Magnetic steel, motor rotor and axial magnetic field motor

A technology of motor rotor and magnetic steel, applied in the direction of magnetic circuit rotating parts, circuits, magnets, etc., can solve problems such as large heat generation and affecting the working efficiency of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

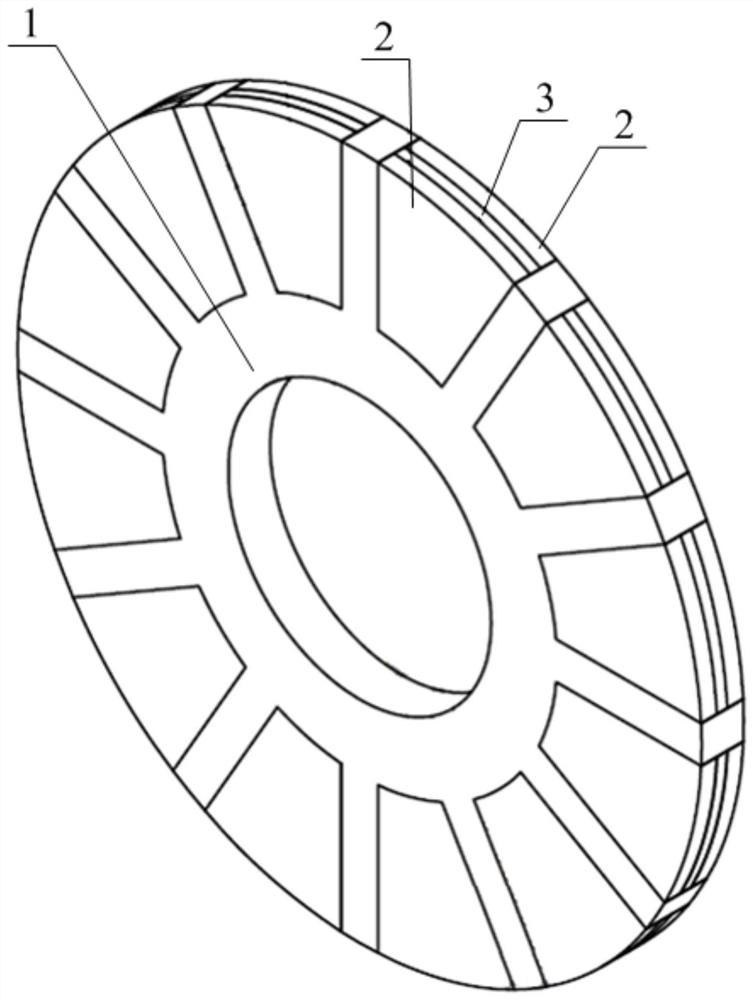

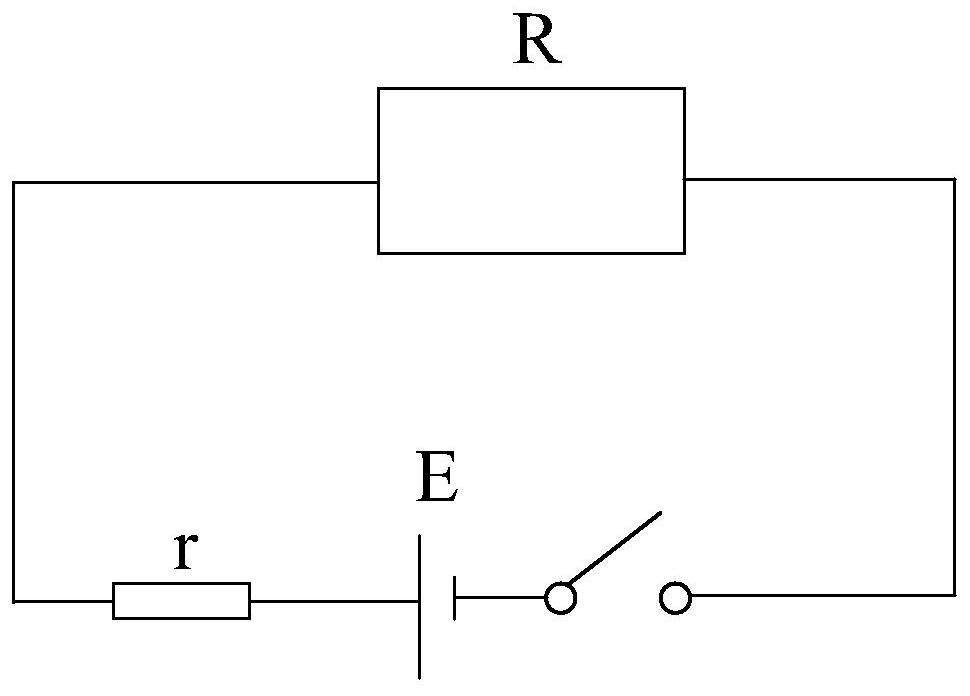

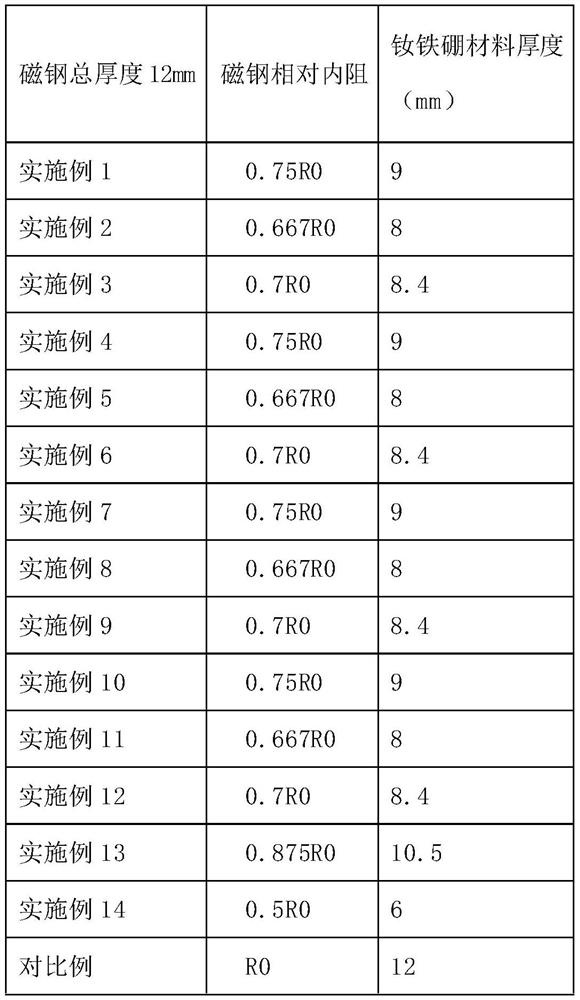

[0038] In Embodiment 1, the magnetic steel includes a three-layer structure, that is, the magnetic steel includes two magnetic layers 2 and a magnetic permeable layer group 3 sandwiched between the two magnetic layers 2, such as figure 1shown. Specifically, the material of the magnet layer 2 is NdFeB, and the magnetically permeable layer group 3 (that is, the magnetically permeable material layer) is specifically a silicon steel sheet. For the boron layer, the magnetic permeability of NdFeB is much smaller than that of the magnetic material layer. The relative magnetic permeability of silicon steel sheet is 7000-10000, and the relative magnetic permeability of NdFeB is 1. Among them, the relative magnetic permeability refers to the ratio of the magnetic permeability of a certain substance to the vacuum magnetic permeability, and the vacuum magnetic permeability is 4×3.14×10^(-7).

[0039] The thickness of the magnetic permeable layer group 3 in this scheme is 1 / 4 of the tota...

Embodiment 2

[0041] In this embodiment, the magnetic steel is still designed as a three-layer structure, including two layers of NdFeB materials and a layer of magnetically permeable material in the middle, wherein the magnetically permeable material is a silicon steel sheet, and the thickness of the rotor disk (ie, the thickness of the magnetic steel) is 12mm , the thickness of the front and rear two NdFeB materials is the same, the difference between embodiment 2 and embodiment 1 is: the thickness of each layer of NdFeB material is 4mm, the thickness of the magnetic material layer is 4mm, and the thickness of the magnetic material layer is 4mm. 1 / 3 of the total thickness, at this time, the relative internal resistance of the magnetic steel is 0.667R0. The simulation test data shows that the effective value of the motor line current is 110A, the motor torque is 160.5N·m, and the motor efficiency is 96.10%.

Embodiment 3

[0043] In this embodiment, the magnetic steel is still designed as a three-layer structure, including two layers of NdFeB materials and a layer of magnetically permeable material in the middle, wherein the magnetically permeable material is a silicon steel sheet, and the thickness of the rotor disc (that is, the thickness of the magnetic steel) is 12mm, the thickness of the front and back two pieces of NdFeB material is the same, the difference between embodiment 3 and embodiment 1 is: the thickness of each layer of NdFeB material is 4.2mm, the thickness of the magnetic material layer is 3.6mm, and the thickness of the magnetic material layer is 3 / 10 of the total thickness of the steel, at this time, the relative internal resistance of the magnetic steel is 0.7R0. The simulation test data shows that the effective value of the motor line current is 110A, the motor torque is 163.7N·m, and the motor efficiency is 96.22%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com