No damage test device of permanent magnet magnetic field intensity

A technology of magnetic field strength and testing device, applied in the direction of the size/direction of the magnetic field, which can solve the problems such as the inability to guarantee the range of the tested magnetic field strength and the test accuracy, poor test result accuracy, limited volume and shape of the tested permanent magnet, etc. , to achieve the effect of convenient magnetic field strength, convenient operation and convenient movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

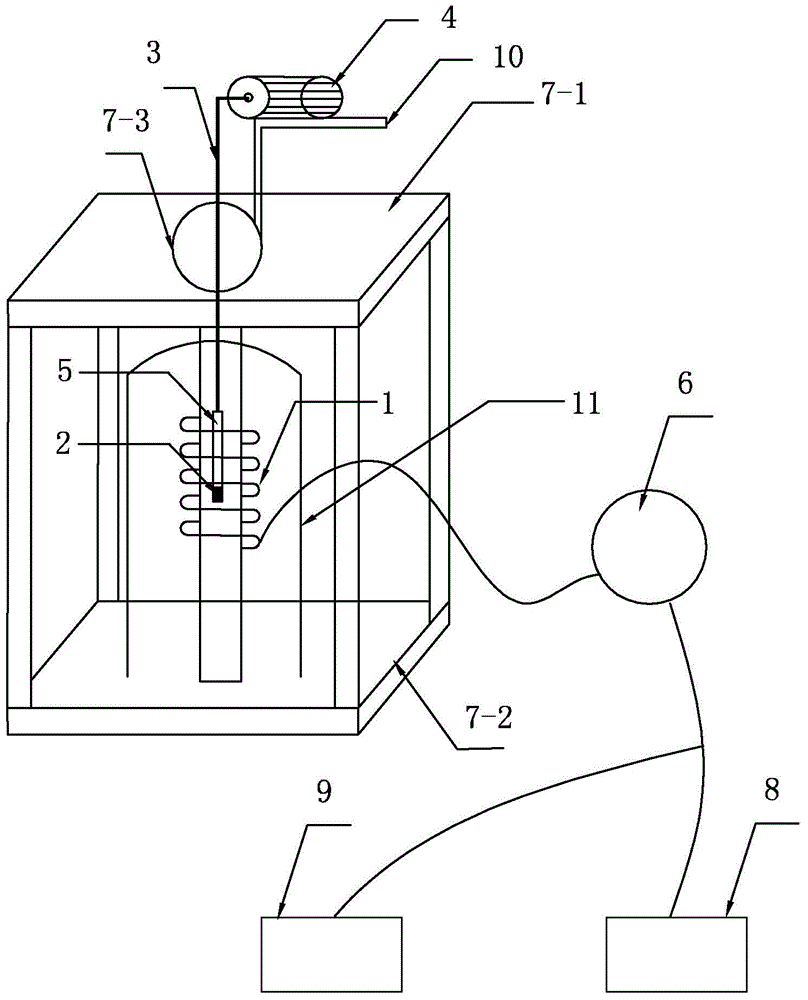

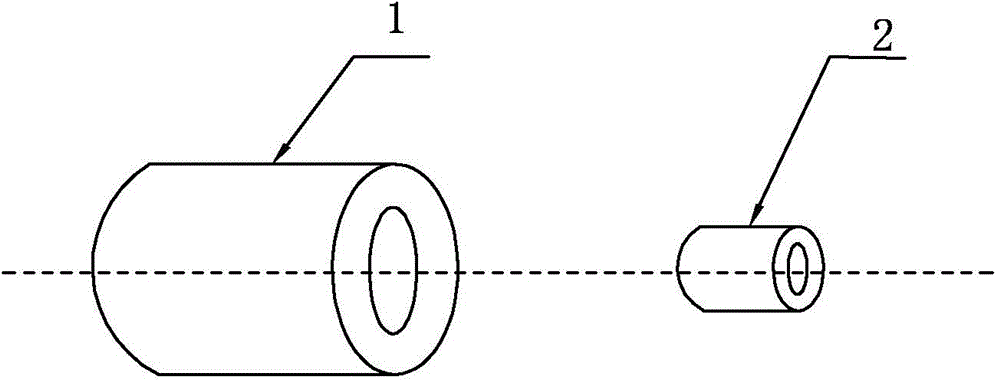

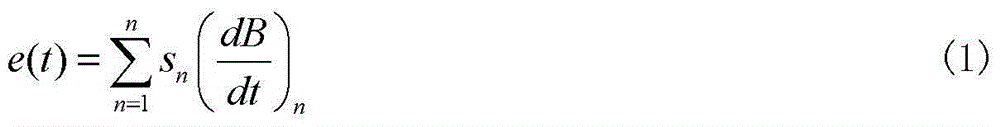

[0012] Specific implementation mode 1. Refer to figure 1 and figure 2 Specifically illustrate this embodiment, the non-destructive testing device of permanent magnet magnetic field strength described in this embodiment, permanent magnet 2 is measured object, and it comprises induction coil 1, telescopic mechanism 3, motor 4, permanent magnet carrier 5, signal detection Device 6 and temperature control box 11;

[0013] The induction coil 1 and the permanent magnet 2 are located in the temperature control box 11; the induction coil 1 is wound into an annular cylinder; the permanent magnet 2 is placed in the permanent magnet carrier 5, and one end of the telescopic mechanism 3 is connected to one end of the permanent magnet carrier 5, and the telescopic mechanism The other end of 3 is connected to the driving end of the motor 4; the permanent magnet 2 is located on the central axis of the induction coil 1; the signal output end of the induction coil 1 is the signal input end of...

specific Embodiment approach 2

[0017] Embodiment 2. This embodiment is a further description of the permanent magnet magnetic field strength non-destructive testing device described in Embodiment 1. In this embodiment, the signal detection device 6 is a sensitive ammeter or a sensitive voltmeter.

[0018] In this embodiment, the use of the sensitive ammeter and the sensitive voltmeter is used to measure the magnitude of the induced current of the induction coil 1, and the sensitive ammeter and the sensitive voltmeter themselves have relatively high precision, so the magnitude precision of the measured induced current is also relatively high , to further ensure the test accuracy of the device.

specific Embodiment approach 3

[0019] Embodiment 3. This embodiment is a further description of the non-destructive testing device for the magnetic field strength of the permanent magnet described in Embodiment 1. In this embodiment, it also includes a bracket 7 and a motor bracket 10;

[0020] The bracket 7 includes an upper baffle 7-1 and a lower baffle 7-2, the upper baffle 7-1 is fixedly connected with the lower baffle 7-2, and the upper baffle 7-1 has a circular hole 7-3;

[0021] The motor 3 is fixed on the motor bracket 10, and the motor bracket 10 is fixed on the upper surface of the upper partition 5-1; the induction coil 1 is fixed on the upper partition 7-1 and the lower partition 7-1. between 2;

[0022] The permanent magnet carrier 5 moves up and down through the circular hole 7-3.

[0023] The bracket and the motor bracket described in this embodiment are used to better complete the test work on the magnetic field strength of the permanent magnet. The use of the bracket ensures the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com