Fine adjustment device for intelligent fine adjustment system of ballastless track slab

A technology of ballastless track and fine adjustment, which is applied in the direction of track, track laying, track maintenance, etc. It can solve the problems of troublesome operation of three-way fine adjuster, reduce the possibility of relative sliding, expand the adjustment range, and strengthen the positioning strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

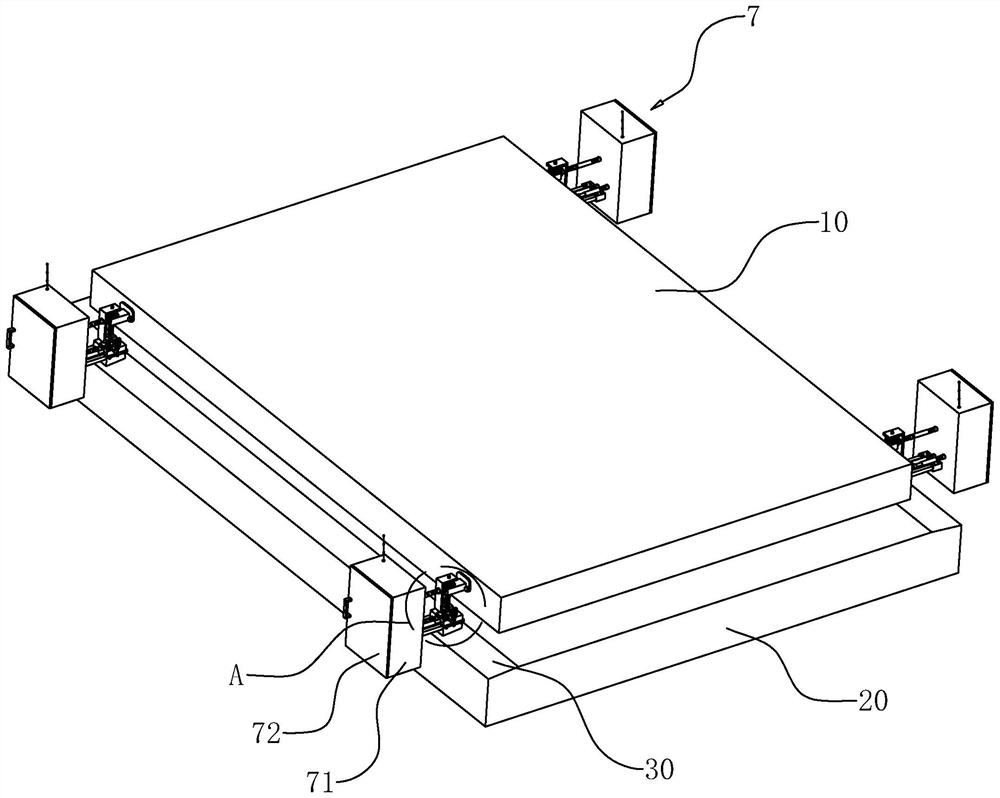

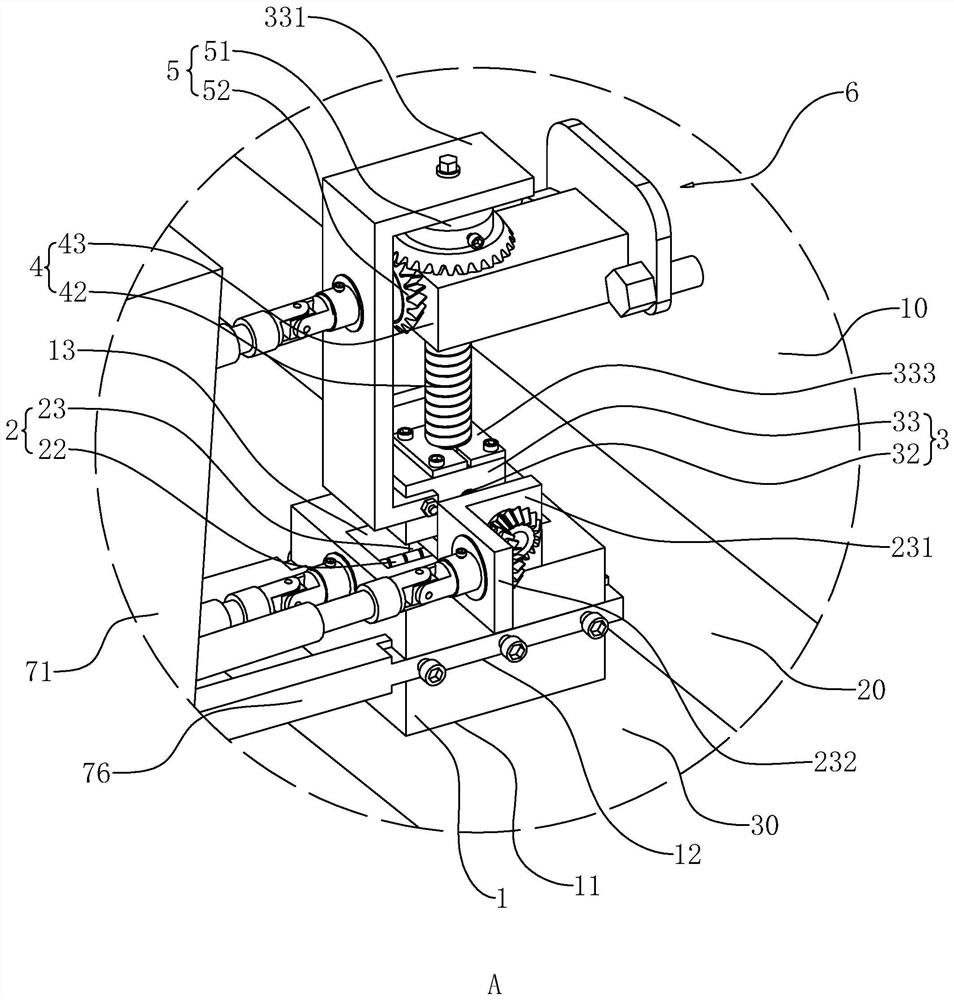

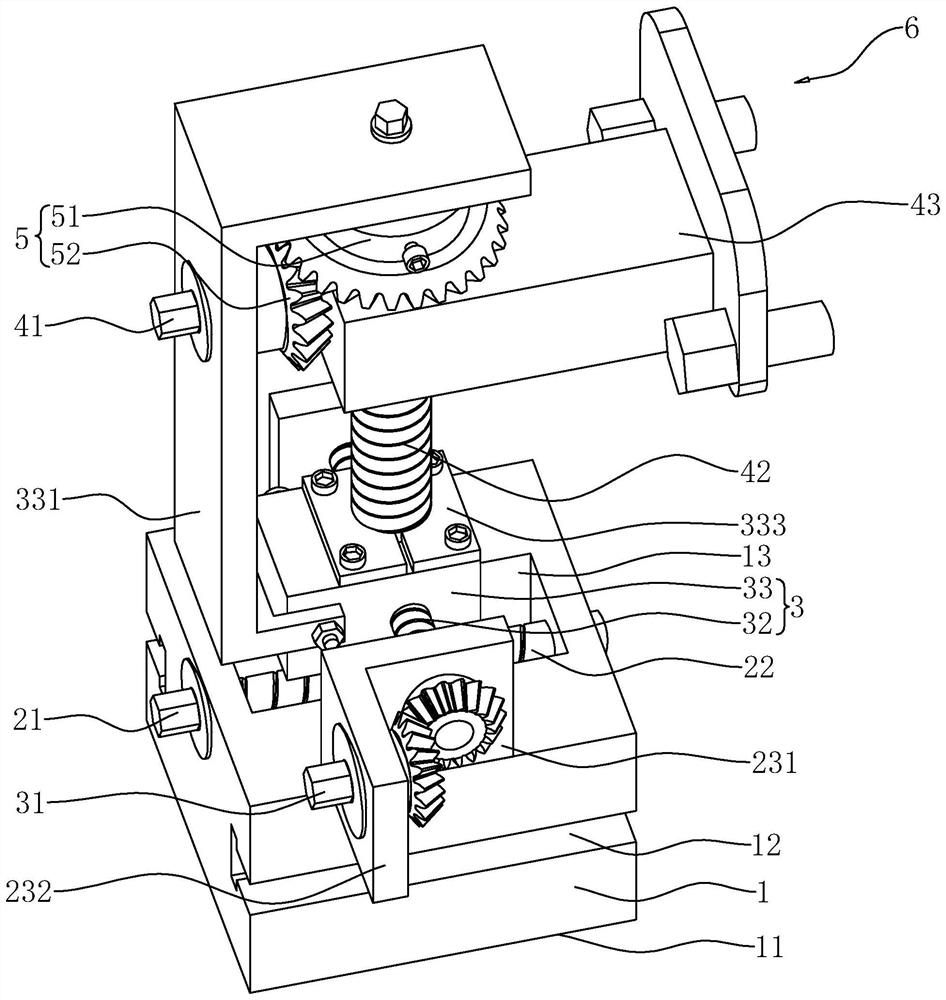

[0047] refer to figure 1 with figure 2 , the fine-tuning device for the intelligent fine-tuning system of the ballastless track slab 10 includes a base 1, and the base 1 is placed on the drainage slopes 30 on both sides of the track seat 20 in the length direction. Base 1 is provided with Y-direction adjustment structure 2, X-direction adjustment structure 3 and Z-direction adjustment structure 4, Y-direction adjustment structure 2 is provided with Y-direction adjustment head 21, X-direction adjustment structure 3 and Y-direction adjustment structure 2 are respectively connected There is a steering mechanism 5, the X-direction adjustment structure 3 is connected with the X-direction adjustment head 31 through the steering structure, the Z-direction adjustment structure 4 is connected with the Z-direction adjustment head 41 through the steering structure, and the Z-direction adjustment structure 4 is provided with a track plate 10 Connector 6 for side wall connection.

[004...

Embodiment 2

[0060] refer to Figure 8 The difference between this embodiment and Embodiment 1 is that the base 1 is provided with the two side walls of the positioning groove 12 and is fixedly connected with the connecting frame 14, and the connecting frame is fixed with a drainage slope 30 towards the track seat 20. A vacuum chuck 141 is provided on the surface, and the mouth of the vacuum chuck 141 is arranged parallel to the attachment slope 11 . After the staff set up the fine adjustment device, the vacuum suction cup 141 is attached to the surface of the drainage slope 30 of the track seat 20, and the staff applies glass sealant between the circumferential side wall of the vacuum suction cup 141 and the drainage slope 30 of the track seat 20, And the glass sealant is compacted to form a rubber seal (not shown in the figure), thereby improving the sealing performance, and then vacuuming the vacuum chuck 141, so that the vacuum chuck 141 is adsorbed on the surface of the drainage slope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com