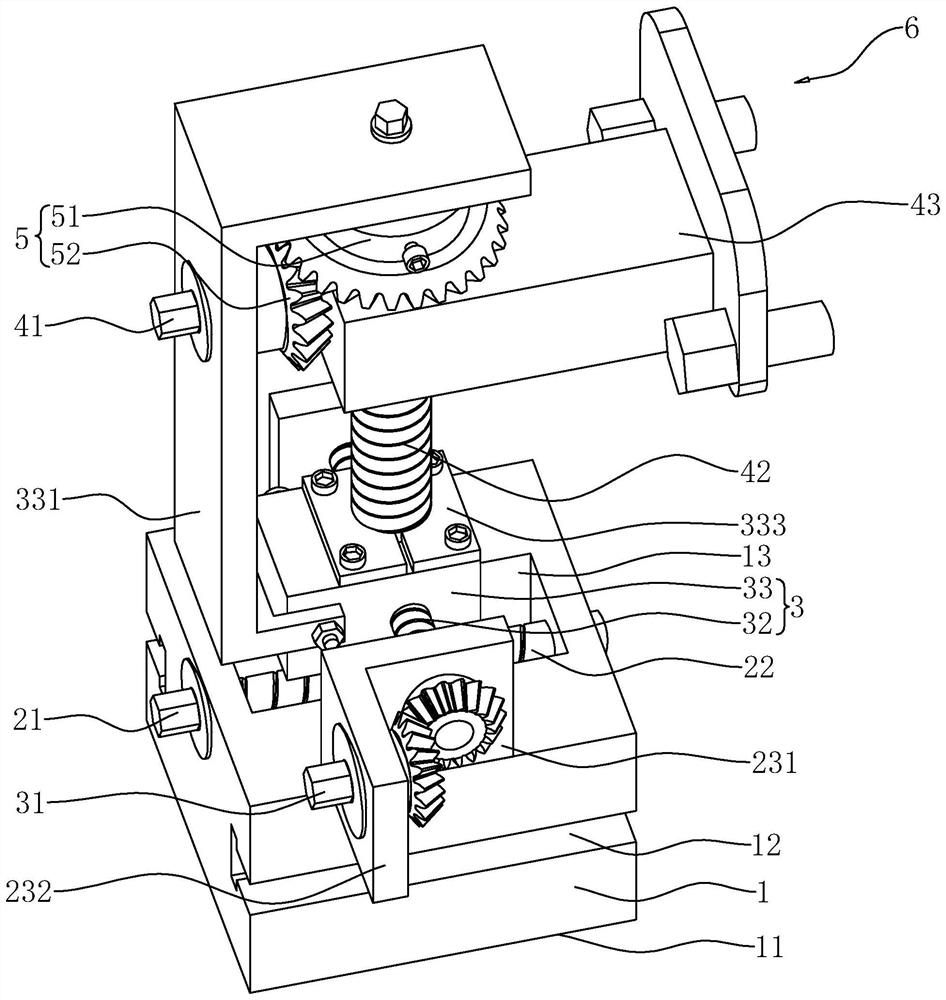

Fine adjustment device for intelligent fine adjustment system of ballastless track slab

ActiveCN112176794AEasy to operateLarge adjustment rangeBallastwayRailway track constructionTrackwayClassical mechanics

The invention relates to a fine adjustment device for an intelligent fine adjustment system of a ballastless track plate. The device comprises a base, a Y-direction adjustment structure is arranged onthe base, a Y-direction adjustment head and an X-direction adjustment structure are arranged on the Y-direction adjustment structure, an X-direction adjustment head and a Z-direction adjustment structure are arranged on the X-direction adjustment structure, and a Z-direction adjustment head is arranged on the Z-direction adjustment structure. Steering mechanisms are arranged between the X-direction adjustment structure and the X-direction adjustment head and between the Z-direction adjustment structure and the Z-direction adjustment head respectively, the steering mechanisms adjust the transmission direction to enable the X-direction adjustment head, the Y-direction adjustment head and the Z-direction adjustment head to face the same direction, and a connecting piece is arranged on the Z-direction adjustment structure. The adjustment device has the effects that all the adjustment structures are arranged to adjust the position of the connecting piece in the space coordinate system, a track plate is straightened and leveled through cooperation of the connecting pieces of the multiple fine adjustment devices, and meanwhile, the orientations of all the adjustment heads are consistentthrough the arrangement of the steering mechanisms, so workers can operate all the adjustment heads more conveniently.

Owner:CHINA RAILWAY NO 3 ENG GRP EAST CHINA CONSTR CO LTD +3

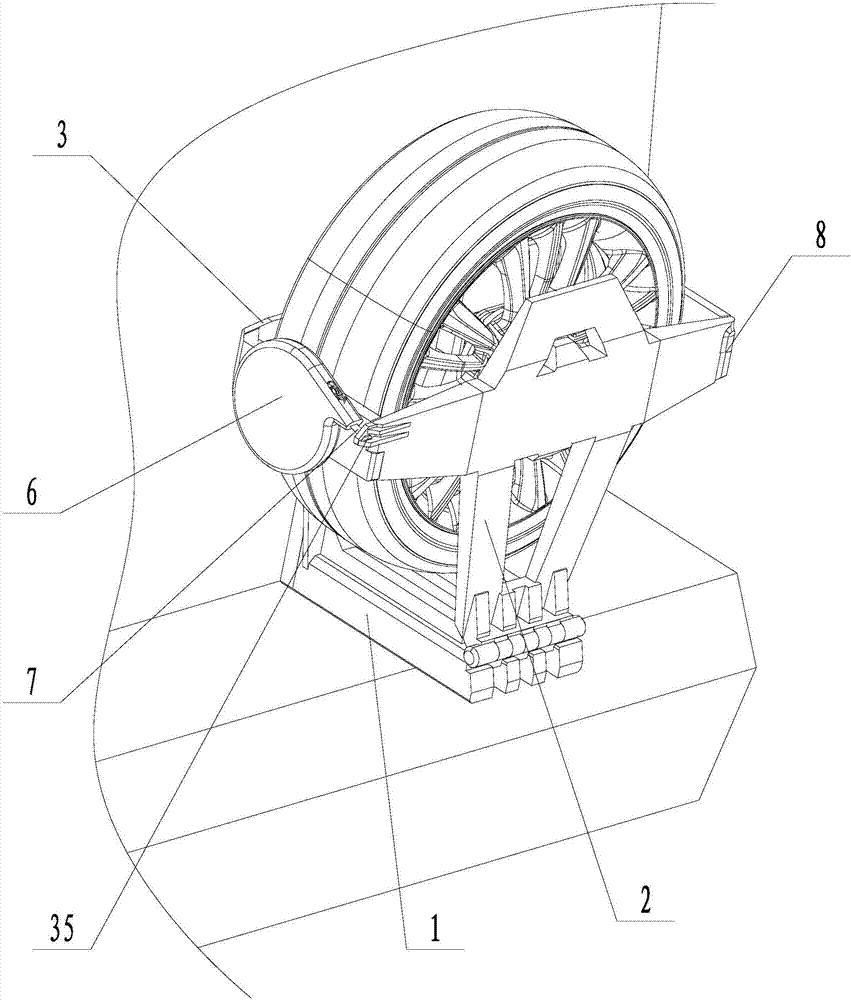

External-hanging type spare tire rapid replacement device and spare tire mounting and detaching method

ActiveCN107089103ALabor-saving spare tire loading and unloading processReduce difficultyWork holdersTyre repairingSpare tireCoil spring

The invention discloses an external-hanging type spare tire rapid replacement device and a spare tire mounting and detaching method. The defects that an existing spare tire rapid replacement device is hard in spare tire mounting and detaching processes, the difficulty of spare tire replacement is increased, spare tire mounting and detaching operation is complex, the stability of a spare tire is not good after mounted on the rapid replacement device, and the safety hidden danger of slipping exists are overcome. The external-hanging type spare tire rapid replacement device comprises a base, a spare tire storage frame and a mounting frame; a left clamping arm and a right clamping arm are arranged on the mounting frame; the spare tire storage frame is connected on the left clamping frame and the right clamping frame in an abutting mode; a spring balancer is mounted on the left clamping arm; a coil spring is arranged in the spring balancer; one end of the coil spring extends out of the balancer and is connected with and tightens the spare tire storage frame; a connecting lock is mounted between the right clamping arm and the spare tire storage frame; a spare tire positioning mechanism is connected on the inner surface of the spare tire storage frame; the spare tire is mounted on the spare tire storage frame and positioned through the spare tire positioning mechanism; and an elastic positioning pin used for being connected on the inner wall of a spare tire rim in an abutting mode is arranged at the upper end of the mounting frame.

Owner:ZHEJIANG LAND ROVER AUTOMOBILE +1

Automatic tolerance adjusting device

PendingCN110153947APrevent movementAvoid insufficient frictionMetal-working hand toolsEngineeringMechanical engineering

The invention provides an automatic tolerance adjusting device. The device comprises an upper housing, a positioning stud, a locking spacer and an elastic adjusting sheet, wherein the upper housing isof a hollow chamber structure, and an inner chamber of the upper housing is divided into a mounting hole and a first inner chamber through a baffle plate; a protruded outer edge is arranged at the opening end of the mounting hole; positioning ribs are arranged on the outer wall of the upper housing; the elastic adjusting sheet is arranged on the outer surfaces of the positioning ribs; a boss which fits the first inner chamber is arranged in the middle part of the positioning stud, and the boss is instead into the first inner chamber; the upper housing is fixed to the positioning stud in a thread connection manner; and the locking spacer is arranged in the first inner chamber and can freely move in a shaft hole clearance which is formed between the end surface of the boss and the baffle plate of the upper housing. According to the device, the dynamic energy through which a bolt rotates and forwards moves is fully utilized to automatically remove tolerance accumulation, thus accurate positioning and assembling can be quickly effectively realized, and the defects of a plurality of processes, high cost, high difficulty in operation technology and low working efficiency in the prior art can be solved.

Owner:SHANGHAI JIAMU AUTO PARTS CO LTD

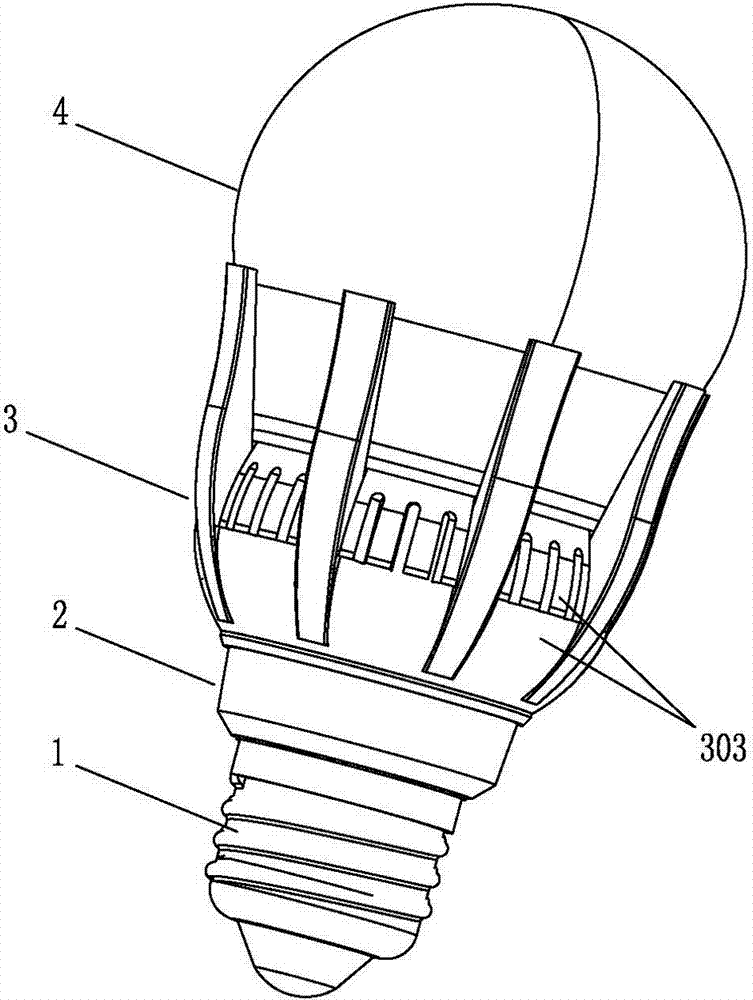

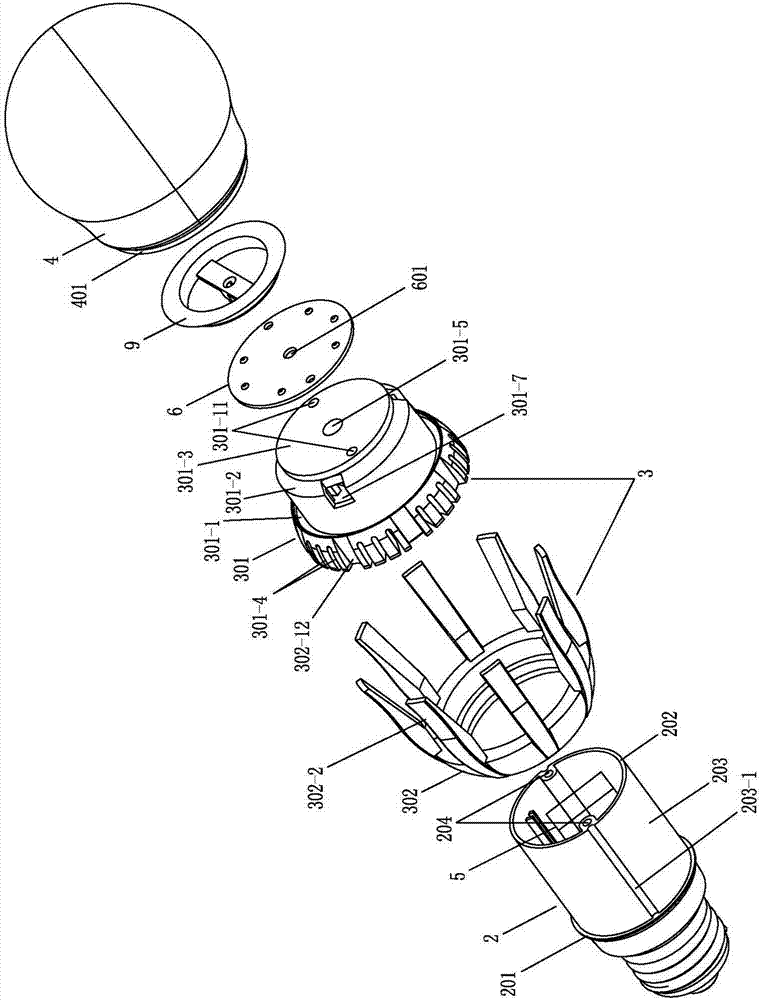

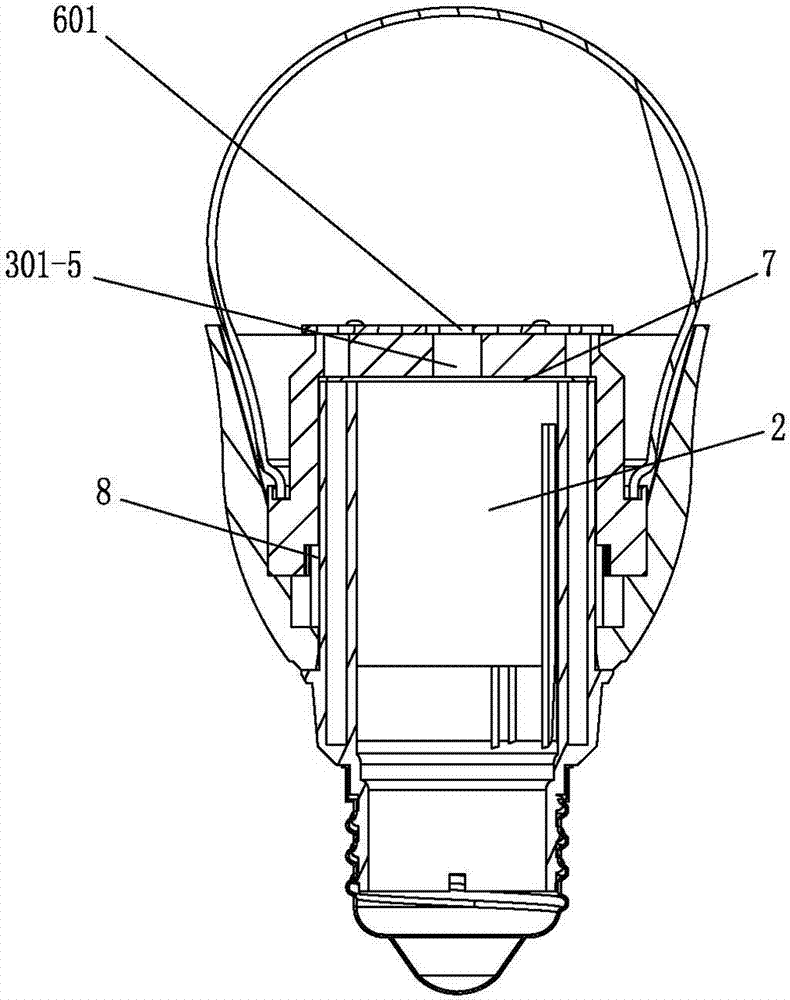

Light emitting diode (LED) lamp bulb

InactiveCN102900982AReduce resistanceTo achieve the purpose of heat dissipationPoint-like light sourceLighting heating/cooling arrangementsGlass coverEngineering

The invention relates to a light emitting diode (LED) lamp bulb, which comprises a metal connector, an insulating sleeve, a radiator and a glass cover, wherein an LED lamp plate is fixed on the top surface of the radiator; the radiator is formed by vertically splicing an upper radiator and a lower radiator and has a hollow sphere shape; a radiating sleeve extends out of the top surface of the upper radiator and is sleeved and fixed on the insulating sleeve; a plurality of upper radiating holes communicated with an inner cavity are formed in the side wall of the upper radiator along the circumferential direction; and an upper central through hole and a lamp plate central through hole which are communicated with the upper radiating holes are respectively formed in the top surface of the radiating sleeve and the LED lamp plate. The LED lamp bulb is simple and rational in structure; the upper radiating holes, the upper central through hole and the lamp plate central through hole are communicated to form a rational gas flow channel, so that a radiating effect is effectively improved, and the service life of the lamp bulb is prolonged.

Owner:佛山市顺德区保利达电器有限公司

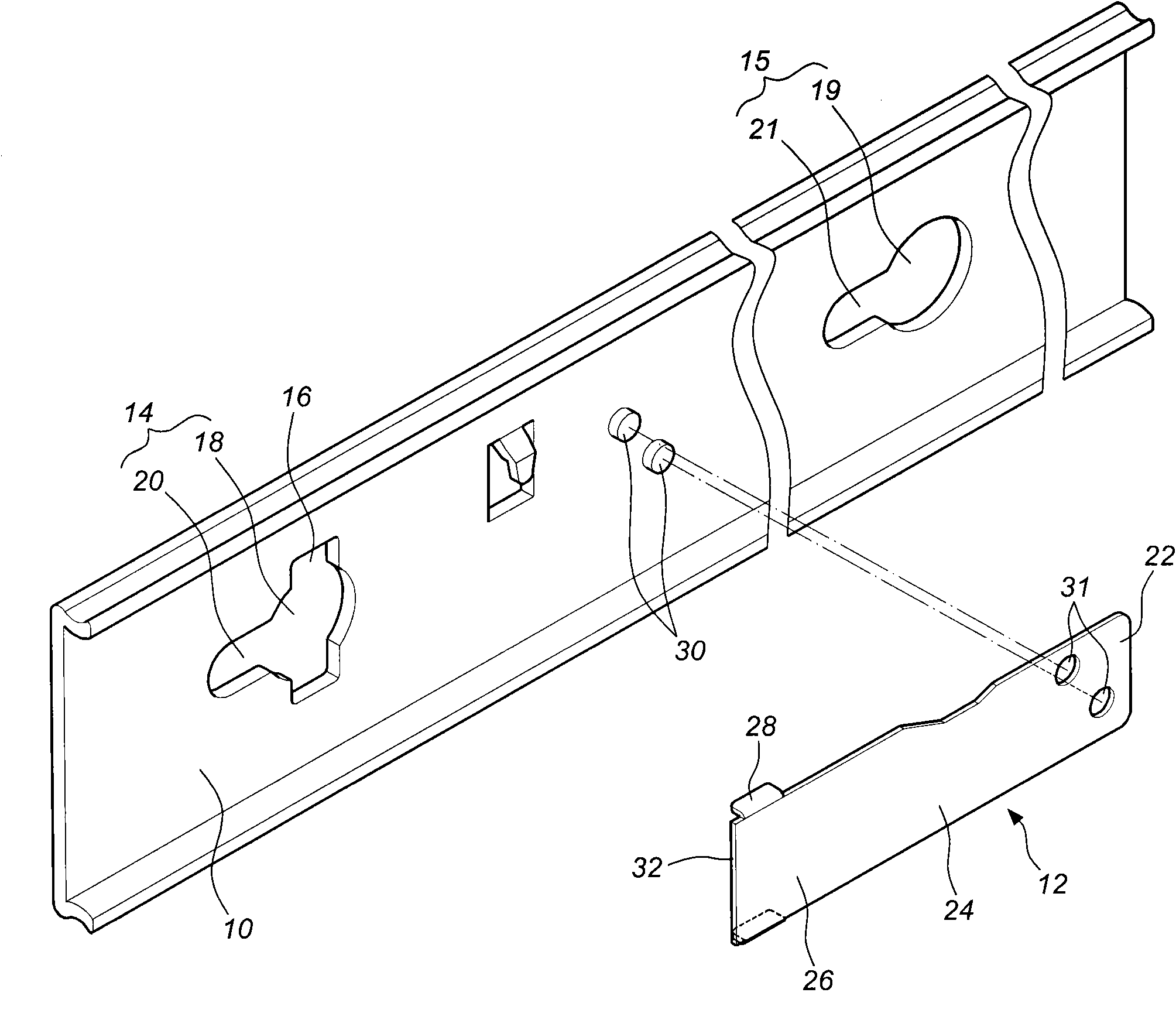

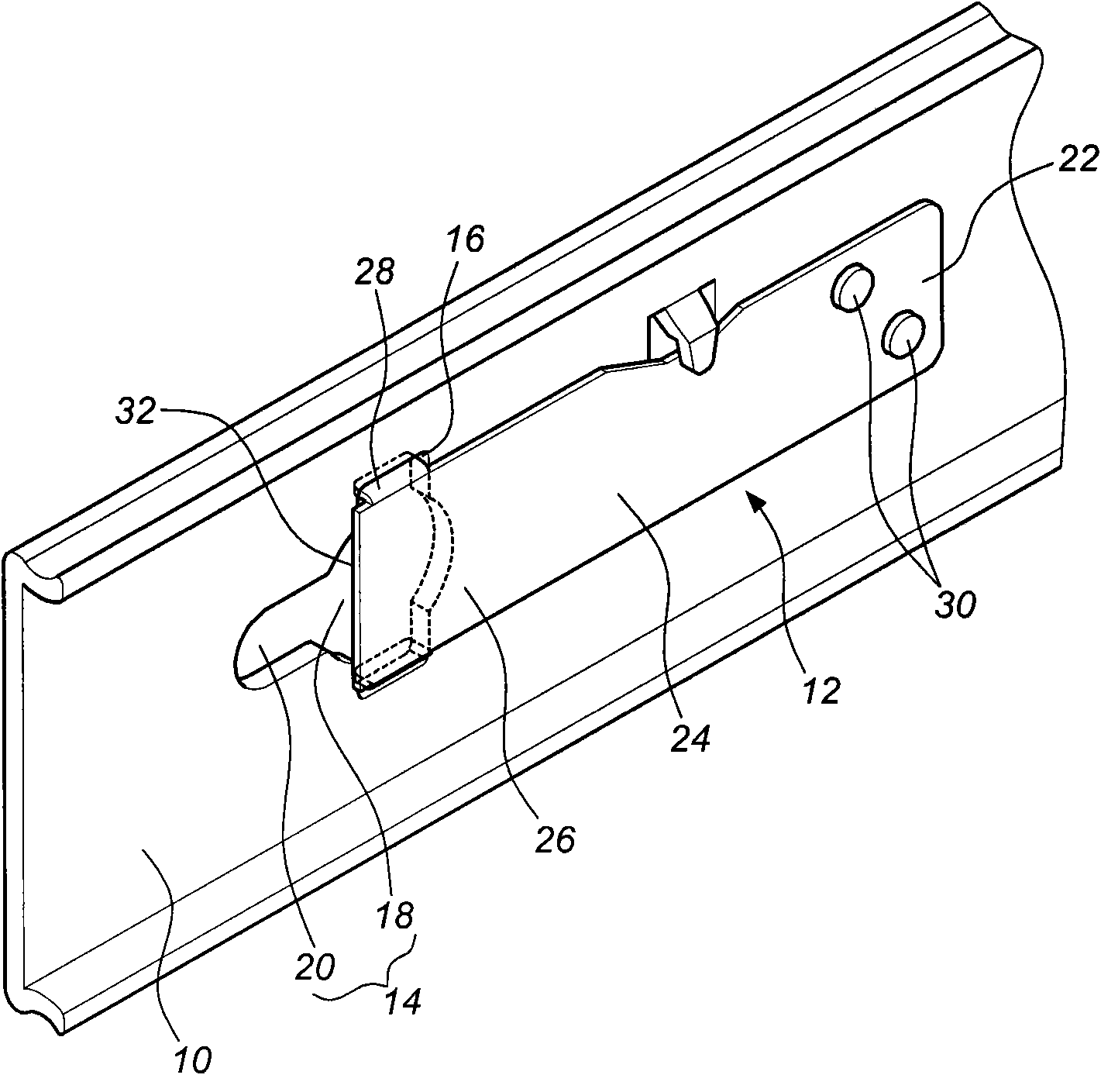

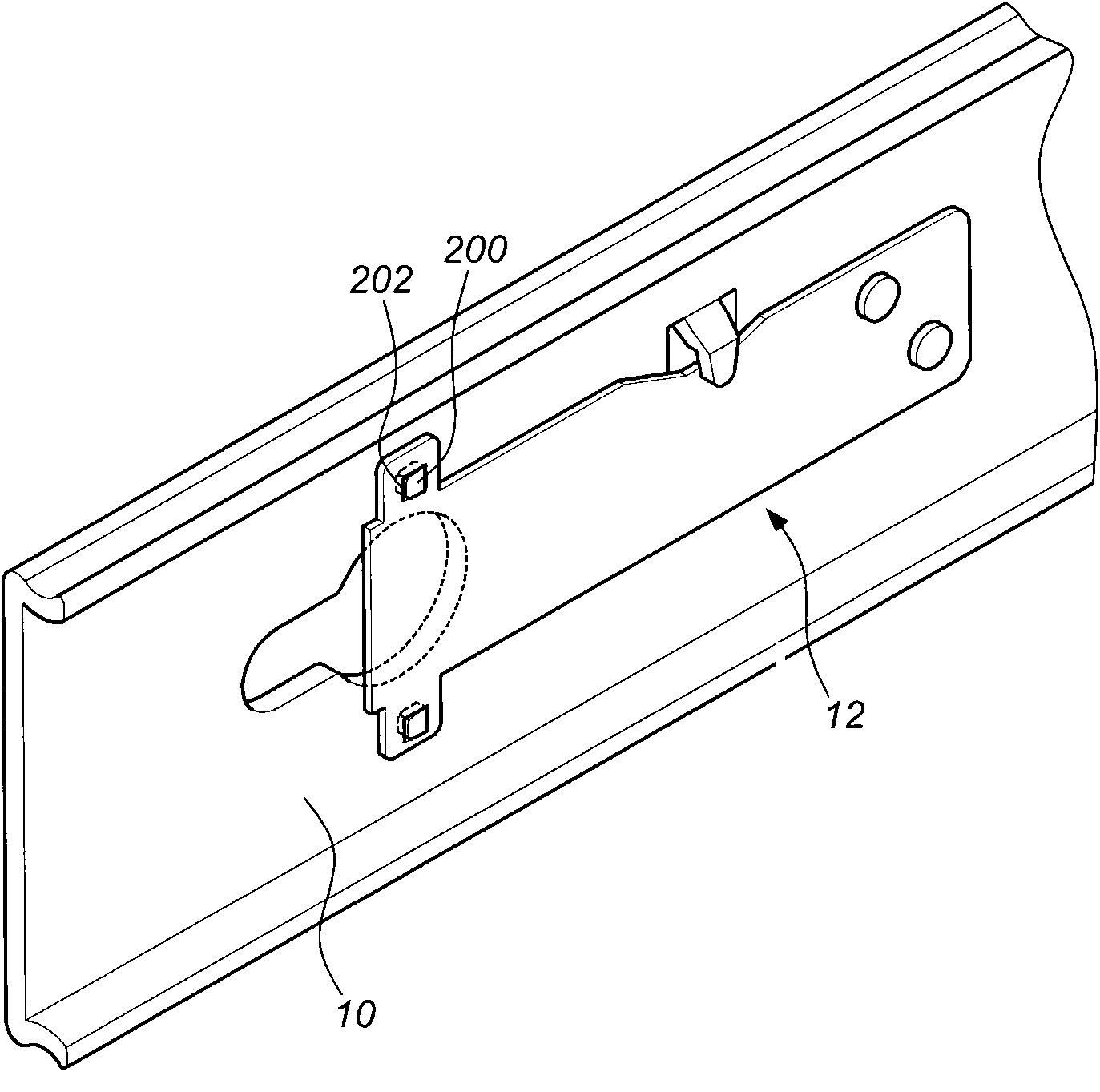

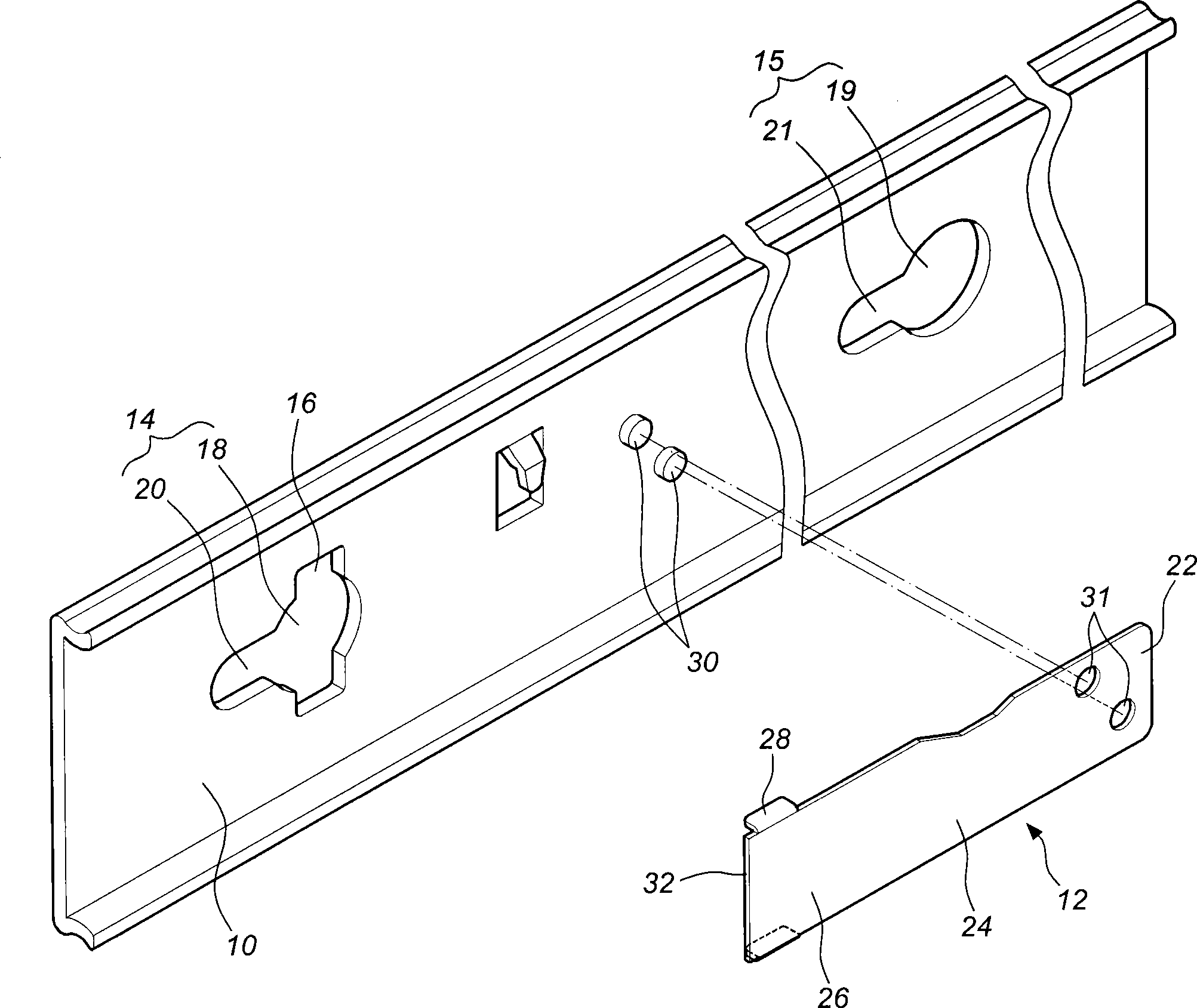

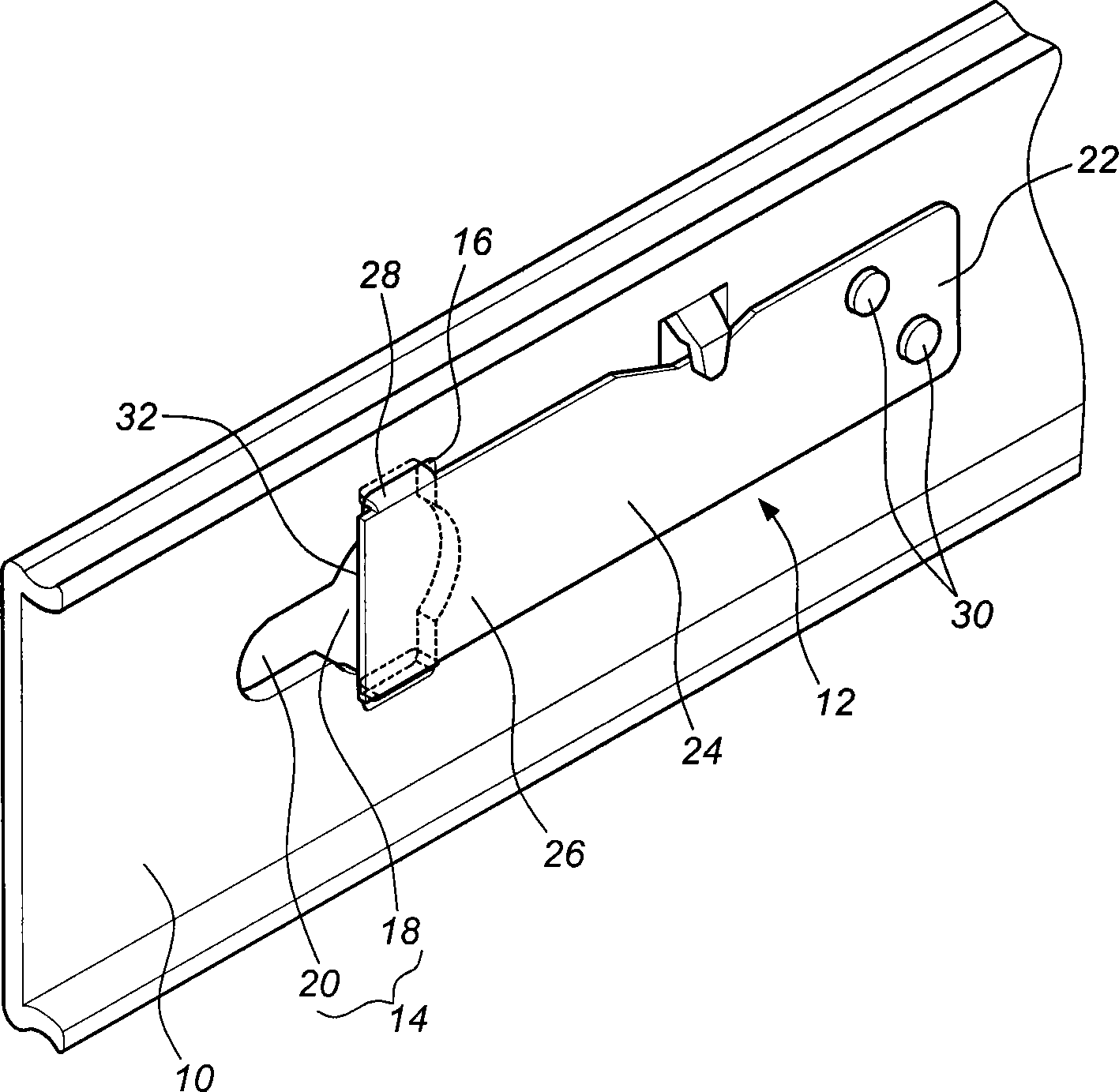

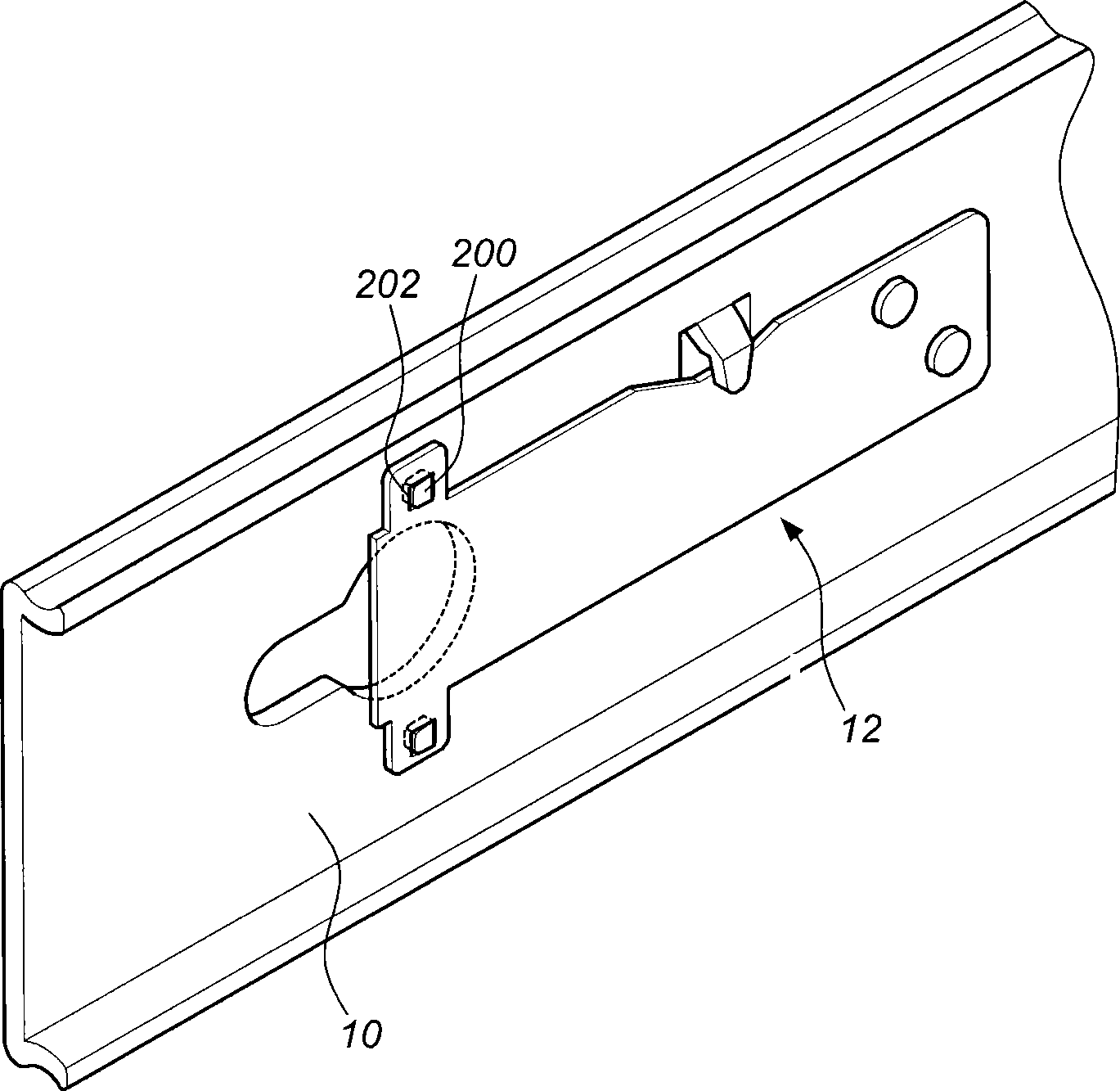

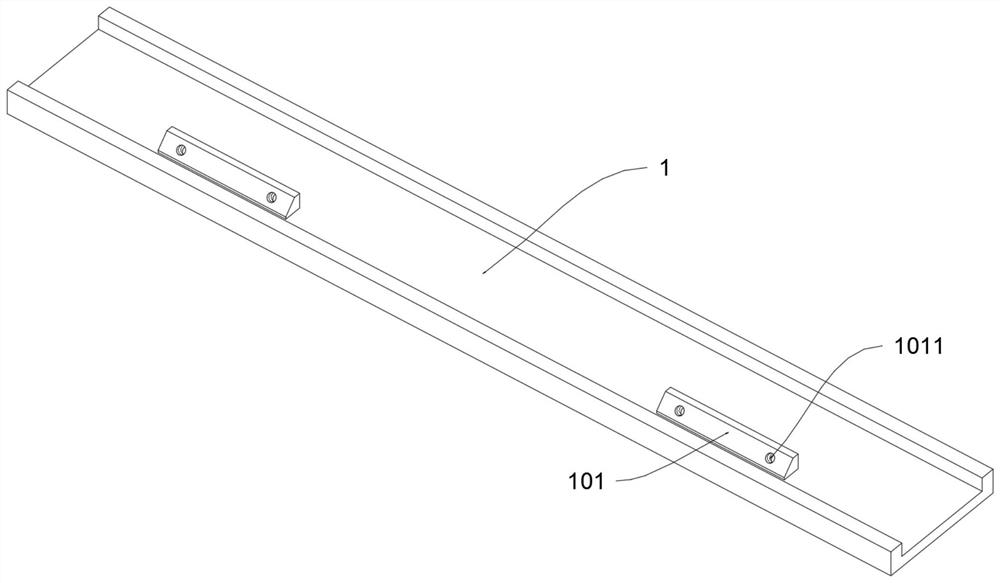

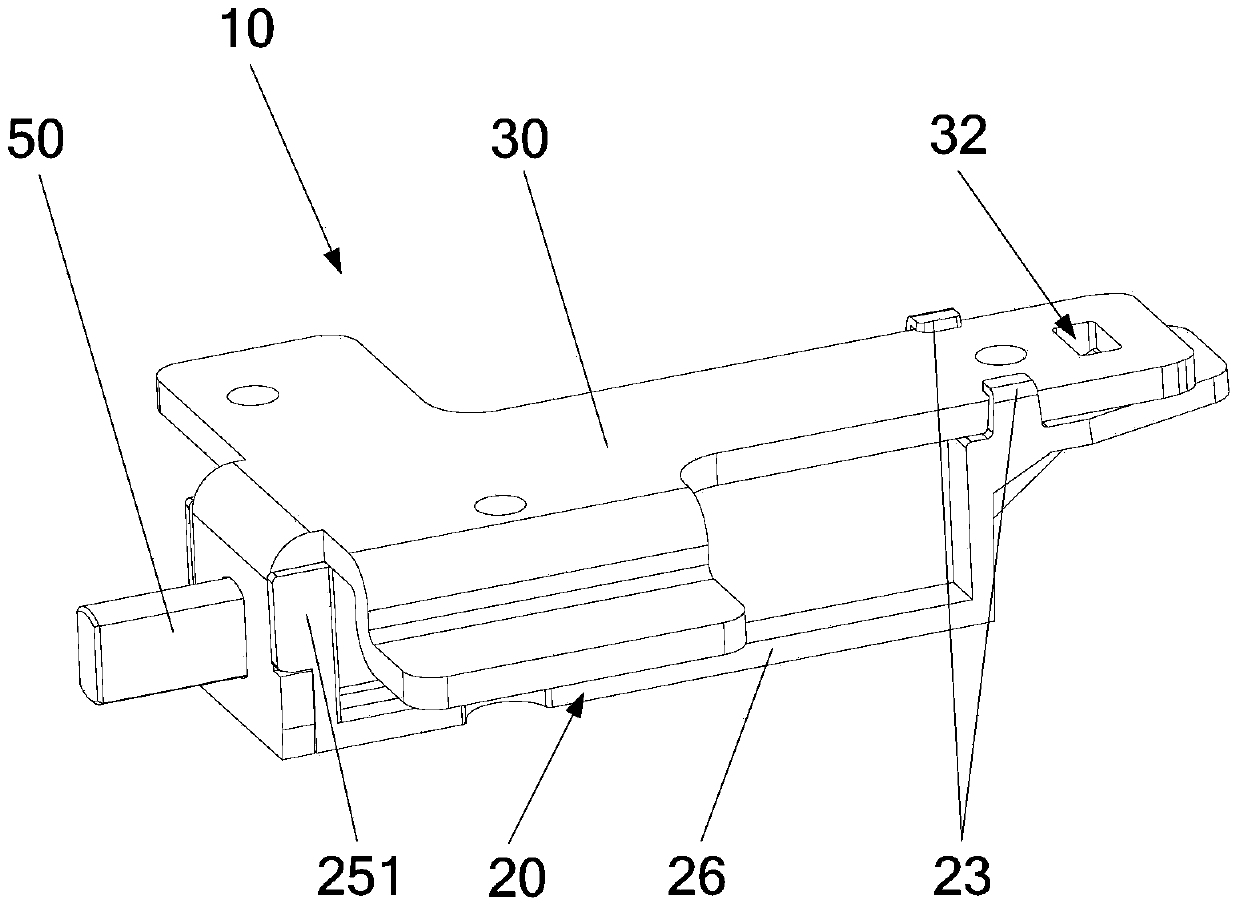

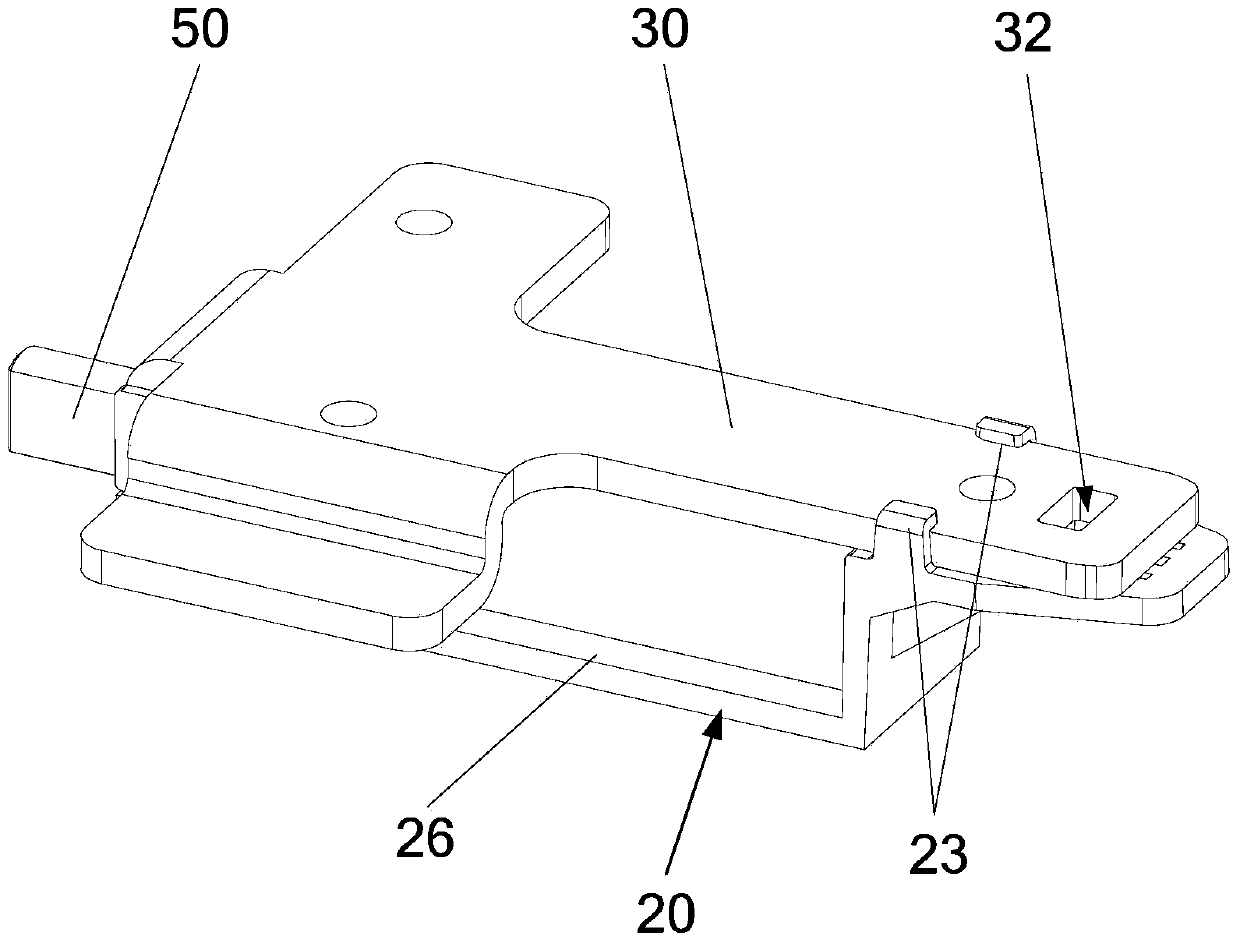

Quick-detachment positioning structure for rail component

ActiveCN102755017AImprove positioning strengthAvoid positioning failureRack/frame constructionSupport structure mountingOpen holeMental detachment

The invention relates to a quick-detachment positioning structure for a rail component. The quick-detachment positioning structure for the rail component comprises an open hole formed in the rail component and a positioning component corresponding to the open hole, wherein the rail component comprises a first stopping part adjacent to the open hole; the open hole comprises an open part and a clamped part communicated with the open part; the positioning component comprises a base part, an elastic arm, a limiting part and a second stopping part; the base part is connected to the rail component and is positioned; the elastic arm extends from the base part and is connected with the limiting part; the limiting part has a first stopping end corresponding to the clamped part; the second stopping part is connected to the limiting part; and when the first stopping end and the clamped part surround into a locked closed area, the second stopping part props against the first stopping part of the rail component, so that the position of the first stopping end is more steady.

Owner:KING SLIDE WORKS CO LTD

Quick-detachment positioning structure for rail component

ActiveCN102755017BImprove positioning strengthAvoid positioning failureRack/frame constructionSupport structure mountingEngineeringOpen hole

The invention relates to a quick-detachment positioning structure for a rail component. The quick-detachment positioning structure for the rail component comprises an open hole formed in the rail component and a positioning component corresponding to the open hole, wherein the rail component comprises a first stopping part adjacent to the open hole; the open hole comprises an open part and a clamped part communicated with the open part; the positioning component comprises a base part, an elastic arm, a limiting part and a second stopping part; the base part is connected to the rail component and is positioned; the elastic arm extends from the base part and is connected with the limiting part; the limiting part has a first stopping end corresponding to the clamped part; the second stopping part is connected to the limiting part; and when the first stopping end and the clamped part surround into a locked closed area, the second stopping part props against the first stopping part of the rail component, so that the position of the first stopping end is more steady.

Owner:KING SLIDE WORKS CO LTD

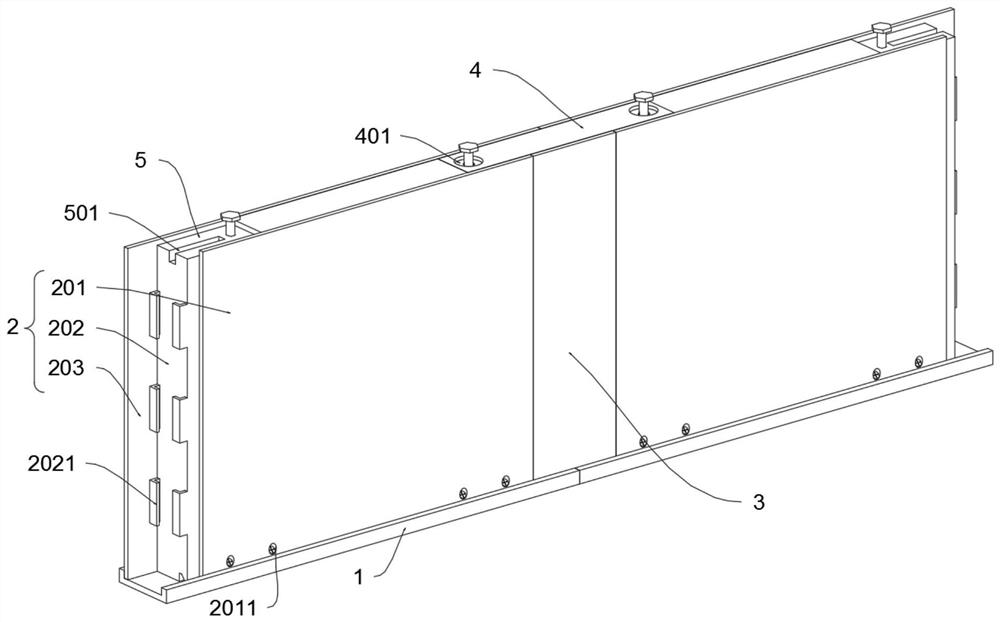

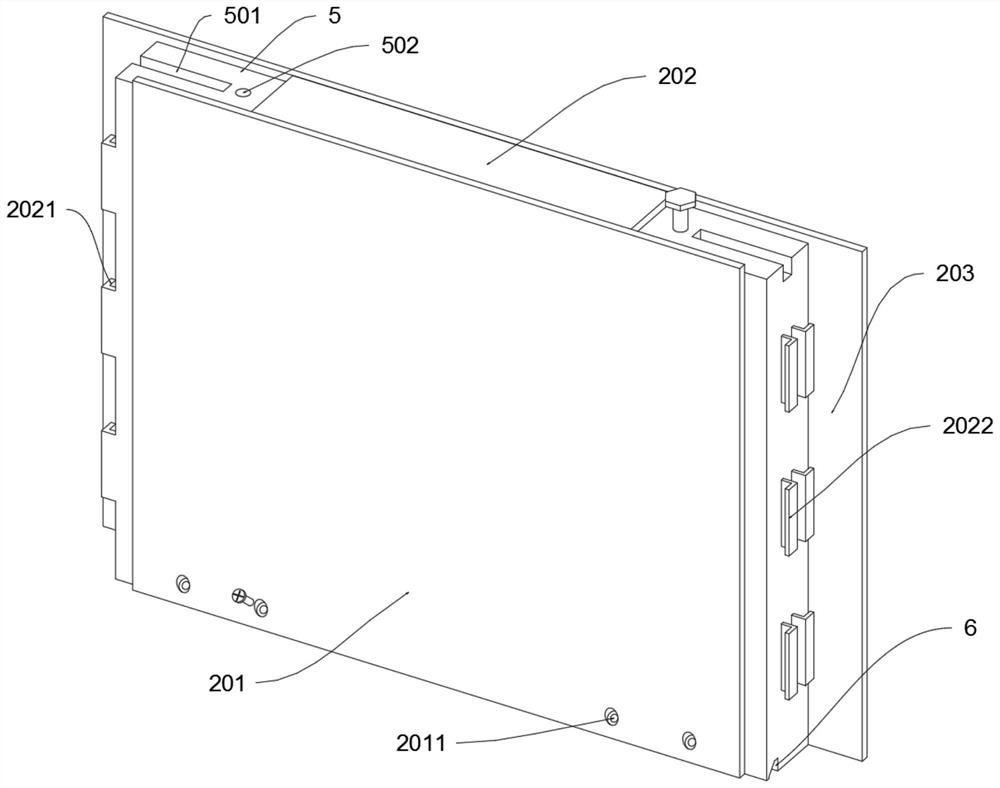

Steel structure building wallboard unit structure easy to assemble

InactiveCN112609892AImprove stabilityReinforced Relative Connection StrengthConstruction materialBuilding material handlingUnit structureUltimate tensile strength

The invention provides a steel structure building wallboard unit structure easy to assemble. The steel structure building wallboard unit structure comprises a mounting underframe, a connecting column, an upper gland, upper positioning grooves and lower positioning grooves, wherein walls are fixedly connected to the upper portion of the mounting underframe, and the lower surfaces of the walls are located in a mounting underframe groove; the connecting column is movably connected between the two sets of walls; the upper positioning grooves are formed in the left sides and the right sides of the upper surfaces of the walls correspondingly in two positions; the upper gland is fixedly connected to the upper portions of the upper positioning grooves through screws; the lower positioning grooves are formed in the lower surfaces of the walls; the mounting underframe is an arched groove body, and a lower reinforcing block of a trapezoidal structure is connected to the upper surface of the mounting underframe in a welded mode; and a lower fixing hole is formed in front of the lower reinforcing block and is an internal threaded hole. Therefore, the connecting mode of the spliced walls is improved, a middle connecting mechanism is improved, and the problems of stress concentration and insufficient airtightness of the wall connecting positions are reduced while the connecting strength is ensured.

Owner:黄海湖

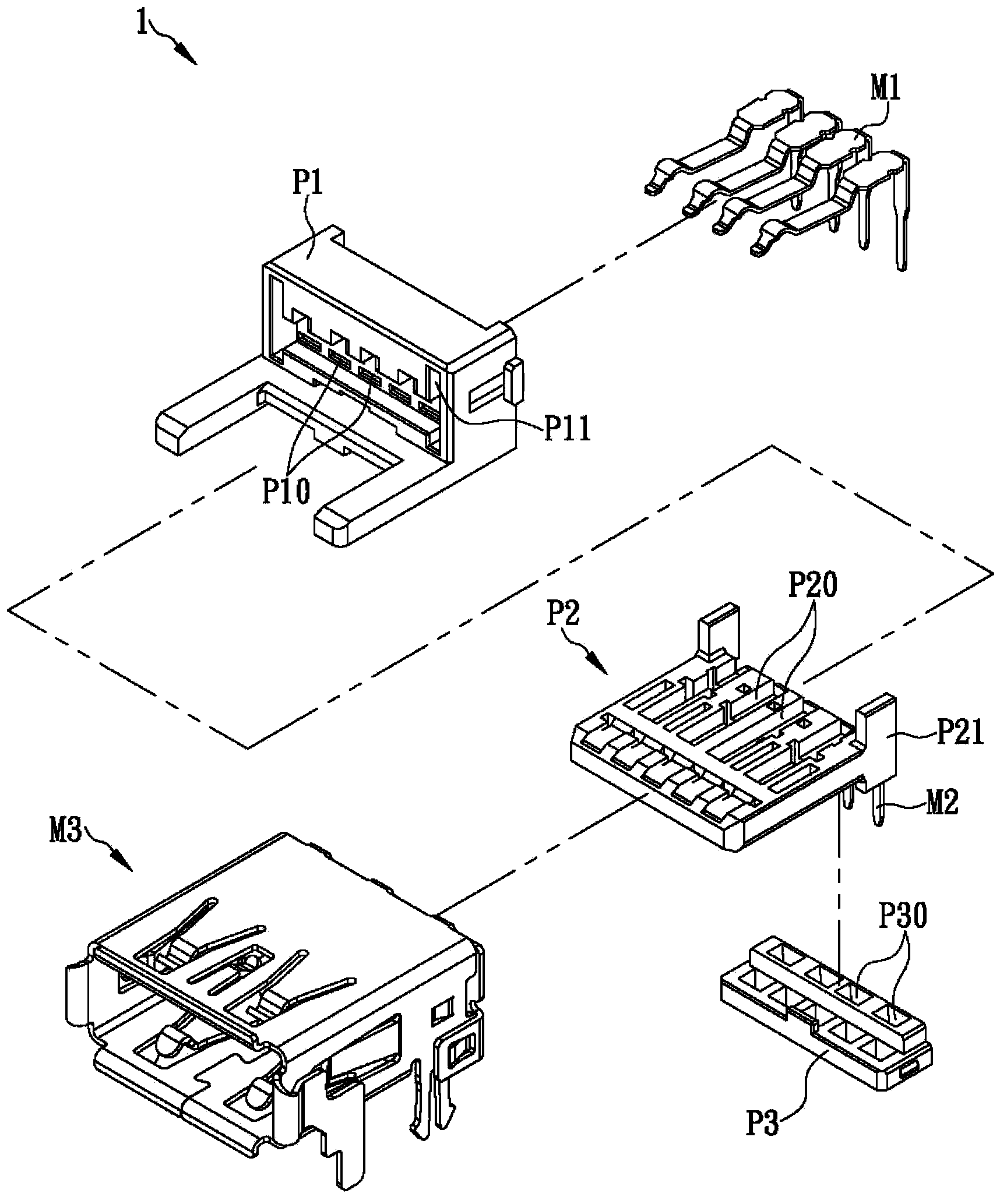

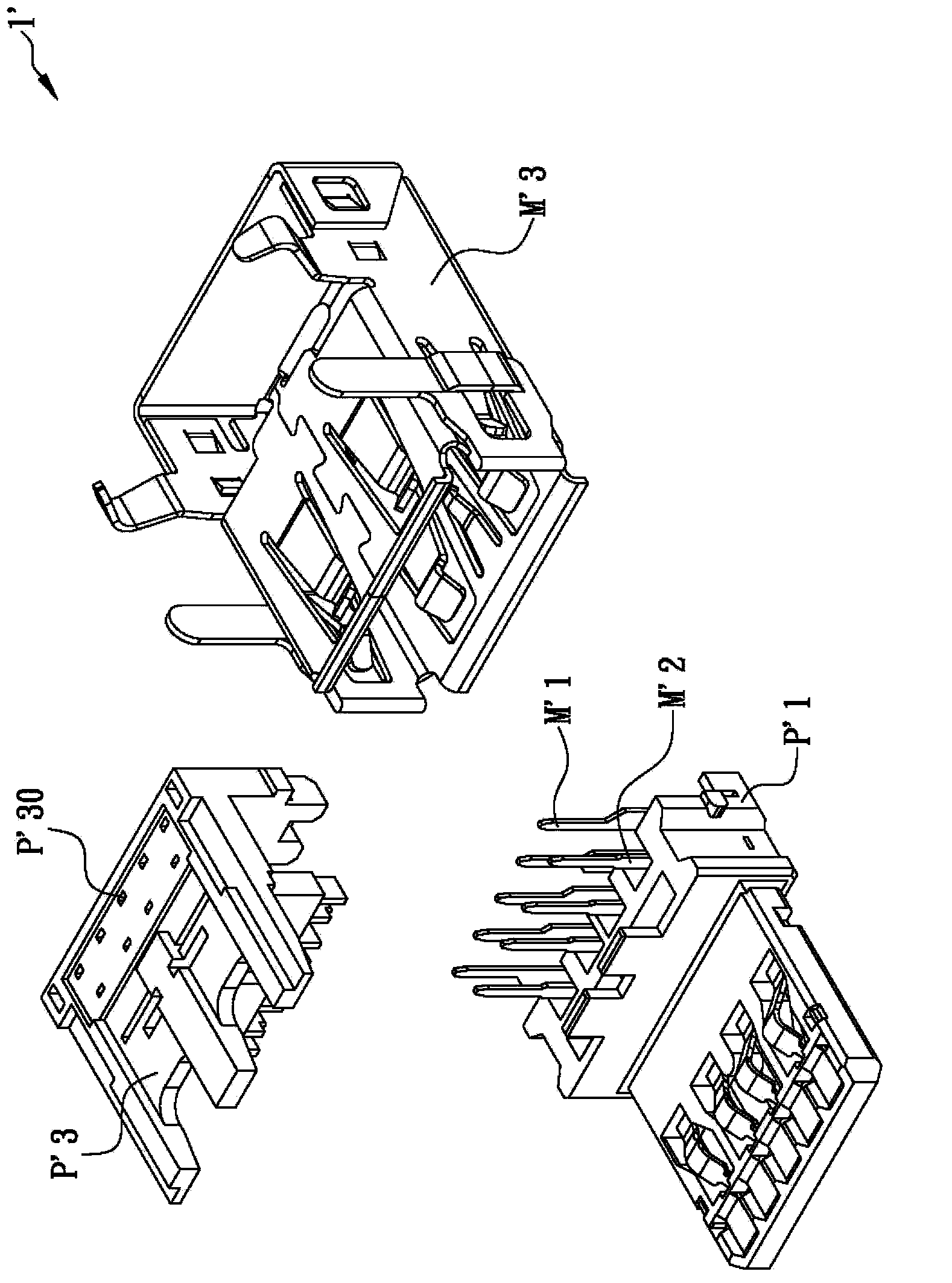

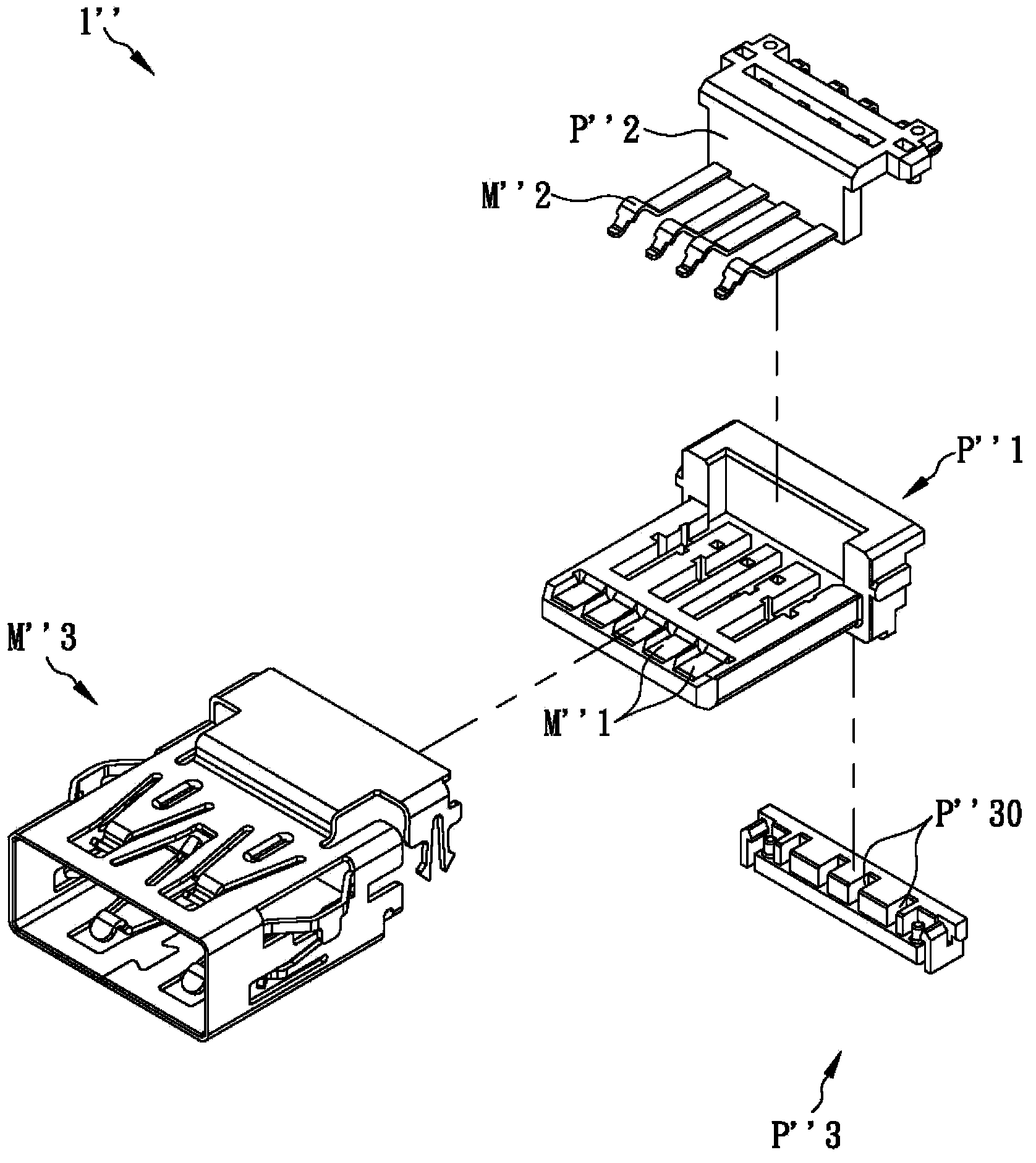

Method for locating connecting terminal by using repeat buried injection technology

InactiveCN103840350AIncreased plugging forceSignal transmission is stableContact member assembly/disassemblySizingEngineering

The invention relates to a method for locating a connecting terminal by using a repeat buried injection technology. The method is used for generating a signal connector and comprises the following steps that multiple first connecting terminals are located in a first mould, a first sizing material is injected to enable the first sizing material to form a first seat body after solidification, and the first seat body is formed on the first connecting terminals; then, the first seat body is located on a second mould, multiple second connecting terminals are located to one side of the first seat body; a second sizing material is injected in the second mould to enable the second sizing material to form a second seat body after solidification, the second seat body and the first seat body are combined in a seamless mode and are formed on the second connecting terminals, and then the signal connector is formed through the combination. In this way, through the buried injection technology, the locating strength of the connecting terminals can be improved effectively, and the production qualified rate and the product efficiency of the signal connector can be improved.

Owner:GUIMA SCI & TECH

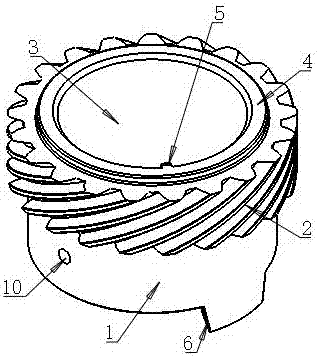

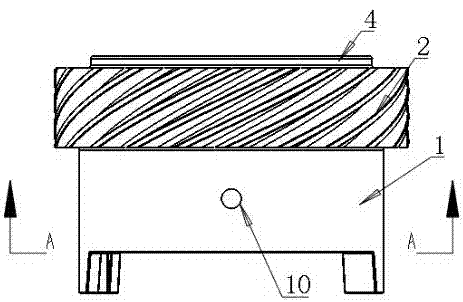

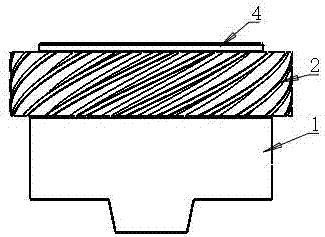

Special close type spiral gear structure

InactiveCN107289087AImprove tightnessGood transmission effectPortable liftingGearing elementsEngineeringUltimate tensile strength

The invention relates to the technical field of gears, in particular to a special close type spiral gear structure. According to the technical scheme, a cylindrical main body structure is included, a spiral gear structure is arranged on the cylindrical surface of the upper end of the main body structure, a cylindrical center mounting hole running through a whole part is formed in the center of the main body structure, a protection boss is arranged in the center of the upper end surface of the spiral gear structure, a central shaft positioning column is arranged on the internal cylindrical surface of the center mounting hole, two uniformly distributed arc-shaped clamping bosses are arranged on the lower end surface of the main body structure, the outer side of the clamping boss and the external cylindrical surface of the main body structure are coplanar, and the inner side of the clamping boss and the cylindrical surface of the center mounting hole are coplanar. The special close type spiral gear structure has the advantages that the tightness is better when the special close type spiral gear structure is matched with other gear structures for use, the anti-fatigue capacity in the use process is higher, the position strength of the clamping effect is higher, the service life is longer, the transmission effect in the transmission process can be better, and assembly connection is conducted more conveniently.

Owner:TAIZHOU LIHUA MACNINERY

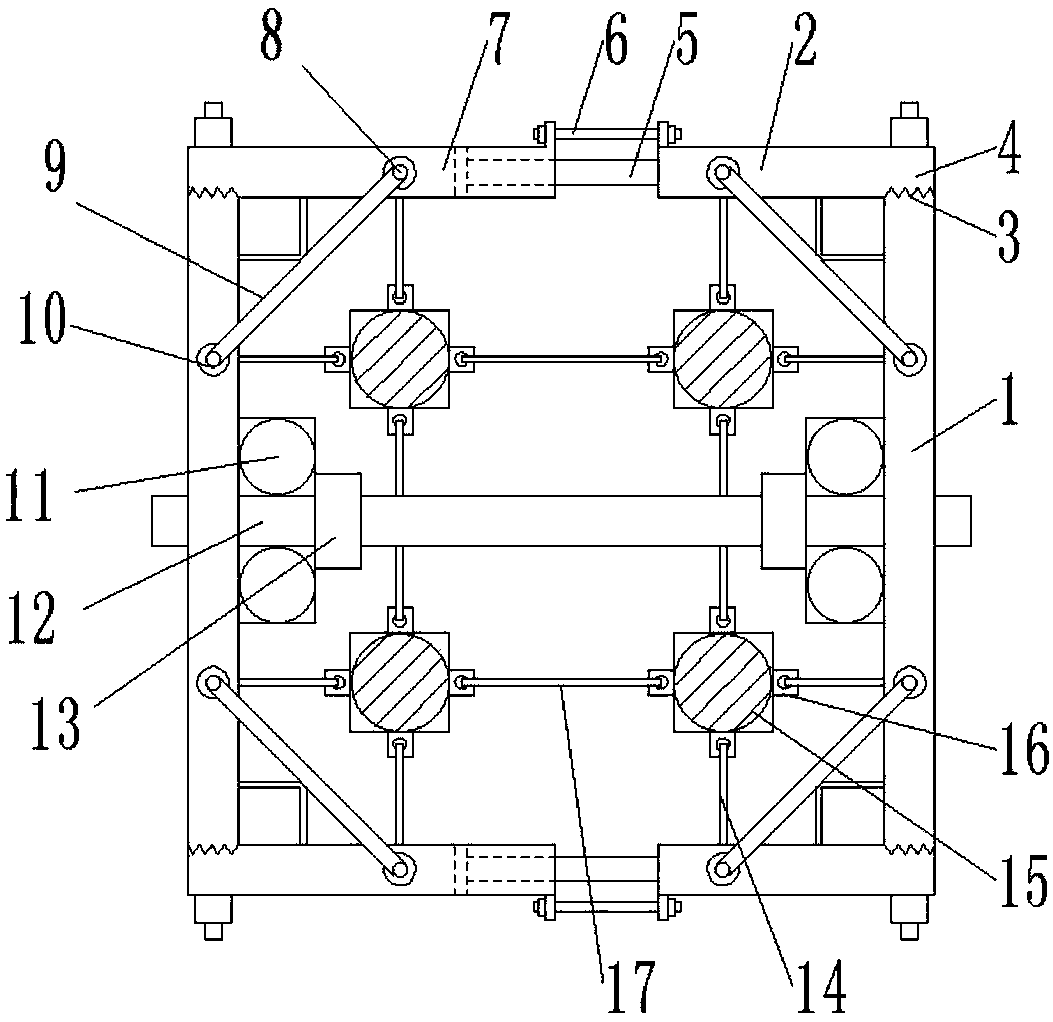

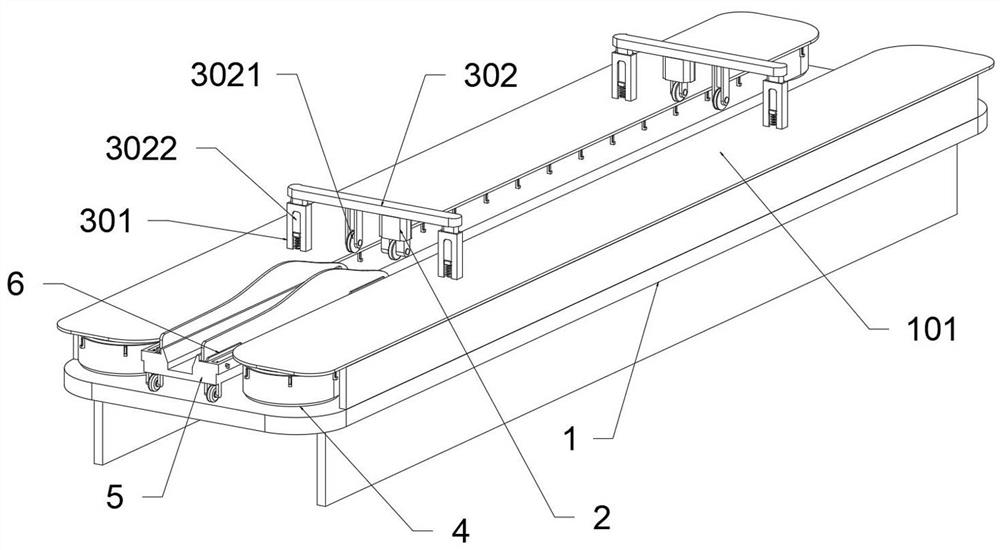

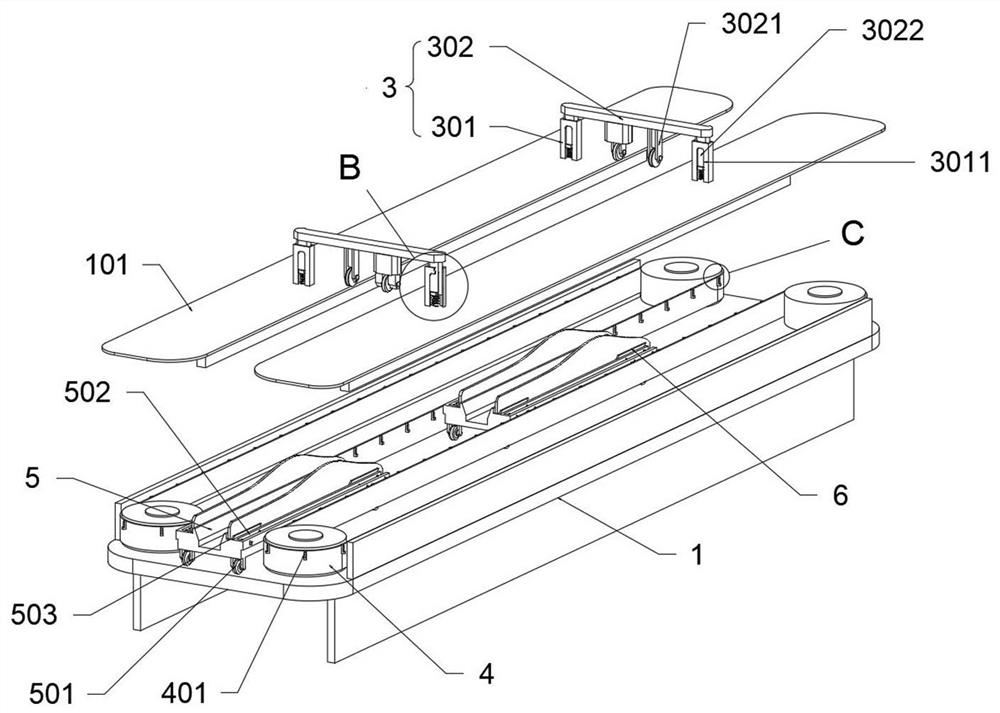

Blade polishing device for wind power generation

ActiveCN113635208AImprove positioning strengthImprove positioning stability performancePolishing machinesGrinding feedersTelescopic cylinderEngineering

The invention provides a blade polishing device for wind power generation, belongs to the technical field of wind power generation part machining, and aims to solve the problem that when blades of a fan are polished, due to the fact that the arc-shaped edges of the blades are of irregular structures, when the edges of the blades need to be polished, numerical control equipment is used for polishing the blades with different arc-shaped structures, and corresponding data calculation and programming need to be carried out for different types of blades, so that small batch blade production is inconvenient. The blade polishing device for wind power generation comprises a conveying frame, wherein two sets of automatic pressing balance frames are fixedly connected to the upper surface of the conveying frame; the two sets of automatic pressing balance frames are fixedly connected to the left side and the right side of the conveying frame correspondingly; and two telescopic cylinders are fixedly connected onto the upper surface of an upper frame cover. Two blades are installed at the same time, and the edges of the blades on the front side and the rear side are polished in sequence, so that operation is easy and convenient; and polishing of the arc-shaped edges of the blades with various structures can be achieved without equipment adjustment, so that compared with numerical control polishing equipment, the steps of programming and equipment size adjustment are omitted.

Owner:南通创智新材料科技有限公司

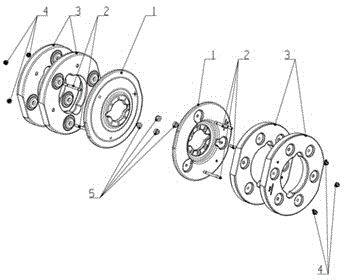

Roller tractor rear balance weight

InactiveCN104972826AAvoidance guaranteeHigh positioning accuracyWheel-ballasting weightsEngineeringTractor

The invention discloses a roller tractor rear balance weight which comprises a first balance weight block and a second balance weight block. The first balance weight block is provided with a center hole. Eight bolt positioning holes evenly distributed along the circumference are formed in the edge of the center hole. Two symmetric bolt positioning holes of the eight bolt positioning holes are in a semi-circular notch shape and used for installing a spacer bush. The other six bolt positioning holes are round holes used for installing bolts. The outer side face of the first balance weight block is provided with three grooves evenly distributed along the circumference. Threaded holes are formed in the circle centers of the grooves of the first balance weight block. Six grooves evenly distributed along the circumference are formed in the outer side of the second balance weight block. Protrusions are arranged opposite to three spaced grooves of the six grooves, the protrusions on the second balance weight block adjacent to the first balance weight block correspond to the grooves of the first balance weight block, and positioning holes are further formed in the circle centers of the grooves of the second balance weight block. Two small planes are symmetrically arranged along the outer circumference of the second balance weight block and used for assembling rear receding valves. The roller tractor rear balance weight is reasonable and simple in structural design, reliable in positioning and convenient to disassemble and assemble, balance weights with different weights can be selectively installed according to requirements, and different practical work requirements are met.

Owner:SHANDONG CHANGLIN DEUTZ FAHR MACHINERY

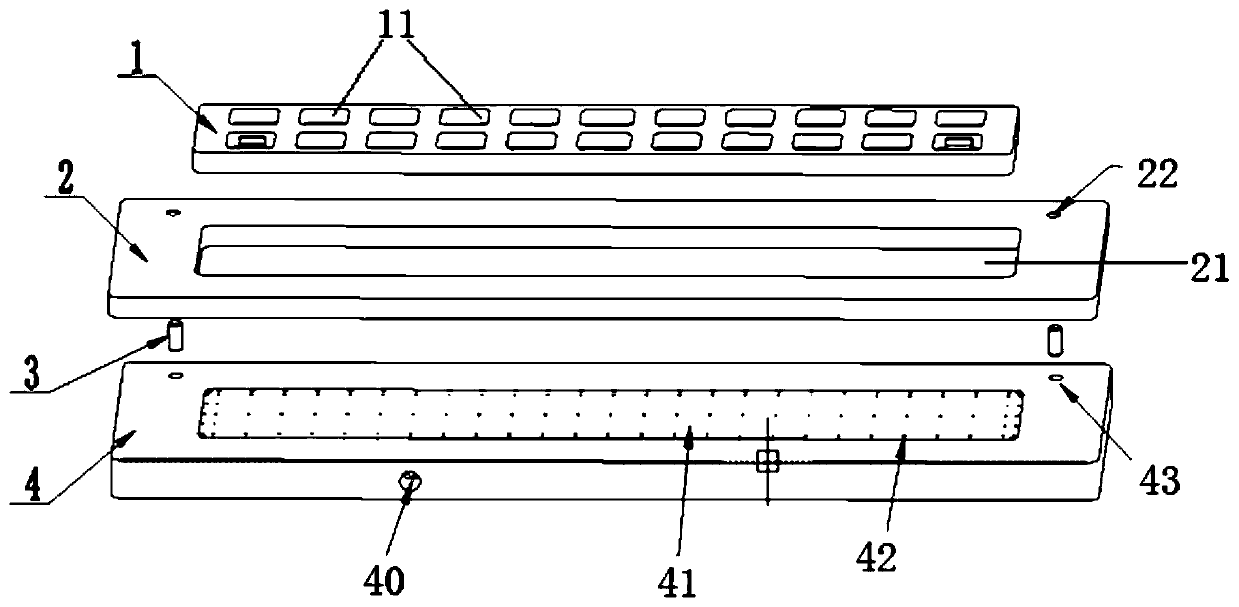

Seven-in-one membrane electrode packaging clamp and proton exchange membrane fuel cell

InactiveCN110828850AResolve positional offsetOvercome wear and tear defectsFuel cellsChemical physicsProton exchange membrane fuel cell

The invention provides a seven-in-one membrane electrode packaging clamp and a proton exchange membrane fuel cell. The seven-in-one membrane electrode packaging clamp comprises an upper cover plate (1) and a lower bottom plate (4). A groove (41) is arranged in the lower bottom plate (4). A size and a shape of the upper cover plate (1) is matched with those of the groove and the upper cover plate can be arranged in the groove (41). The groove (41) can bear a seven-in-one membrane electrode, the upper cover plate (1) can cover the seven-in-one membrane electrode, a vacuum adsorption flow channel(42) is arranged in a bottom surface, bearing the seven-in-one membrane electrode, of the groove (41), and the seven-in-one membrane electrode can be adsorbed and positioned through low pressure whenthe vacuum adsorption flow channel (42) works. In the invention, the seven-in-one membrane electrode located on a base plate can be adsorbed in a vacuumizing manner so that a positioning effect is effectively achieved, positioning precision is improved, positioning and fixing capabilities are good, assembling time is saved, and a yield is improved.

Owner:浙江锋源氢能科技有限公司 +1

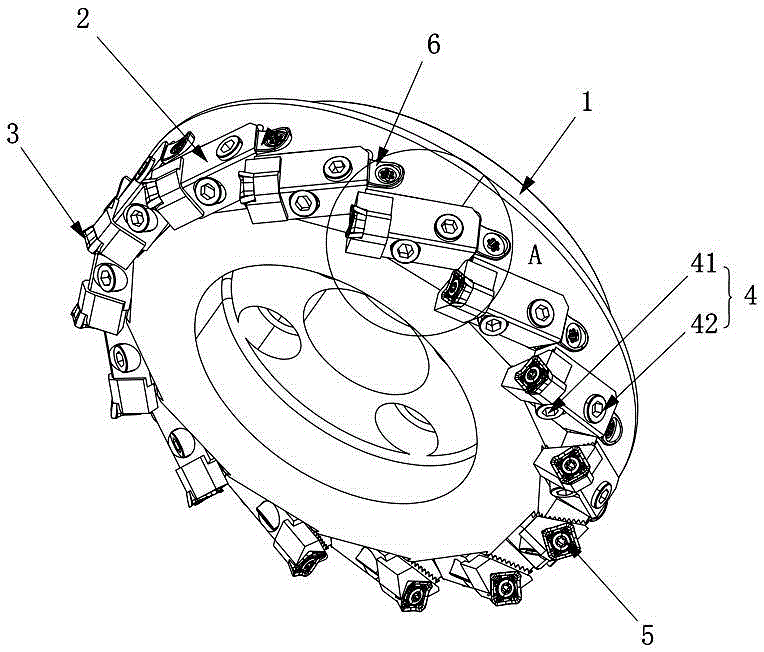

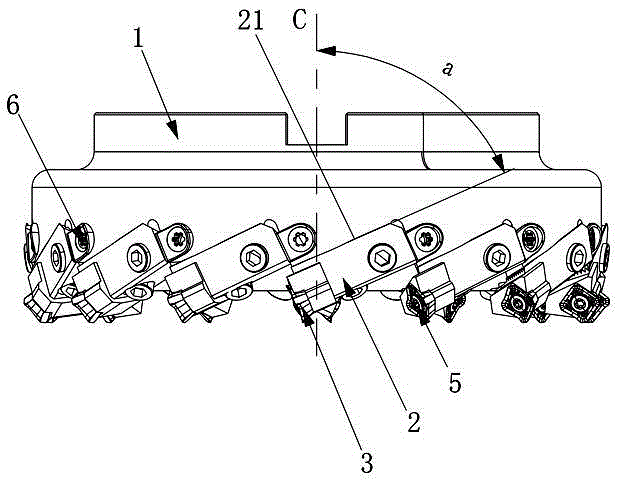

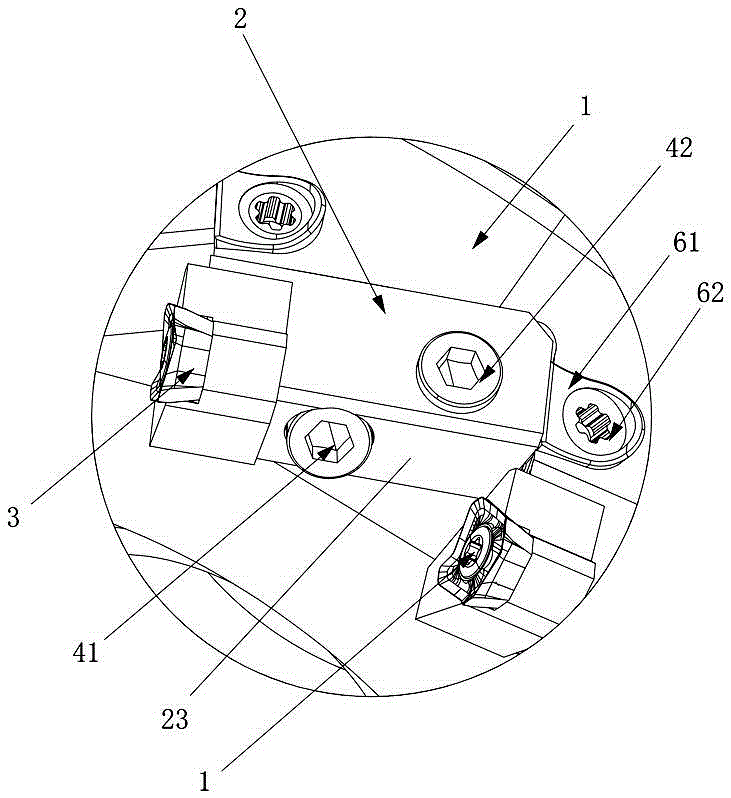

Rotary machining cutter

ActiveCN105328224AGuarantee the quality of the machined surfaceExtended service lifeCutting insertsTurning toolsMachiningFastener

The invention discloses a rotary machining cutter which comprises a rotary cutter body, wherein cutter slots are formed in the outer edge at the front end of the rotary cutter body; cutter holders are mounted in the cutter slots through cutter holder fastening components; cutting blades are mounted at the head parts of the cutter holders through cutting blade fasteners; adjusting structures are also mounted in the cutter slots; the adjusting structures are located between the tail part surfaces of the cutter holders and the tail part positioning surfaces of the cutter slots; all the surfaces, located between the tail part surfaces and the end surfaces of the cutter holders, of the cutter holders are circumferential surfaces of the cutter holders; each cutter holder fastening component comprises at least two cutter holder fasteners; and the cutter holders are locked by the cutter holder fasteners in different directions of the circumferential surfaces of the cutter holders. The rotary machining cutter provided by the invention has the advantages of positioning stability, strong vibration resistance, long service life, high machining precision and the like.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

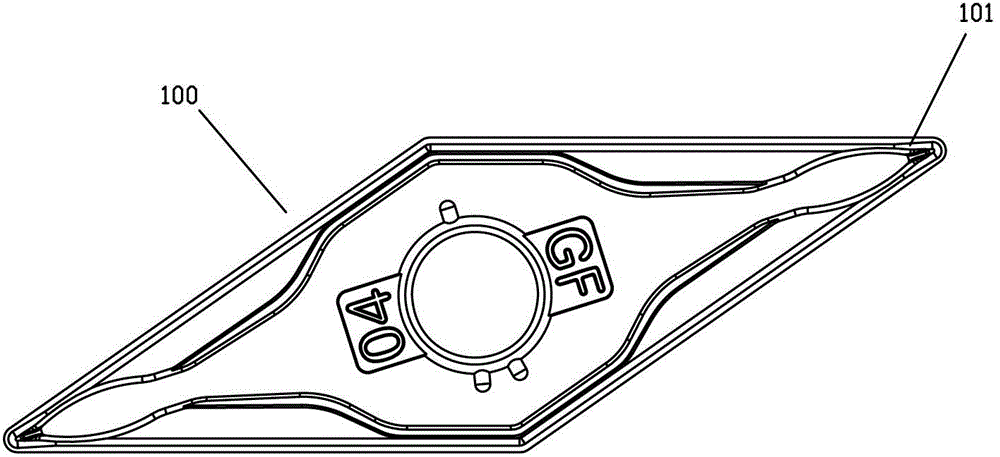

A kind of indexable blade and its tool holder

ActiveCN103357907BHigh strengthImprove positioning accuracy and clamping strengthTurning toolsAcute angleKnife blades

The invention discloses an indexable blade and a cutter bar. The indexable blade is in a basic shape capable of being projected into a regular triangle in a plane, wherein three corners form cutting heads respectively; a vertex angle of each cutting head is a 35-degree acute angle; cutting edges are formed between the adjacent cutting heads; each cutting edge is an inward recessed V shape along the edge of the regular triangle, and is intersected with the side edge of a circle concentric with an inscribed circle of the regular triangle; the radius of the concentric circle is less than that of the inscribed circle of the regular triangle, and greater than two thirds of the radius of the inscribed circle of the regular triangle; circular arc bulges are arranged in the middles of the cutting edges of the blade, and clamped with side supporting surfaces correspondingly arranged at a mounting seat of the cutter bar; and the indexable blade can be fastened on the mounting seat by a clamping device. With the adoption of the structure, the positioning accuracy and the clamping strength of the blade are improved; cutter head displacement due to too great cutting force is avoided; and the indexable blade has the characteristics of high economic performance, high strength and high machining precision.

Owner:XIAMEN GOLDEN EGRET SPECIAL ALLOY

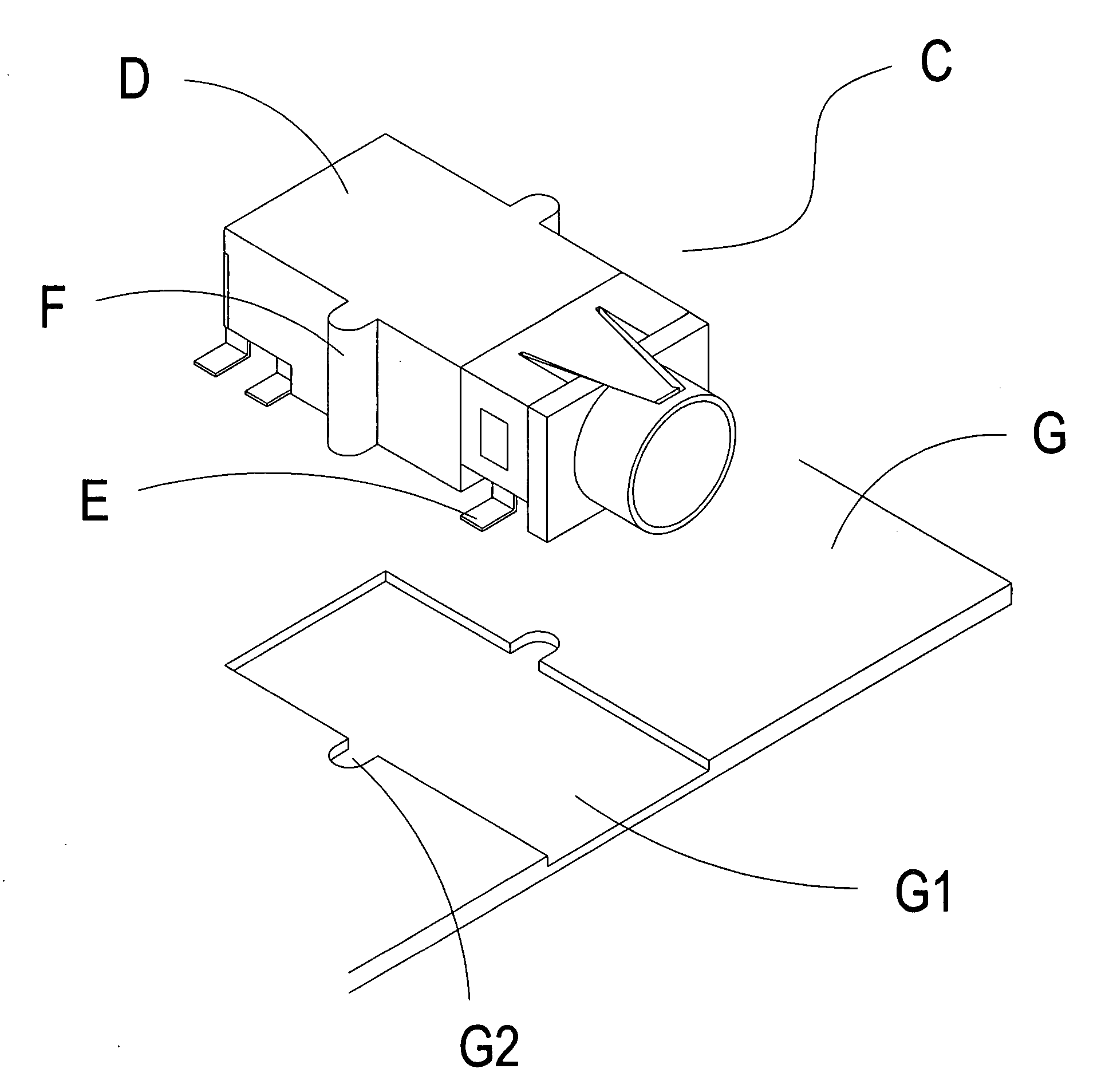

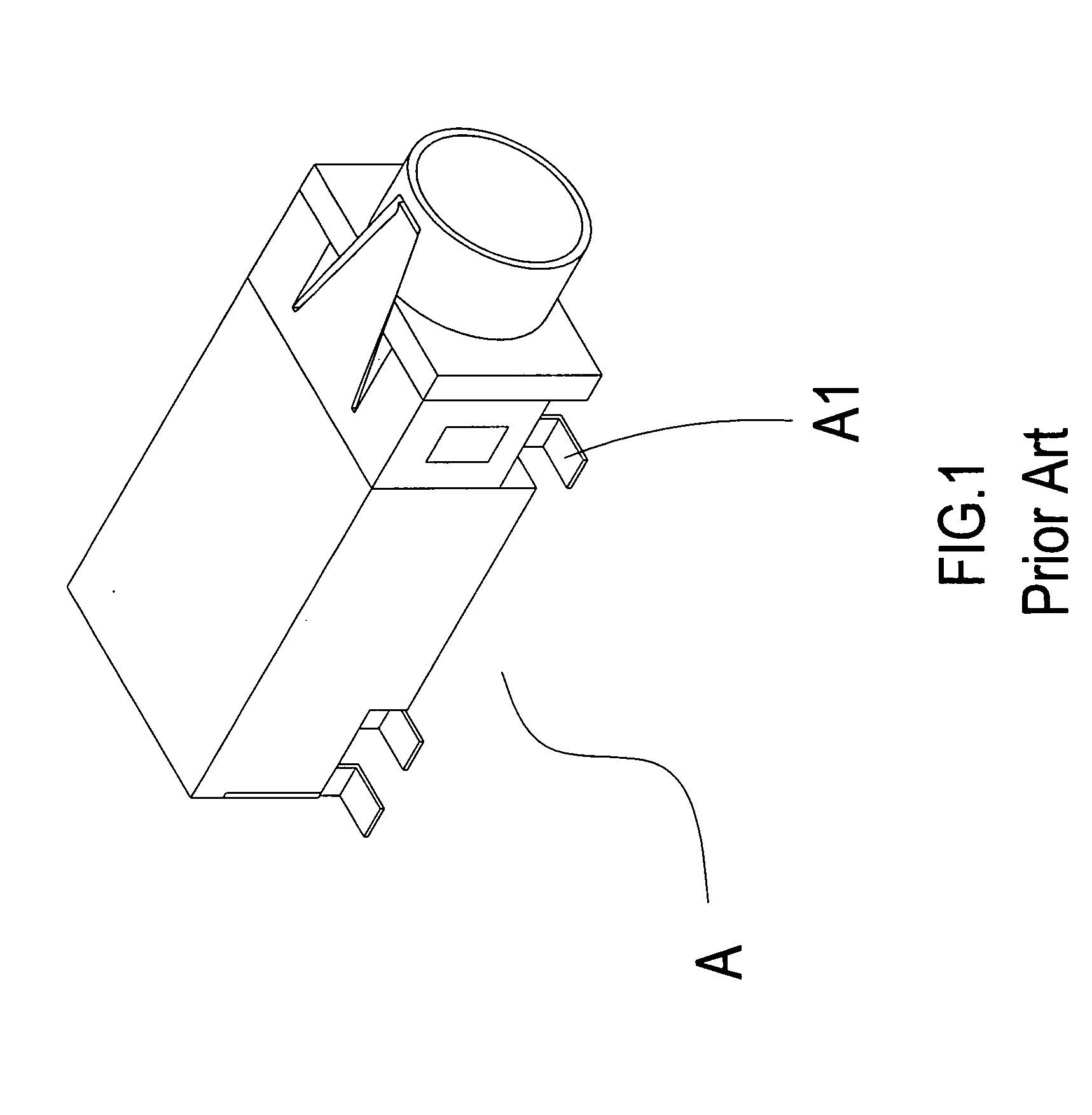

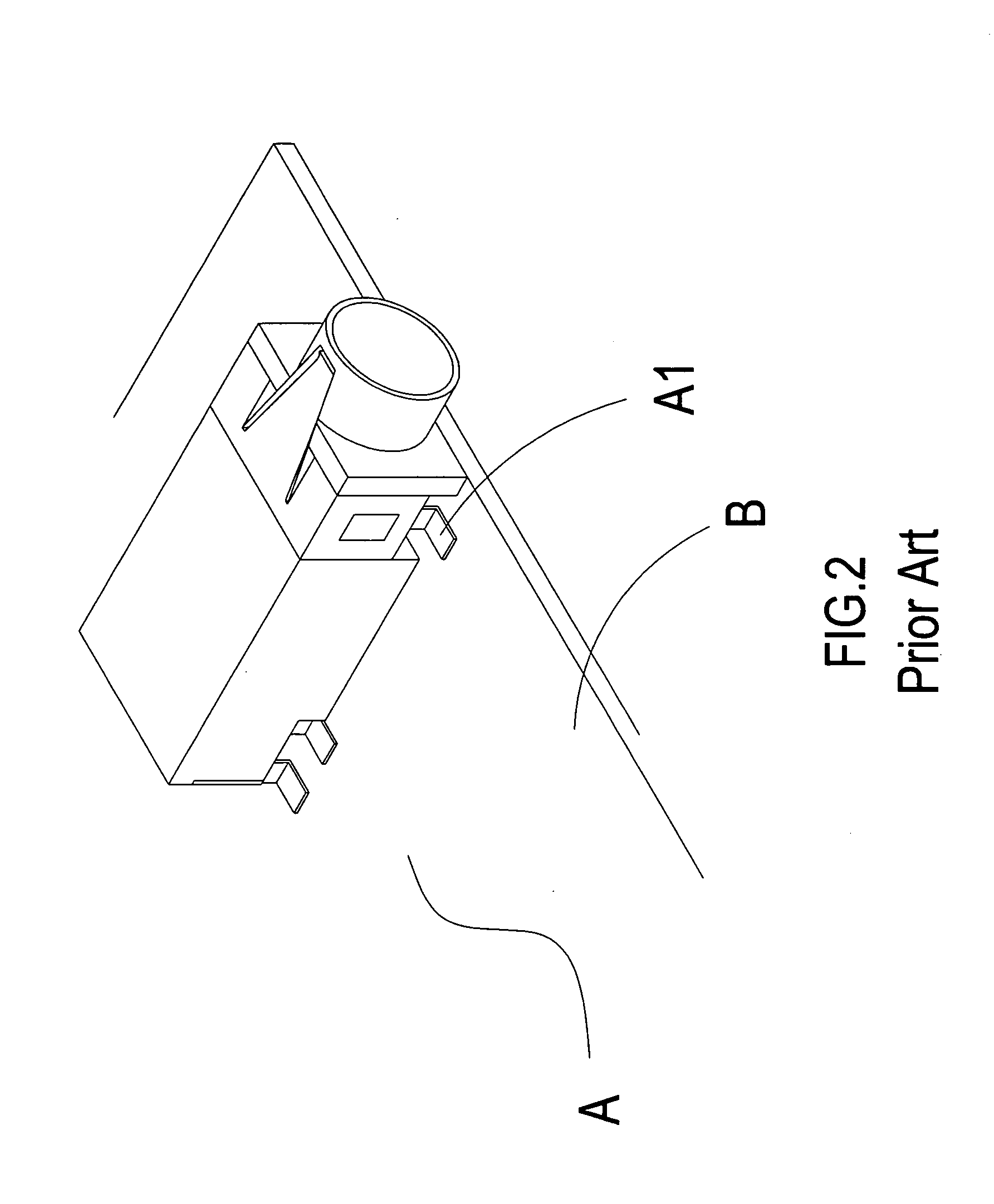

Electrical connector structure

InactiveUS20080085629A1Improve positioning strengthOptimum electric conducting effectivenessCoupling device detailsElectrical connectorElectrical and Electronics engineering

Owner:SINGATRON TECH HONG KONG CO

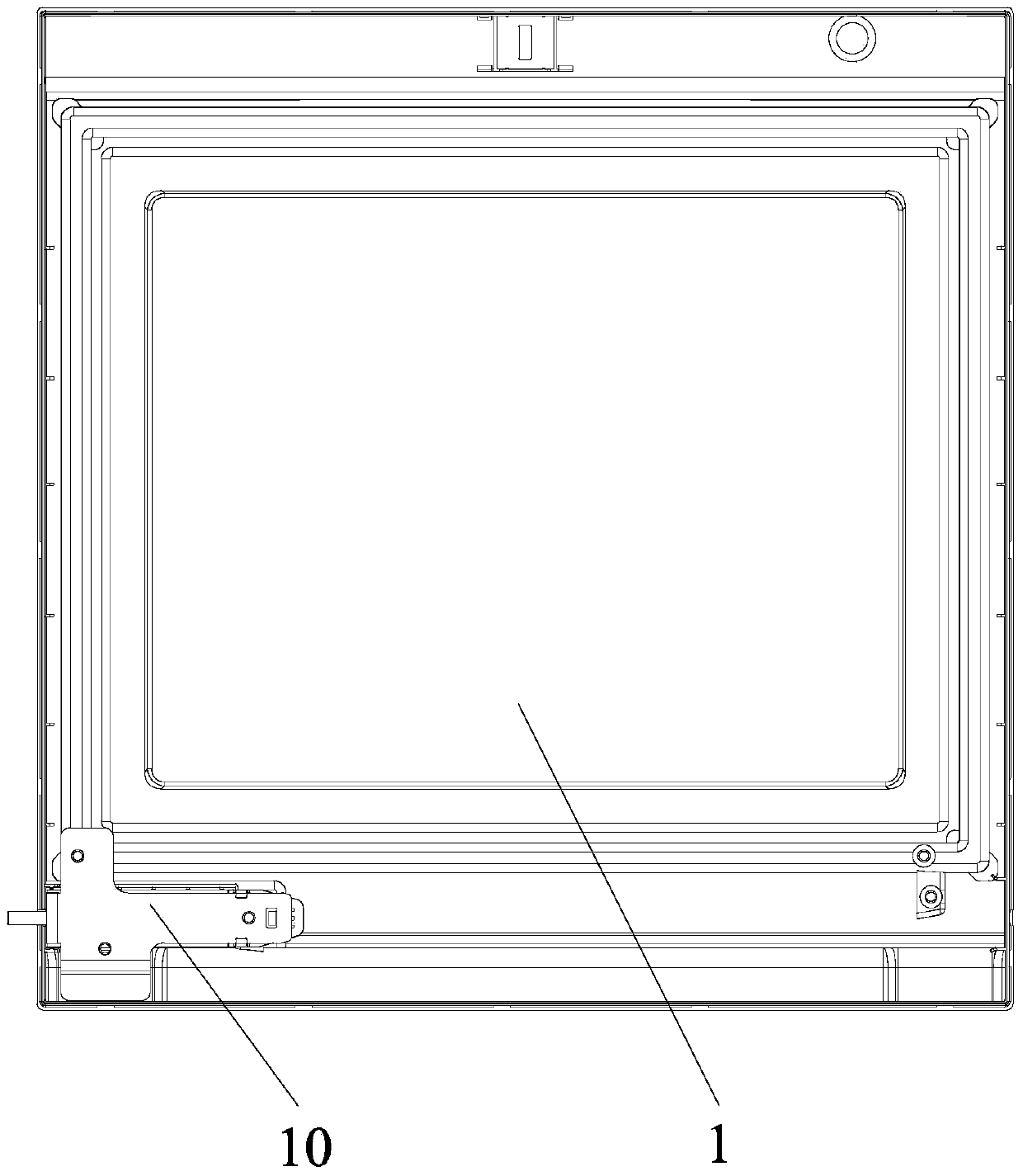

Refrigerator door counter installation component and refrigerator door

ActiveCN104197619ATo achieve a fixed connectionEasy to fixDomestic cooling apparatusLighting and heating apparatusRefrigerator carEngineering

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

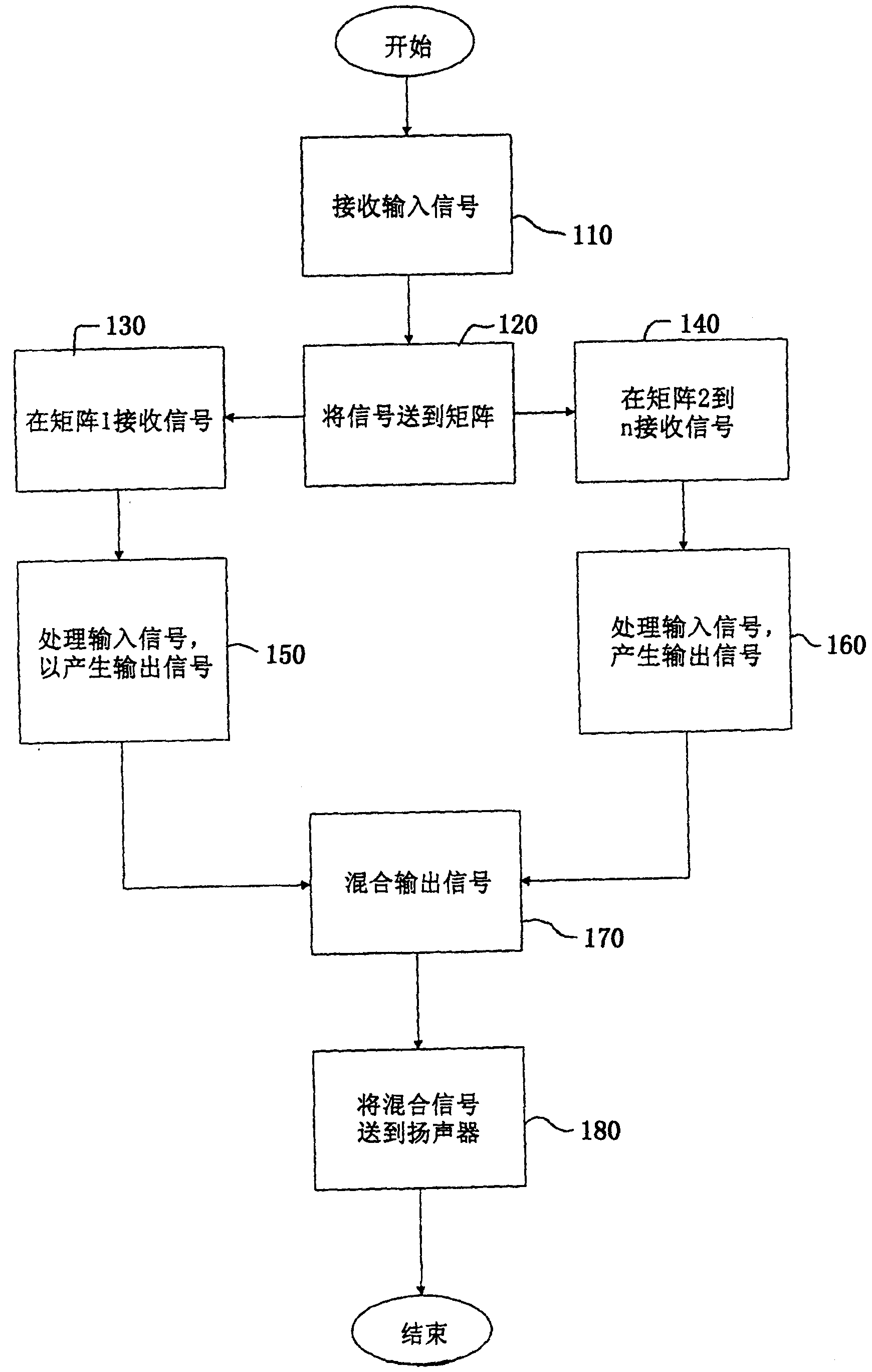

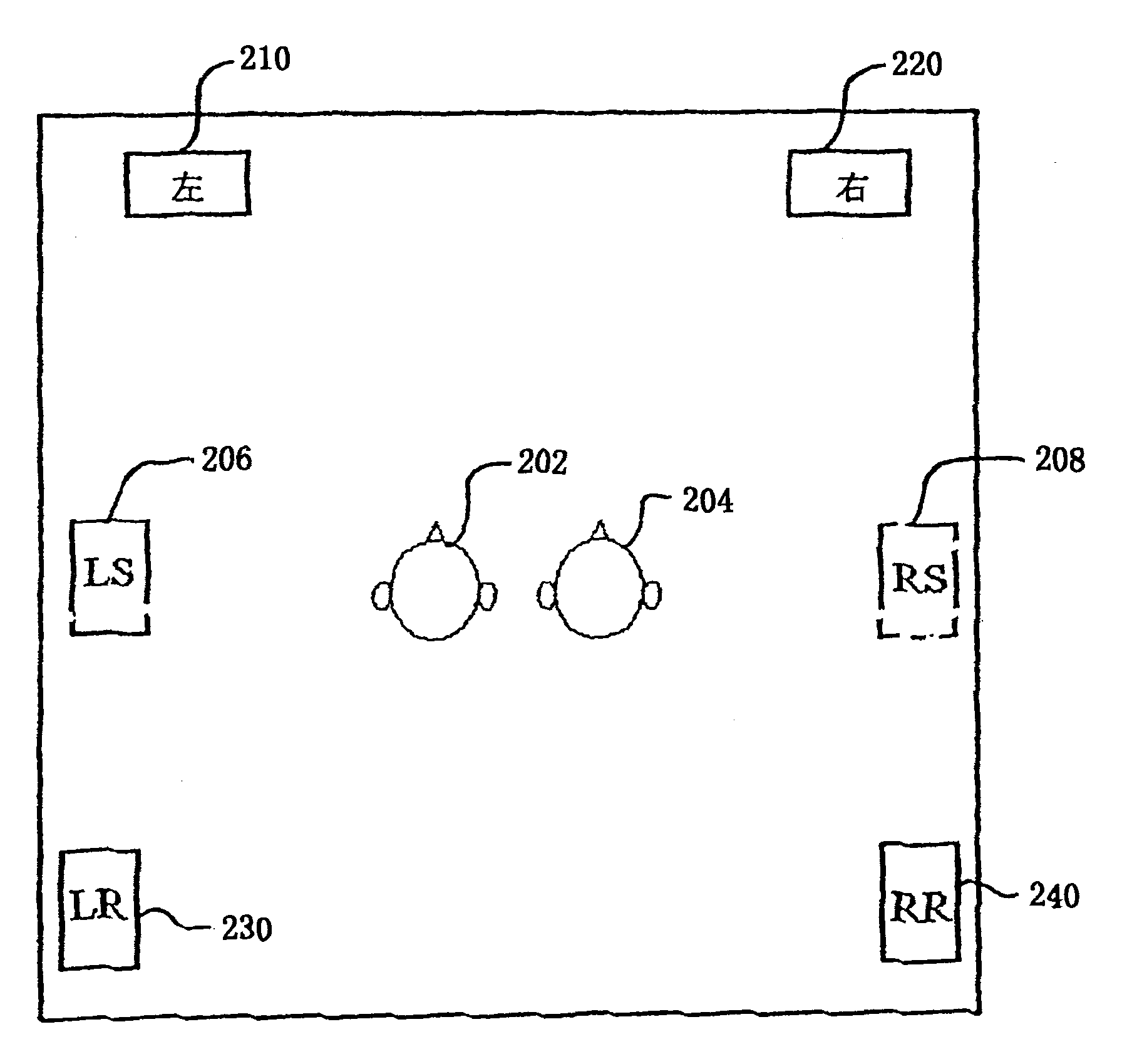

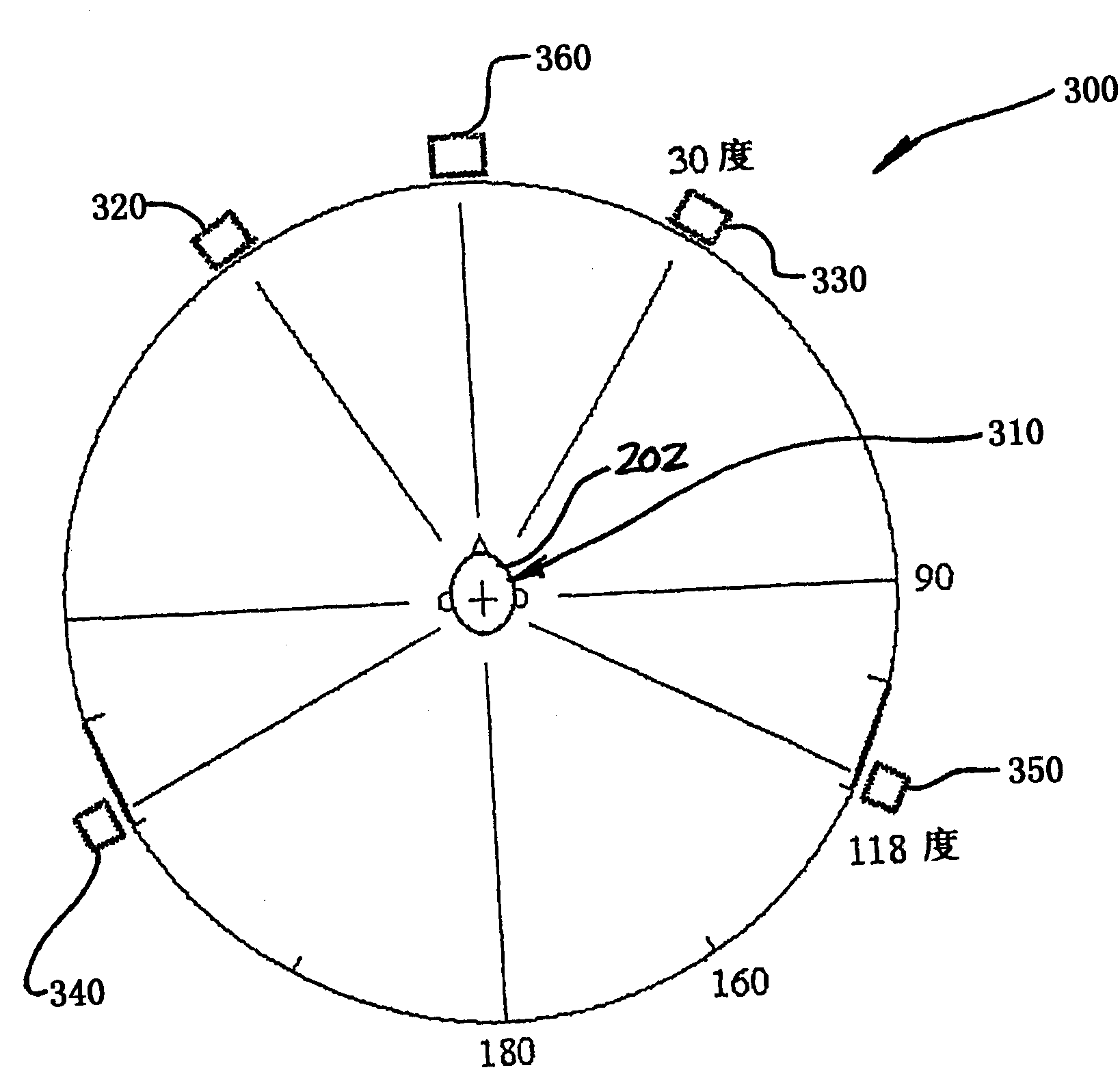

Discrete surround audio system for home and automotive listening

InactiveCN1586091BImprove positioning strengthImprove space efficiencyGain controlPseudo-stereo systemsVocal tractEngineering

Owner:HARMAN INT IND INC

Auxiliary positioning mechanism

InactiveCN106151190AReduce chippingAchieve assembly strengthSheet joiningEngineeringUltimate tensile strength

The invention provides an auxiliary positioning mechanism. The auxiliary positioning mechanism comprises positioning members and elastic sleeves. Each positioning member is provided with a sleeve, a first stop blocking part and a second stop blocking part are arranged on the two opposite sides of an internal containing groove of the sleeve, a positioning part is further arranged on the outer side of the first stop blocking part, and the corresponding elastic sleeve is arranged in the containing groove. During practical application, the positioning parts of the multiple positioning members are fixed to a plurality of perforated holes in a first object, then a plurality of column bodies of a second object are arranged in the containing grooves of the multiple positioning members in a penetrating mode, and due to the fact that the inner diameter of the elastic sleeves is smaller than the outer diameter of the column bodies, the column bodies located in the containing grooves support and abut against the elastic sleeves outwards to form the close-fit positioning state. In this way, the second object is positioned on the surface of the first object in an auxiliary mode, and thus the assembly strength can reach a certain extent with few screws locked and fixed between the first object and the second object.

Owner:HANWIT PRECISION IND LTD

Lubricating pump, pump body and pump cover thereof

InactiveCN101846236BPrecise positioningImprove accuracyRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

The invention discloses a pump body of a lubricating pump, comprising a pump shaft support hole, a rotor cavity and a big end surface. The big end surface is used for mounting the pump cover and recesses inwards along the radial direction of the rotor cavity to form stepped-holes. The invention also discloses a pump cover of the lubricating pump, comprising the pump body and the pump cover. The pump cover is embedded into the stepped-holes and matched with the stepped-holes in transition. The invention also discloses a lubricating pump, comprising the pump body, the pump cover, an inner rotor, an outer rotor and a pump shaft. The edge of the pump cover is matched with the stepped-holes in transition and seals the rotor cavity, the pump shaft passes through the pump shaft support hole, theend part of the pump shaft extends into the support hole at the end part of the pump shaft, the pump shaft is also internally provided with an overflow circumfluence hole which extends from one end of the pump shaft far from the pump cover along the radial direction of the pump shaft, and the axial length of the overflow circumfluence hole is shorter than that of the pump shaft. The invention improves the locating accuracy and the locating strength of the pump cover, simplifies the assembling flow, improves the working efficiency, avoids the engine oil leakage phenomenon, and has simple and compact structure and easy implementation.

Owner:南京腾源机械制造有限公司

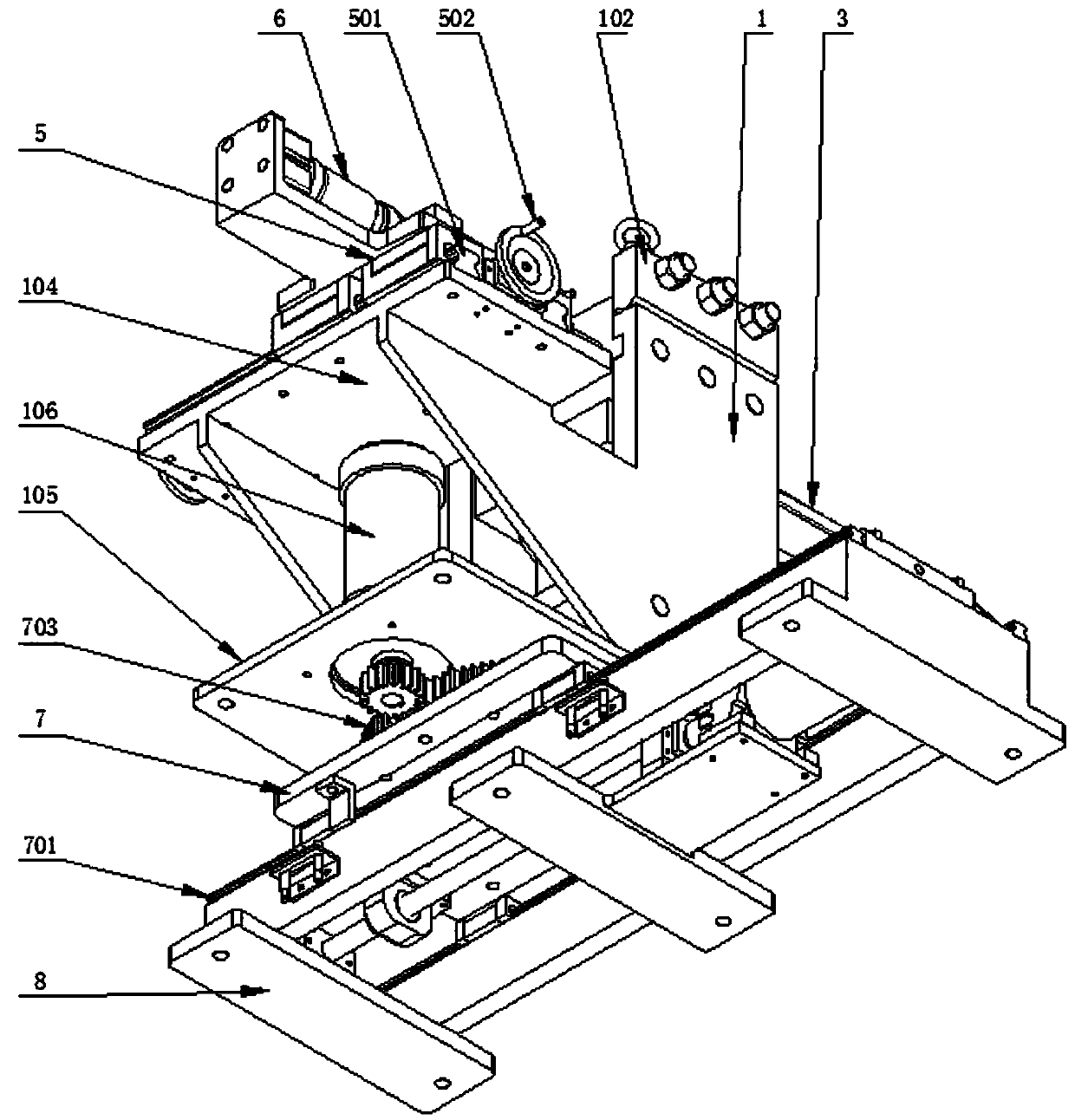

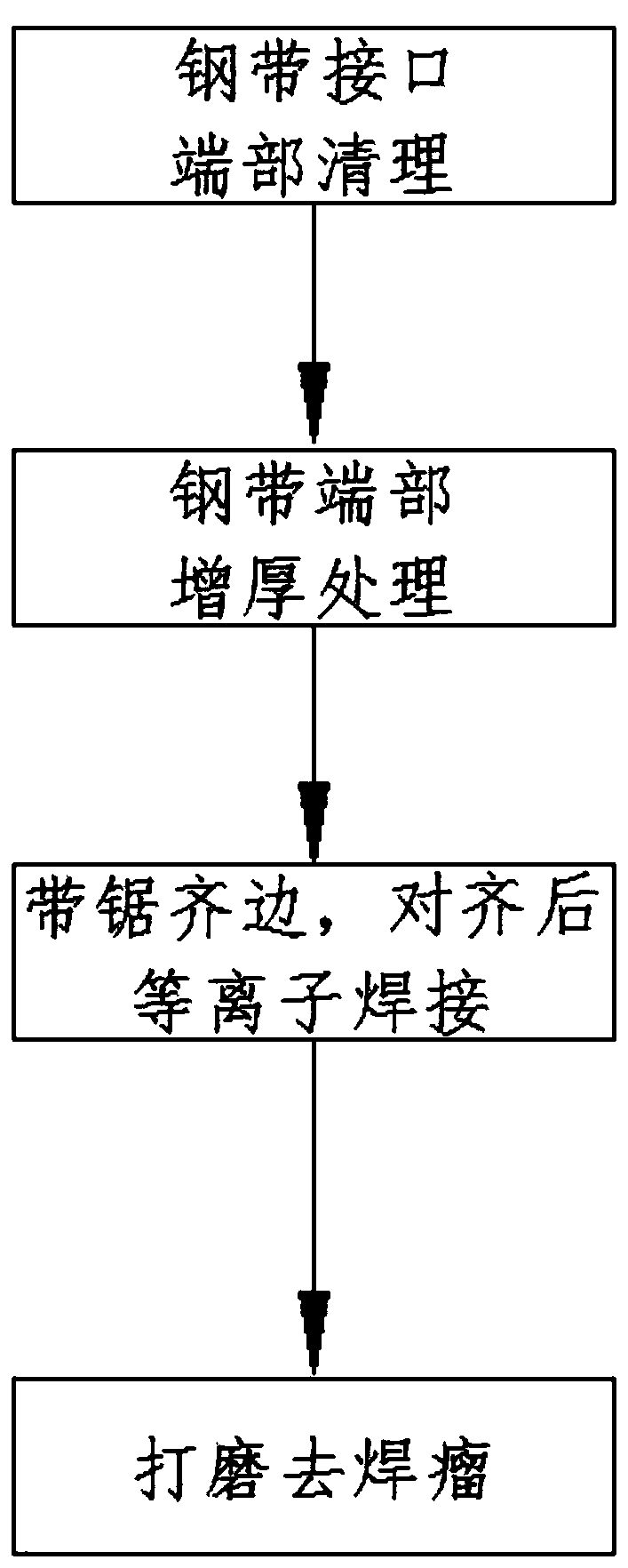

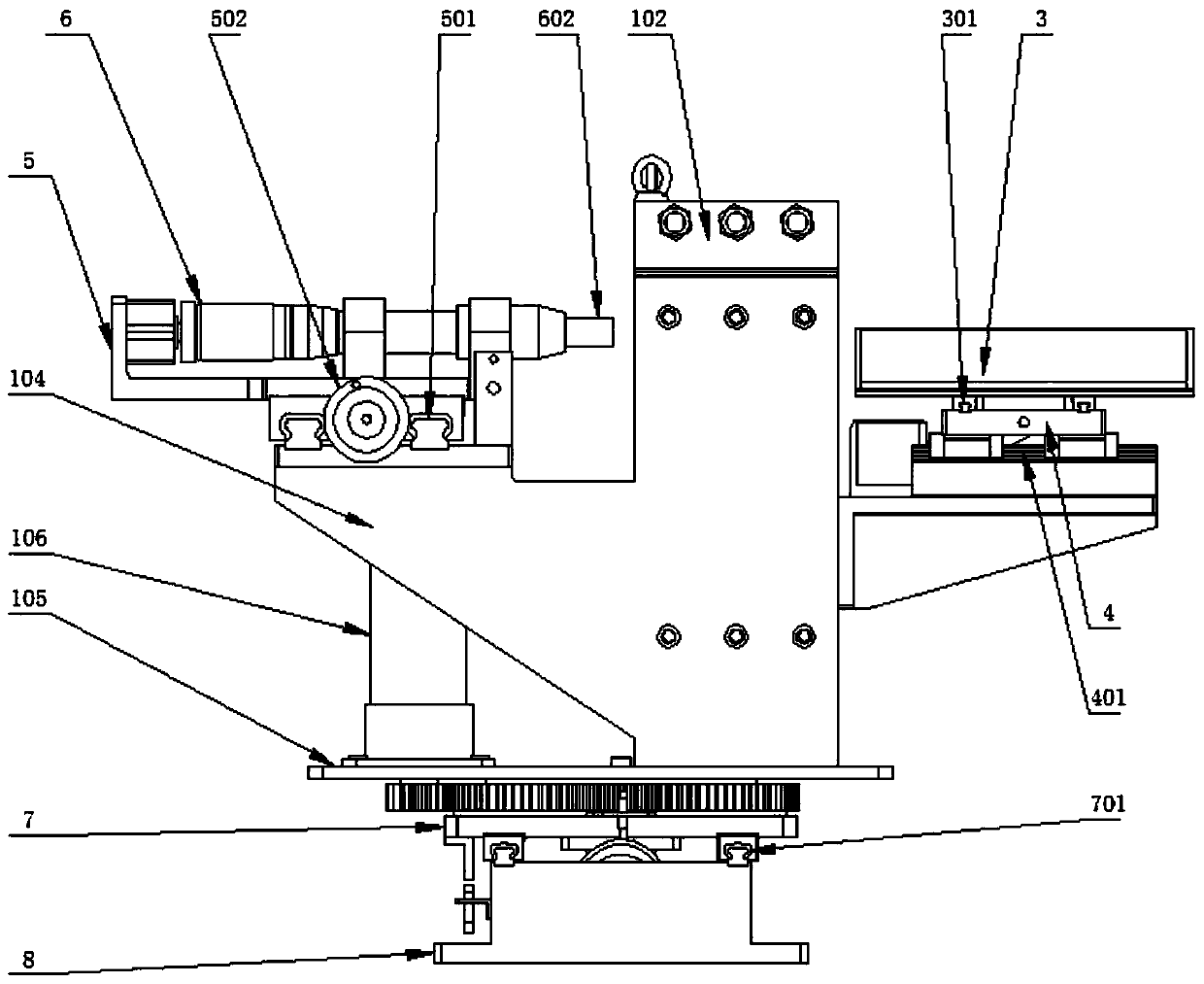

Coiled tubing steel strip butt joint process and raw material thickening equipment applied in butt joint process

ActiveCN110860773ASolve burning edgeSolve the phenomenon of grinding thinningEdge grinding machinesPlasma welding apparatusButt jointCoiled tubing

The invention discloses a coiled tubing steel strip butt joint process, and belongs to the technical field of coiled tubing machining and manufacturing. The coiled tubing steel strip butt joint process comprises the following steps that S1, the end parts of coiled tubing steel strip joints are cleaned, and dirt, impurities and burrs are removed; S2, the end parts of the coiled tubing steel strip joints are subjected to the wall thickness increasing treatment by using an end face hammering mode; S3, the end parts of the two coiled tubing steel strip joints to be subjected to butt joint are trimmed to be orderly, then are tightly abutted and aligned, and are welded firmly and reliably by using a plasma welder; and S4, the welded junction part is finished, and welding burrs and overlaps are removed through grinding. According to the butt joint process, the edge burning and excessive penetration conditions in the welding process can be effectively reduced, the thickness of the wall of thewelding area after finishing and grinding is prevented from being reduced, and the welding quality of the steel strip butt joint is improved. The invention further discloses steel strip butt joint rawmaterial thickening equipment used in the process for hammering and thickening the end parts of the coiled tubing steel strip joints.

Owner:XINDA KECHUANG TANGSHAN PETROLEUM EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com