Patents

Literature

66results about How to "Guaranteed magnetic field strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

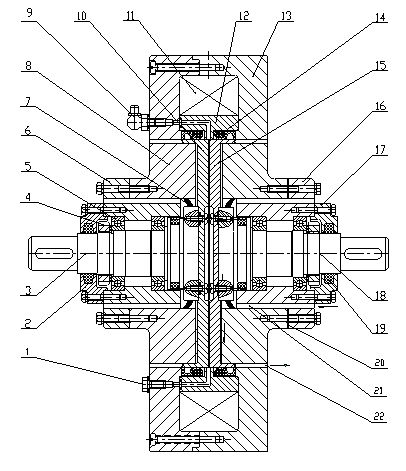

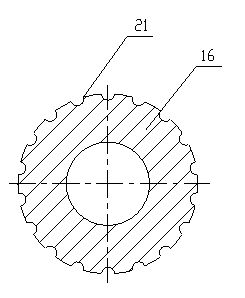

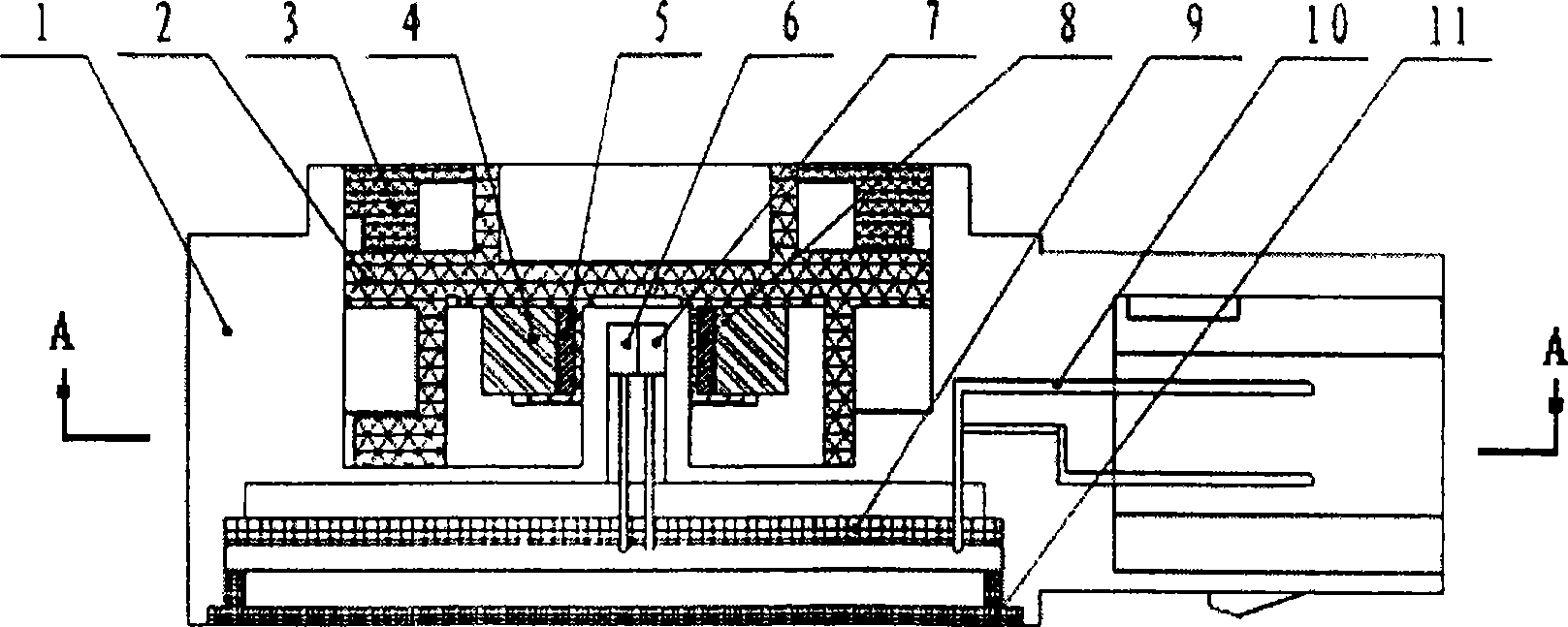

Double-disk type magnetorheological clutch

InactiveCN102080692ASpeed up the flowIncrease the magnetic field strengthFluid clutchesRing deviceDrive shaft

The invention relates to a double-disk type magnetorheological clutch which comprises a driving disk, a driven disk, a magnetorheological fluid, a transmission shaft, a rotating blade, a magnetic conduction shell, a magnet exciting coil, an insulation ring, a fluid inlet, a fluid outlet, a bearing and a sealing element, wherein the driving disk is connected to a driving shaft; the driven disk is connected to a driven shaft; the magnetorheological fluid is filled between primary and secondary magnetic conduction disks through the fluid inlet; a sealing ring device is rotated so as to keep the magnetorheological fluid between the two disks; the magnet exciting coil is fixed in the magnetic conduction shell with no need of an electric brush; and the magnetorheological fluid is sealed between the two disks, and the rotating blade is arranged on the transmission shaft. The rotating blade is rotated under the driving of the transmission shaft, so air is guided to circularly flow through an air vent, and the excellent radiating property is maintained. The double-disk type magnetorheological clutch has the advantages of compact structure and good radiation property, and can be used for natural air cooling.

Owner:CHINA UNIV OF MINING & TECH

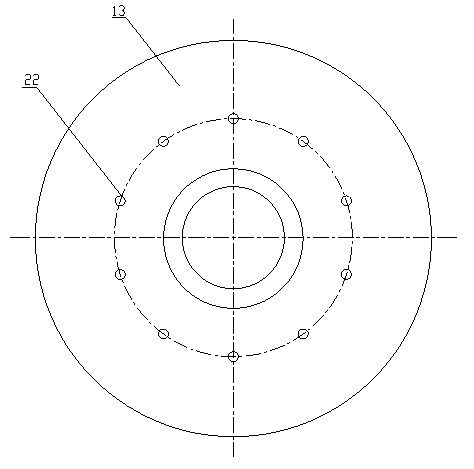

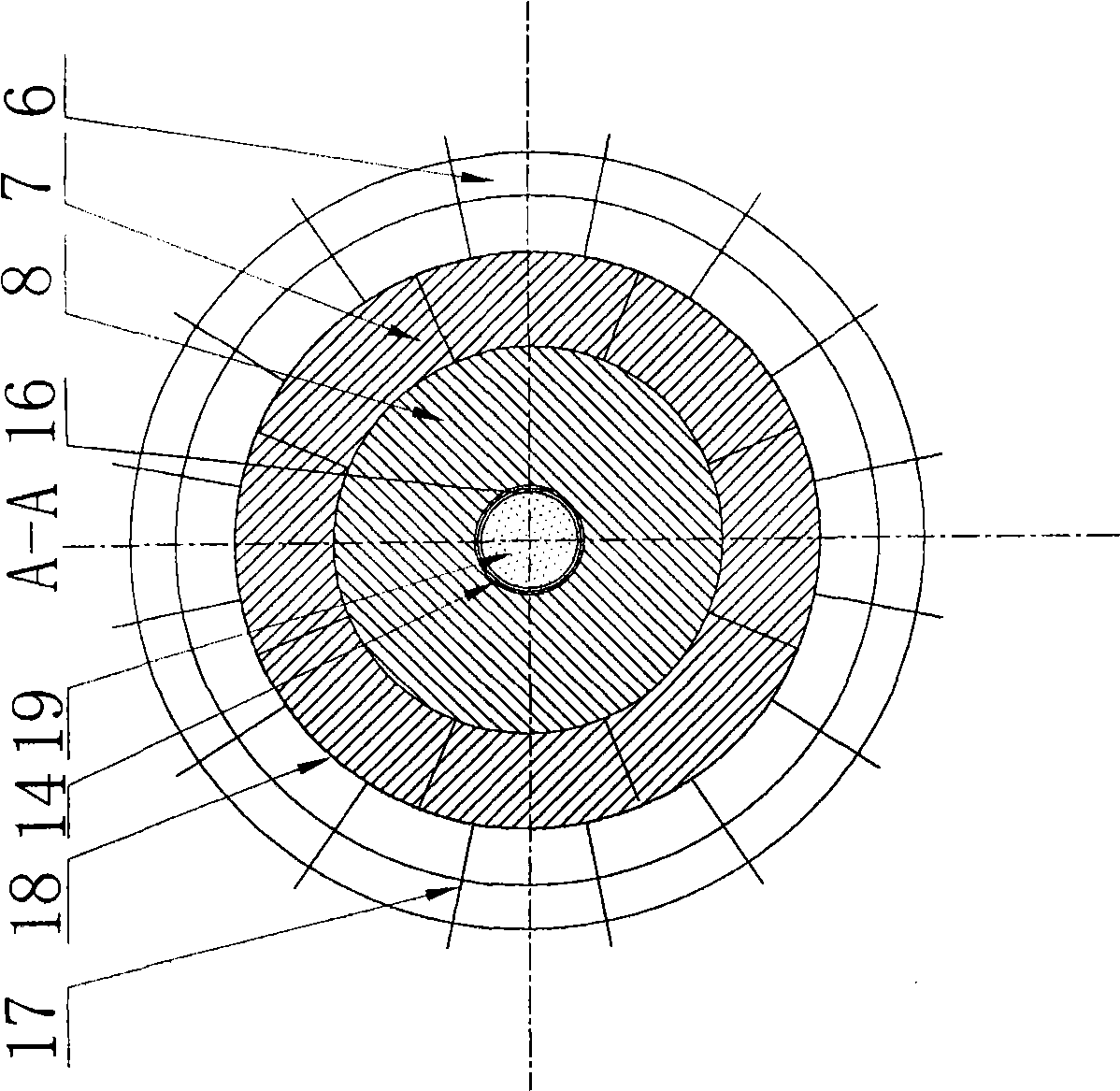

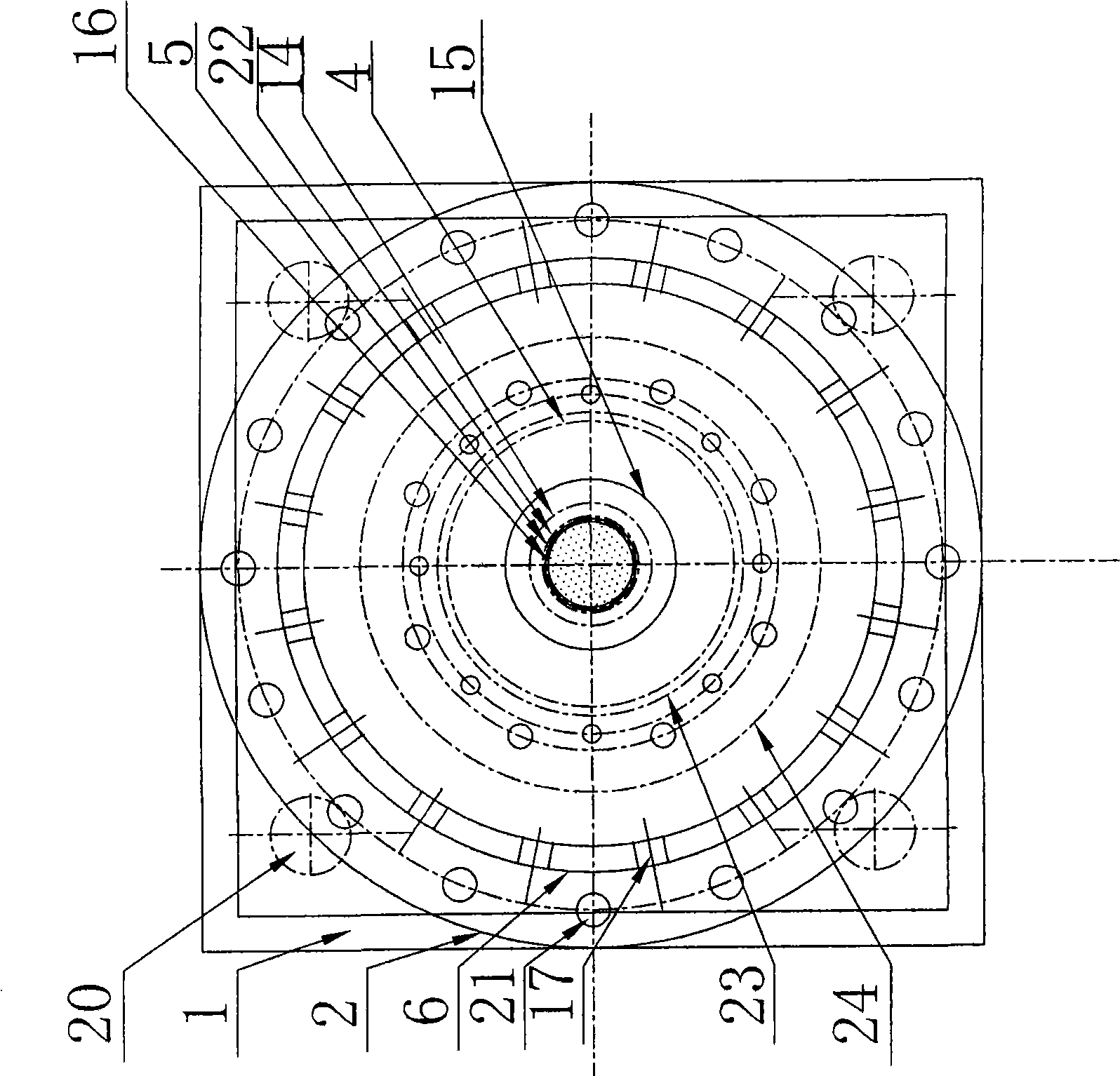

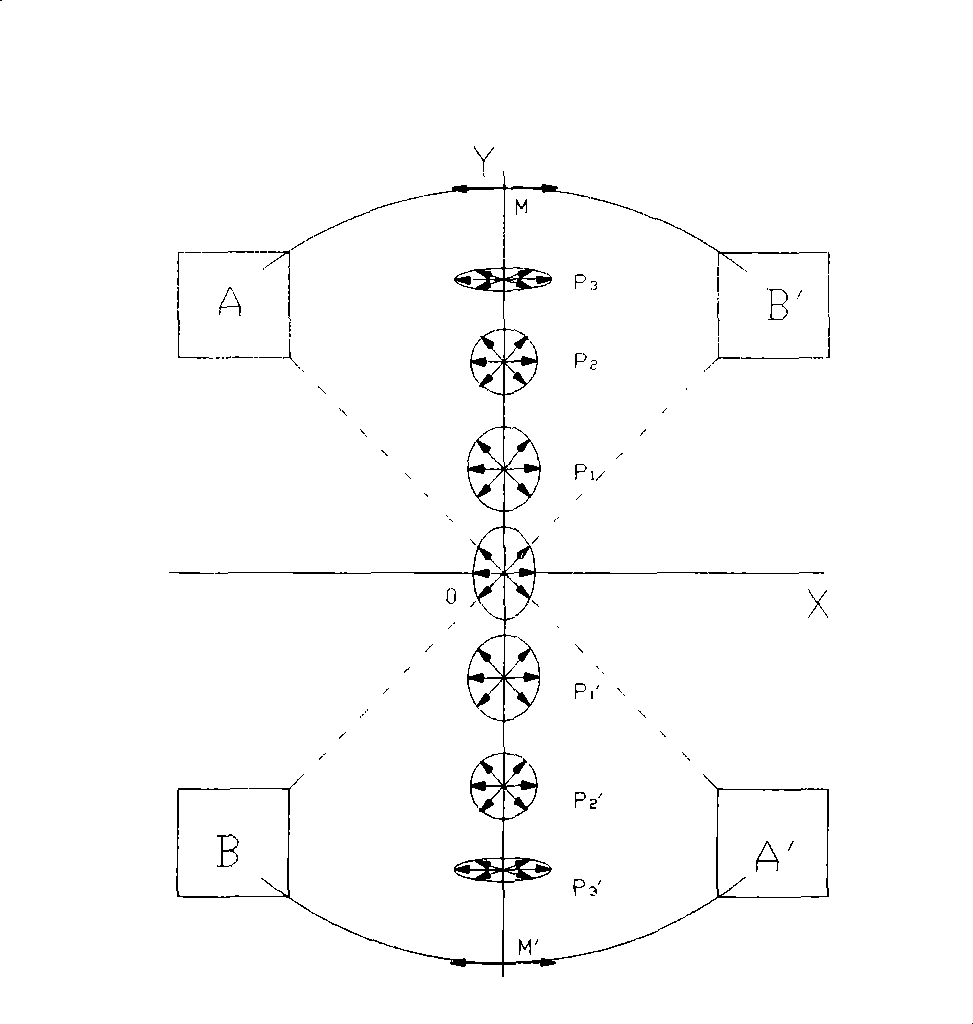

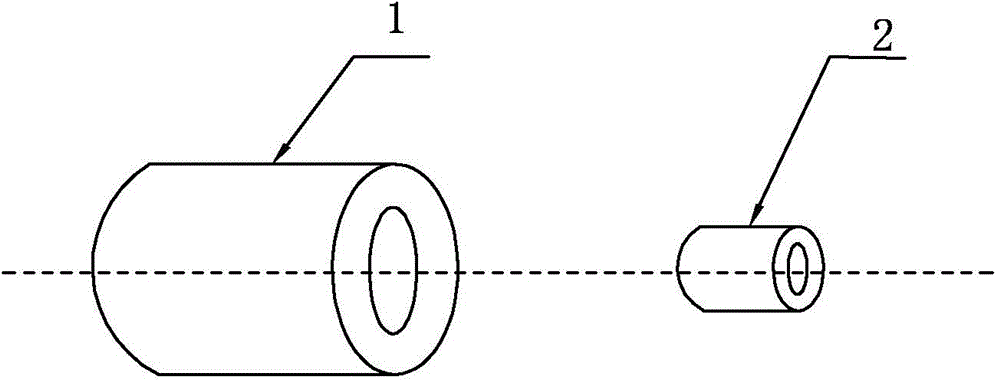

Permanent magnet high-field intensity magnetic filter

InactiveCN101474593AIncrease magnetic fluxIncrease the magnetic field strengthMagnetic separationPhysicsCoaxial line

The invention relates to a permanentmagnet magnetic filter with high field intensity, and is characterized in that the magnetic filter comprises a plurality of permanentmagnet rings (8) and a main magnetic system (25), wherein the permanentmagnet rings (8) are connected in series on a coaxial-line, and the main magnetic system (25) is composed of high permeability yoke pieces (9) extrudedbetween every two permanentmagnet rings mutually overlapped; the inner ring cavity of each permanentmagnet ring (8) is used as a sorting space, and the magnetic rings on both sides of the same yoke piece (9) have the same polarity; and the outer ring faces surrounding the permanentmagnet rings are armed by a plurality of fan-shaped magnetic steel pieces to form auxiliary magnetic poles (26), and every magnetic ring is extruded by the upper, the lower and the outer faces so as to improve the magnetic flux of the sorting space, thereby gaining high magnetic-field intensity. As the inner ring cavity of each permanentmagnet ring is used as the sorting space and the closure magnetic system is formed by the trilateral homopolar extrusion technology in the design of the magnetic system, the magnetic-field intensity on the central axis of the sorting cavity can be ensured to be 1.3T.

Owner:HENAN POLYTECHNIC UNIV

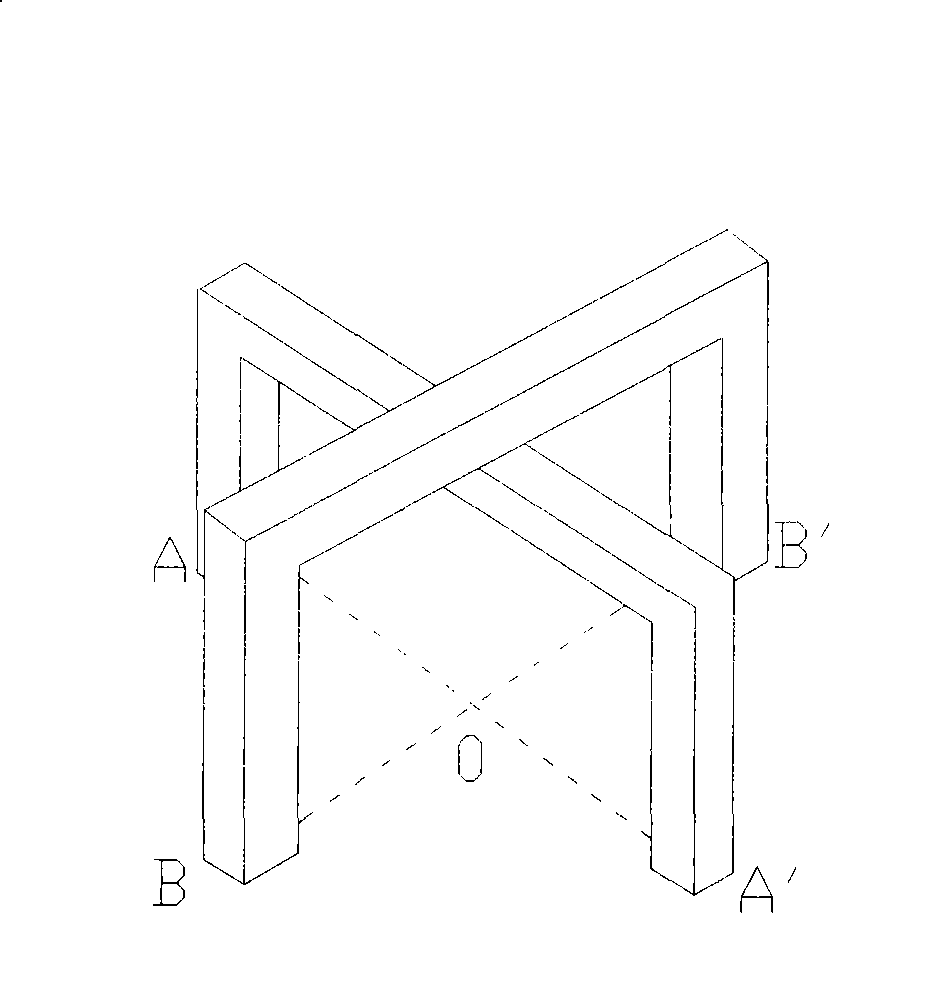

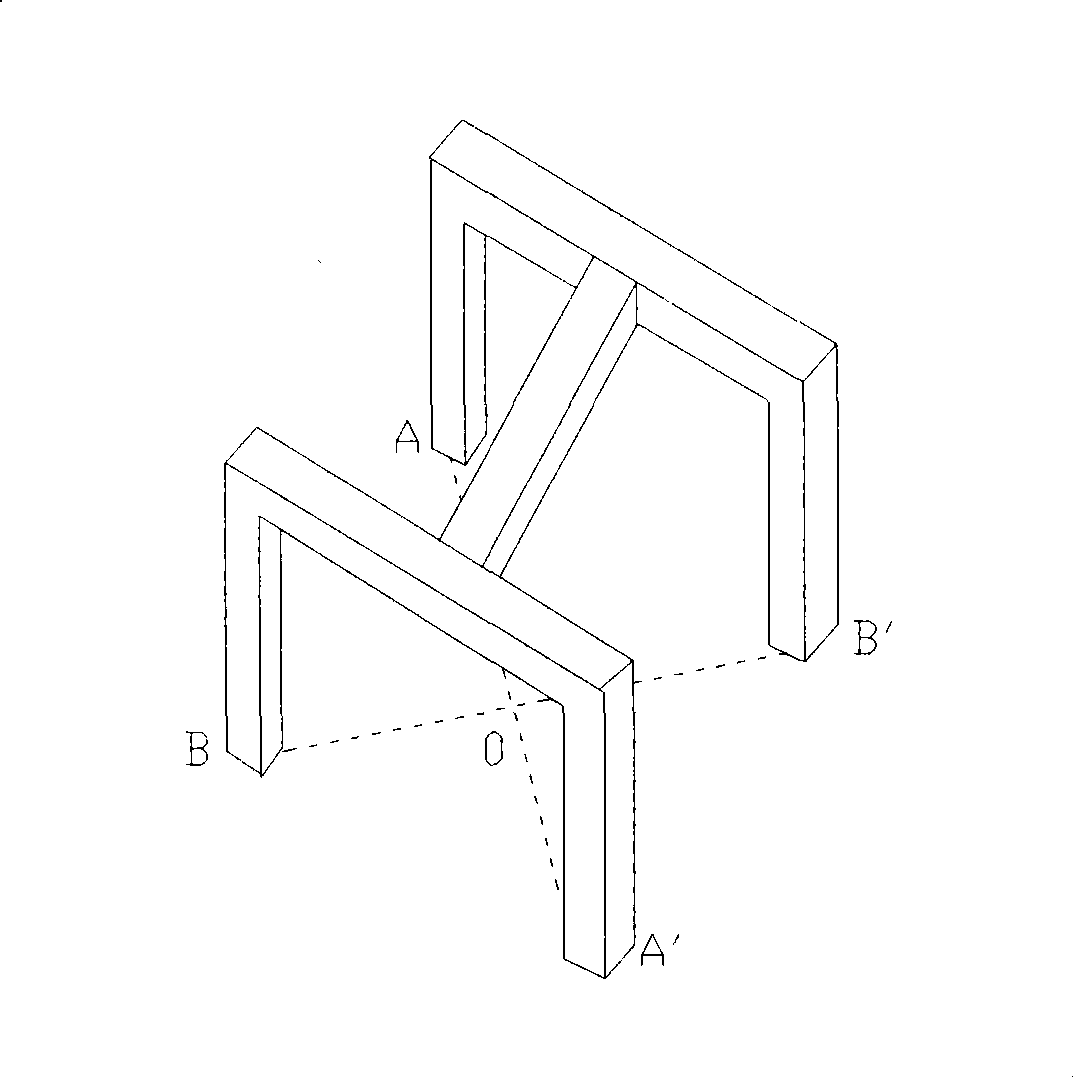

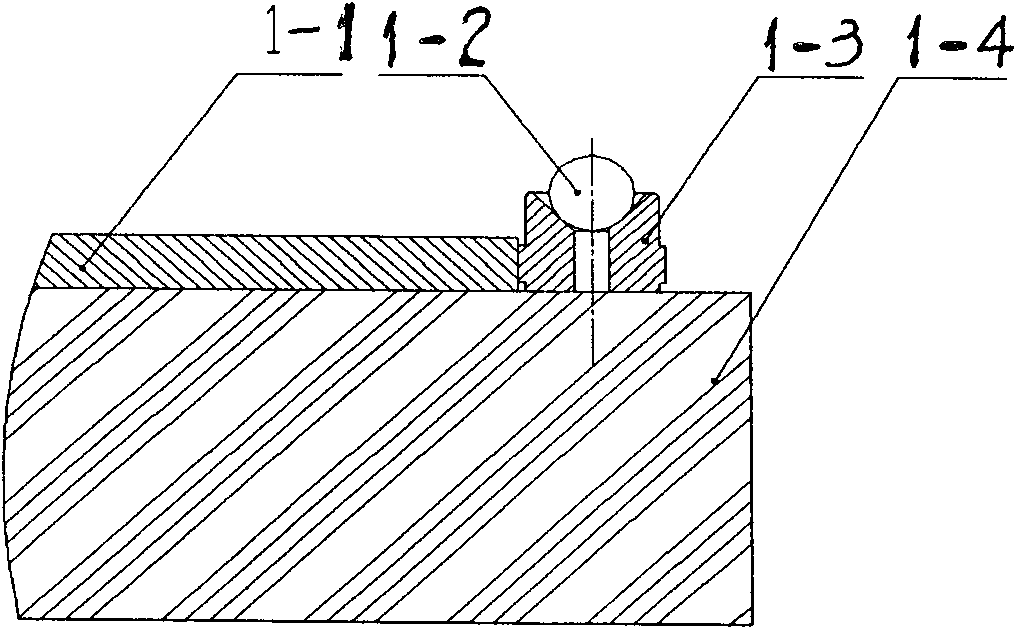

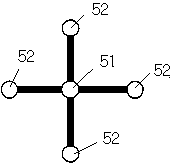

Telescopic cross magnet yoke fluorescent magnetic powder flaw detection machine

InactiveCN101435797ARealize the scaling functionWith telescopic functionMaterial magnetic variablesMagnetic polesUltimate tensile strength

The invention provides a telescopic crossed yoke fluorescent magnetic powder inspection machine. A crossed yoke comprises a fixed yoke parallel to the surface of a workpiece to be tested and a moving yoke perpendicular to the surface of the workpiece to be tested, the moving yoke passes through a sliding bushing and is in sliding connection with the fixed yoke, and the moving yoke is provided with a pressure spring. The invention successfully realizes that each magnetic pole of the magnetic powder inspection machine has telescopic function so as to closely contact the workpiece by dividing the crossed yoke into the fixed yoke and the moving yoke, thereby guaranteeing the magnetic-field intensity during the fault detection. The magnetic powder inspection machine is also provided with a CCD image acquisition device, and realizes the program control of working procedures of feeding, magnetization, CCD observation and discharge as well as on-line detection monitoring and automatic fault detection through the program control operation of a PLC.

Owner:瑞迪世纪(北京)探伤设备有限公司

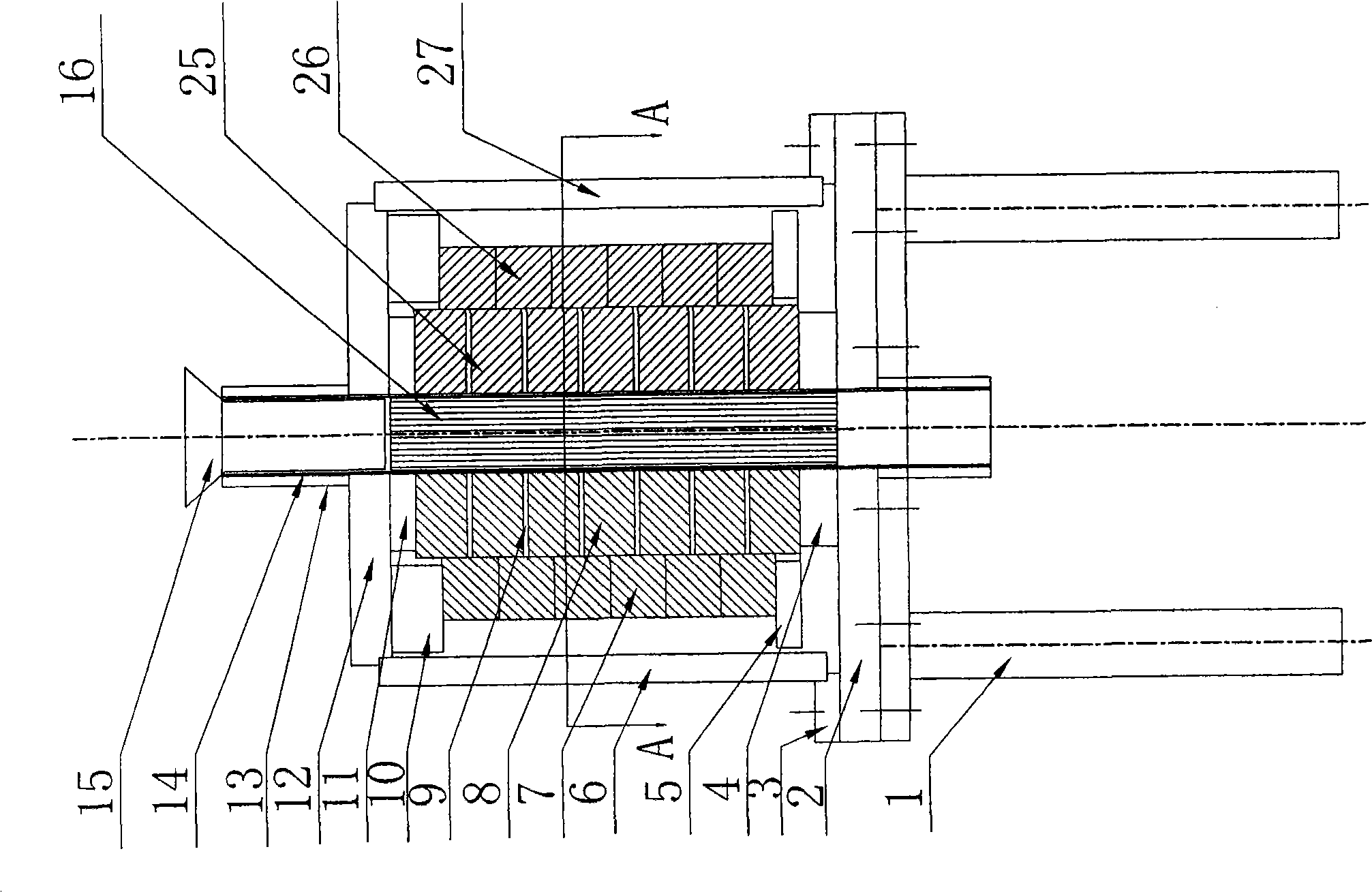

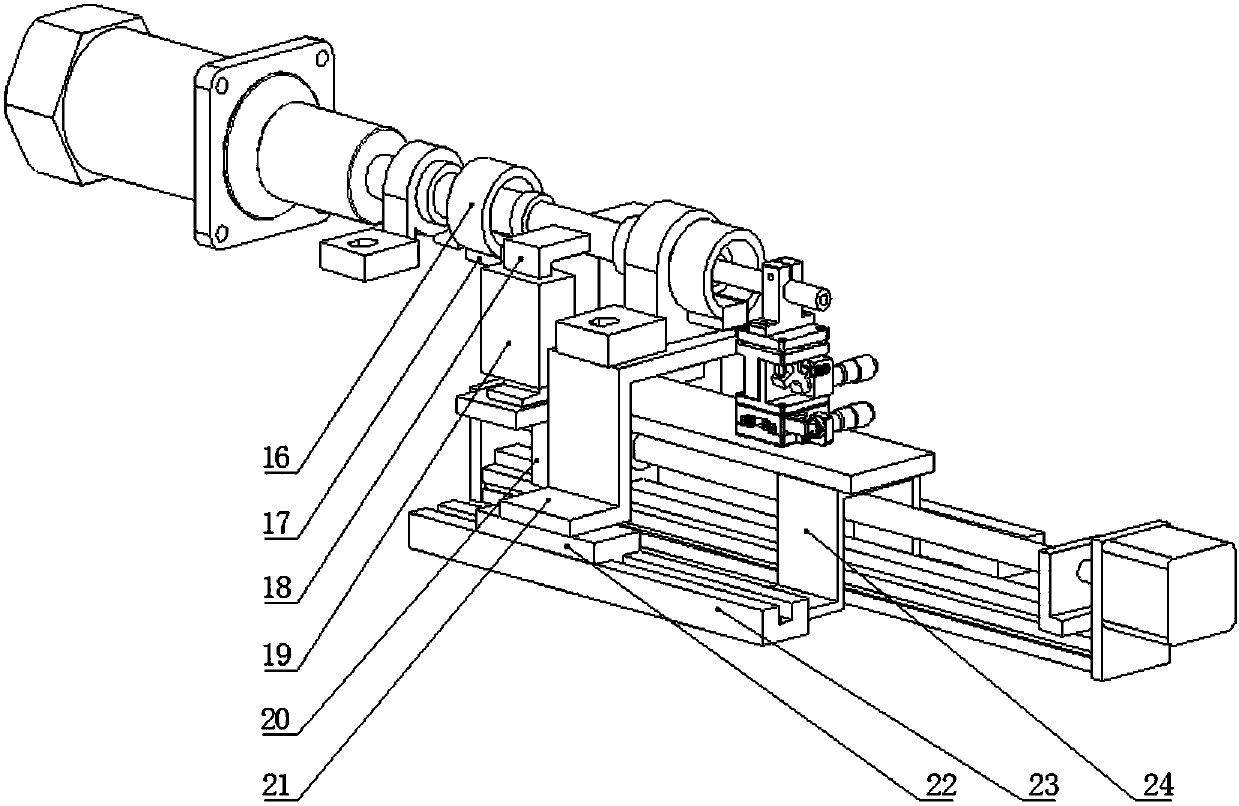

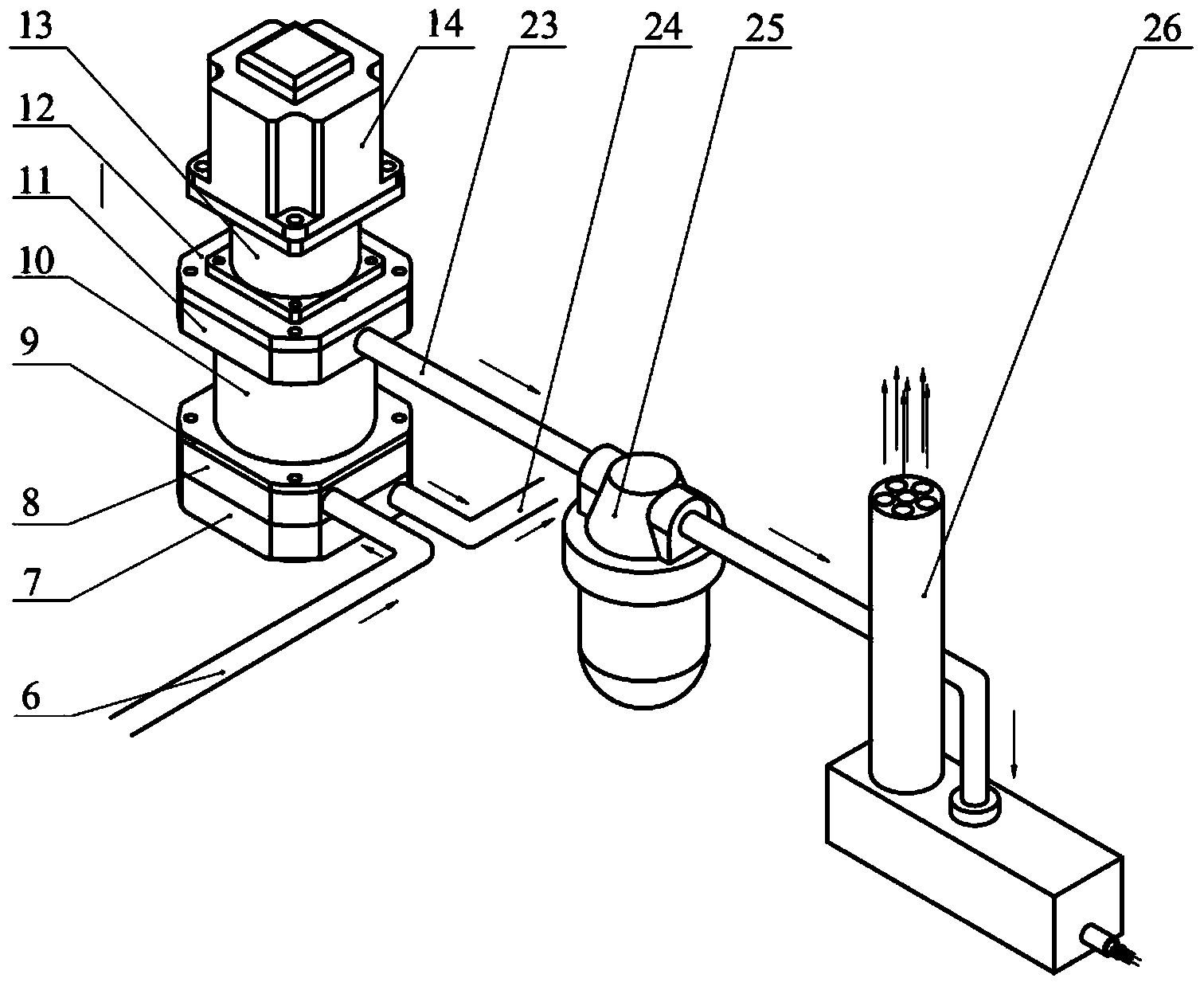

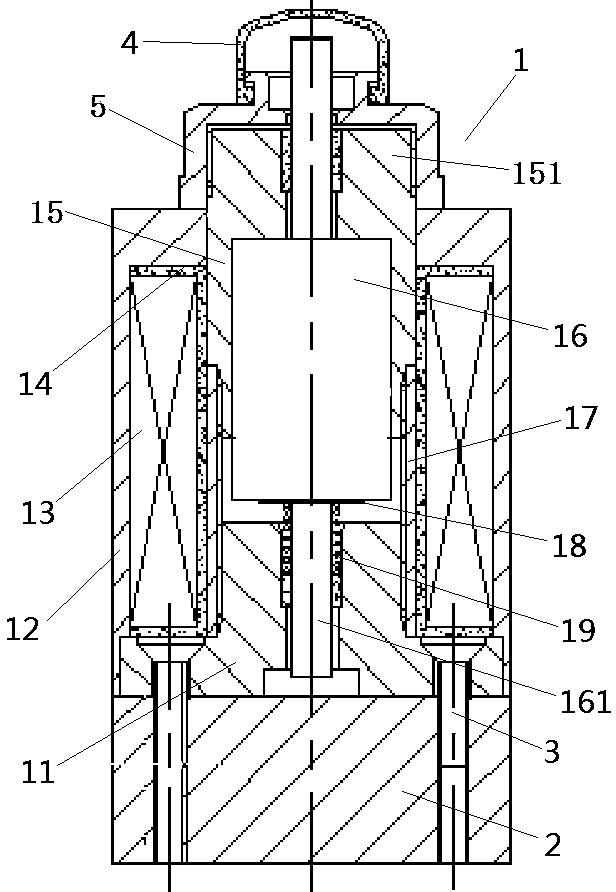

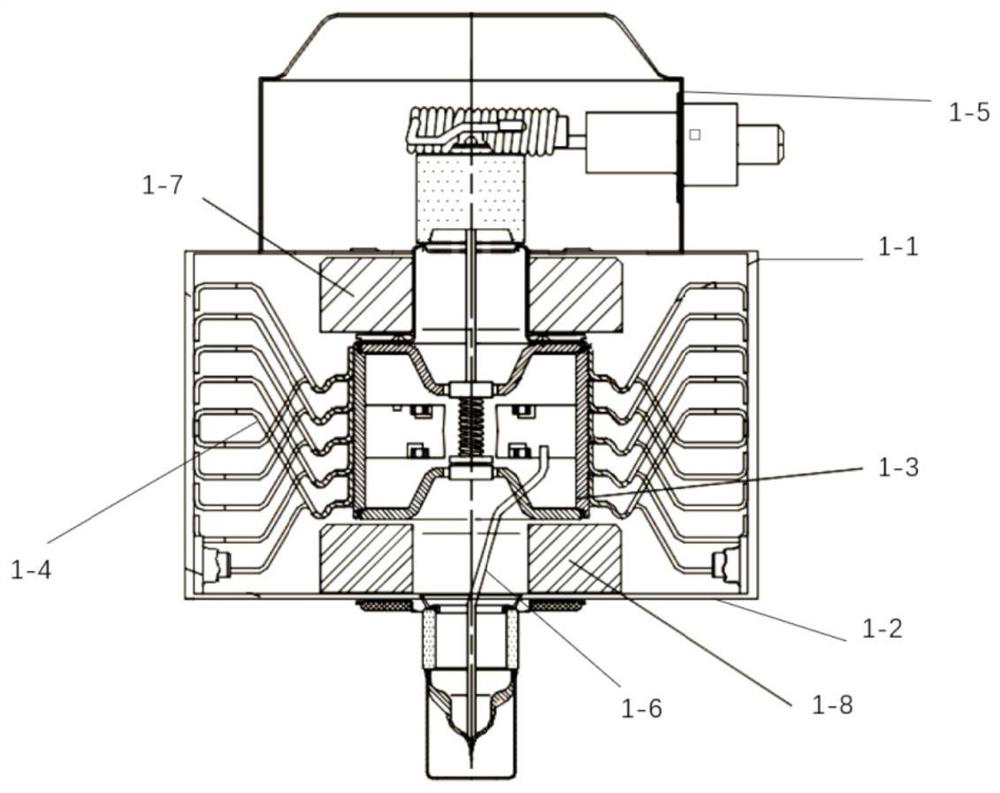

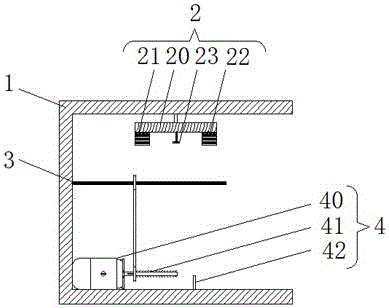

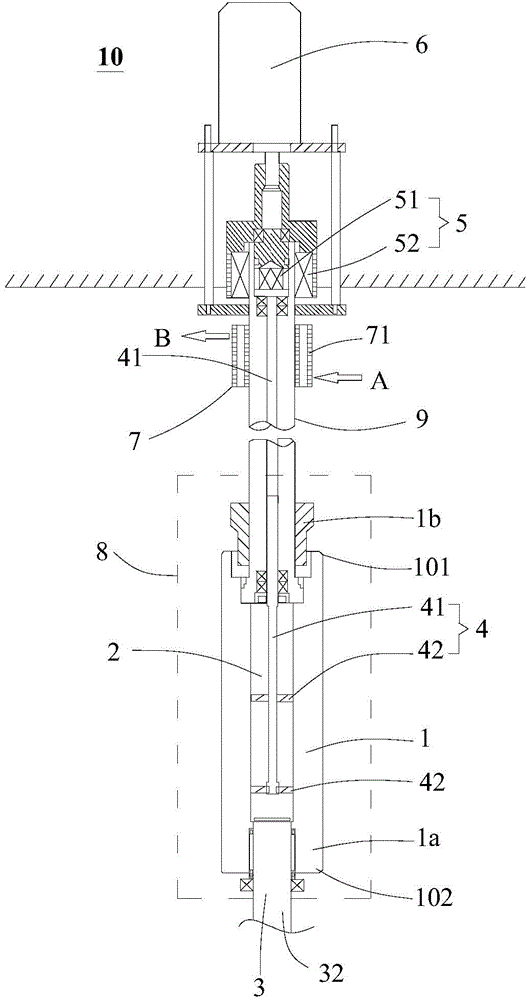

Titanium alloy pipe inner wall magneto-rheological polishing method and device

ActiveCN107791107AGood controllabilityImprove material removal ratePolishing machinesGrinding work supportsApparent viscosityMagnetic current

The invention provides a titanium alloy pipe inner wall magneto-rheological polishing method and device. Magneto-rheological liquid is pumped into a polishing head inner cavity along the inner surfaceof a transmission rod under the effect of a creepage pump, and flows over through rectangular holes around the middle of a polishing head, the liquid flows to the polishing area from the left side and the right side, under the effect of a magnetic field, the apparent viscosity and the shear yield stress of the magneto-rheological liquid are rapidly increased, a Bingham medium with certain viscousplasticity is formed, along with relative motion of the polishing head and the pipe wall, the Bingham medium carries out shear removal on the pipe wall material, the magneto-rheological liquid obtained after polishing is collected through magneto-rheological liquid collecting mechanisms on the two sides of a pipe fitting, through filtering and stirring, the polishing process is continuously carried out, and circular utilization of the magneto-rheological liquid is achieved; in the magneto-rheological liquid circulation process, heat generated in the polishing area is brought away. The inner wall of the titanium alloy pipe can be automatically polished, the beneficial effects of being easy to control, good in polishing uniformity, high in work efficiency and the like are achieved, and themethod and device are particularly suitable for polishing treatment of the inner wall surface of the fine and long titanium alloy pipe.

Owner:NORTHEASTERN UNIV

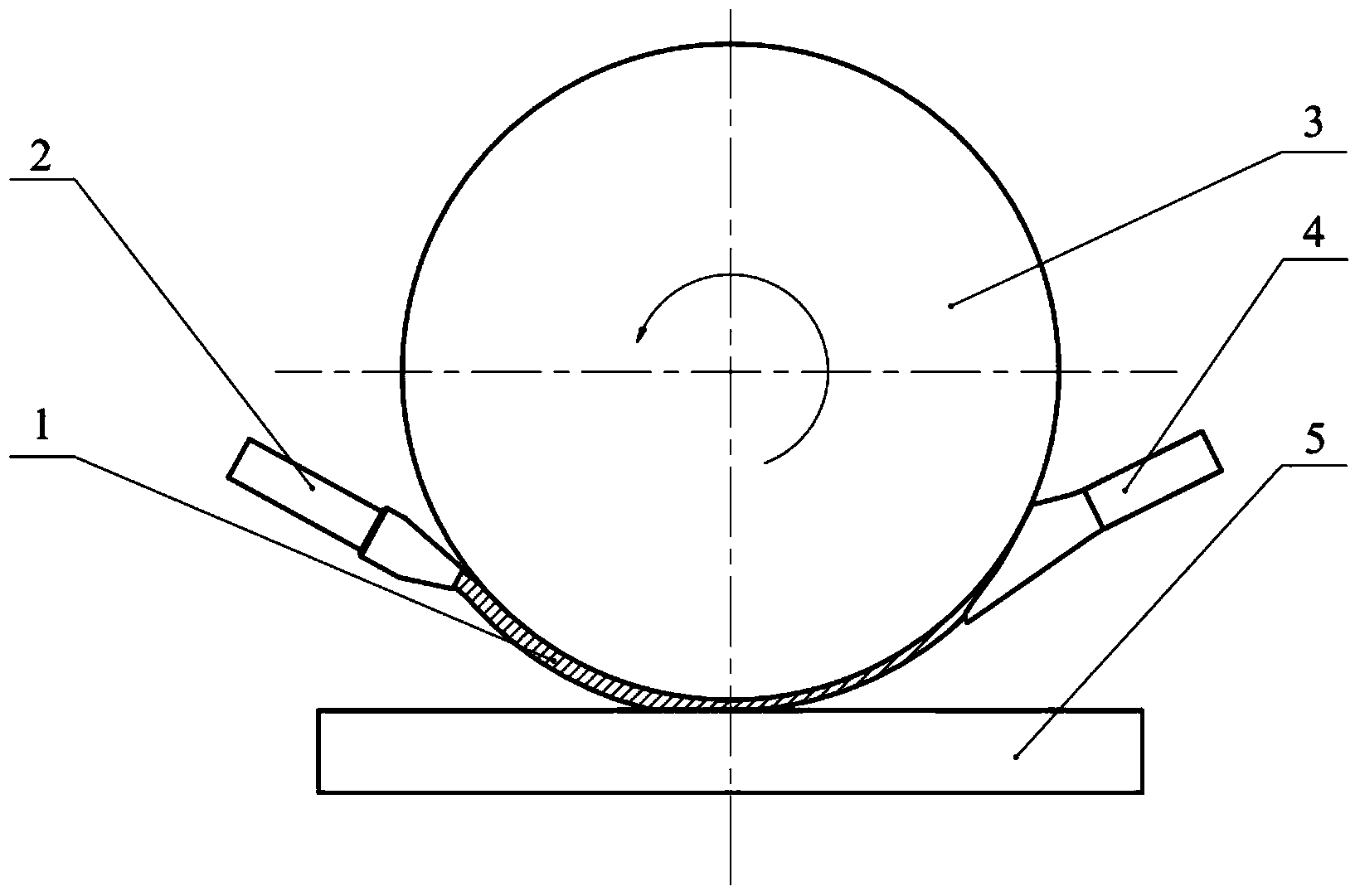

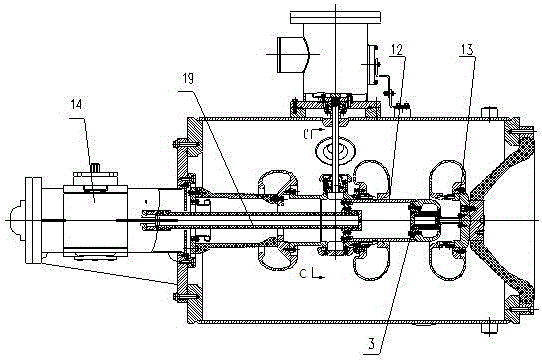

High-flow magnetorheogical fluid recycling device

InactiveCN104290038AGuaranteed magnetic field strengthIncrease speedGrinding/polishing apparatusEngineeringStreamflow

The invention relates to a high-flow magnetorheogical fluid recycling device. The device comprises a recycling head which is arranged nearby the position where magnetorheogical fluid just breaks away from a polishing area and keeps flexible linear contact with a polishing wheel, and a vacuum generating device, wherein the recycling head is used for receiving the magnetorheogical fluid thrown out of the bottom of the polishing wheel, and the vacuum generating device is used for providing power for recycling the magnetorheogical fluid. According to the recycling device, a recycling connector is arranged nearby the position where the magnetorheogical fluid just breaks away from the polishing area, at the moment, the magnetic field intensity is moderate, it can be guaranteed that the magnetorheogical fluid is smoothly separated from the polishing wheel, the magnetic field force intensity can also be guaranteed, and therefore the rotating speed of the polishing wheel and the size of a nozzle can be increased, and the polishing efficiency is increased from two aspects.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

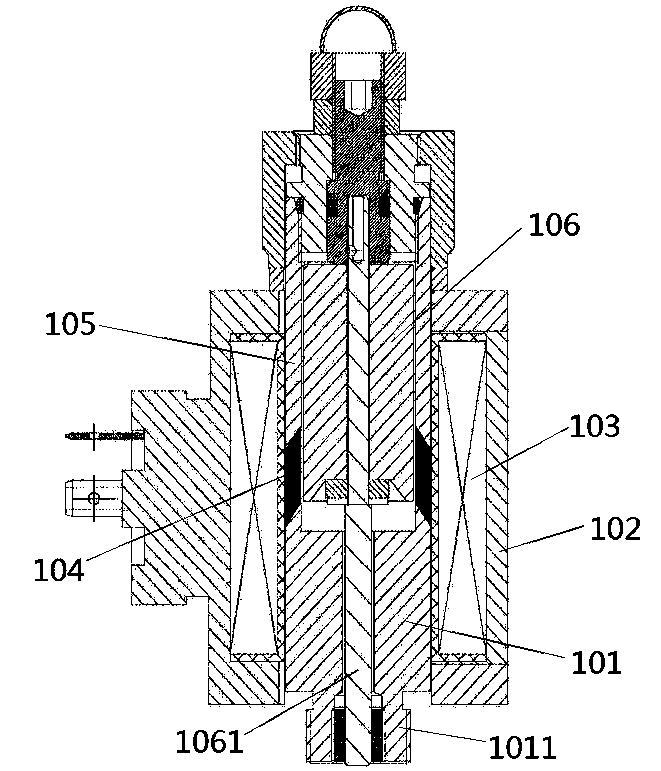

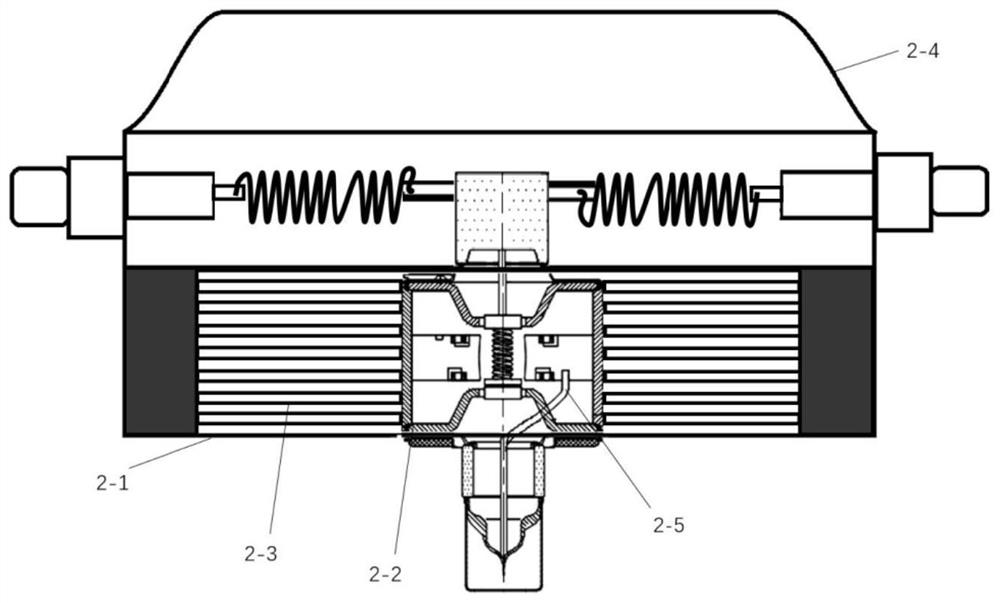

Magnetic steel piston type magneto-rheological damper with double ejection rods

InactiveCN102182785AHigh viscosityLow viscosityNon-rotating vibration suppressionPower flowNon magnetic

The invention discloses a magnetic steel piston type magneto-rheological damper with double ejection rods, comprising a working cylinder, a piston and two piston rods; the working cylinder is filled with magneto-rheological fluid; the piston is made of magnetic steel, two piston rods are both made of non-magnetic materials, a magnet exciting coil and a magnetizing-demagnetizing coil are wound in the middle of the piston, and the magnetic steel piston can be magnetized and demagnetized by controlling a power source, therefore, the magnetic steel piston has certain magnetic field intensity and the magnetic steel piston type magneto-rheological damper with double ejection rods has certain output damping force, and the output damping force of the magnetic steel piston type magneto-rheological damper with double ejection rods is regulated by changing the size and the direction of current input to the magnet exciting coil of the magnetic steel piston.

Owner:谭晓婧

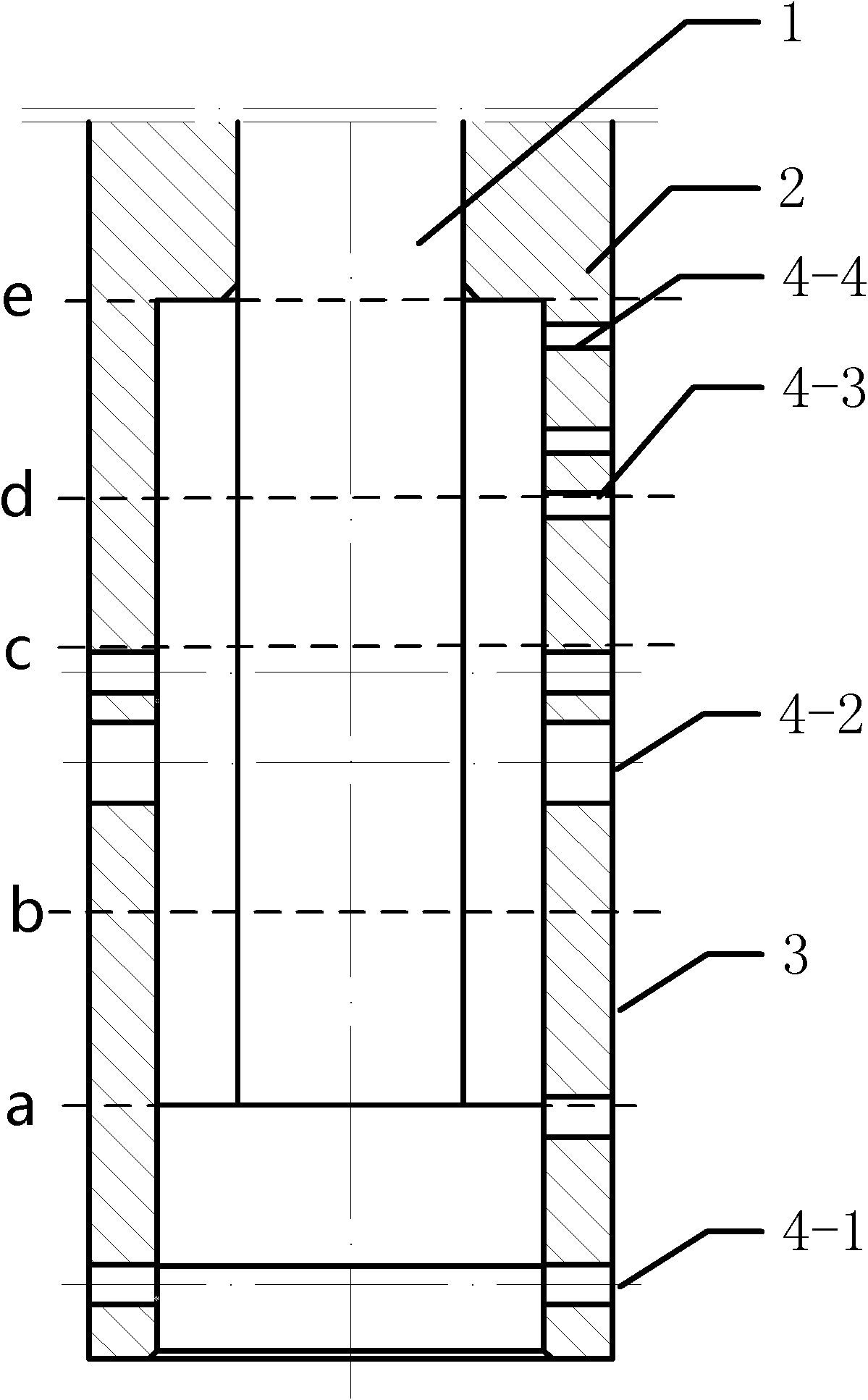

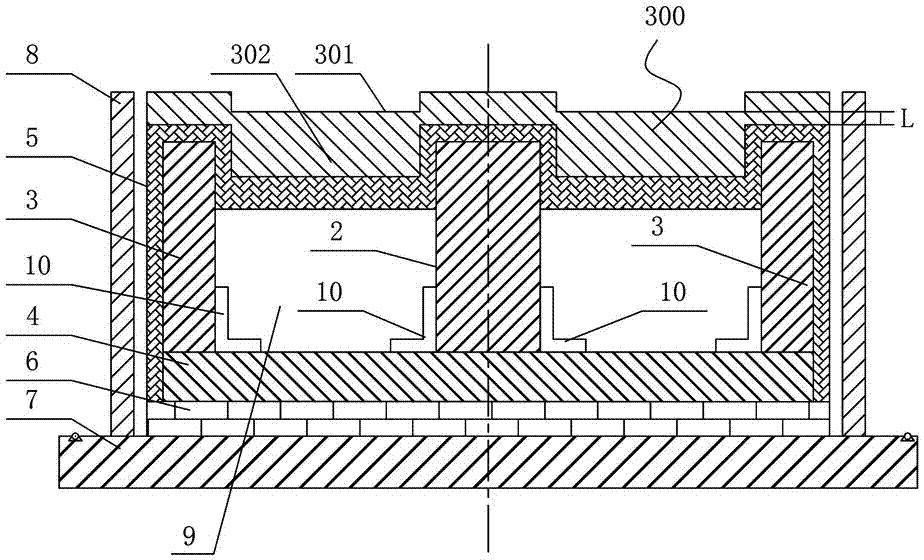

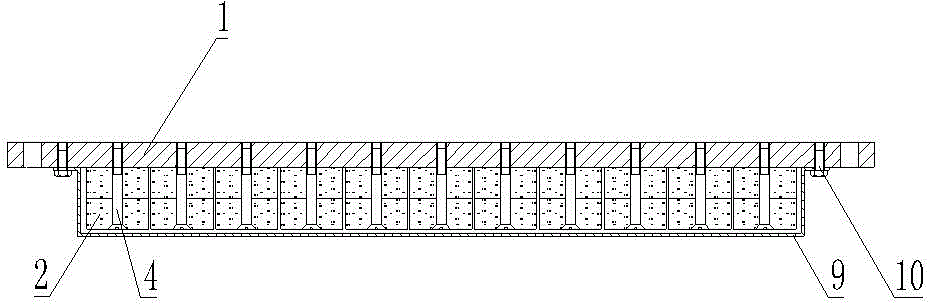

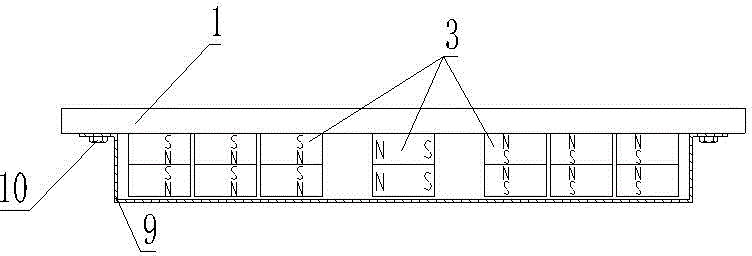

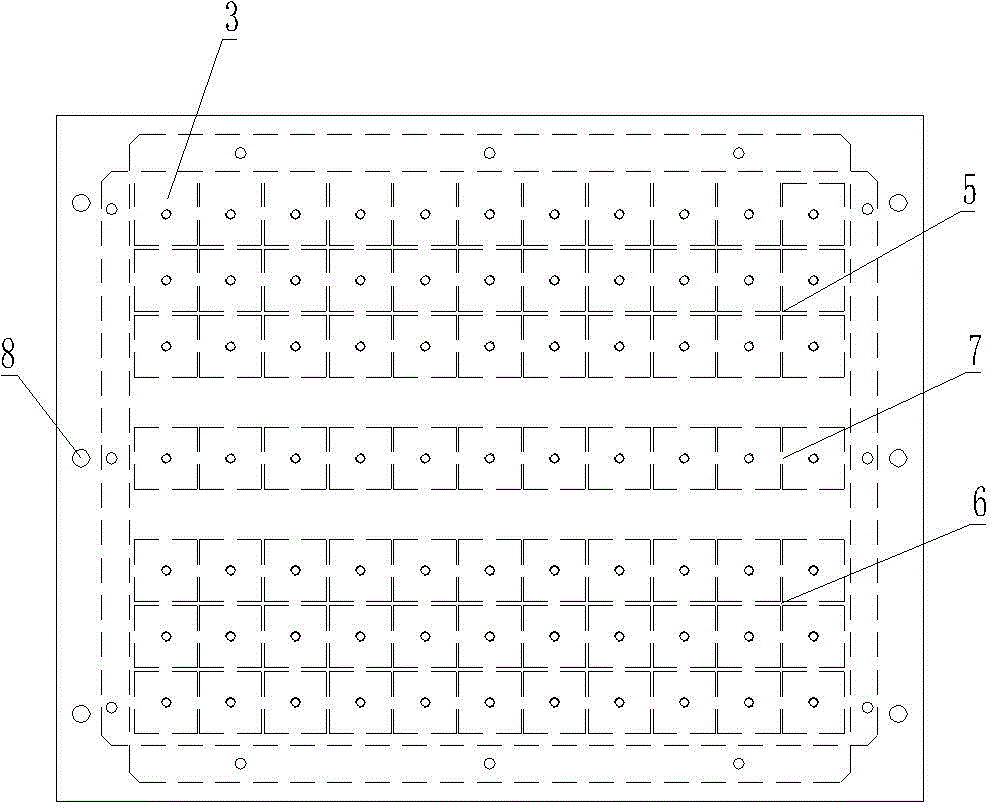

Economical and practical embedded freezing and cold storage fresh-keeping and preservation low-intensity magnetic field modularization device

ActiveCN113192719AGuaranteed validityGuaranteed magnetic field strengthElectromagnets without armaturesDomestic cooling apparatusMagnetic field magnitudeCool storage

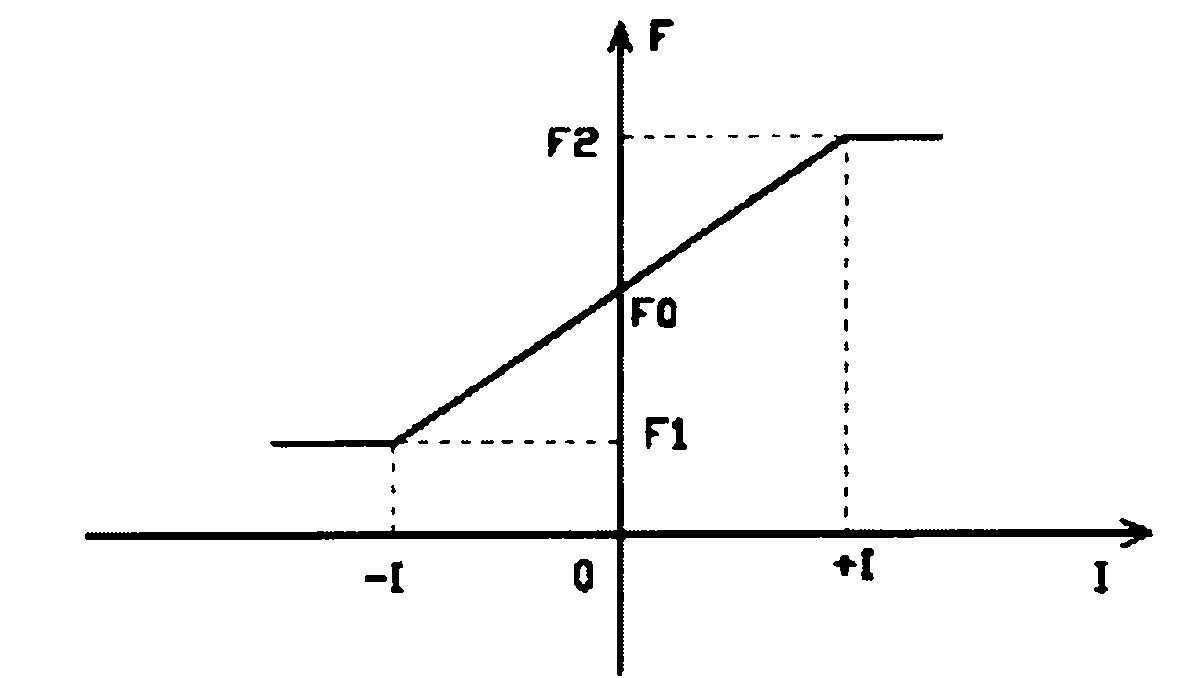

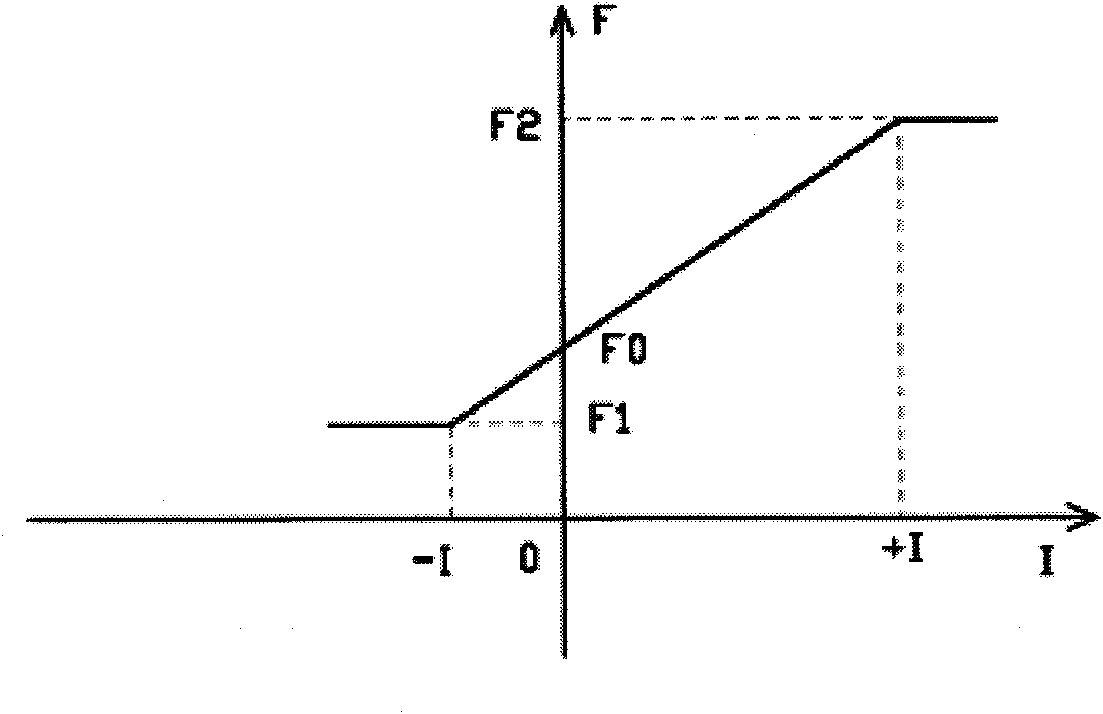

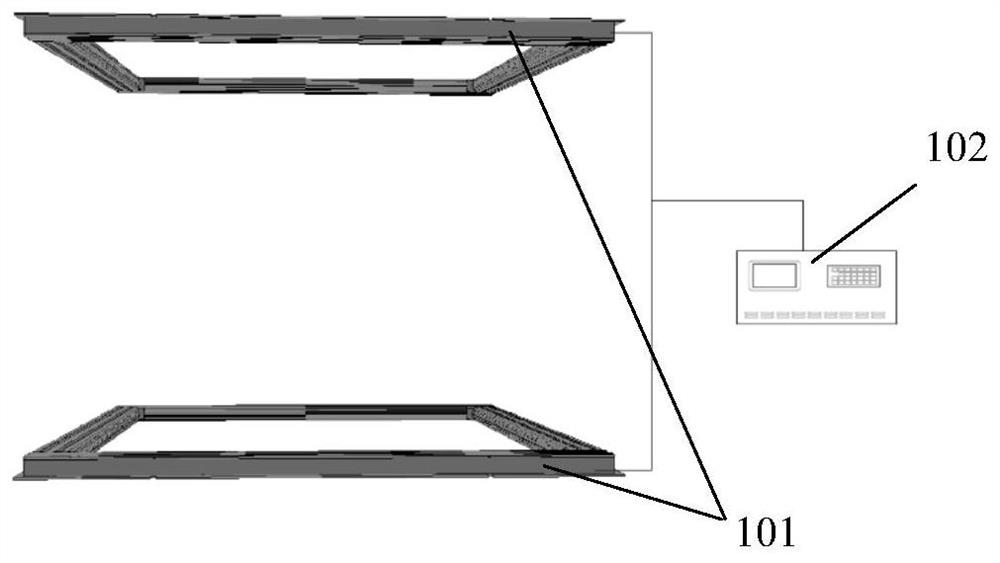

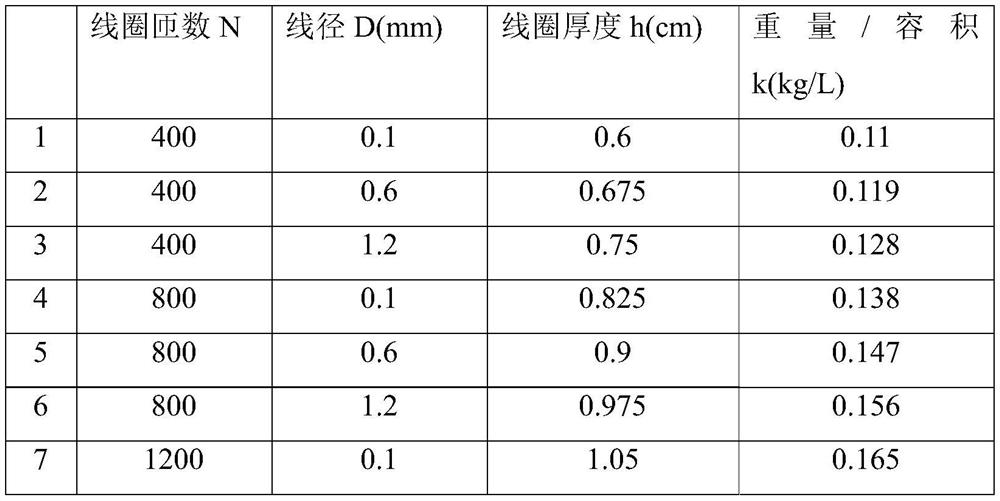

The invention discloses an economical and practical embedded freezing and cold storage fresh-keeping and preservation low-intensity magnetic field modularization device which can be applied to refrigerators, intelligent cabinets, wine cabinets, warehouse logistics equipment and the like. The device comprises a coil frame, a magnet exciting coil and a control circuit, the magnet exciting coil is arranged in the coil frame so as to generate a steady low-intensity magnetic field or a pulse steady low-intensity magnetic field; and the control circuit is connected with the magnet exciting coil and used for adjusting the magnetic field intensity of the steady low-intensity magnetic field or the pulse steady low-intensity magnetic field and the magnetic field frequency and the duty ratio of the pulse steady low-intensity magnetic field. According to the device, a small-size coil frame and a small-size wire diameter are adopted, so that the ratio range of the weight of the device to the effective storage volume of embedded equipment is 0.05-0.5 kg / L, the unit volume energy consumption of the embedded equipment is 0.03-5.0 W / L, important factors such as weight, magnetic field intensity and frequency, coil heat dissipation, magnetic field duty ratio and the like are balanced, high-quality and low-energy-consumption freezing and refrigeration of food, medical supplies, agricultural product raw materials, fresh flowers, plant seeds and the like by the magnetic field are kept to the maximum extent.

Owner:INDUC SCI CO LTD

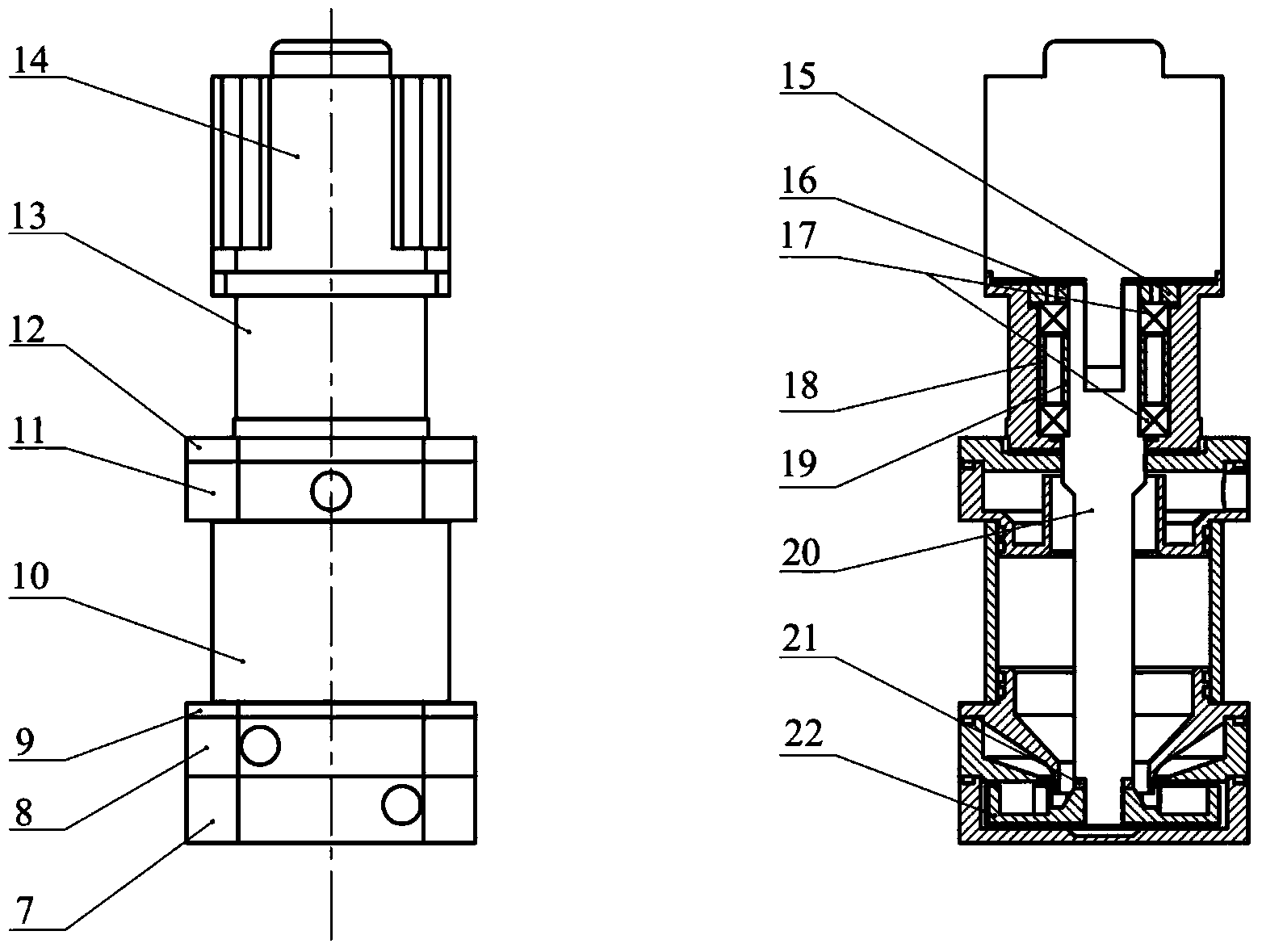

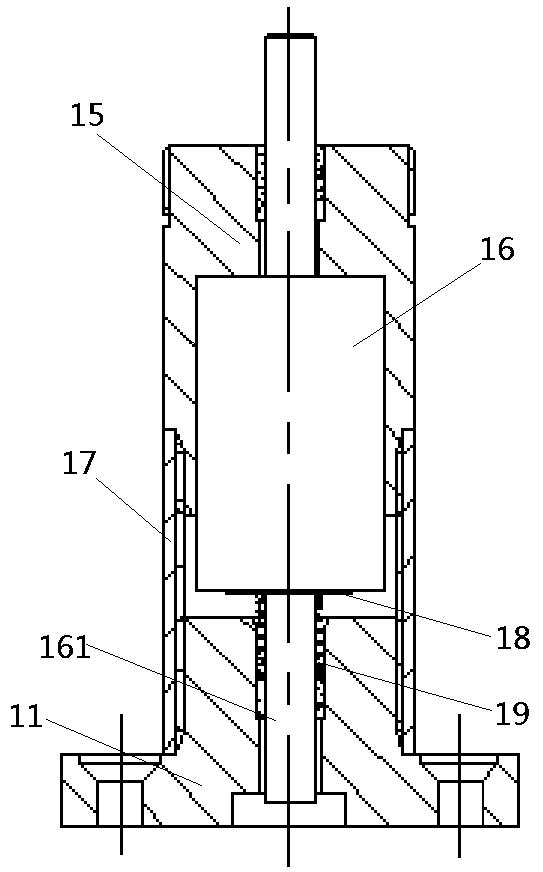

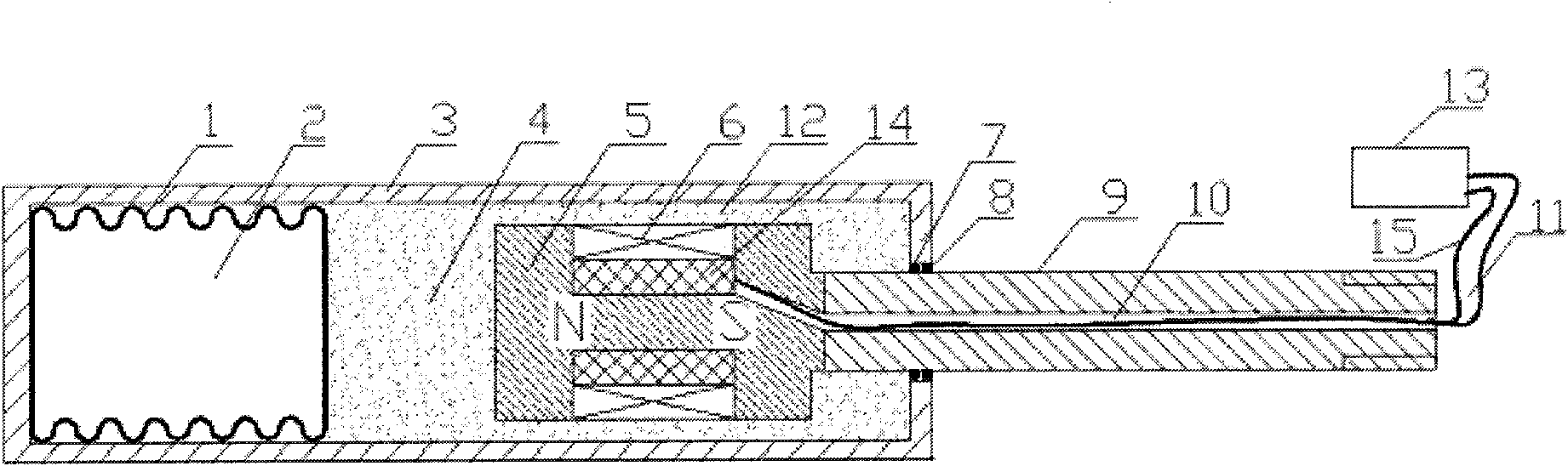

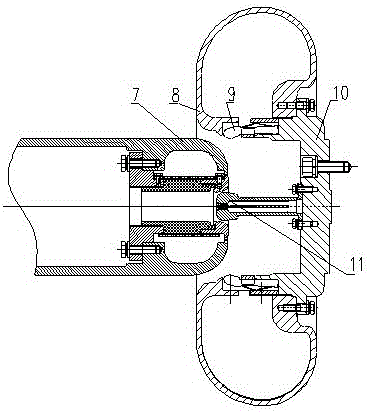

Electromagnet for solenoid valve

InactiveCN109630739AEasy to useAvoid changes in the magnetic fieldOperating means/releasing devices for valvesSolenoid valveEngineering

The invention relates to an electromagnet for a solenoid valve. The electromagnet for the solenoid valve comprises an armature assembly and a coil assembly which sleeves the armature assembly, the armature assembly comprises an iron core base, an internal static iron core and an armature, and a non-magnetic conducting component is arranged between the iron core base and the internal static iron core in a separating mode. A top rod is arranged on the armature, and a through hole for the top rod to penetrate through downward is formed in the iron core base. The coil assembly comprises a coil andan external static iron core, an installation cavity for mounting into the coil is formed in the external static iron core, and a blocking and stopping part capable of preventing the coil from movingup is arranged on the installation cavity. The iron core base comprises a chassis and an armature seat, the upper end surface of the chassis is matched at the lower end of the coil in a supporting mode, a blocking and stopping surface matched with the upper end surface of the chassis in a blocking and stopping mode is arranged on the lower part of the external static iron core, an upper end partpenetrating through the upper end of the external static iron core is arranged on the inner static iron core, and a fastener pressing the external static iron core sleeves the upper end part of the internal static iron core. The electromagnet ensures the convenient disassembly and assembly of the coil, and ensures the continuous stability of a magnetic field produced by the coil.

Owner:HENAN PINGGAO ELECTRIC +2

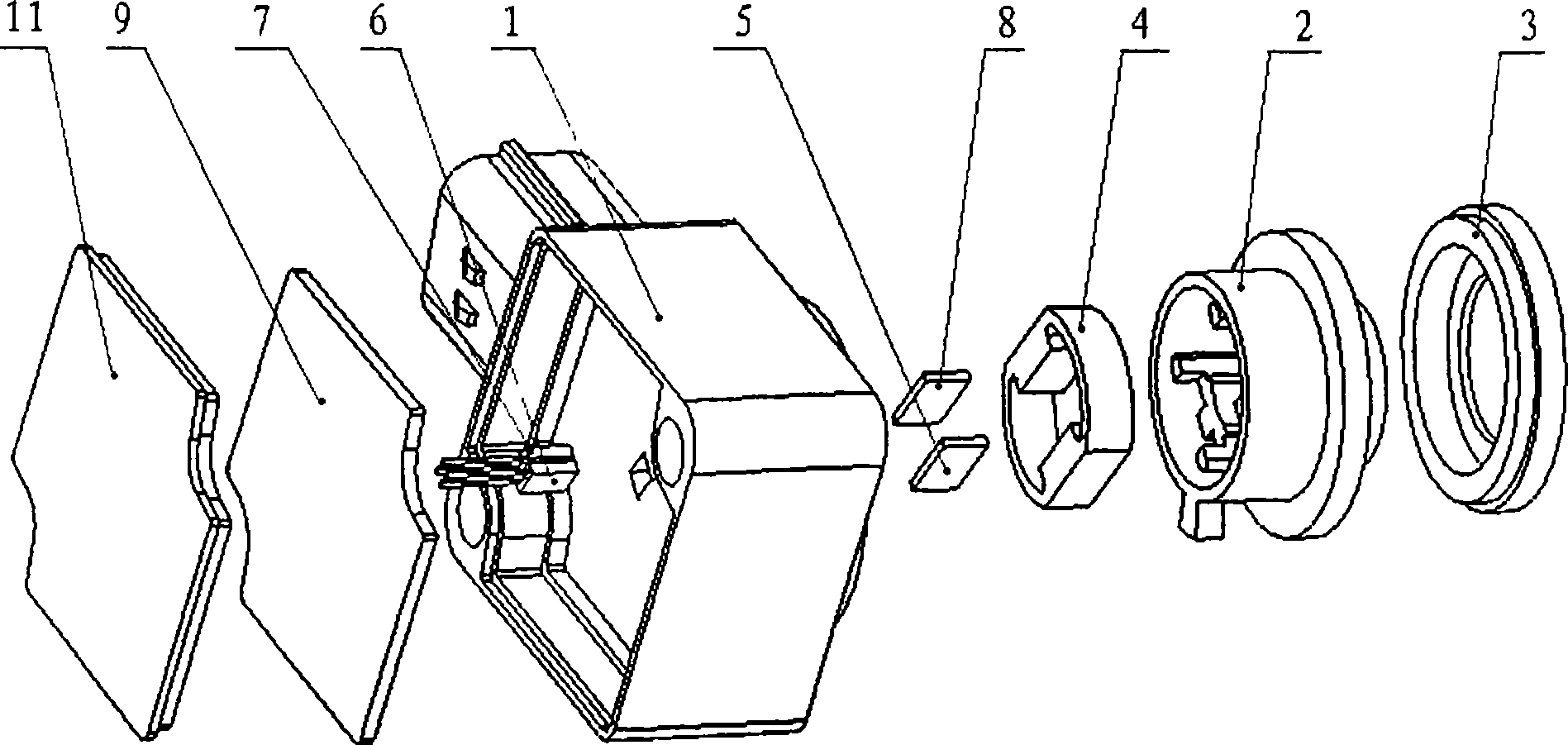

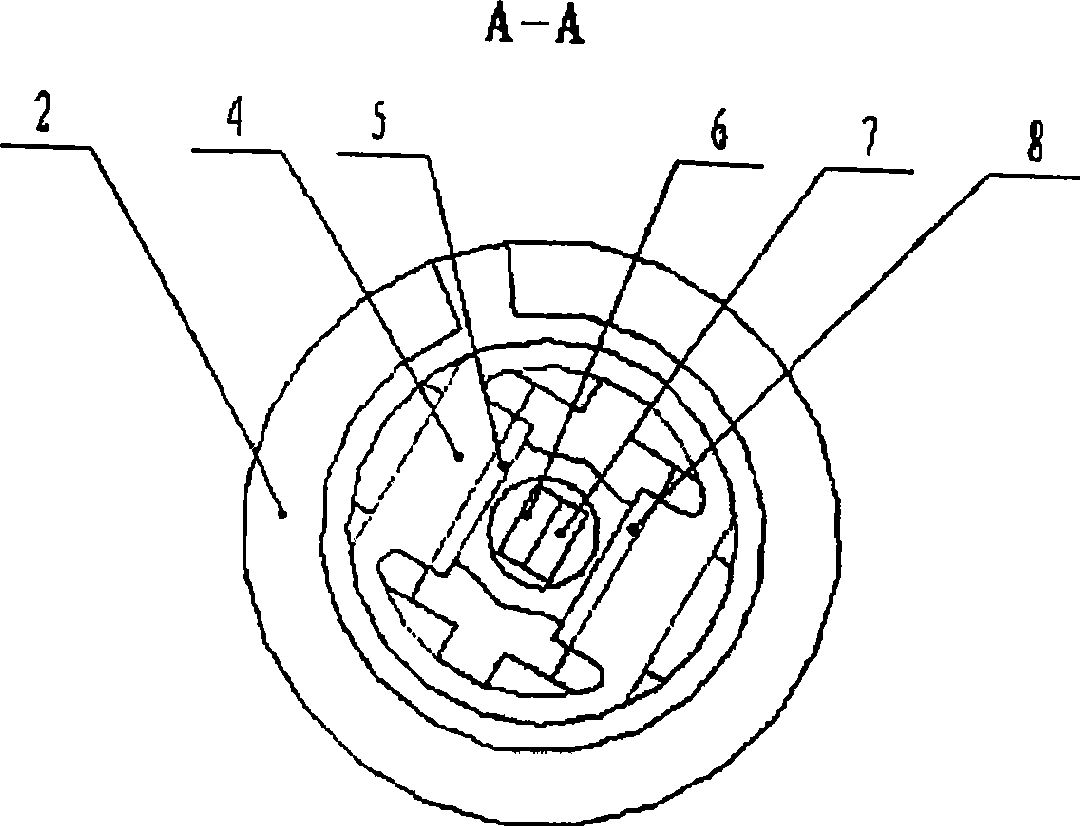

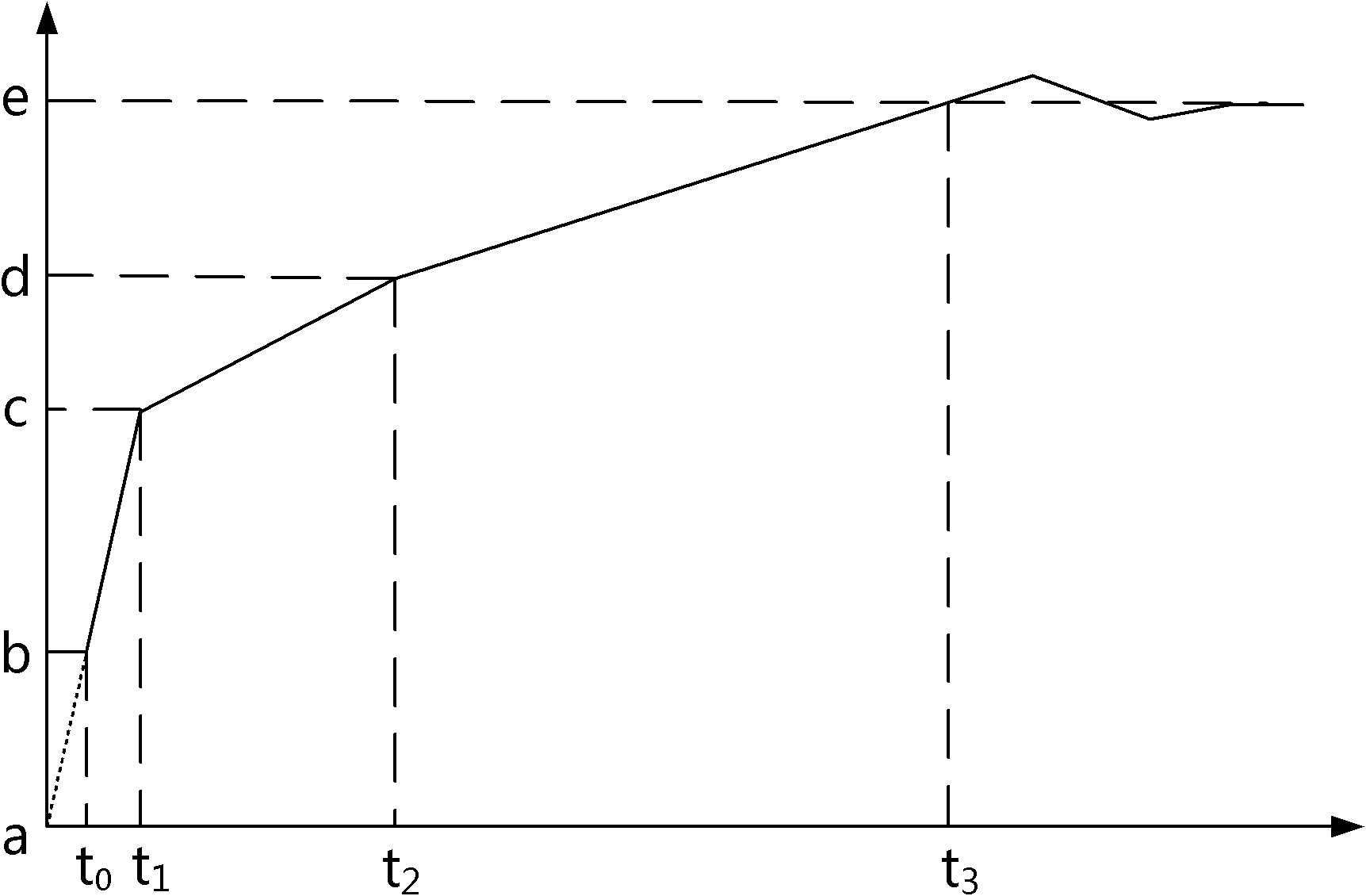

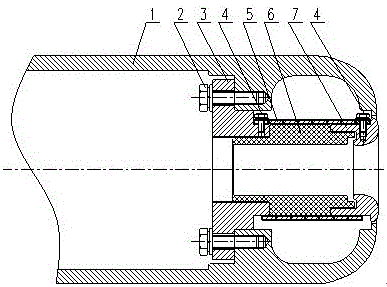

Non-contact clutch position sensor

ActiveCN101393036AExtend working lifeGood linear output characteristicsConverting sensor output electrically/magneticallyElectrical conductorContact failure

The invention relates to a position sensor for a non-contact clutch, which solves the problems that the poor contact existing in the prior position sensor of the non-contact clutch leads to poor operational reliability and so on, The position sensor for the non-contact clutch comprises a shell, a rotor, a circuit board and so on, wherein a magnetic steel ring is arranged in the cylindrical rotor, the inner wall of the magnetic steel ring is symmetrically provided with two permanent magnet blocks respectively, and a cavity is formed between the two permanent magnet blocks; and the middle part of the circuit board is connected with an A Hall chip and a B Hall chip through two conducting member bars respectively, and the A Hall chip and the B Hall chip are positioned in the cavity between the two permanent magnet blocks. The sensor solves the problem of contact wear and prolongs service life; the sensor has good linear output characteristic and ensures that an output signal is more accurate and stable; the adopted Hall chips have functions of programmable property and temperature compensation, can flexibly change parameters of output voltage according to the requirement of customers, and automatically compensate and calibrate the magnetic field drift when the magnetic field intensity of a magnet drifts with the change of the temperature.

Owner:HEFEI BANGLI ELECTRONICS

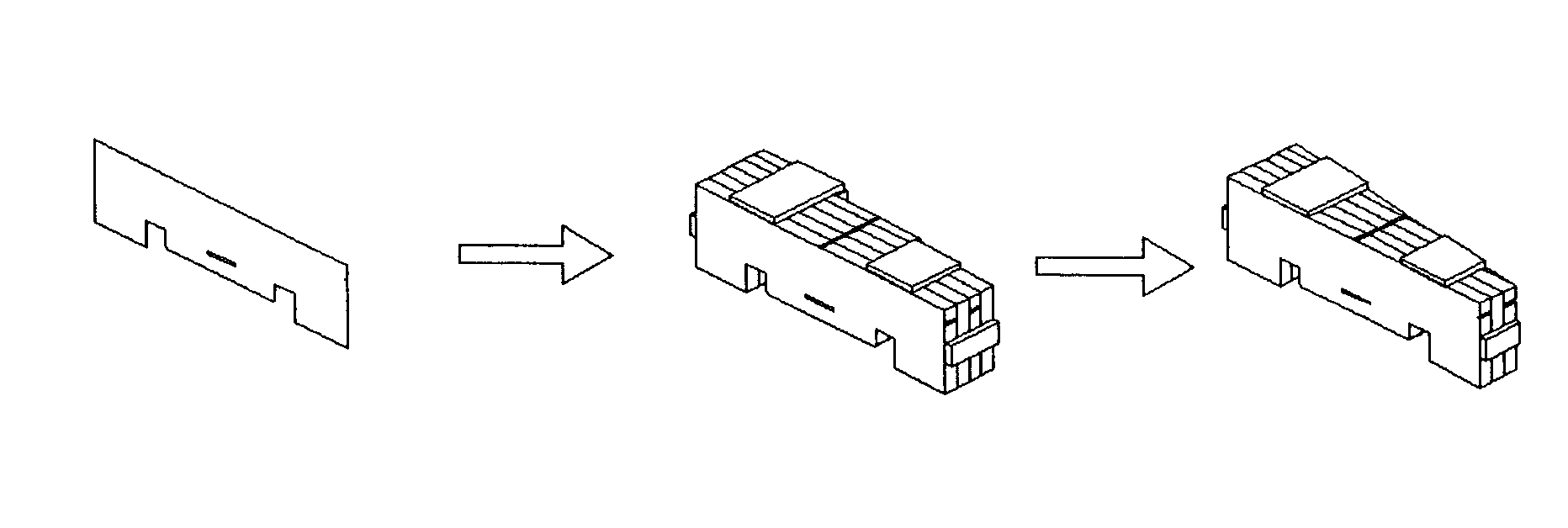

Method for manufacturing large-size superconducting magnet laminated iron core

ActiveCN101968997ASmall sizeSave human resourcesInductances/transformers/magnets manufactureSuperconducting magnets/coilsSuperconducting CoilsEngineering

The invention relates to a method for manufacturing a superconducting electromagnet used for charged particle transmission. A method for manufacturing a large-size superconducting magnet laminated iron core is mainly characterized by comprising the following steps of: stamping, detecting, end plate bonding, machining, half-iron core laminating, welding, and overall iron core assembling, wherein guide posts are arranged between an upper magnet and a lower magnet; the guide posts are respectively arranged on an upper iron core and a lower iron core; the guide posts are well matched with the upper and lower iron cores by debugging; the positions of the upper and lower guide posts are fixed; and during assembling, when the upper iron core is close to a superconducting coil Dewar box in a descending process, the guide posts start to work so as to prevent the Dewar box from being damaged because the upper iron core cannot be aligned. The method has the advantages that: a superconducting magnet of which the laminated magnet iron core is over 20T can be manufactured; and mechanical dimensions of the iron cores can be maintained by adopting a welding structure after the magnet iron cores are laminated. The magnetic field intensity and the magnetic field precision of a magnet are ensured and simultaneously a reasonable and practical manufacturing process is adopted; and the transformation from physical design to project implementation is finished in a plurality of processes such as stamping, laminating, roasting, detecting, and the like.

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

Buffer used for 126kV-vacuum circuit breaker

InactiveCN101847541AHigh speedGuaranteed magnetic field strengthContact vibration/shock dampingHigh-tension/heavy-dress switchesCombustionCylinder block

The invention discloses a buffer used for a 126-vacuum circuit breaker. The buffer consists of a piston cylinder, a piston rod and a moveable piston, wherein the piston rod and the moveable piston fixed at the end thereof are both arranged in the piston cylinder; and the piston cylinder is provided with a plurality of bottom orifices, middle orifices, upper orifices and top orifices from the cylinder bottom to the top in turn. Due to the adoption of the buffer of the invention, a just-opening speed is very high; the breaking time of a short arcing can be reduced; a lower average opening speedis provided for keeping a magnetic field intensity between contacts; stable and uniform combustion of an electric arc is ensured; and the breaking performance of a long arcing in an arc extinguish chamber can be increased.

Owner:XI AN JIAOTONG UNIV

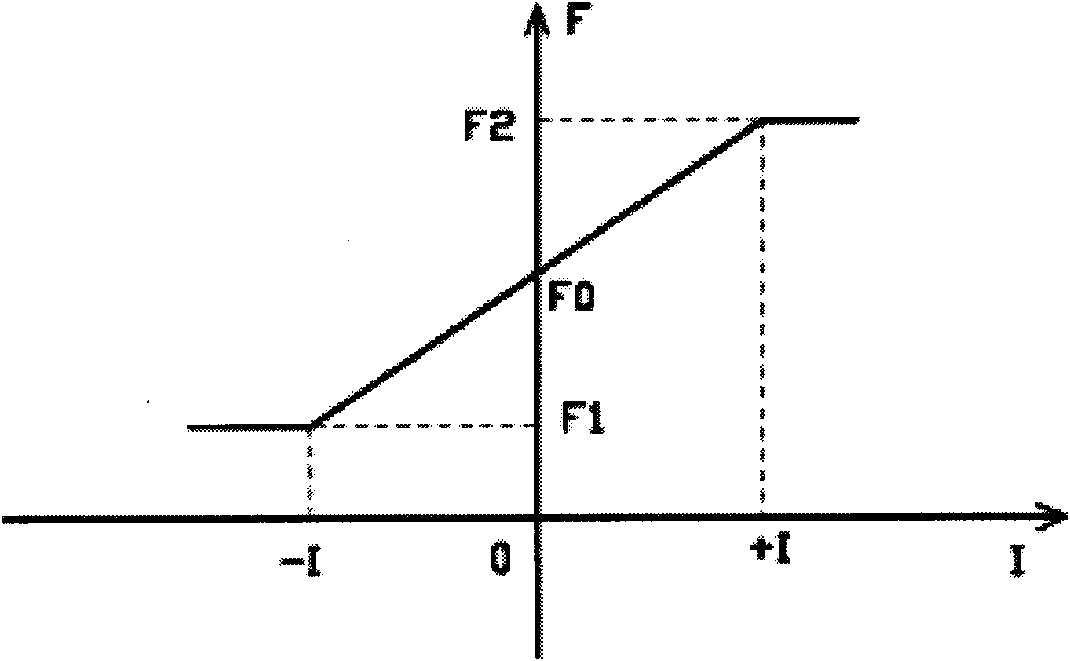

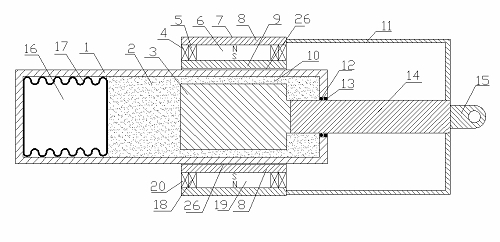

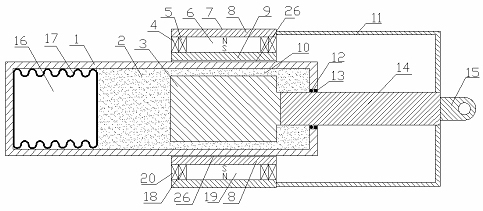

Alnico piston-type magneto-rheological damper with single piston rod

InactiveCN102135154AHigh viscosityLow viscosityNon-rotating vibration suppressionControl powerMagneto rheological damper

The invention provides an alnico piston-type magneto-rheological damper with a single piston rod, comprising a working cylinder, a piston, a piston rod and a compensating gasbag, wherein the working cylinder is filled with magneto-rheological fluid; the piston consists of alnico; the middle part of the piston is wound by an exciting coil and a magnetizing / demagnetizing coil; the alnico piston can be magnetized or demagnetized by a control power supply so that the alnico piston has certain magnetic field intensity, therefore, the alnico piston-type magneto-rheological damper with the single piston rod has certain output damping force; and subsequently the output damping force of the alnico piston-type magneto-rheological damper with the single piston rod can be adjusted by changing the size and the direction of a current input in the alnico piston exciting coil.

Owner:CHONGQING MATERIALS RES INST

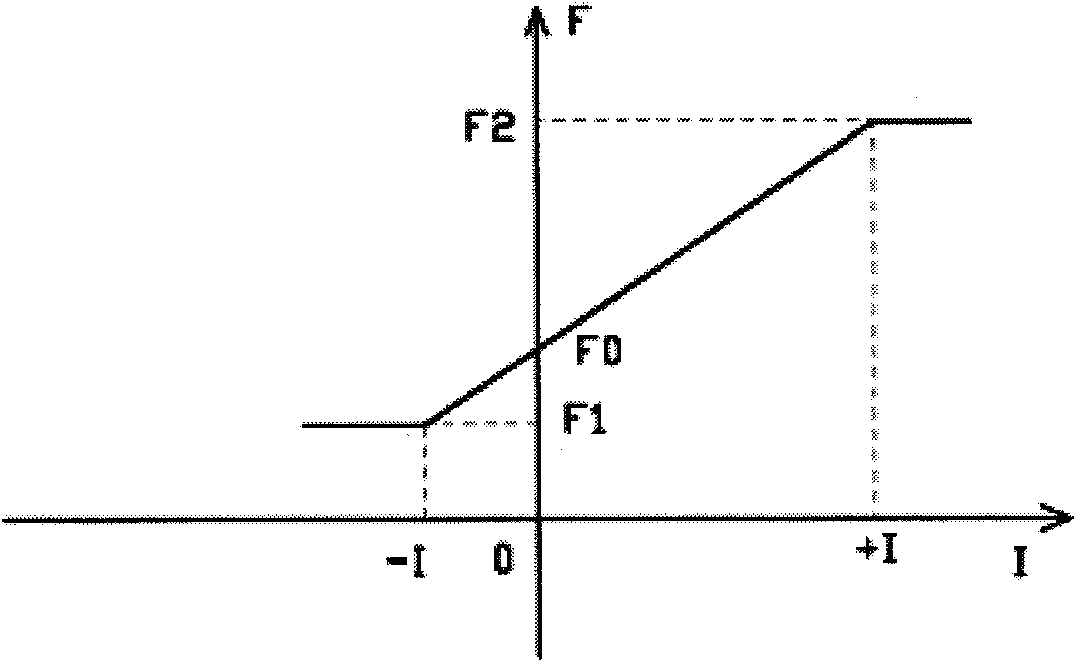

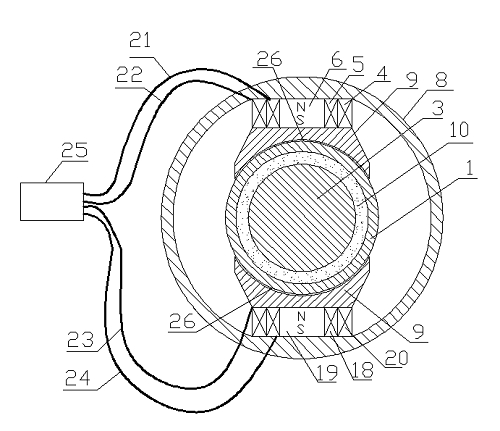

Magnetorheological damper with external electromagnet

InactiveCN102155515AThe magnetic field strength is stableThe magnetic field strength reachesNon-rotating vibration suppressionExcitation currentEngineering

The invention discloses a magnetorheological damper with an external electromagnet. The magnetorheological damper consists of a working cylinder, a piston, a piston rod, an external sliding electromagnet, a bearing frame and a compensating air bag, wherein a shell of the external sliding electromagnet is cylindrical; at least two pieces of rectangular magnet steel are uniformly distributed and fixed on the inner circumference of the cylindrical shell; a pole shoe is fixed at the other end of each piece of rectangular magnet steel; an excitation coil and a magnetizing / demagnetizing coil are wound on each piece of rectangular magnet steel; the external sliding electromagnet is arranged on the outer circumference of the working cylinder; one end of the bearing frame is fixed with the external sliding electromagnet, and the other end of the bearing frame is fixed with the tail end of the piston rod; and when the piston rod drives the piston to move in the working cylinder, the external sliding electromagnet is driven to synchronously slide outside the working cylinder by the bearing frame, and the magnitude of exciting current entering the excitation coils of the rectangular magnet steel on the external sliding electromagnet is adjusted, so that the output damping force of the magnetorheological damper with the external electromagnet can be adjusted.

Owner:CHONGQING MATERIALS RES INST

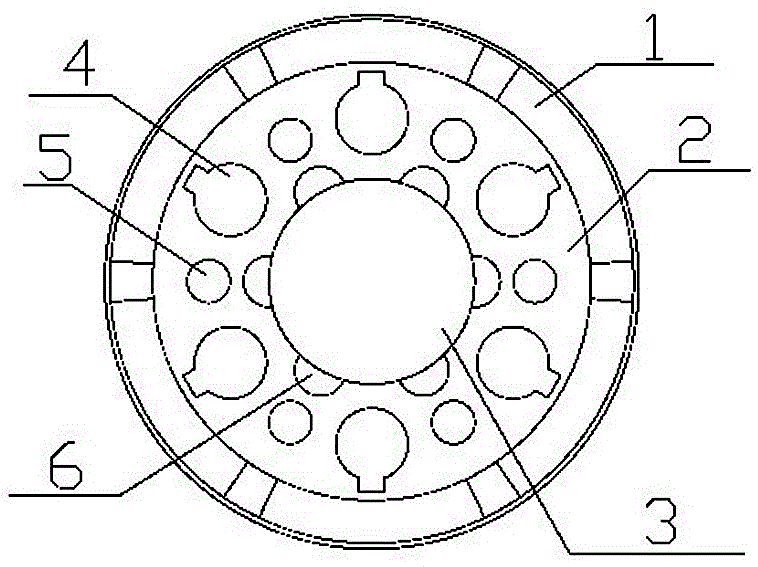

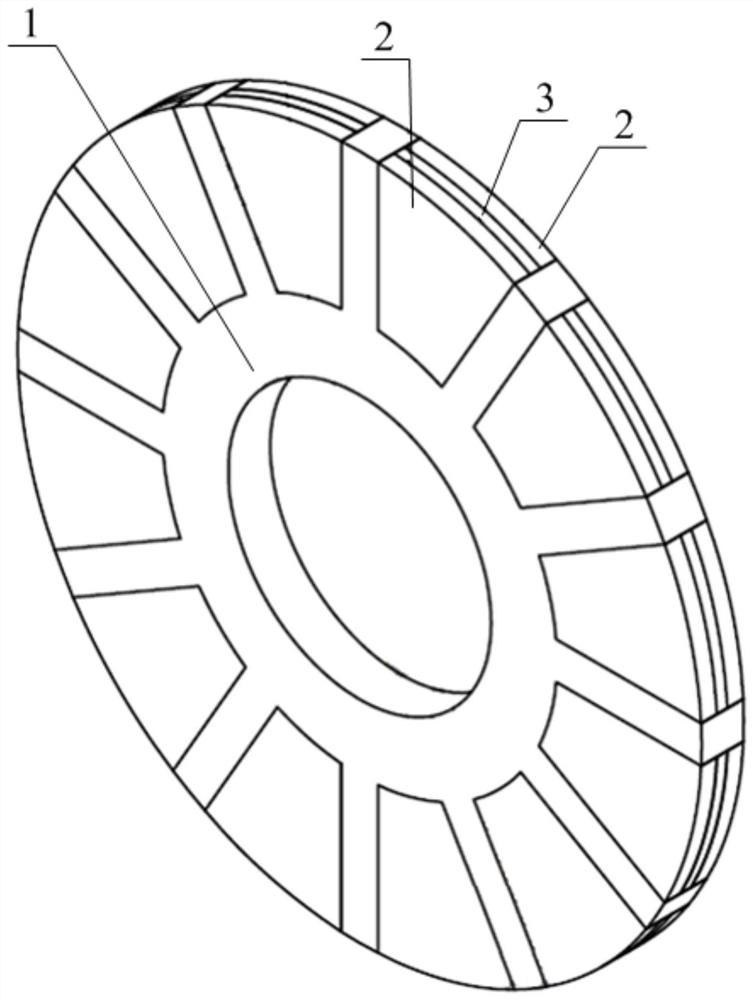

Permanent magnetic synchronous generator rotor for wind power generation

InactiveCN105490417ASimple structureImprove reliabilityMagnetic circuit rotating partsInterference fitPermanent magnet synchronous motor

The invention discloses a permanent magnetic synchronous generator rotor for wind power generation. The permanent magnetic synchronous generator rotor comprises permanent magnetic steel bars, a rotor core and a rotating shaft. The permanent magnetic synchronous generator rotor further comprises first hole slots and air slots. The permanent magnetic steel, the rotor core and the rotating shaft are successively distributed in a clinging manner from outside to inside in one circumferential axis. The rotating shaft is a solid shaft. Hot interference fit is utilized between the rotating shaft and the circumference which engages with the rotor core. Furthermore one side circumference of the rotor core is provided with a plurality of semicircular air slots. The central circumference between the outer diametric plane and the inner diametric plane of the rotor yoke is provided with a plurality of circular first hole slots. The number of the first hole slots is equal with that of the permanent magnetic steel bars. Furthermore the center of each first hole slot is in the central axis of each magnetic steel bar. The permanent magnetic synchronous generator rotor satisfies technological requirements of small weight, high control flexibility, simple structure, high vibration resistance, high efficiency and high reliability in a power generator in a wind power generation field.

Owner:STATE GRID GASU ELECTRIC POWER RES INST +2

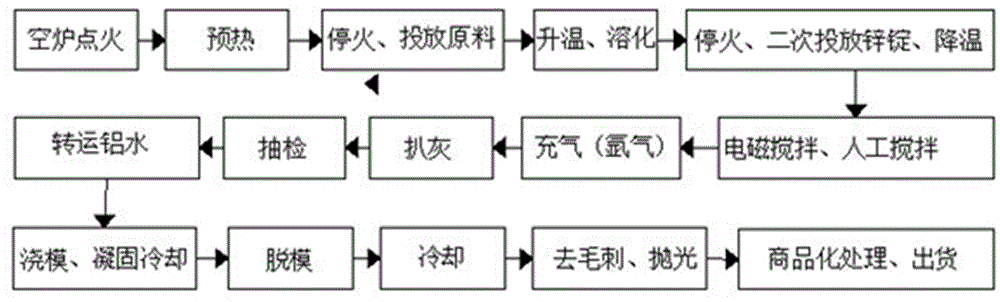

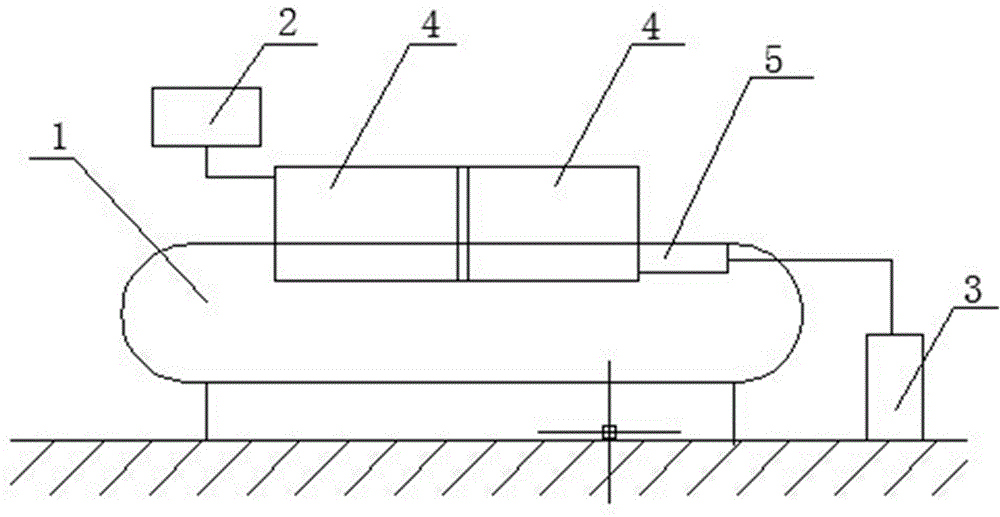

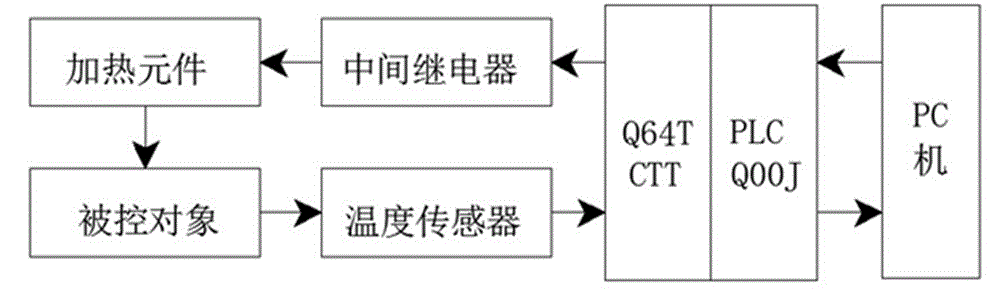

Preparation method of zinc-aluminum-silicon-(cerium, lanthanum) rare earth alloy

The invention discloses a method for preparing a zinc-aluminum-silicon-(cerium, lanthanum) rare earth alloy. The components of the zinc-aluminum-silicon-(cerium, lanthanum) rare earth alloy include: aluminum 15-21 part, 0.1-0.3 part of silicon, 0.3-0.6 part of mixed rare earth of cerium and lanthanum, 0-0.01 part of impurity, and the balance is zinc; the method comprises the following steps: ignition of alloy melting furnace in empty furnace; preheating; cease-fire, feeding raw materials ; heating, melting; ceasefire, secondary zinc ingots, cooling; electromagnetic stirring, manual stirring; argon filling; ash removal; random inspection; transfer of aluminum water; casting, solidification cooling; demoulding; cooling; deburring, polishing; The alloy melting furnace has a closed-loop temperature control system based on PLC-PC, and the casting, solidification and cooling processes are completed in the recovery and utilization of phase change heat energy alloy ingot casting machine. The present invention improves by introducing mixed rare earths of cerium and lanthanum to Substituting aluminum for zinc greatly reduces zinc content, and the preparation method of the invention has high product quality and production efficiency, low energy consumption and low production cost.

Owner:JIANGXI XIN JIAN PRECISION ALLOY

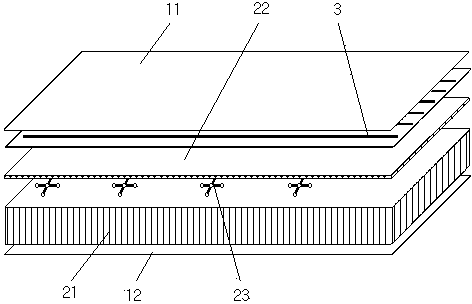

Magnetic latex mattress

InactiveCN103431680AEnsure sleeping comfortImprove circulationStuffed mattressesSpring mattressesMagnet

The invention discloses a magnetic latex mattress, relating to the technical field of daily necessities and solving the technical problems of an existing mattress. The magnetic latex mattress comprises an inner core and a protection sleeve covering the inner core. The magnetic latex mattress is characterized in that the inner core is provided with a plurality of structure layers; the structure layers of the inner core are stacked in sequence from top to bottom and are a wool layer, a stereoscopic magnet frame layer and a latex layer respectively in sequence from top to bottom; the stereoscopic magnet frame layer comprises a plurality of magnet frames; the magnet frames are uniformly arranged along the upper surface of the latex layer at intervals; magnets are fixed on the magnet frames. The mattress provided by the invention is favorable for the health of a human body.

Owner:HEZUN HEALTH TECH SHANGHAI

Magnetization treatment technique for agriculture and forestry production and soil ecological remediation

InactiveCN104030416AReduce usageImprove Nutrient Utilization EfficiencyWater/sewage treatment by magnetic/electric fieldsFresh water organismMagnetization

The invention provides a magnetization treatment technique for agriculture and forestry production and soil ecological remediation. Irrigation water flows through a magnetization water treater with a special structure and magnetic field strength so as to irrigate crops, fruit trees, frost, flowers and vegetables, then the growth is remarkably promoted, and the yield and the quality are improved; the utilization rates of soil nutrient components are remarkably increased, the use amount of fertilizers is reduced, and the economic benefits of planting industry are improved; the soil degradation caused by use of excessive pesticides and chemical fertilizers is effectively remedied, and the desalting process of salinity soil is accelerated; salt-tolerant plants can be irrigated by using hypersalinity underground water, the land utilization rate and the productivity of an area short of fresh water resource are improved, and the ecological remediation progress in a salination area is accelerated.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Isolation switch and contact assembly thereof

ActiveCN106571262AThe effect of shunting is smallGuaranteed magnetic field strengthHigh-tension/heavy-dress switchesAir-break switchesPower flowUltimate tensile strength

The invention relates to an isolation switch and a contact assembly thereof; the contact assembly comprises a main contact and an arc contact, wherein the main contact is provided with an insulation support; the arc contact is arranged on the insulation support; the arc contact is electrically connected with the main contact through a petersen coil winding on the periphery of the insulation support, thus ensuring electric current to pass the arc contact, the coil and the main contact in order, ensuring the magnetic field intensity in the coil, further improving arc extinguishing effect, and minimizing the arc contact diversion effect; in addition, the end portion of the petersen coil can be only provided with the arc contact of a small structure, thus saving cost.

Owner:HENAN PINGGAO ELECTRIC +2

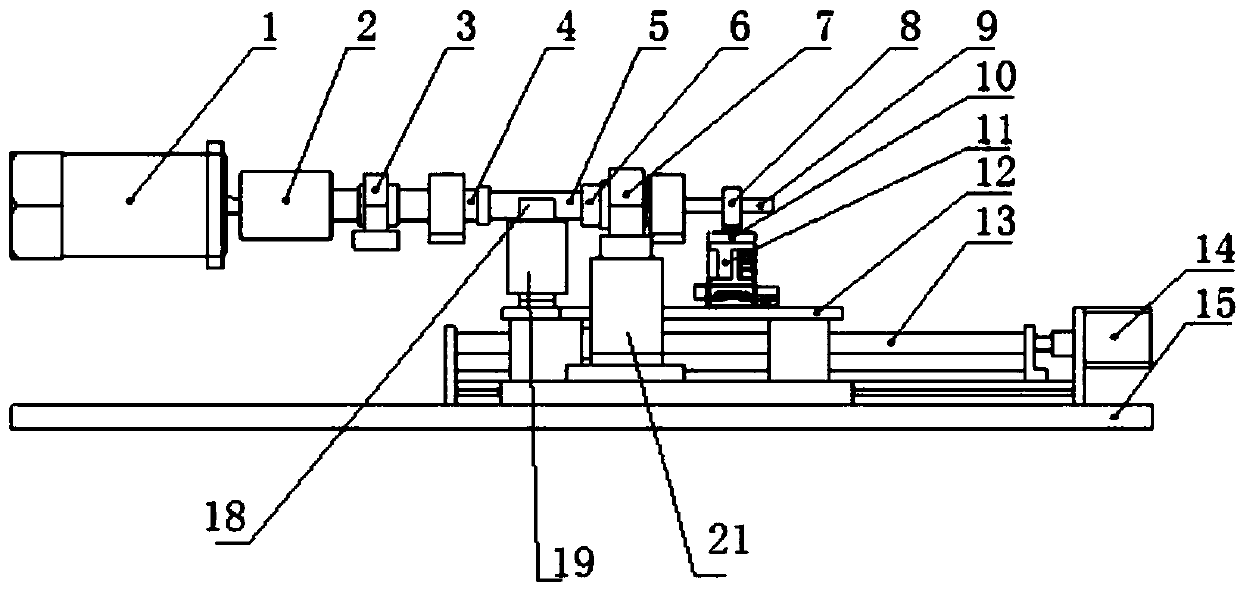

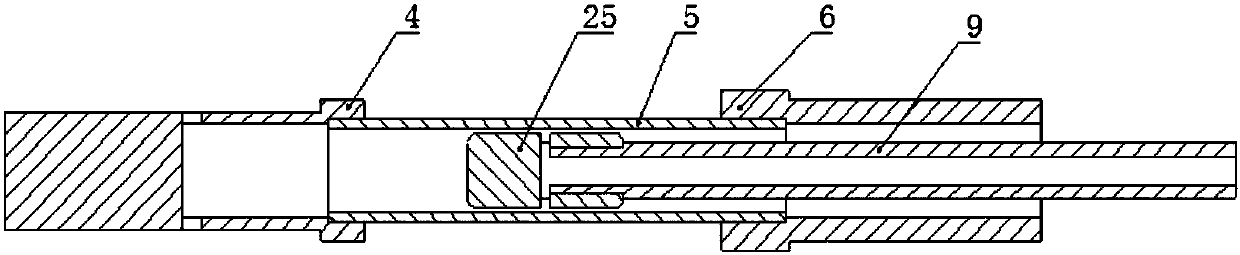

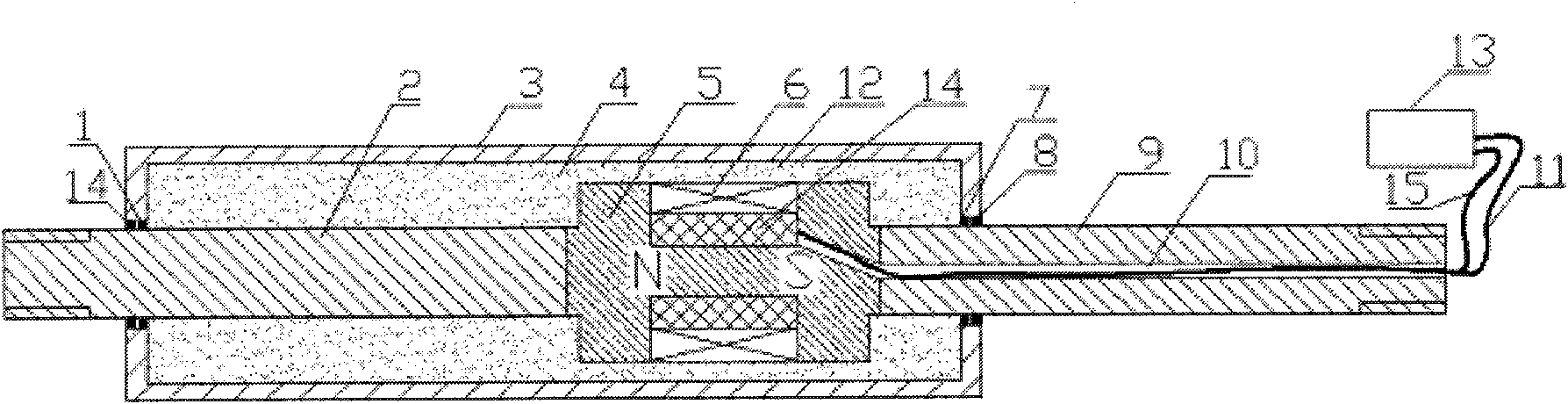

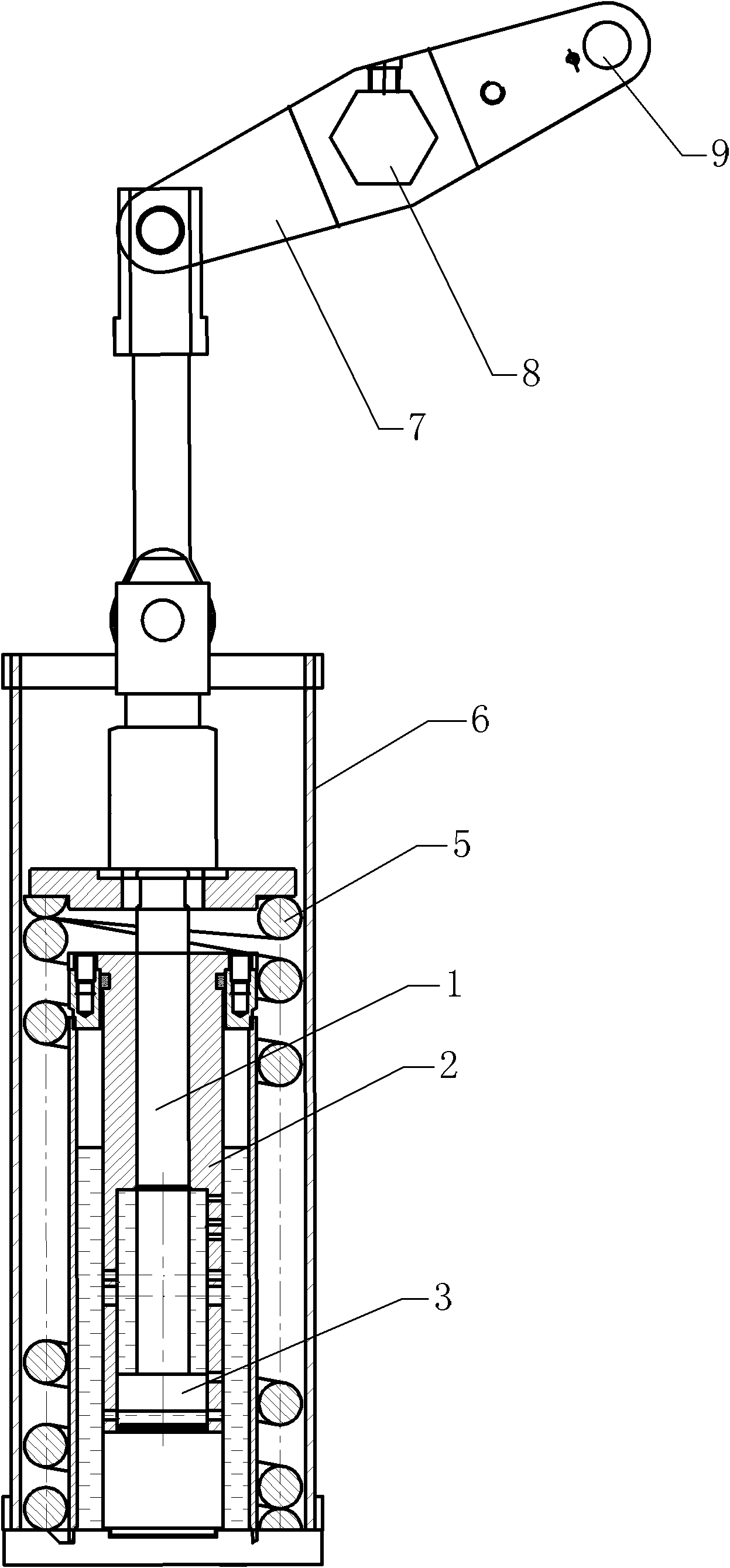

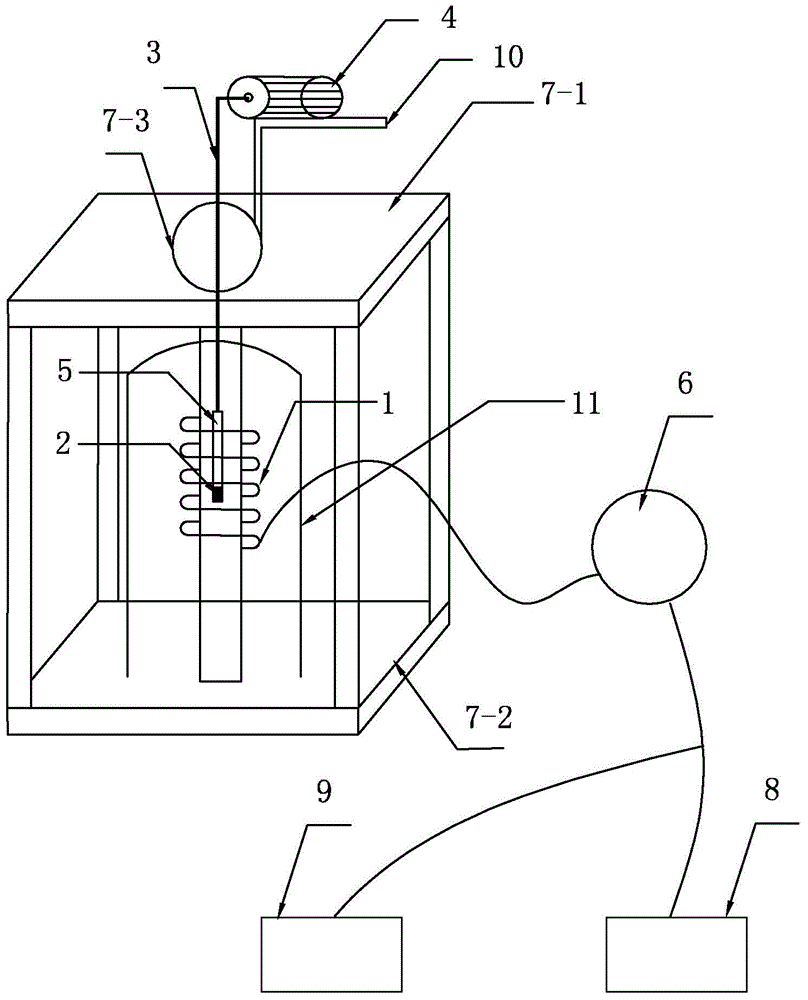

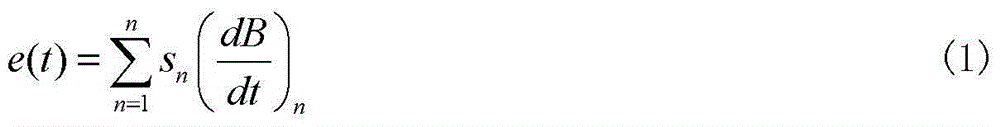

No damage test device of permanent magnet magnetic field intensity

ActiveCN104155618APromote sportsGuaranteed magnetic field strengthMagnitude/direction of magnetic fieldsTemperature controlMagnetic stability

The invention relates to a no damage test device of permanent magnet magnetic field intensity, and relates to the field of the time stability test of the magnetic performance of a permanent magnet. The test device provided by the invention solves the problem that the existing permanent magnet magnetic field intensity test device has poor test result precision, is limited by the volume and the shape of a tested permanent magnet, and cannot ensure the test magnetic field intensity range and the test precision at the same time. The test device comprises an induction coil, the permanent magnet, a telescopic mechanism, a motor, a permanent magnet carrier, a signal detection device and a temperature control box. The induction coil and the permanent magnet are located in the temperature control box. The induction coil is wound into a circular cylinder. The permanent magnet is arranged in the permanent magnet carrier. One end of the telescopic mechanism is connected with one end of the permanent magnet carrier, and the other end of the telescopic mechanism is connected with the drive end of the motor. The permanent magnet is located on the center axis of the induction coil. The signal output end of the induction coil is connected with the signal input end of the signal detection device. The test device provided by the invention is suitable for testing the shape of the permanent magnet on the magnetic stability.

Owner:HARBIN XIANGKE NEW MATERIAL

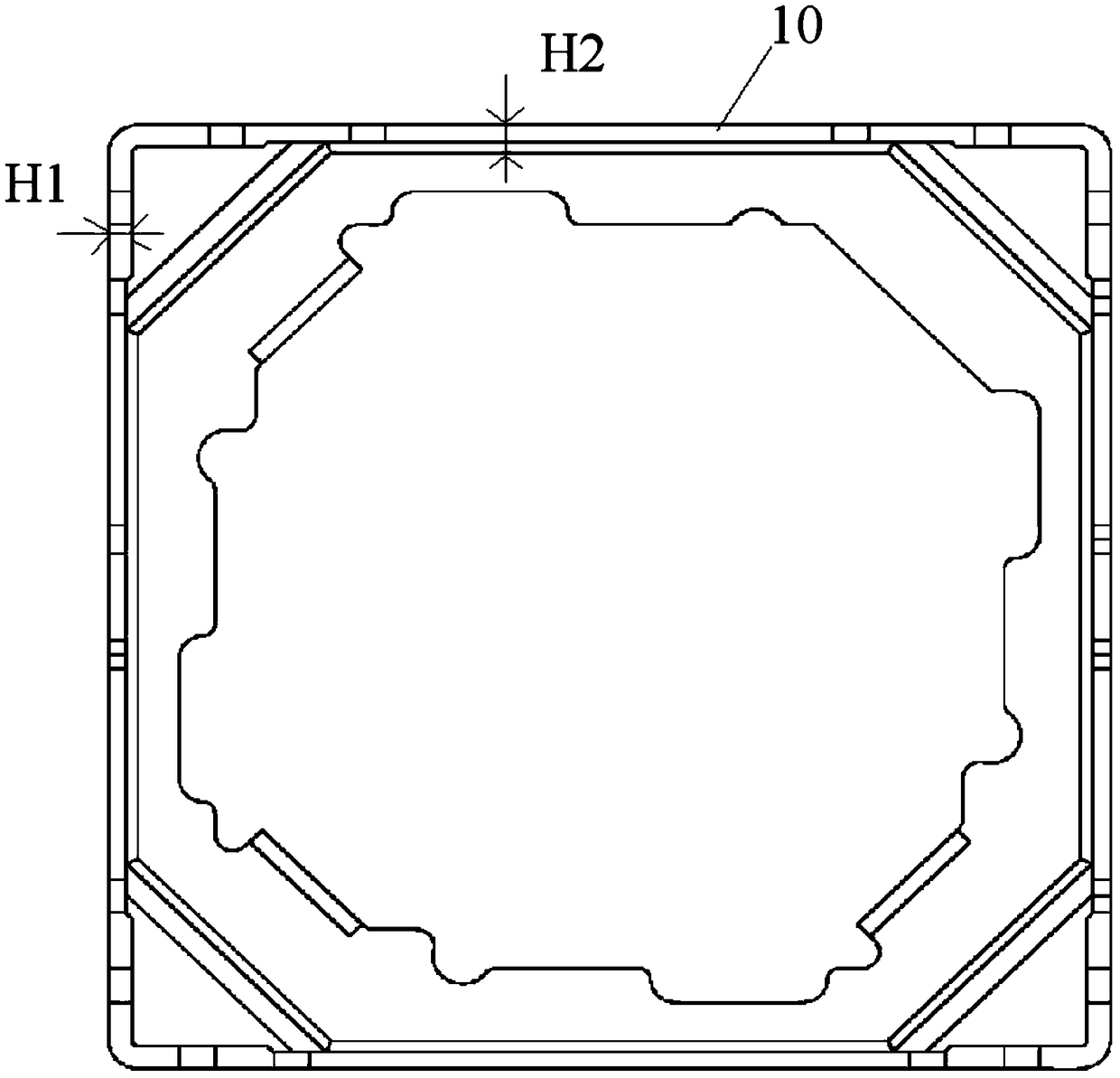

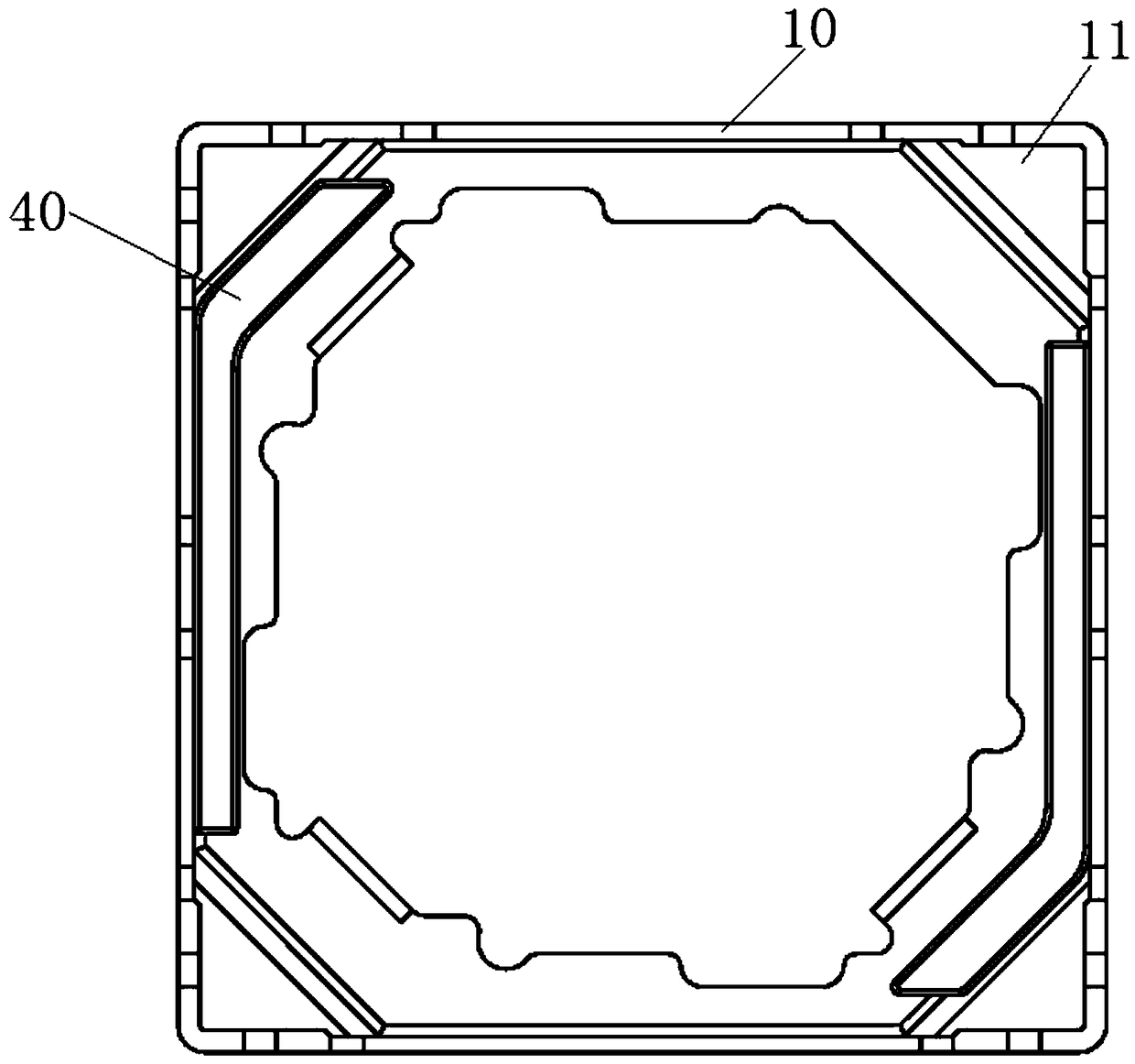

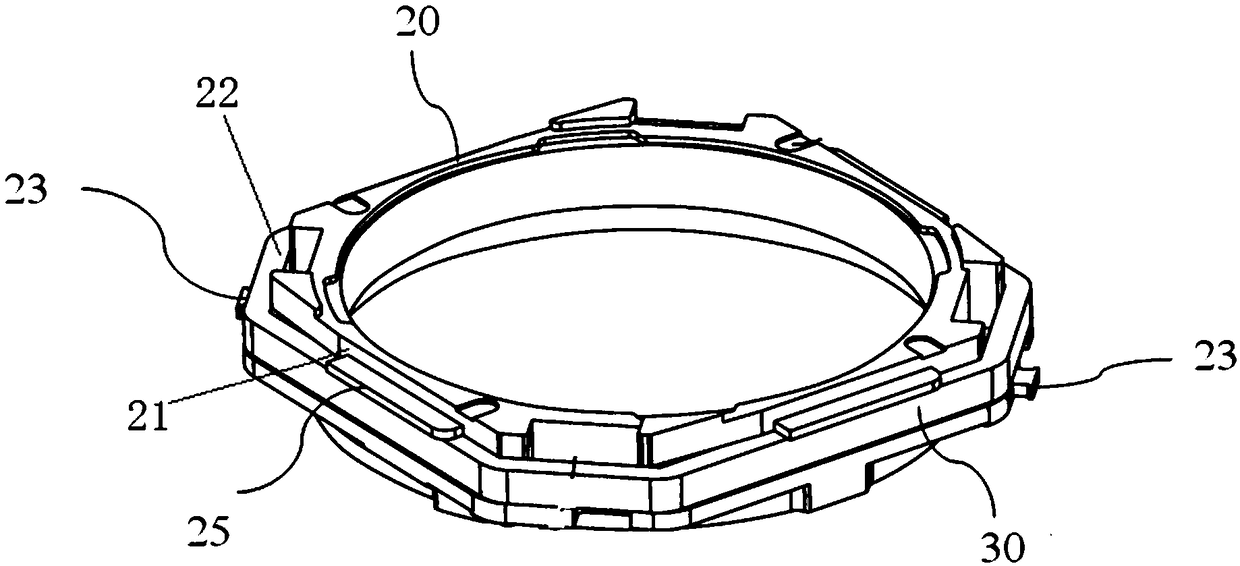

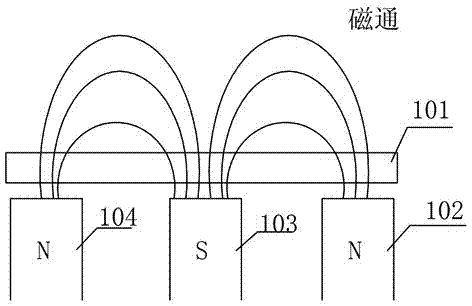

Lens drive motor, camera and mobile terminal device

PendingCN108710189ASmall magnetic permeabilityGood magnetic performanceWindingsProjector focusing arrangementTerminal equipmentComputer terminal

The invention provides a lens drive motor, a camera and a mobile terminal device. The lens drive motor comprises a shell, a lens support, a coil and a magnet component and is characterized in that thecoil winds the lens support and is arranged in the shell, the magnet component is arranged between the shell and the lens support, the part, corresponding to the magnet component, of the shell is made of a first material, the other part of the shell is made of a second material, and the magnetic permeability of the second material is smaller than that of the first material. By the lens drive motor, the problem that a lens drive motor in the prior art is insufficient in driving force is solved.

Owner:SHANGHAI BILLU ELECTRONICS CO LTD

Cathode magnetic control sputtering target device

ActiveCN107151784AGuaranteed magnetic field strengthImprove uniformityVacuum evaporation coatingSputtering coatingMagnetAtomic physics

The invention discloses a cathode magnetic control sputtering target device which comprises a magnetic target material and magnets arranged on the back face of the magnetic target material. The front of the magnetic target material is provided with a rectangular annular groove. The back face of the magnetic target material is provided with a rectangular annular protrusion corresponding to the rectangular annular groove. The magnets comprise a center magnet and outer magnets which are opposite in polarity. The center magnet is arranged in the center of the rectangular annular protrusion. The four outer magnets are arranged on the periphery of the rectangular annular protrusion. The cathode magnetic control sputtering target device has the beneficial effects of being capable of reinforcing magnetic field strength of the surface of the target material, improving uniformity of sputtering of the target material, reducing frequency of replacing the target material, reducing the production cost and the like.

Owner:48TH RES INST OF CHINA ELECTRONICS TECH GROUP CORP

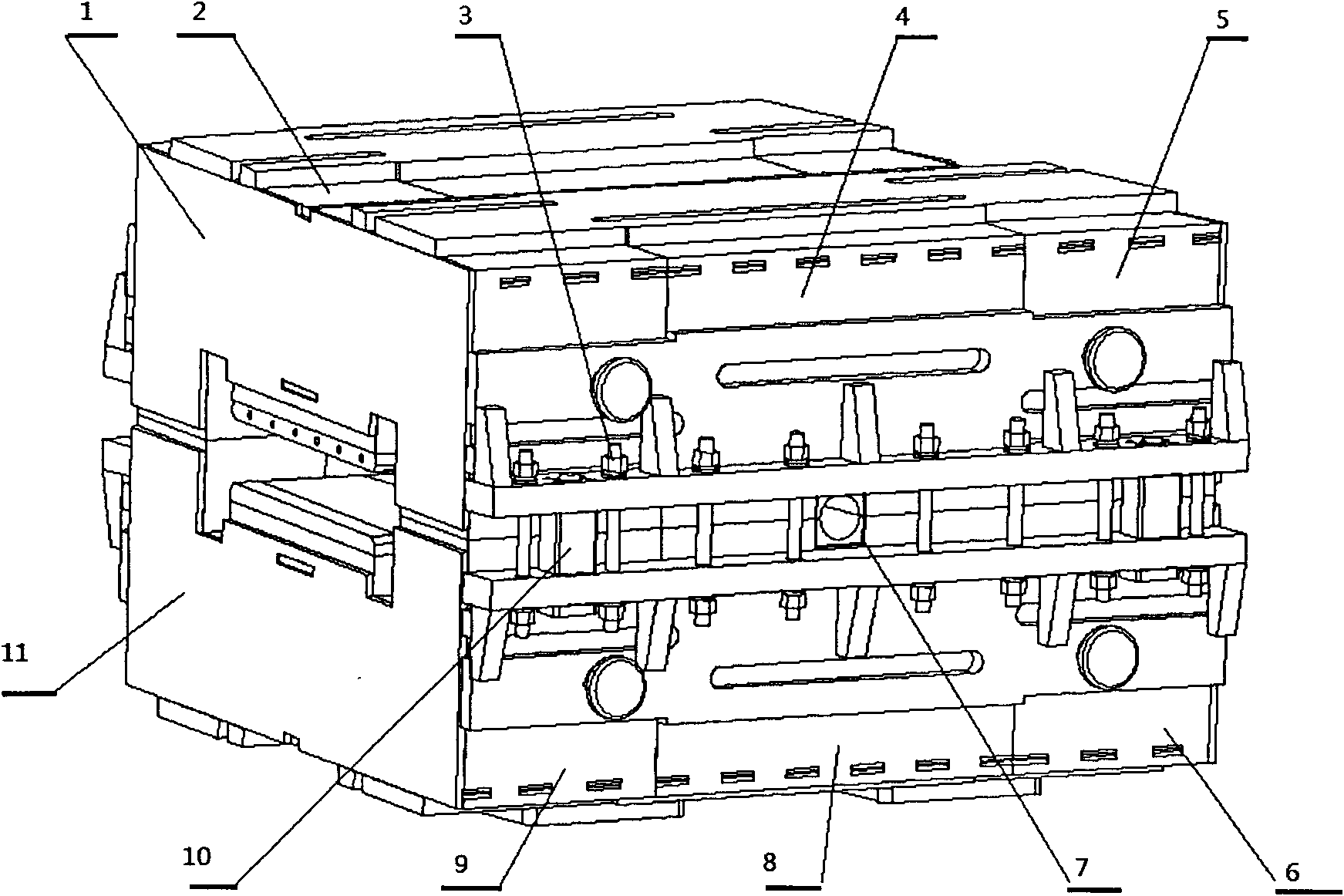

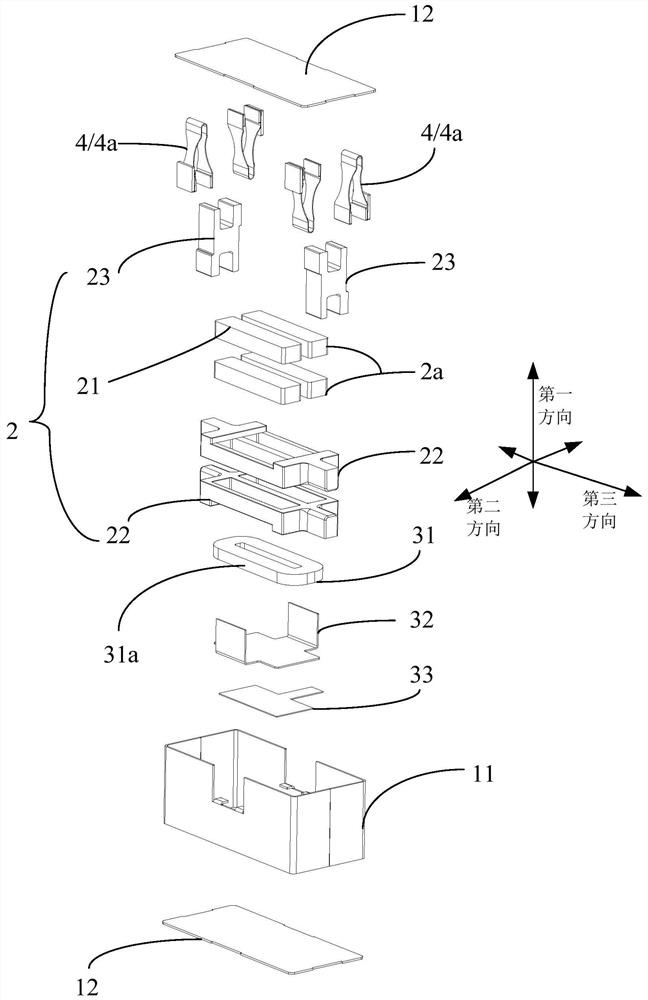

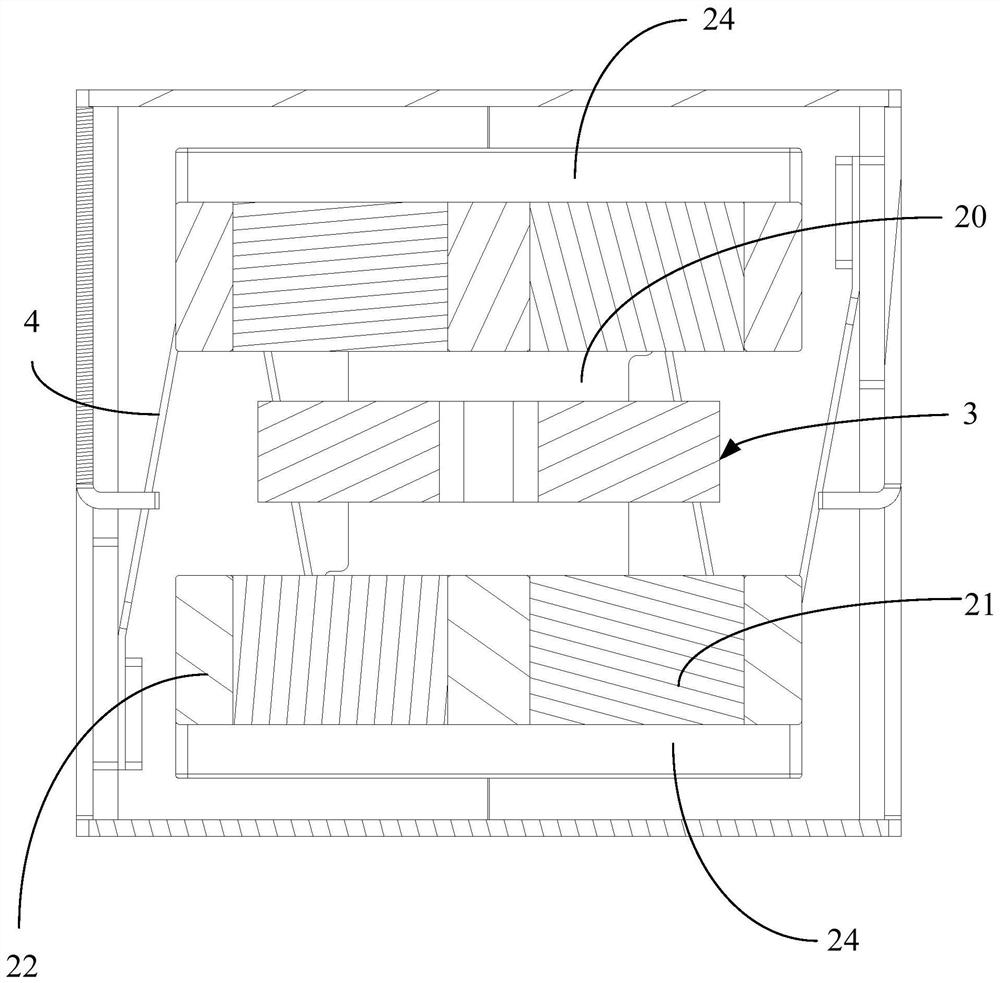

Miniaturized magnetron structure

ActiveCN111739773ASmall sizeStable jobTransit-tube leading-in arrangementsMagnetronsMiniaturizationEngineering

The invention belongs to the field of vacuum electronic devices, and particularly provides a miniaturized magnetron structure. According to the present invention, a neodymium iron boron or samarium cobalt permanent magnet material placed on an external support of a magnetron is adopted to replace an original ferrite magnetic ring so as to ensure the magnetic field intensity in an interaction space. The ferrite magnetic ring is not needed in the magnetron structure, and a neodymium iron boron or samarium cobalt permanent magnet is placed on the external support of the magnetron, so that the height and the width of the magnetron can be greatly reduced, and the magnetron structure is cuboid-shaped and can be matched with the shapes and the structures of the cooling fins and a filtering assembly synchronously, especially the filtering assembly. According to the invention, the output of an original same-direction choking coil from one end is improved into the output of a heterodromous choking coil from the left end and the right end, so that the miniaturized magnetron structure can stably work while being matched with a magnetic circuit structure. In conclusion, the invention provides the novel magnetron structure, and the miniaturization design of the magnetron structure is further realized.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Device for magnetic leakage flaw detection of surface of steel pipe

InactiveCN105116047AGuaranteed magnetic field strengthComprehensive detectionMaterial magnetic variablesSteel tubeFixed frame

The invention discloses a device for magnetic leakage flaw detection of the surface of a steel pipe. The device comprises a base platform, a detection device, an object carrying rod and a cleaning device, the detection device is mounted on the upper portion of the base platform, the object carrying rod is mounted in the middle of the base platform, the cleaning device is mounted at the bottom of the base platform, a permanent magnet is arranged on the detection device, a magnet A and a magnet B are mounted at the left end and the right end of the permanent magnet, a probe component is mounted between the magnet A and the magnet B and fixed in the middle of the permanent magnet, a servo motor is arranged on the left side of the cleaning device, a hairbrush rod is mounted on the servo motor, a fixing frame is mounted below the hairbrush rod, the object carrying rod is movably connected with the servo motor through a belt, and the detection device and the servo motor are in electrical connection. The device can clean a detected object to guarantee penetrating power of a magnetic field, and can rotate the detected object to guarantee the same to be detected comprehensively, and detection accuracy is improved.

Owner:江苏建研建设工程质量安全鉴定有限公司

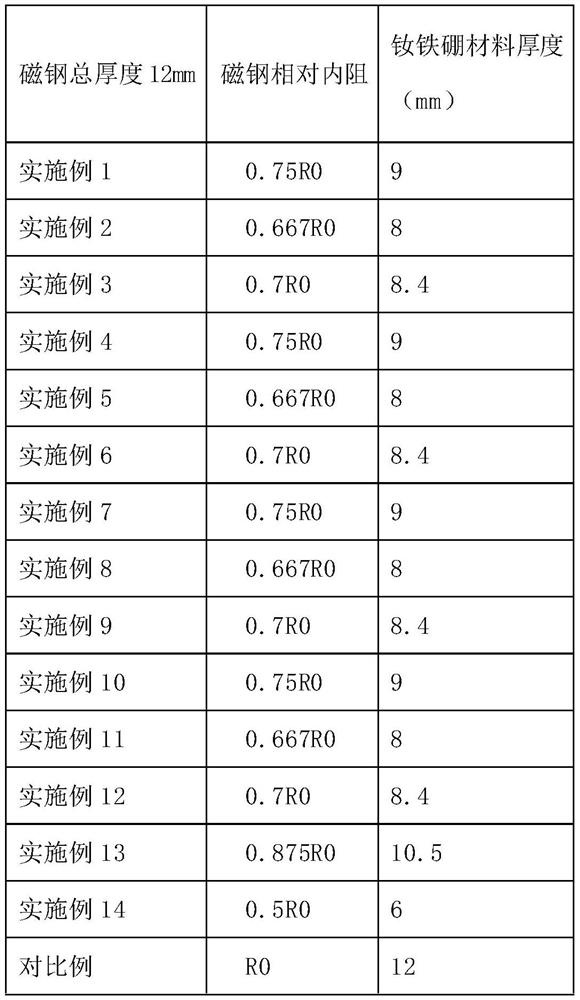

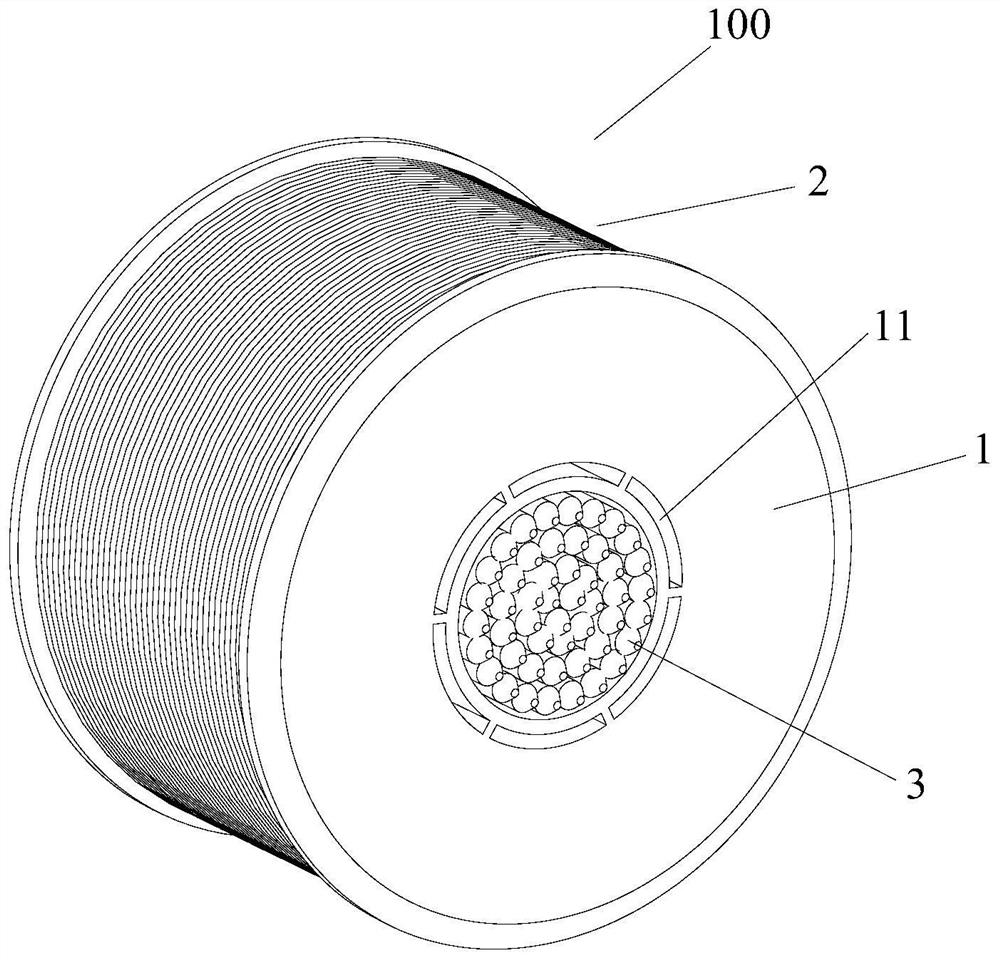

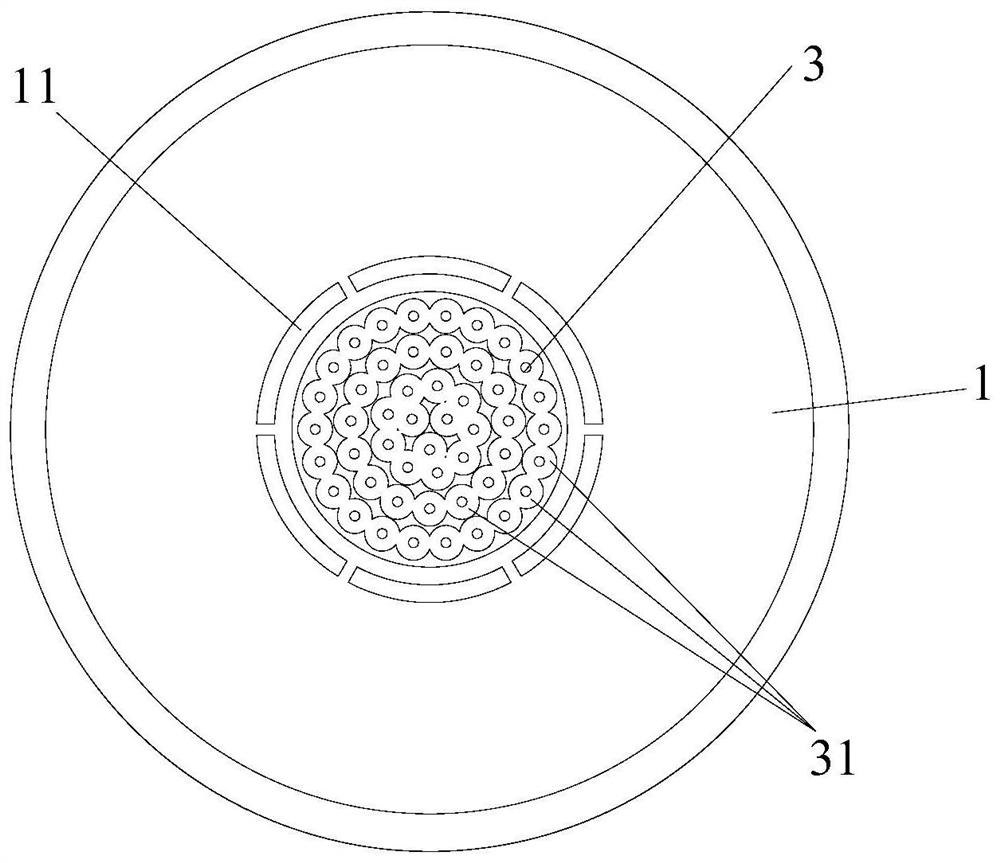

Magnetic steel, motor rotor and axial magnetic field motor

PendingCN112271833AGuaranteed magnetic field strengthLower internal reluctanceMagnetic circuit rotating partsPermanent magnetsElectric machineMaterials science

The invention discloses magnetic steel, which comprises a magnetic conductive layer group and magnet layers clamped at two sides of the magnetic conductive layer group, and the relative permeability of the magnetic conductive layer group is greater than that of the magnet layers. Compared with the prior art, according to the scheme, the thickness of the magnet layer is reduced, and the magnetic conductive layer group with relatively high magnetic conductivity is added, so that the internal magnetic resistance of the whole magnetic steel can be greatly reduced on the premise of ensuring the original magnetic field intensity of the magnetic steel, the relatively high working efficiency of the motor is kept, the scheme can also effectively reduce the use amount of magnet materials, can improve the utilization rate of magnetic steel materials, and further can reduce the manufacturing cost of the motor. The invention further discloses a motor rotor comprising the magnetic steel and an axialmagnetic field motor.

Owner:ZHEJIANG PANGOOD POWER TECH CO LTD

Heat dissipation type electromagnetic coil device and electromagnetic physiotherapy equipment thereof

PendingCN113077958AIncrease contact areaImprove cooling efficiencyElectromagnets without armaturesElectrotherapyEngineeringPhysical therapy

The invention discloses a heat dissipation type electromagnetic coil device and electromagnetic physiotherapy equipment thereof. The electromagnetic coil device comprises a hollow framework, a coil is wound on a supporting wall on the side face of the framework, a magnetic core composed of a plurality of magnetic needles arranged in a bundle shape is arranged in the hollow portion of the framework, and a plurality of heat dissipation holes are formed in the supporting wall of the framework. Cooling air passes through the heat dissipation holes. The electromagnetic coil device aims to solve the problems that an existing electromagnetic coil device is poor in heat dissipation, too much heat is transferred to a magnetic core through a coil, the temperature of the magnetic core is increased, and the magnetic field intensity is insufficient.

Owner:佛山玉玄宫科技股份有限公司

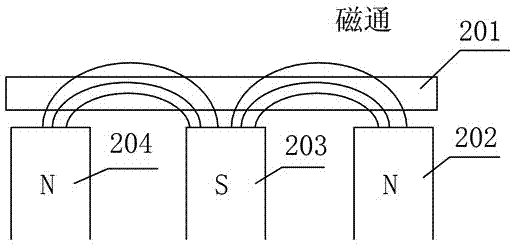

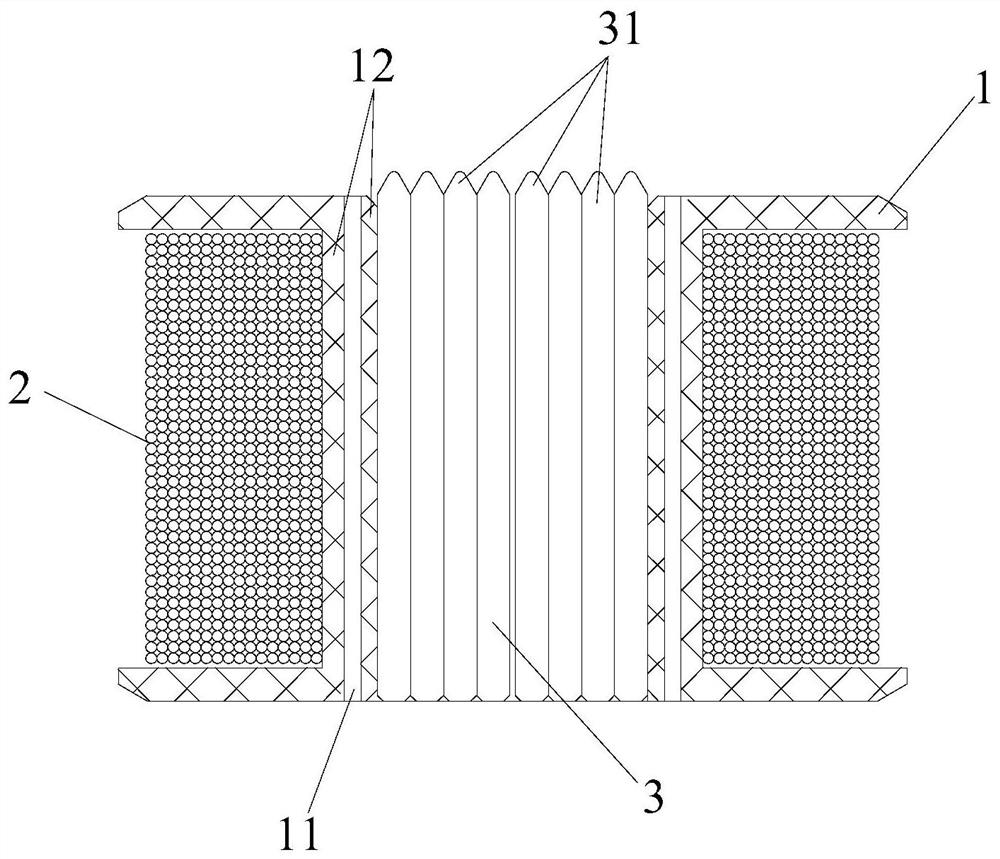

Magnetic system of magnetic separator

InactiveCN104588204AGuaranteed magnetic field strengthIncrease the magnetic field strengthMagnetic separationMagnetic separatorMagnet

The invention provides a magnetic system of a magnetic separator, and the magnetic system is simple in structure and good in property of separating magnetic substances. The magnetic system of the magnetic separator comprises a magnet yoke plate and magnets, the magnet yoke plate is provided with magnet lattices, the magnets are fixed in the magnet lattices through screws, the magnetic system is characterized in that the magnet lattice comprises a front magnet lattice and a rear magnet lattice, a middle partition is formed between the front magnet lattice and the rear magnet lattice, the S pole of the magnet in the front magnet lattice is upward fixed in the magnet lattice, and the N pole of the magnet in the rear magnet lattice is upward fixed in the magnet lattice, and the magnet in the middle partition is horizontally arranged on the magnet yoke plate with the N pole facing the front magnet lattice and the S pole facing the rear magnet lattice.

Owner:WUXI KANGHUI MACHINE BUILDING

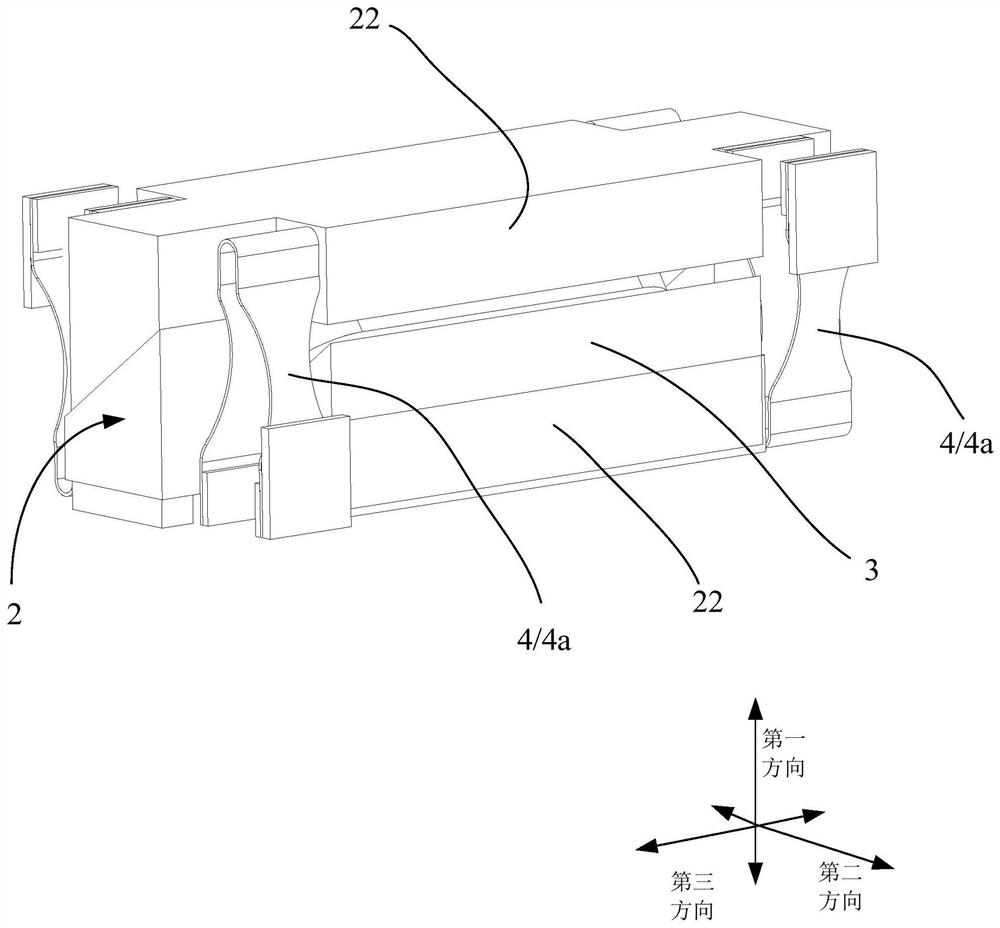

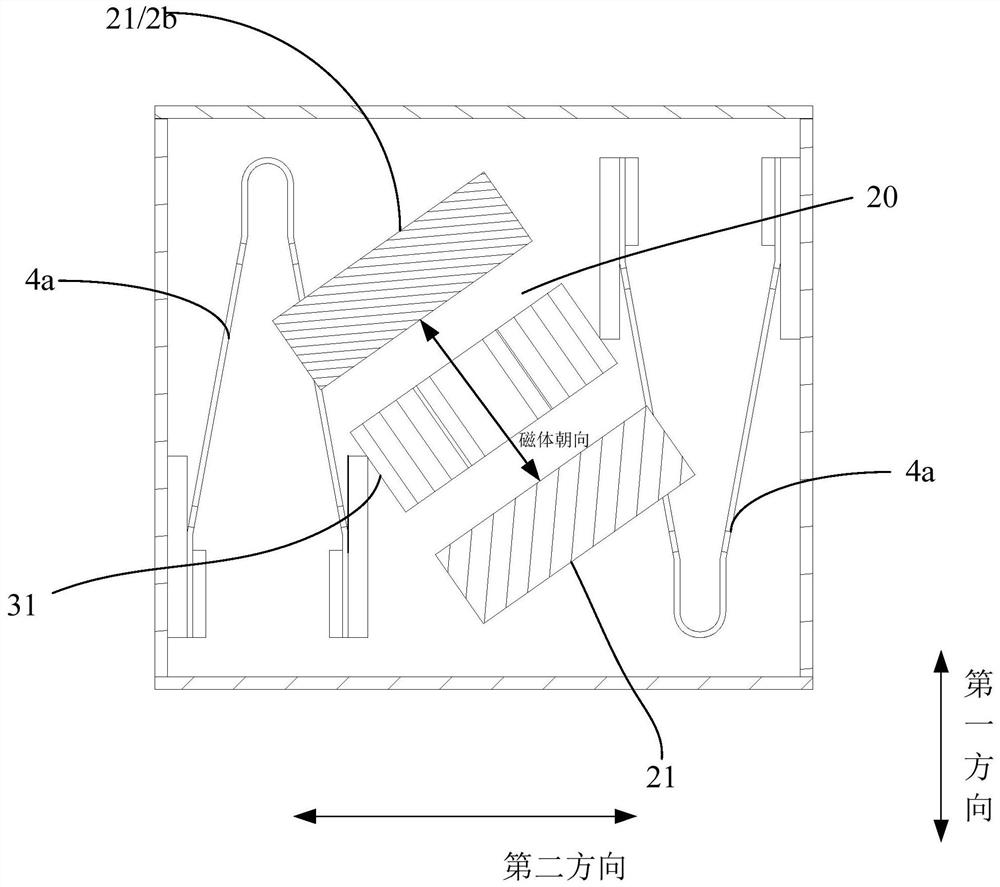

Vibration device and electronic equipment

PendingCN111641318AEnsure reasonable distributionGuaranteed magnetic field strengthDynamo-electric machinesEngineeringAlternate current

The invention discloses a vibration device and electronic equipment. The vibration device comprises a shell, a magnetic circuit assembly, a coil assembly and an elastic supporting piece, wherein at least part of the magnet of the magnetic circuit assembly or the coil assembly is arranged to be a vibration piece, the elastic supporting piece is connected with the shell and the vibration piece, themagnetizing direction of the magnet of the magnetic circuit assembly is inclined relative to a first direction so as to make each of the first direction and a second direction have a component, the inclination angle between the magnetizing direction and the first direction is alpha; alpha is greater than or equal to 5 degrees and less than or equal to 85 degrees, a coil is provided with a conducting wire section extending along a third direction, at least the conducting wire section of the coil is arranged in the magnetic gap, and the third direction is orthogonal to the first direction and the second direction, so that when the coil is electrified with alternating current, a vibrator vibrates in the first direction and the second direction. According to the invention, the problem that inthe prior art, when vibration in two directions is needed, a plurality of vibration devices are correspondingly needed is solved.

Owner:GOERTEK INC

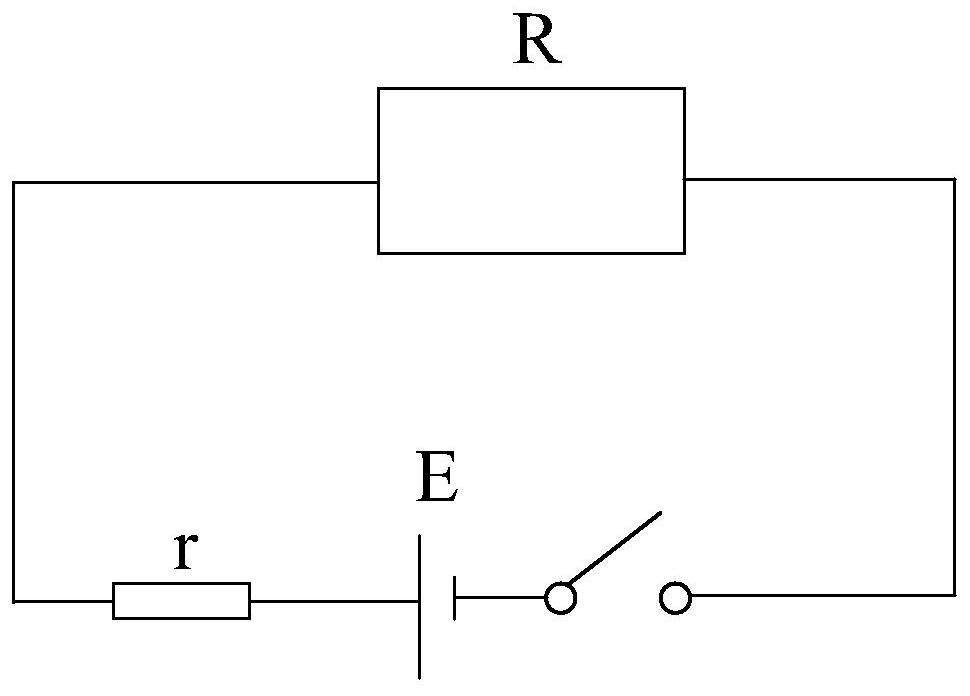

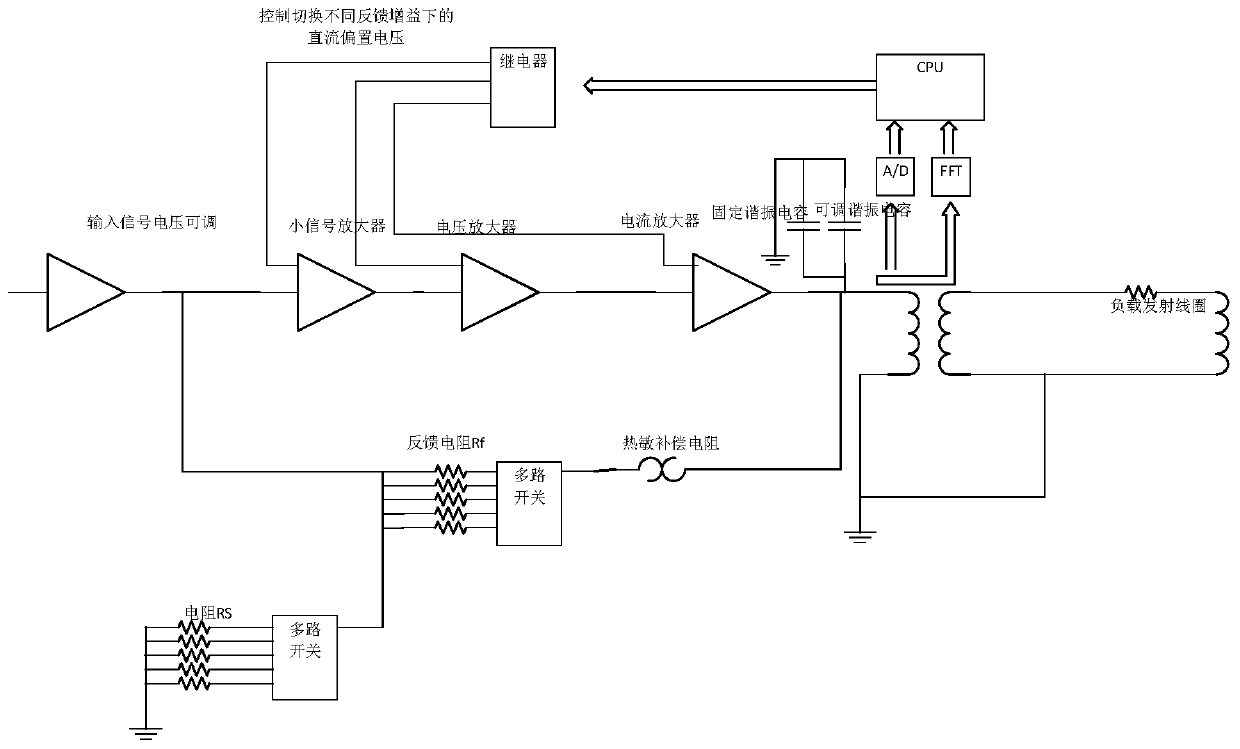

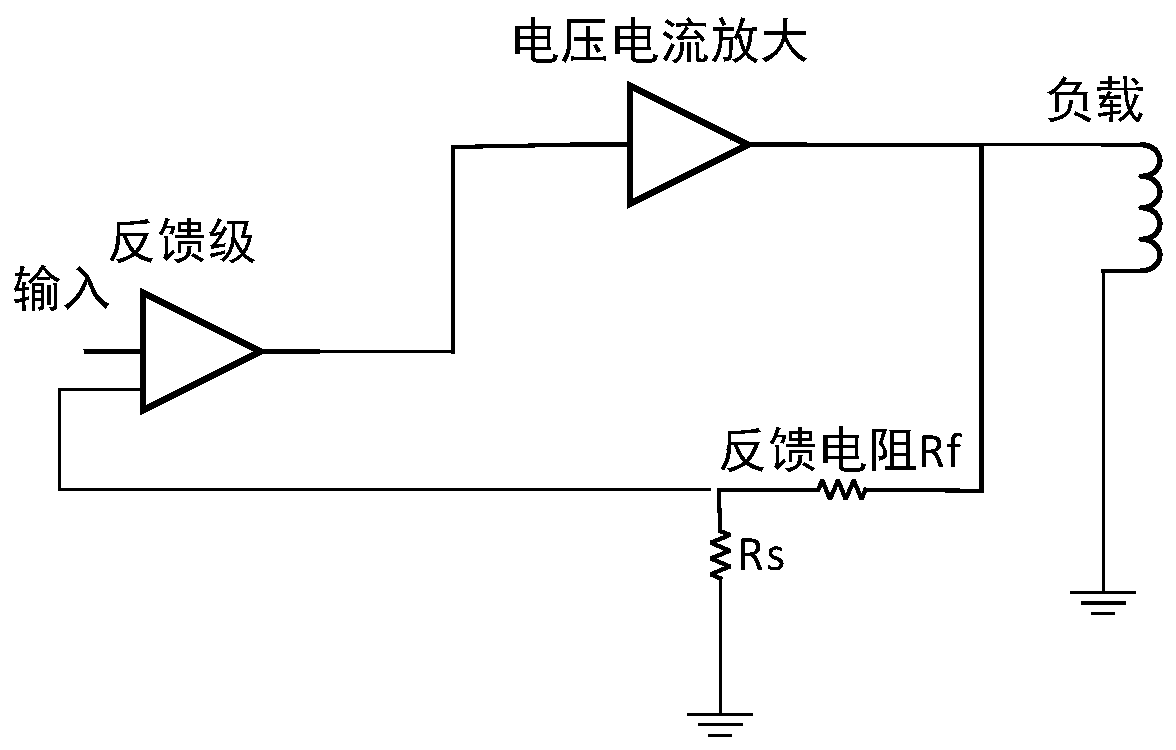

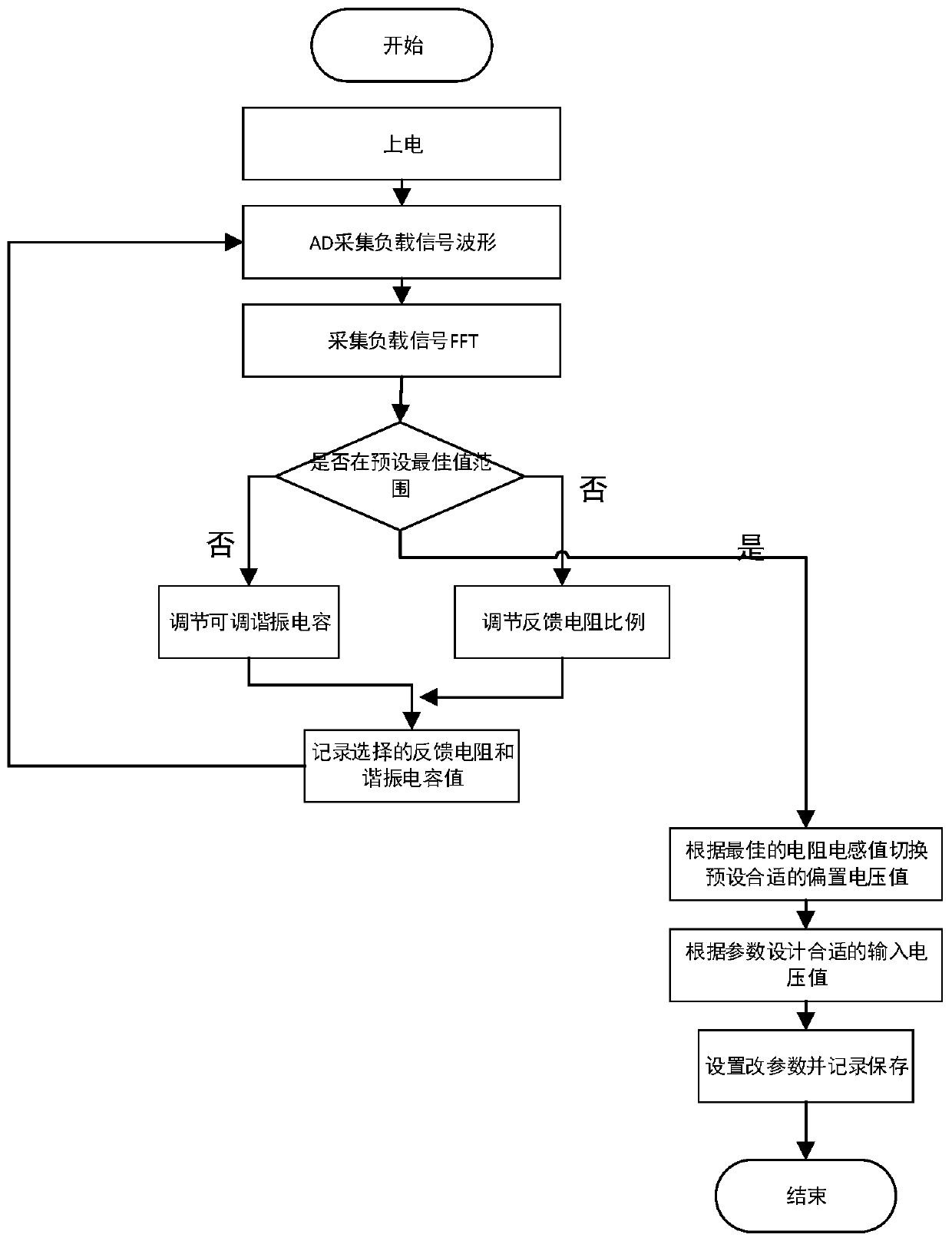

Transmitting coil drive circuit and method

ActiveCN110703339AGuaranteed magnetic field strengthGuaranteed detection accuracyElectric/magnetic detectionAcoustic wave reradiationHemt circuitsEngineering

The invention relates to a transmitting coil drive circuit and method. The drive circuit includes a collection control debugging module, an amplification module, and a feedback circuit module. One endof the feedback module is connected to a transmitting module, and the other end is connected to an input end of the amplification module. The input end of the amplification module is also connected to the collection control debugging module, and an output end is connected to the transmitting module. When a load transmitting coil changes, the collection control debugging module controls a coil resonance voltage by adjusting the feedback module, to ensure magnetic field intensity and detection accuracy. Compared with the prior art, the invention has the advantages such as being capable to compensate to a certain extent for product differences caused by different coil crafts.

Owner:TECHIK INSTR SHANGHAI

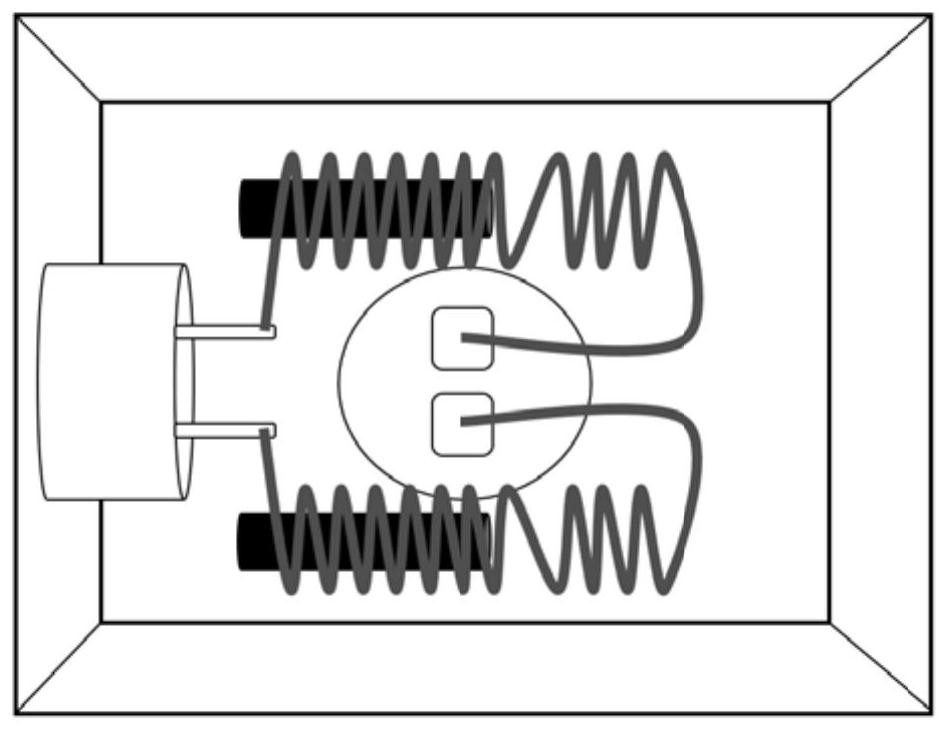

Magnetic stirring apparatus

ActiveCN104888650AAvoid significant declineGuaranteed stirring effectMixersEngineeringMagnetic tension force

The present invention relates to a magnetic stirring apparatus, which comprises: a stirring kettle with a sealed stirring chamber; a stirring assembly, wherein the stirring assembly comprises a stirring shaft extending to the stirring chamber from the outer of the stirring kettle, a stirring member arranged on the stirring shaft, and a power source driving the stirring shaft through a magnetic transmission assembly; and a scattering assembly adjacent to the magnetic assembly and used for heat elimination on the magnetic assembly. According to the magnetic stirring apparatus of the present invention, the influence of the temperature on the magnetic field of the magnetic stirring apparatus can be effectively reduced so as to avoid the significant stirring effect reducing.

Owner:CHINA PETROLEUM & CHEM CORP +1

Vibration device and electronic equipment

PendingCN111641319AEnsure reasonable distributionGuaranteed magnetic field strengthDynamo-electric machinesMagnetic tension forceEngineering

The invention discloses a vibration device and electronic equipment. The vibration device comprises a shell, a magnetic circuit assembly, a coil assembly and an elastic supporting piece, wherein at least part of the magnet of the magnetic circuit assembly or the coil assembly is arranged to be a vibration piece, the elastic supporting piece is connected with the shell and the vibration piece, themagnet of the magnetic circuit assembly is inclined relative to a first direction so as to form an inclined included angle between the direction of the magnetic field formed in the magnetic gap and the first direction to make each of the first direction and a second direction have a component, a coil is provided with a conducting wire section extending along a third direction, at least part of theconducting wire section is arranged in the magnetic gap so as to vibrate a vibrator in the first direction and the second direction when the coil is electrified with alternating current to achieve vibration in the two directions, and the inclination angle alpha between the magnet and the first direction is larger than 0 degree and smaller than or equal to 85 degrees, so that reasonable distribution of the magnetic field intensity, namely the corresponding magnetic force, in the first direction and the second direction is guaranteed.

Owner:GOERTEK INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com