Magnetic system of magnetic separator

A technology of magnetic separator and magnetic system, which is applied in the field of magnetic system of magnetic separator, can solve the problems of wasting resources, environmental pollution, etc., and achieve the effect of improving magnetic field strength, good performance and uniform magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

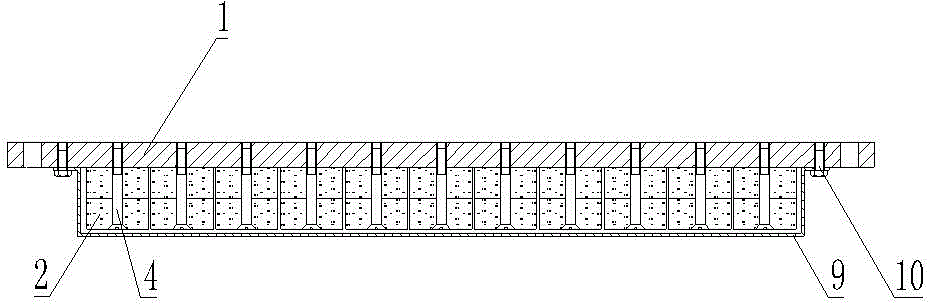

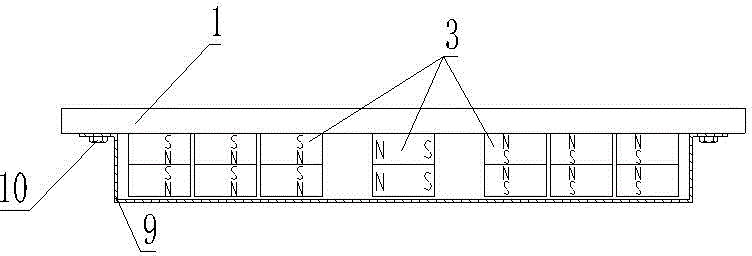

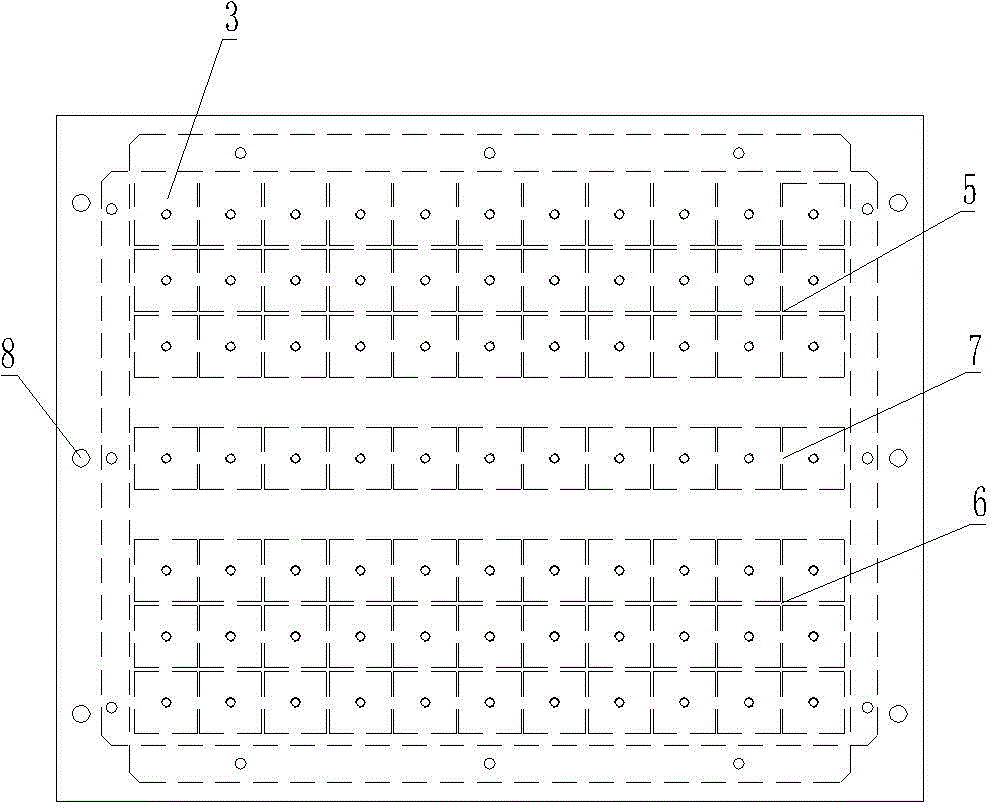

[0017] See figure 1 , figure 2 , image 3 , the present invention includes a yoke plate 1 and a magnetic block 2, the magnetic block 2 is a square magnetic steel made of NdFeB material, the yoke plate 1 is provided with a magnetic lattice 3, and the magnetic lattice 3 is arranged on the yoke plate 1 On the lower surface, the magnetic block 2 is fixed in the magnetic grid 3 by screws 4, and the magnetic grid 3 is composed of a front magnetic grid 5 and a rear magnetic grid 6 respectively, and a septum 7 is arranged between the front magnetic grid 5 and the rear magnetic grid 6 , the front magnetic grid 5 and the rear magnetic grid 6 are respectively provided with three rows of magnetic grids 3, and the septum 7 is provided with a row of magnetic grids 3; The N-level of the magnetic block 2 set in the rear magnetic grid 6 is fixed upward in the magnetic grid 3, the N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com