Roller tractor rear balance weight

A wheeled tractor, rear counterweight technology, applied in wheel counterweight and other directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

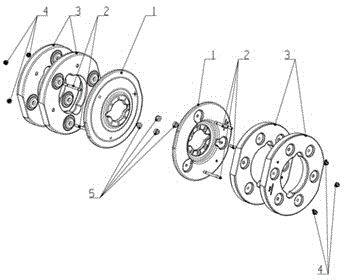

[0021] Embodiment 1, according to the actual operation requirements of the tractor, the counterweight after assembly is 810kg. After calculation, a pair of the first counterweight 1 (150kg) and a pair of the second counterweight 3 (255kg) are assembled to meet the rear counterweight requirement of 810kg.

[0022] During assembly, the spacer 5 is installed in the semicircle gap at the center of the first counterweight 1, positioning holes are set on the peripheral edge of the semicircle gap at the center, and 8 bolts pass through the respective positioning holes respectively, and the first 8 bolts are tightened by tightening the 8 nuts. A counterweight 1 is fastened to the rear wheel hub of the tractor;

[0023] When assembling the counterweight 3, the three protrusions of the second counterweight 3 cooperate with the three grooves of the counterweight 1, and the axes of the protrusions and the grooves are all set to pass through the studs One end of the stud 2 is passed throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com