Patents

Literature

48results about How to "Uniform magnetic field strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

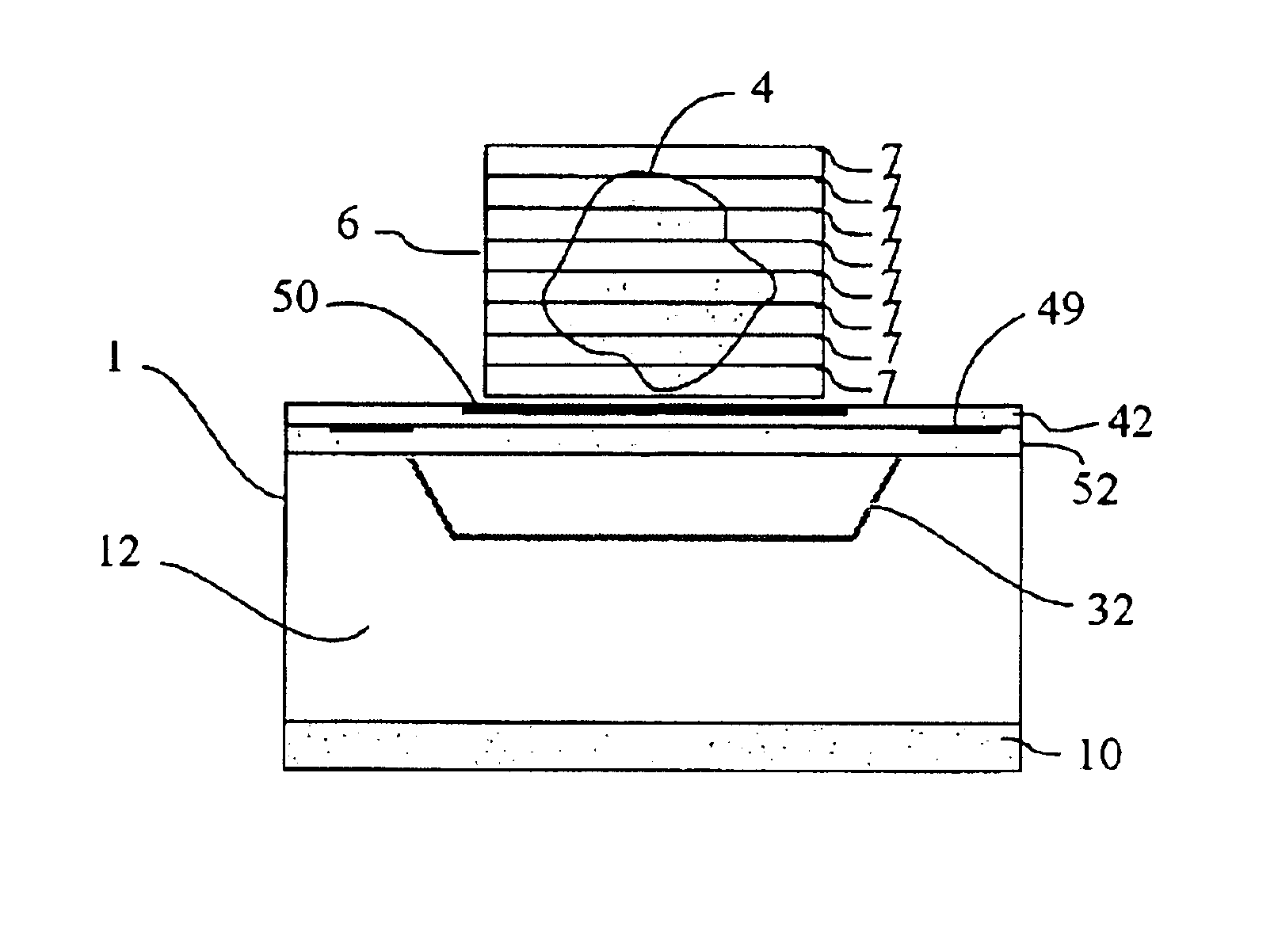

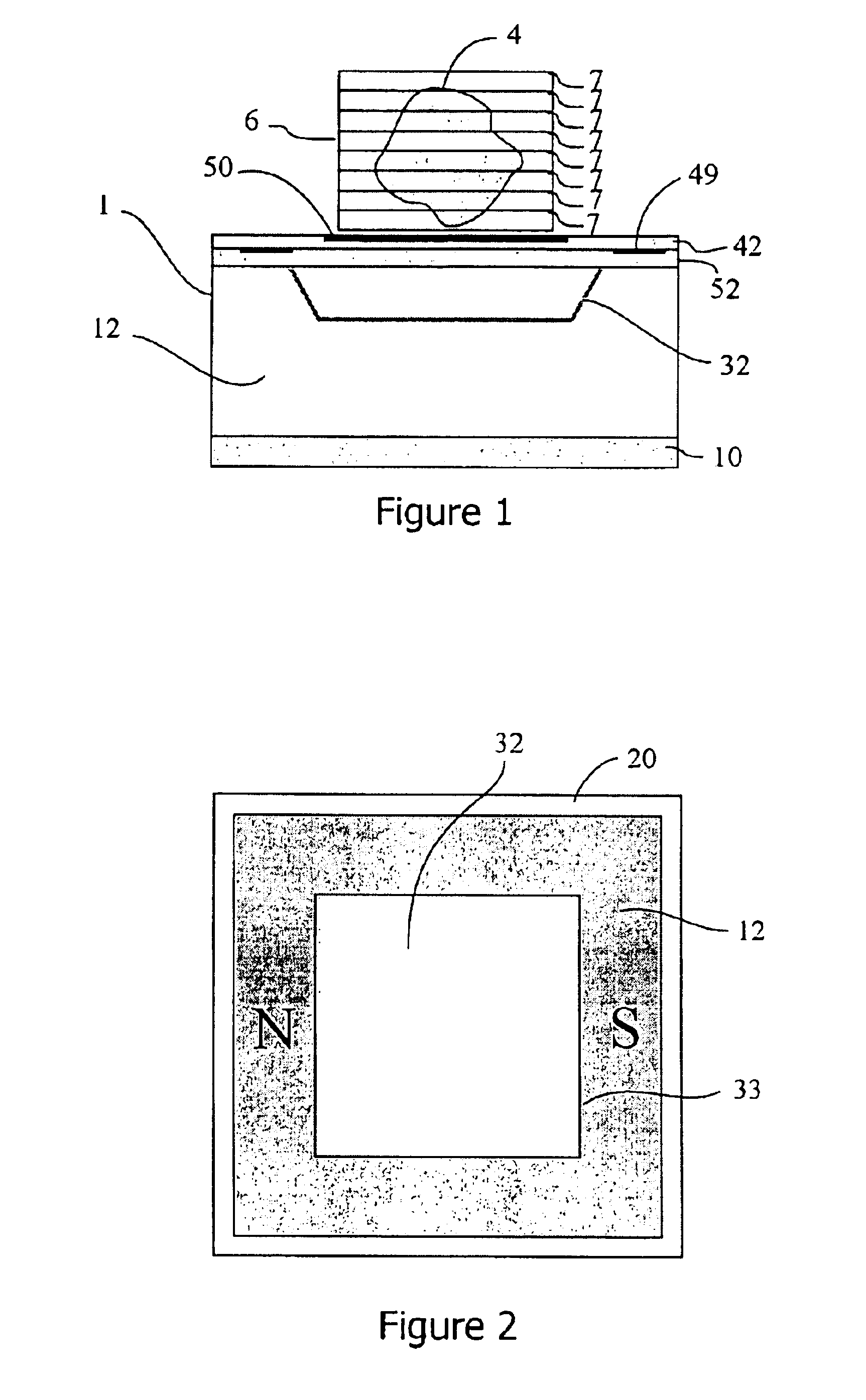

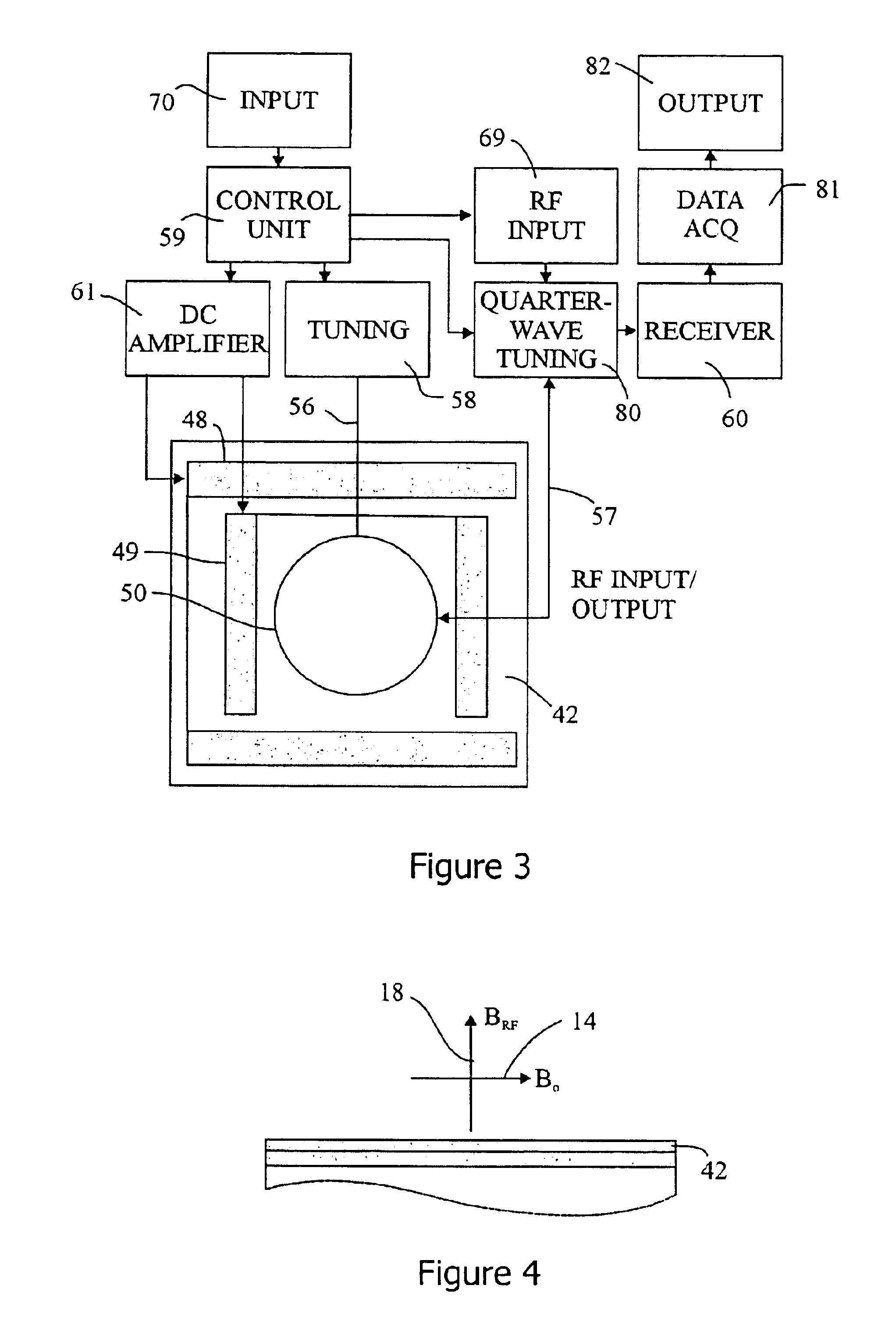

System and method for single-sided magnetic resonance imaging

InactiveUS6977503B2Uniform magnetic field strengthMeasurements using NMR imaging systemsElectric/magnetic detectionMagnetic field gradientRF probe

A magnetic resonance imaging apparatus and method having a magnet assembly, which provides substantially flat surfaces of constant magnetic field outside the assembly and a set of magnetic field gradients. One-, two-, and three-dimensional images are rendered. The static magnetic field is virtually uniform within horizontal degrees of freedom and decreases monotonically in a direction away from the surface. An RF probe, for example, a coil, located adjacent the surface, produces a field substantially perpendicular to the static magnetic field. A magnetic field gradient is set to horizontally scan a given level within the sensitive volume. Received magnetic resonance signals are detected by the coil for a depth corresponding to the excitation frequency. As the tuning and excitation frequency is switched to lower values, signals are generated for layers progressively farther from the surface. The RF probe is automatically tuned. Depth profiles are rendered by concatenating the signals collected at various frequencies. Horizontal resolution is attained by the use of controlled magnetic field gradients.

Owner:QUANTUM MAGNETICS

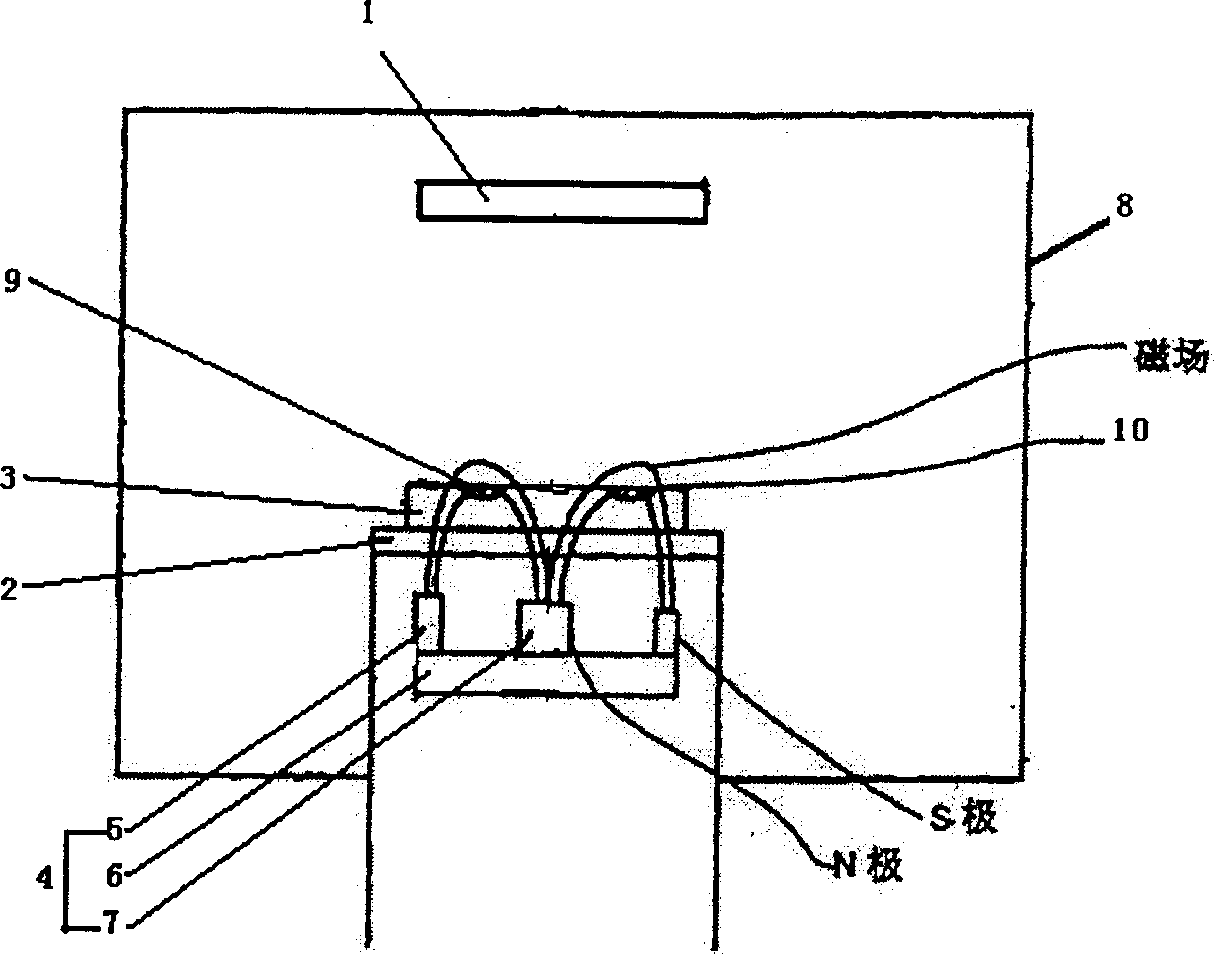

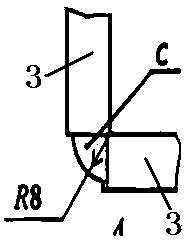

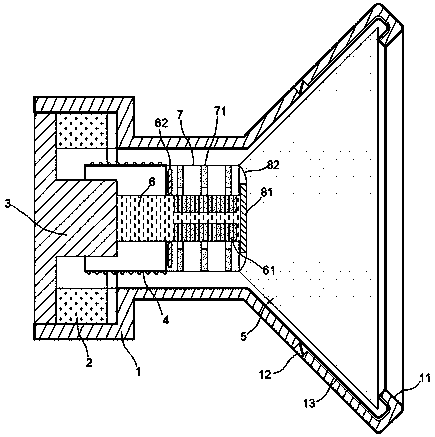

Rotary magnetic field planar target magnetic-controlled sputtering apparatus

InactiveCN1743498AIncrease profitMany particlesVacuum evaporation coatingSputtering coatingSputteringDrive shaft

This invention relates to a magnet control sputtering coating device of a rotary magnetic field plane target including a chip tray, a target base, a target material and a vacuum cavity, among which, the tray, the target base and the material are in the vacuum cavity, the tray is above the base and the material, the material is installed on the base characterizing in also including a magnetic steel group and a rotation motor, among which, the group is composed of a base plate and magnetic steels, more than one magnetic steels are set on the base eccentrically, the entire group is under the place close to the base, the rotation motor is connected with the center of the base via a driving shaft to drive rotation of the group.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

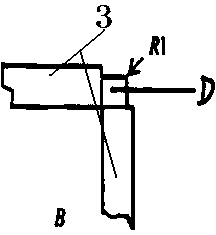

Inductive coupling source

ActiveCN1937880AUniform magnetic field strengthReduce dependenceTransformersInductancesPhysicsMicroelectronics

The invention relates to microelectronics technology. The invention includes inductively coupled source inductance coupling coil, coil inductance coupling is a linear three-dimensional multi-coil turns. Inductively Coupled coil symmetrical layout of a number of nested right, with the series divided into the within the coil groups and the outer coil group. The strengths and positive effect of the source inductance coupling invention is: the invention, fully three-dimensional symmetric coil structure is designed for electromagnetic fields in the reaction chamber of the internal distribution of symmetry, thereby improving the response of the plasma within the chamber evenly distributed, make the chip surface at various points of the etching rate closer. The invention of the technology programs can be well controlled from the chip to the edge of the central etching rate and uniformity even with the increasing size of the chip.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Magnetron sputtering plating film cathode device

ActiveCN101812667AUniform cooling effectSmall temperature differenceVacuum evaporation coatingSputtering coatingMagnetEngineering

The invention relates to a magnetron sputtering plating film cathode device which comprises a target barrel and a magnetic rod tubing, wherein the magnetic rod tubing is arranged in the target barrel. The target barrel comprises a target inner barrel and a spattering target which covers the outside surface of the target inner barrel. A magnet of a spattering magnetic field is arranged in the magnetic rod tubing, and a cooling water passage is arranged in the magnetic rod tubing. The cooling water passage comprises a water inlet passage, a plurality of water inlet holes and water return holes and a water return passage, wherein the water inlet holes and the water return holes are distributed around the magnetic field area in the length direction of the magnetic rod tubing. By arranging the water outlet holes on the surface near the spattering area of the magnetic rod tubing, the cooling water can be uniformly sprayed to the target inner barrel from the water inlet passage through the water outlet holes. Compared with the traditional single-end water inlet cooling, the cooling effect of the cooling water in the length direction is uniform, the magnetic field strength of the cathode magnetic rod tubing has little change in length direction during rotation, and the temperature difference of the spattering target in the length direction is small, thereby obviously improving the uniformity of the plating film.

Owner:CSG HOLDING

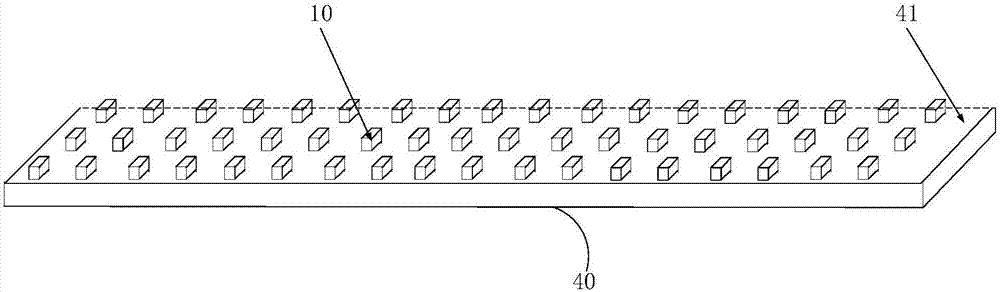

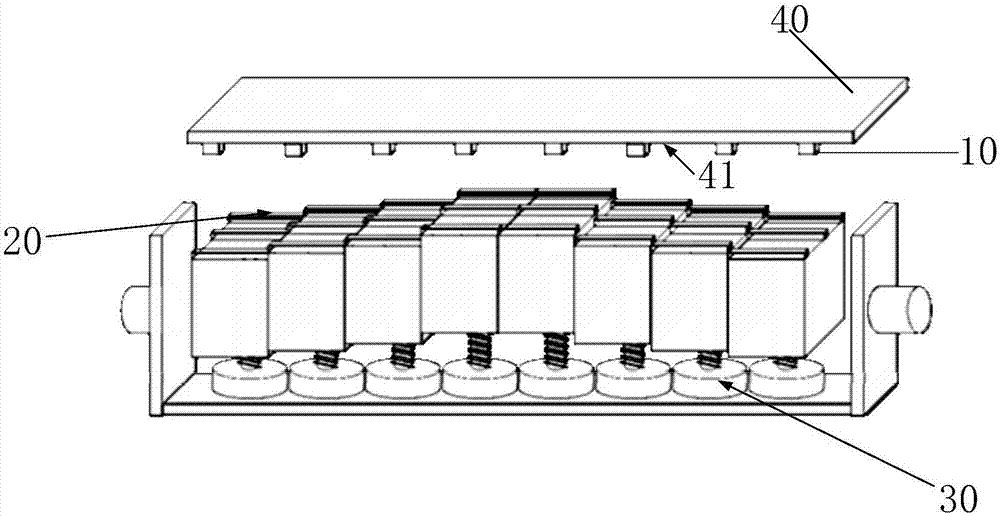

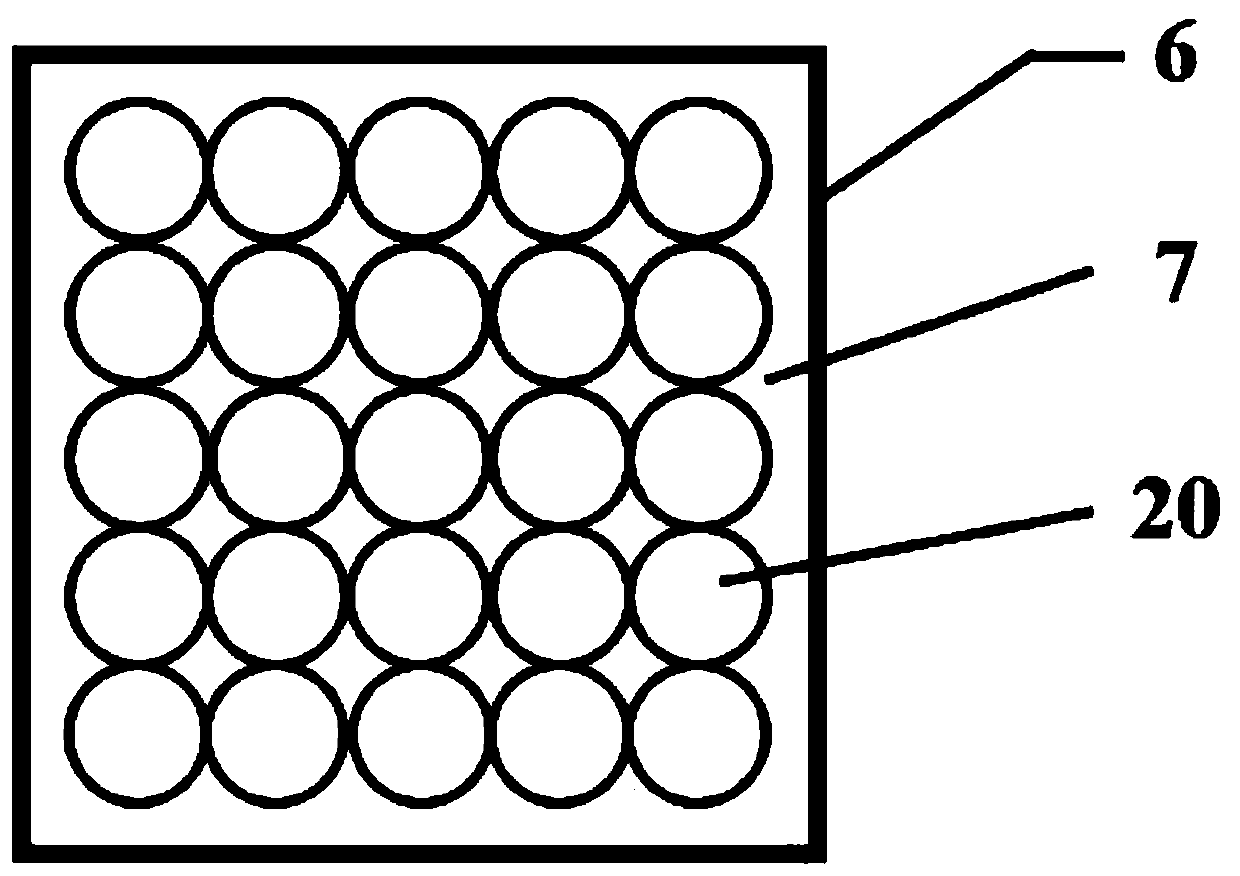

Magnetic field providing device, magnetron sputtering equipment and method using same

InactiveCN107012440ASolve the problem that the magnetic field is not a uniform magnetic fieldUniform magnetic field strengthVacuum evaporation coatingSputtering coatingHomogeneous magnetic fieldMagnet

The invention provides a magnetic field providing device, magnetron sputtering equipment and a method using the magnetron sputtering equipment. The magnetic field providing device comprises a plurality of magnetic field detecting elements, a plurality of magnet units and a plurality of adjusting structures. The multiple magnetic field detecting elements are distributed in an array mode in a detecting plane and used for detecting the magnetic field intensities of different positions in the detecting plane. The multiple magnet units are arranged opposite to the detecting plane, and the multiple magnetic field detecting elements are located in magnetic fields of the magnet units. Each magnet unit is connected with one corresponding adjusting structure. By the adoption of the adjusting structures, the magnet units can adjust the magnetic field detecting elements to detect the obtained magnetic field intensities relative to distance change of the detecting plane, and the magnetic field intensities on the detecting plane are uniform. According to the magnetic field providing device, the magnetic field detecting elements are used for detecting the magnetic field intensities on the detecting plane away from the magnet units by a preset distance, the adjusting structures connected with the magnet units are used for adjusting the magnetic field intensities at the detecting plane position, and the uniform magnetic field intensities can be obtained on the detecting plane.

Owner:BOE TECH GRP CO LTD

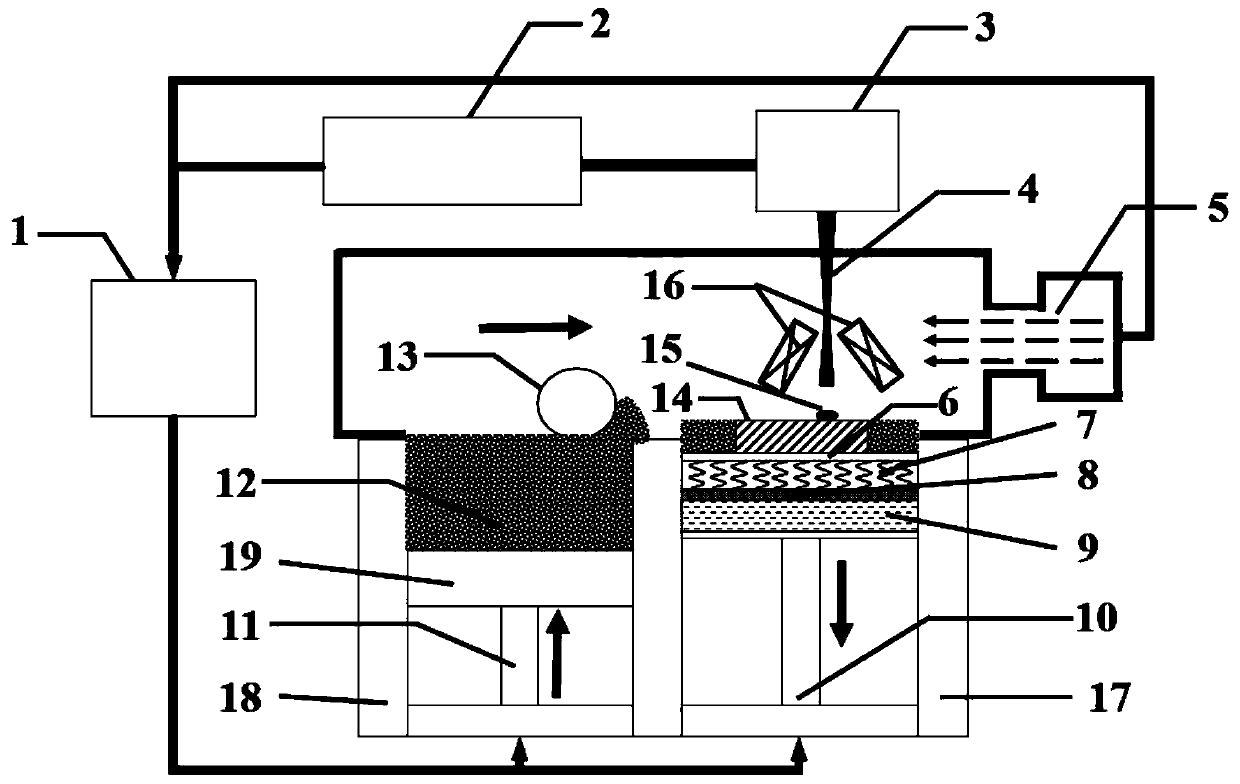

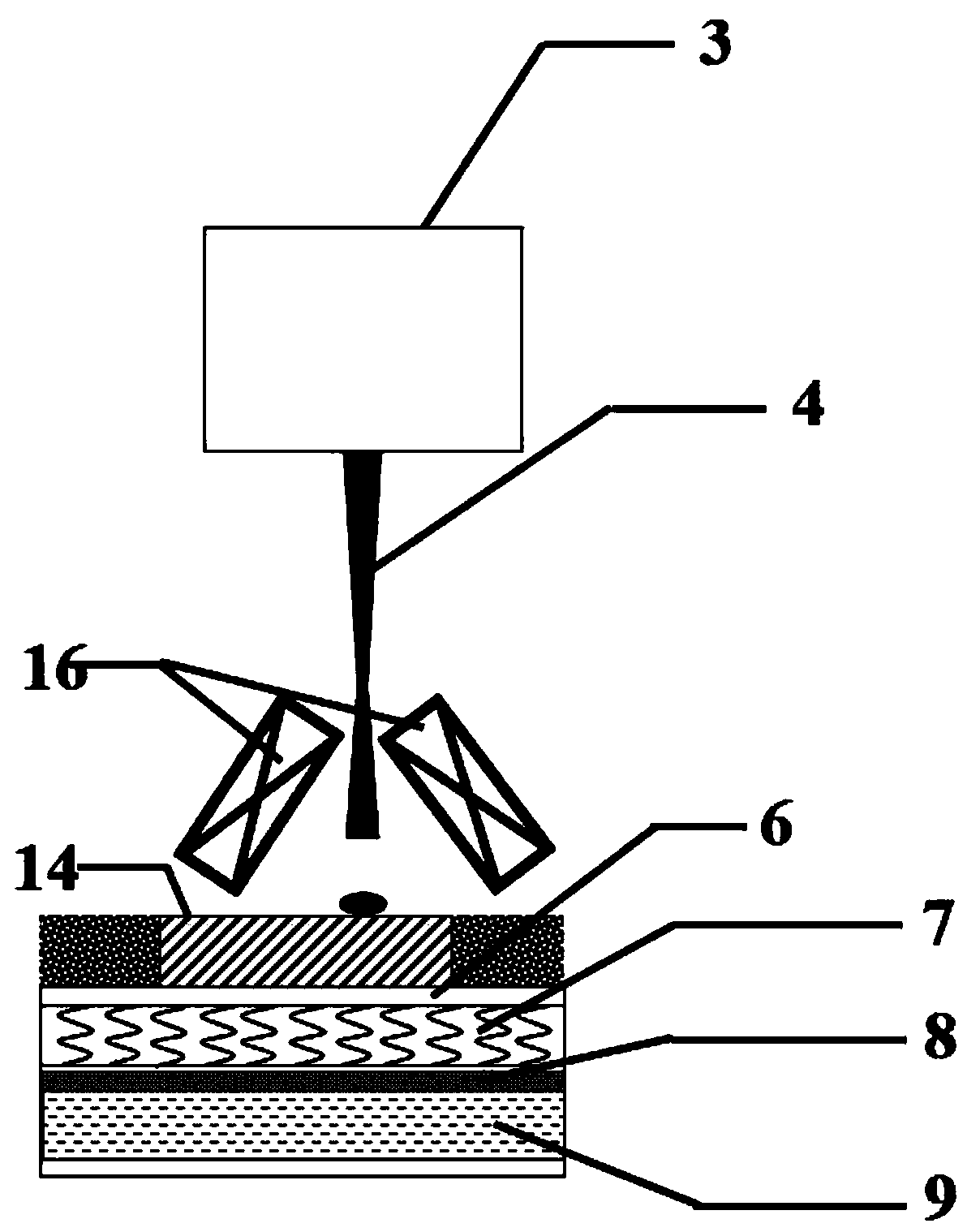

High-energy beam additive manufacturing forming device and forming method

InactiveCN111558718AImprove control efficiencyImprove controlAdditive manufacturing apparatusIncreasing energy efficiencyMechanical engineeringHigh energy beam

The invention discloses a high-energy beam additive manufacturing forming device and method. The device comprises a magnetic field unit for assisting additive forming, and further comprises a formingbase for placing a to-be-processed material, and a high-energy beam generation device which emits a high-energy beam, acts on the to-be-processed material, and forms a molten pool. The magnetic fieldunit comprises a first magnetic field generating device, and the first magnetic field generating device comprises an induction coil arranged below the molten pool. The first magnetic field generatingdevice is detachably arranged below the surface, used for containing the to-be-processed material, of the forming base; a second magnetic field generating device is arranged above the forming base; the induction coil is arranged below the molten pool, and the molten pool is located in the area, where the clustered magnetic induction lines are emitted, of the induction coil, so that the clustered magnetic induction lines penetrate through the molten pool, therefore, the magnetic field intensity of the molten pool is concentrated, the control effect of the magnetic field on additive forming is improved, and the control efficiency of the magnetic field unit on the molten pool is improved.

Owner:SHANGHAI UNIV

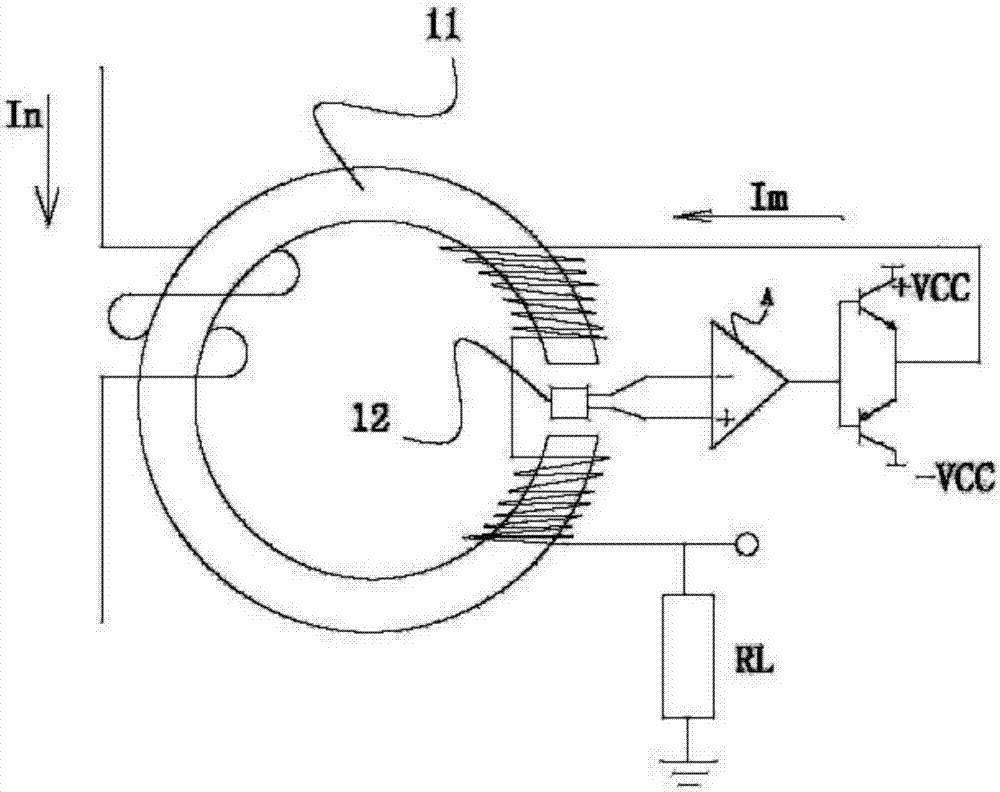

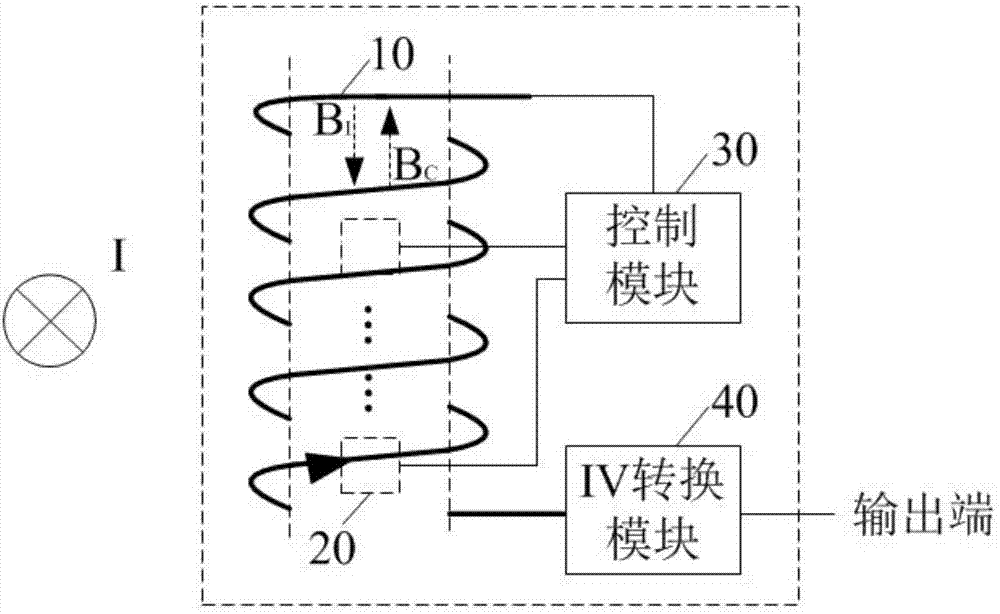

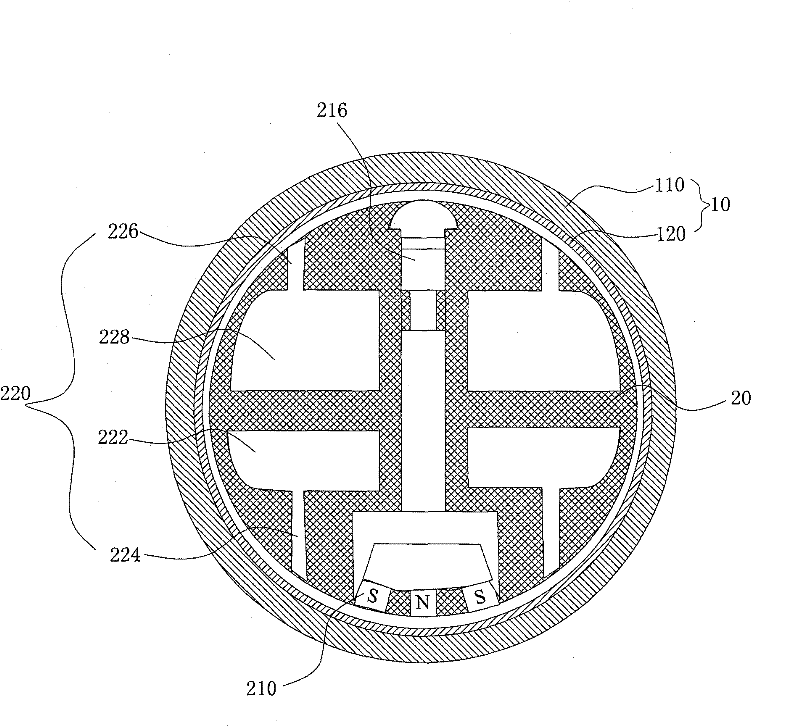

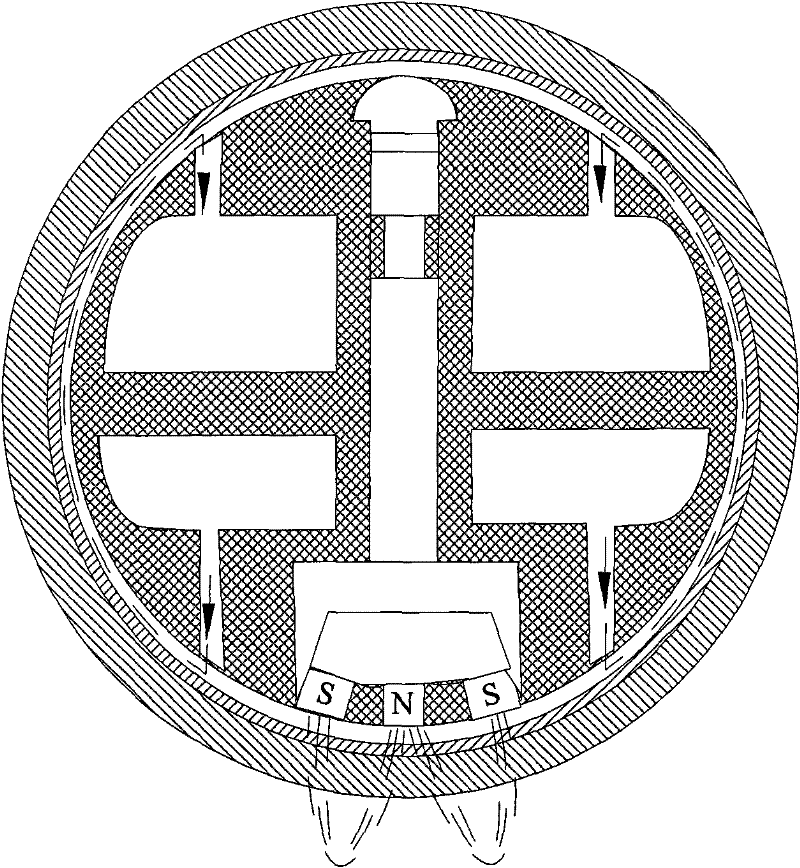

Closed loop current sensor

PendingCN107462758AUniform magnetic field strengthReduce volumeCurrent measurements onlyVoltage/current isolationPhysicsMagnetic core

The invention discloses a closed loop current sensor which comprises at least one compensation coil, at least one magnetic sensing chip, a control module and an IV conversion module, wherein the compensation coils are arranged at preset positions on a lead wire where to-be-detected current flows; each magnetic sensing chip is arranged in a tube cavity of one compensation coil, and is used for measuring intensities of a magnetic field of the to-be-detected current and a superposed magnetic field of the compensation coil; the control module is used for outputting current at preset magnitude according to output signals of the magnetic sensing chips; an input end of the control module is connected with output ends of the magnetic sensing chips, and an output end of the control module is connected with one end of each compensation coil; an input end of the IV conversion module is connected with the other end of each compensation coil, and an output end of the IV conversion module is used as an output end of the closed loop current sensor. As the magnetic field intensities in the tube cavities of the compensation coils are relatively uniform, the magnetic sensing chips of the closed loop current sensor can accurately measure the intensity of the superposed magnetic field in the absence of a magnetic core. The closed loop current sensor without the magnetic core is relatively small in volume, relatively light in weight and low in manufacturing cost.

Owner:NING BO SINOMAGS ELECTRONICS TECH CO LTD

Three-phase permanent-magnet synchronous motor rotor punching sheet suitable for both line starting and variable frequency starting

InactiveCN104079095AReduce vibrationHigh out of step torqueMagnetic circuit rotating partsSynchronous machine detailsPunchingPermanent magnet synchronous motor

The invention relates to a three-phase permanent-magnet synchronous motor rotor punching sheet suitable for both line starting and variable frequency starting. The three-phase permanent-magnet synchronous motor rotor punching sheet is an iron core punching sheet which is super-ultra-high in efficiency and suitable for a rotor of a high pull-out torque three-phase rare-earth permanent magnet synchronous motor and a rotor of a variable-frequency and variable-speed motor three-phase permanent magnet synchronous motor, and is used for a permanent magnet synchronous motor with a 132 base. The three-phase permanent-magnet synchronous motor rotor punching sheet is provided with a rotor punching sheet body made of a low-loss silicon steel sheet in a punching mode. Starting rod holes are evenly distributed on the outer circumference of the rotor punching sheet body, and W-shaped magnetic steel grooves are evenly formed in the rotor punching sheet body. A magnetic isolation bridge A is arranged between the lower portions of the starting rods and the magnetic steel grooves, and a magnetic isolation bridge B and a magnetic isolation bridge C are arranged between every two adjacent magnetic steel grooves. Rigidity reinforced screw holes and rotor shaft holes are formed in the rotor punching sheet body.

Owner:JIANGSU JIUZHI MOTOR TECH

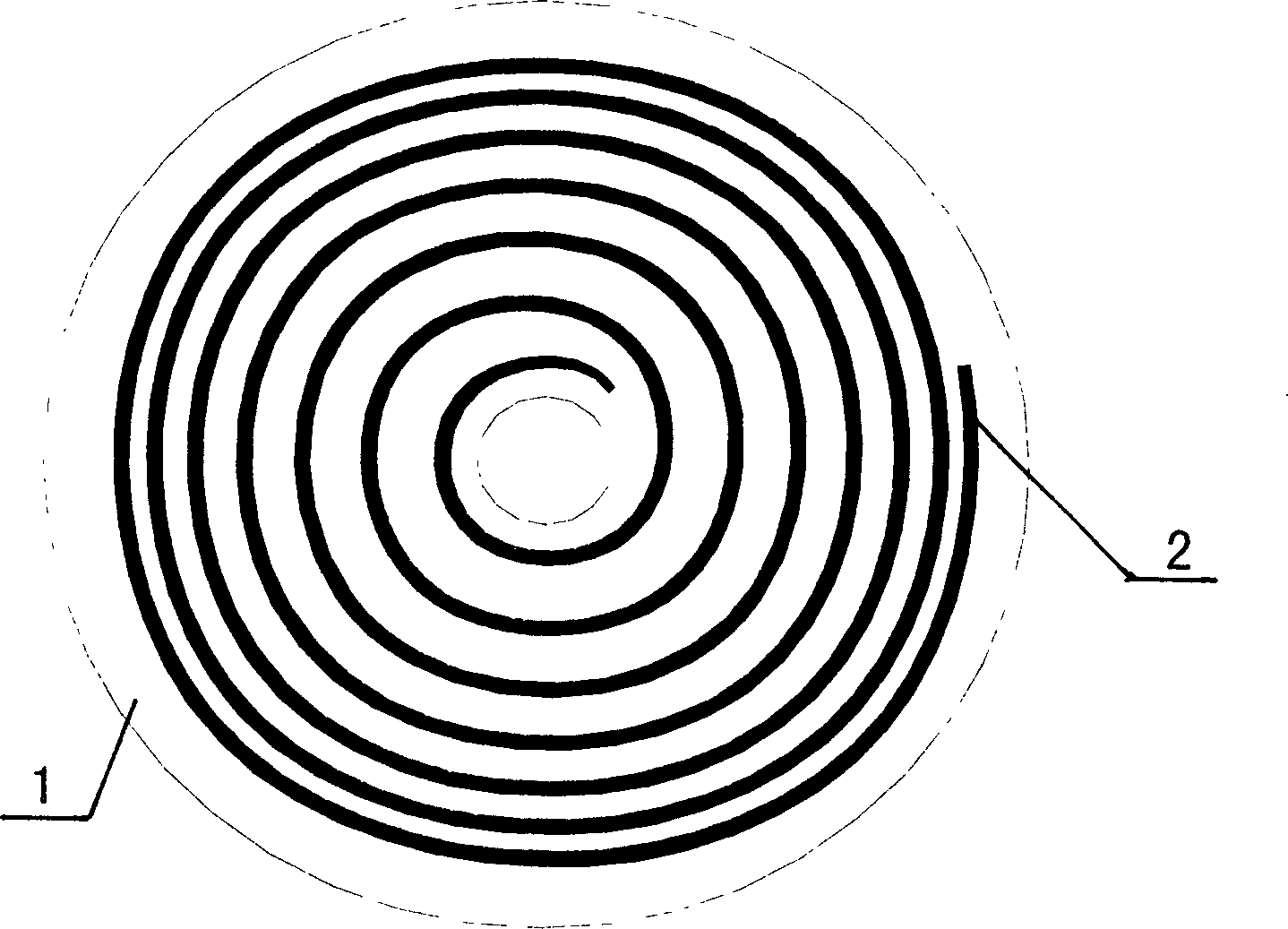

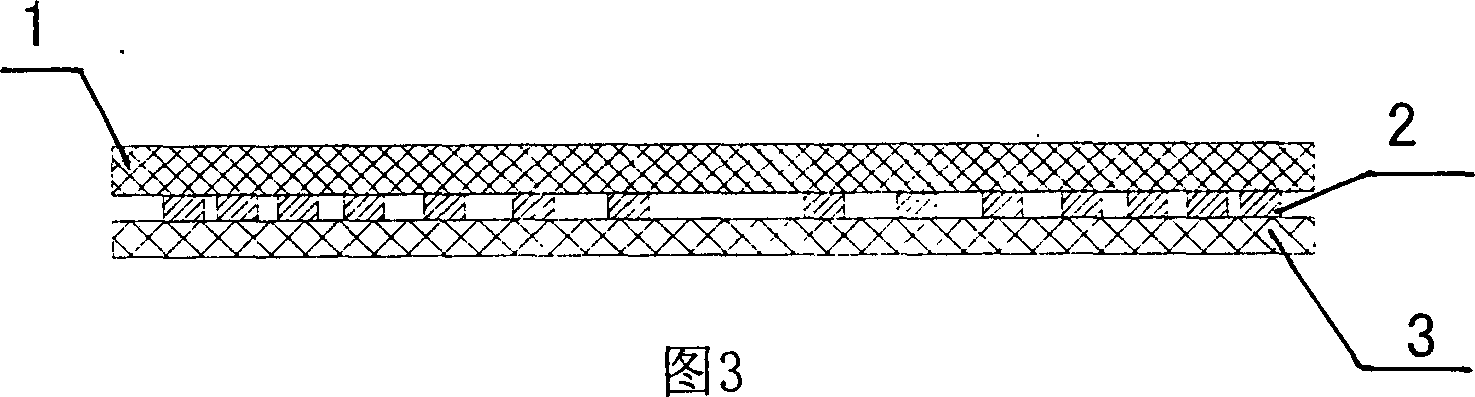

An electromagnetic induction heating coil

The invention discloses a electromagnetic induction heating winding. It includes non- magnetizer basis material covered by copper film, winding covered by copper film and non-magnetizer material board. Its lengthways section from from the top down are non-magnetizer material board, winding covered by copper film and non- magnetizer basis material covered by copper film. The distance of each two wind is equal, or inner wide outer narrow to form the style of inner sparse outer dense bit by bit. It can also be wind which is covered by copper film on double surfaces. The character of the invention is advisable designing, simple technics; average magnetic field strength, the inductive pyrotoxin is not limited by position, it can produce same heating energy; the invention is suitable to all kinds of heating equipment, especially when the inductive pyrotoxin is smaller than heating winding and the position is not be ensured.

Owner:韩秀艳

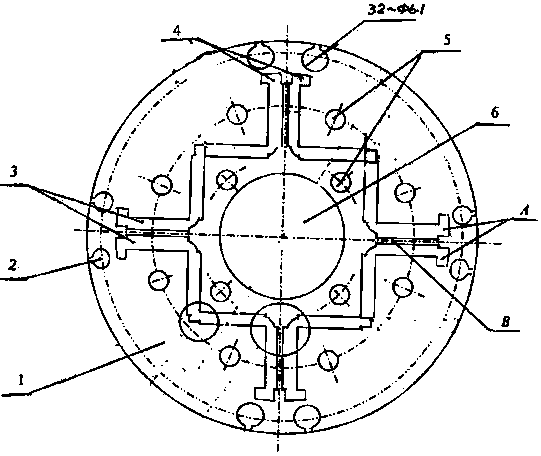

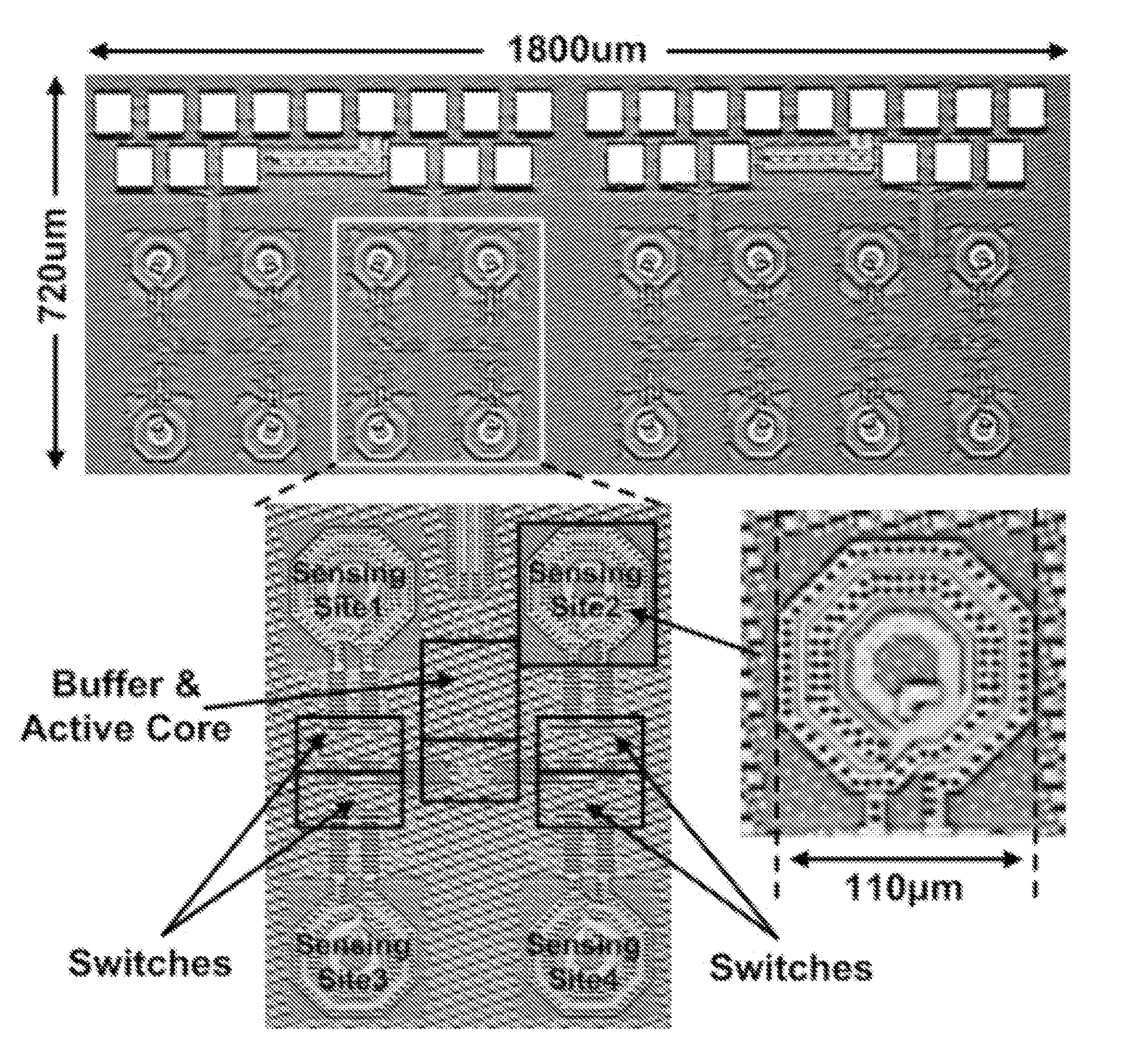

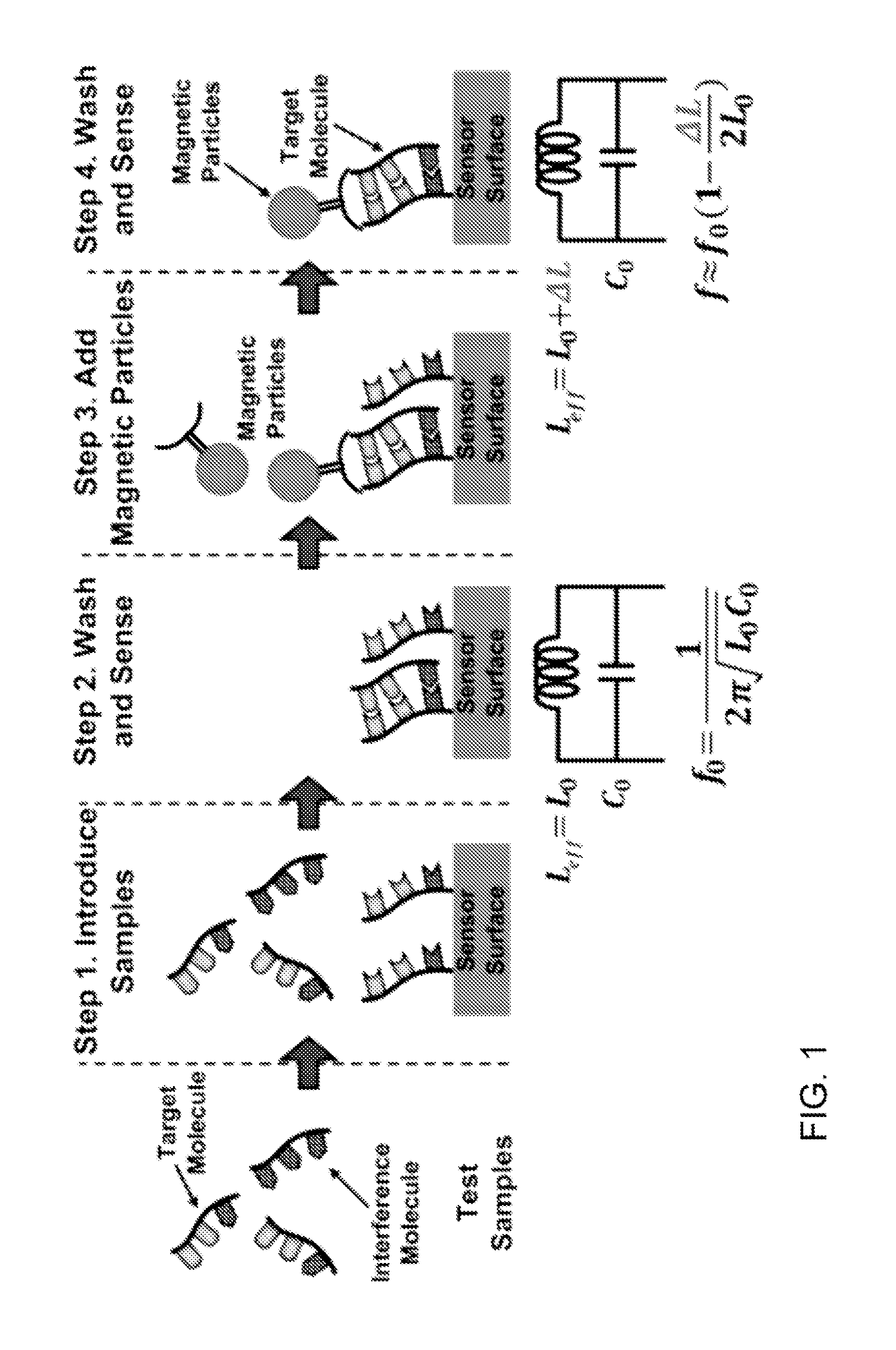

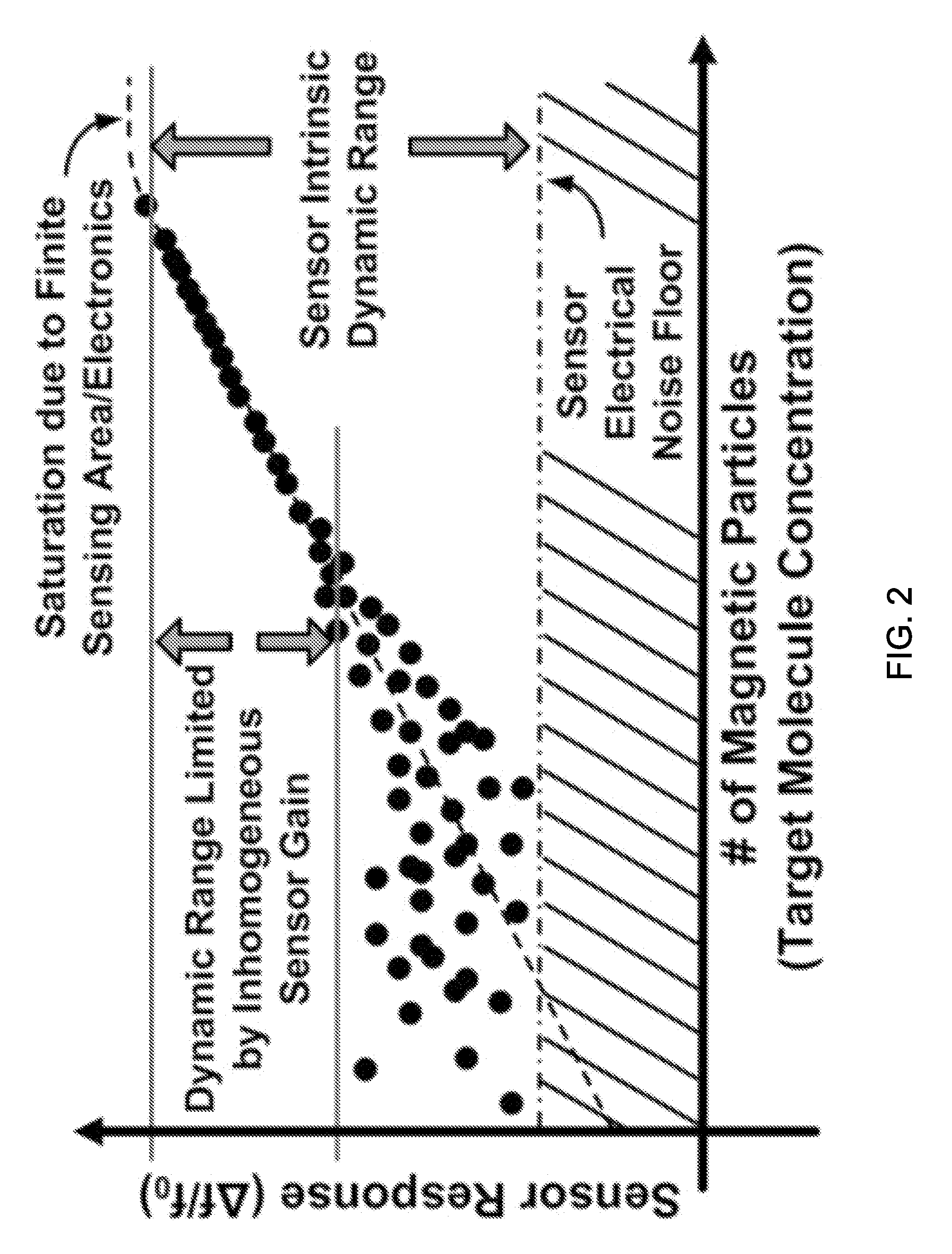

Inductors with uniform magnetic field strength in the near-field

InactiveUS20110175602A1Uniform magnetic field strengthMagnetic property measurementsTransformers/inductances detailsElectromagnetic couplingEngineering

An integrated inductor includes a plurality of coils. Each of the plurality of coils is electromagnetically coupled together to form an inductor between a first inductor terminal and a second inductor terminal. At least one of the plurality of coils is disposed in a layer on an integrated structure and at least another of one of the plurality of coils disposed in a layer of the integrated structure. One of the plurality of coils is spaced with respect to another of the plurality of coils to cause a substantially uniform magnetic field strength across a surface of the integrated inductor. An integrated magnetic particle sensor system, an integrated inductor having a section having a different width than another section, an integrated inductor having at least one gradual transition section, and an integrated inductor having at least one floating metal structure are also described.

Owner:CALIFORNIA INST OF TECH

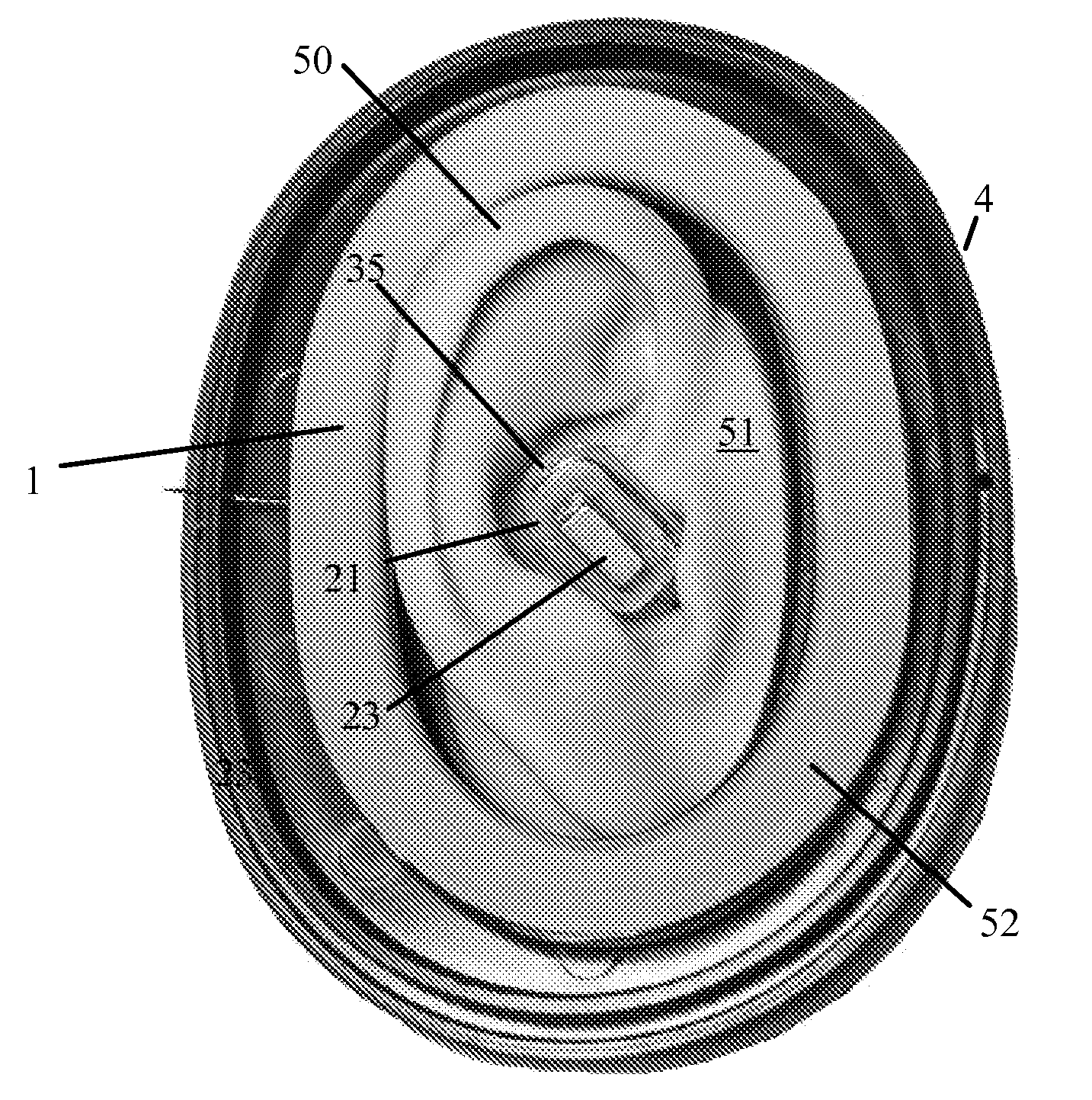

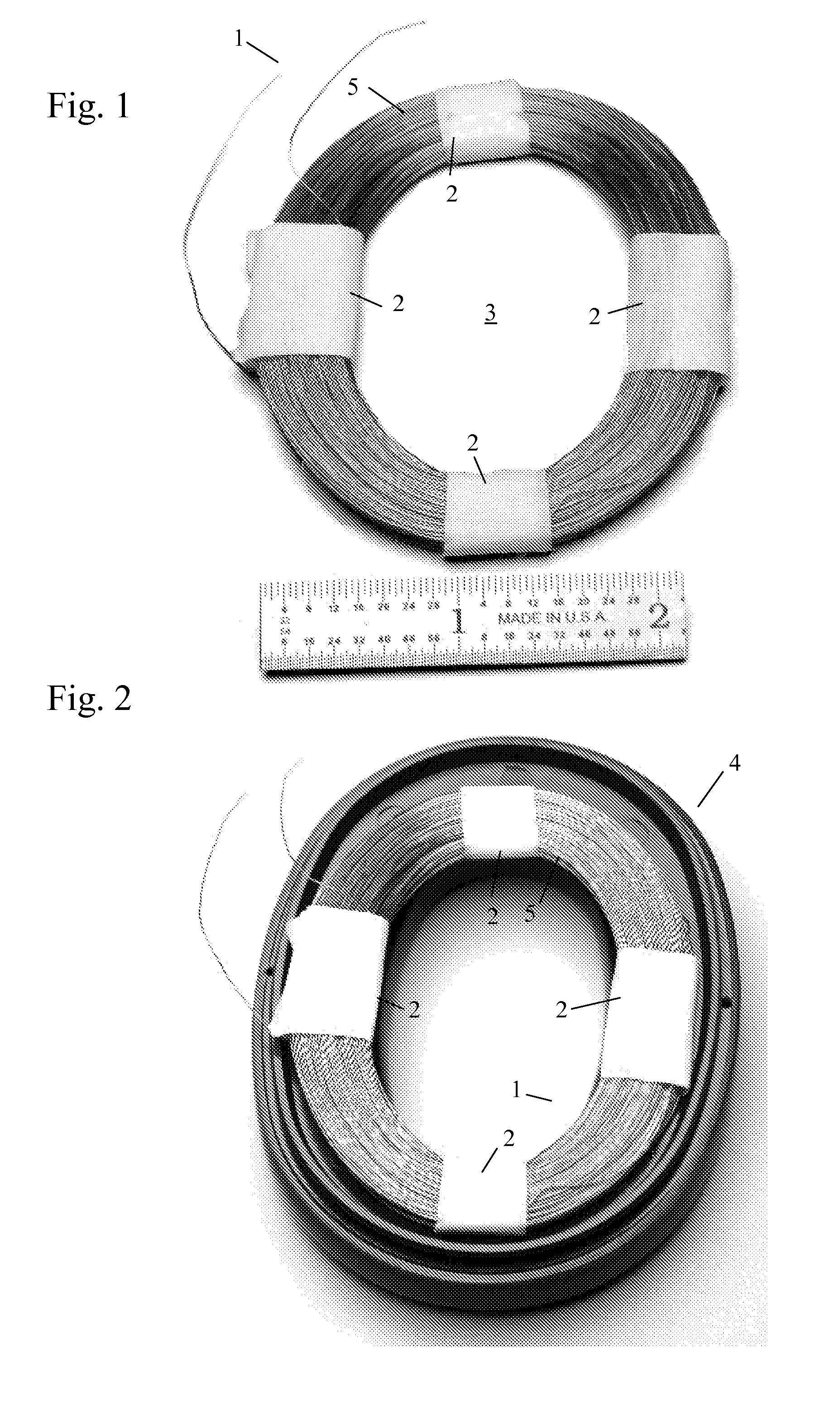

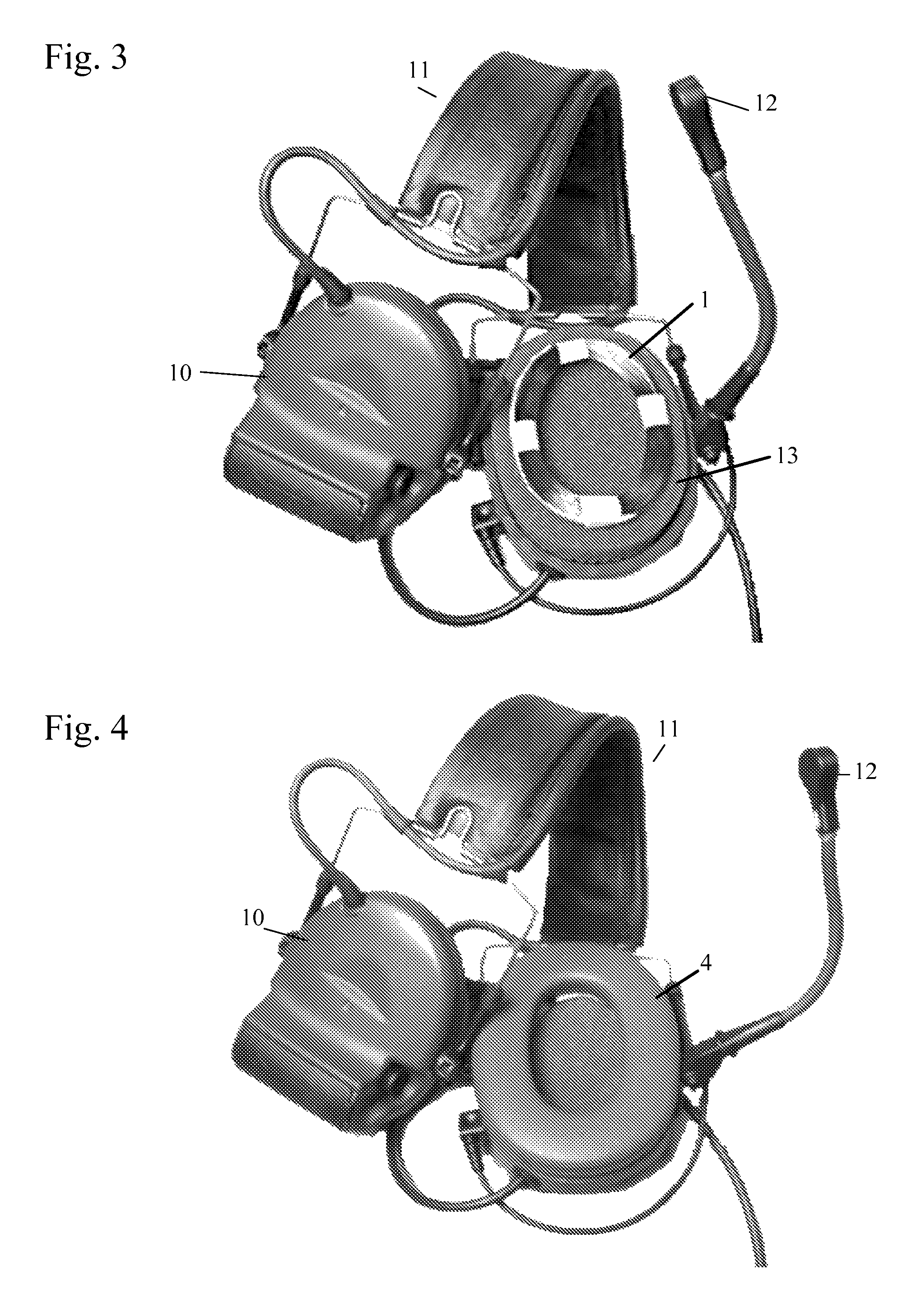

Wireless communications headset system employing a loop transmitter that fits around the pinna

ActiveUS8688036B2Eliminate the problemEasily into aviation headsetNear-field transmissionFrequency response correctionAviationMagnetic field coupling

Owner:RED TAIL HAWK CORP

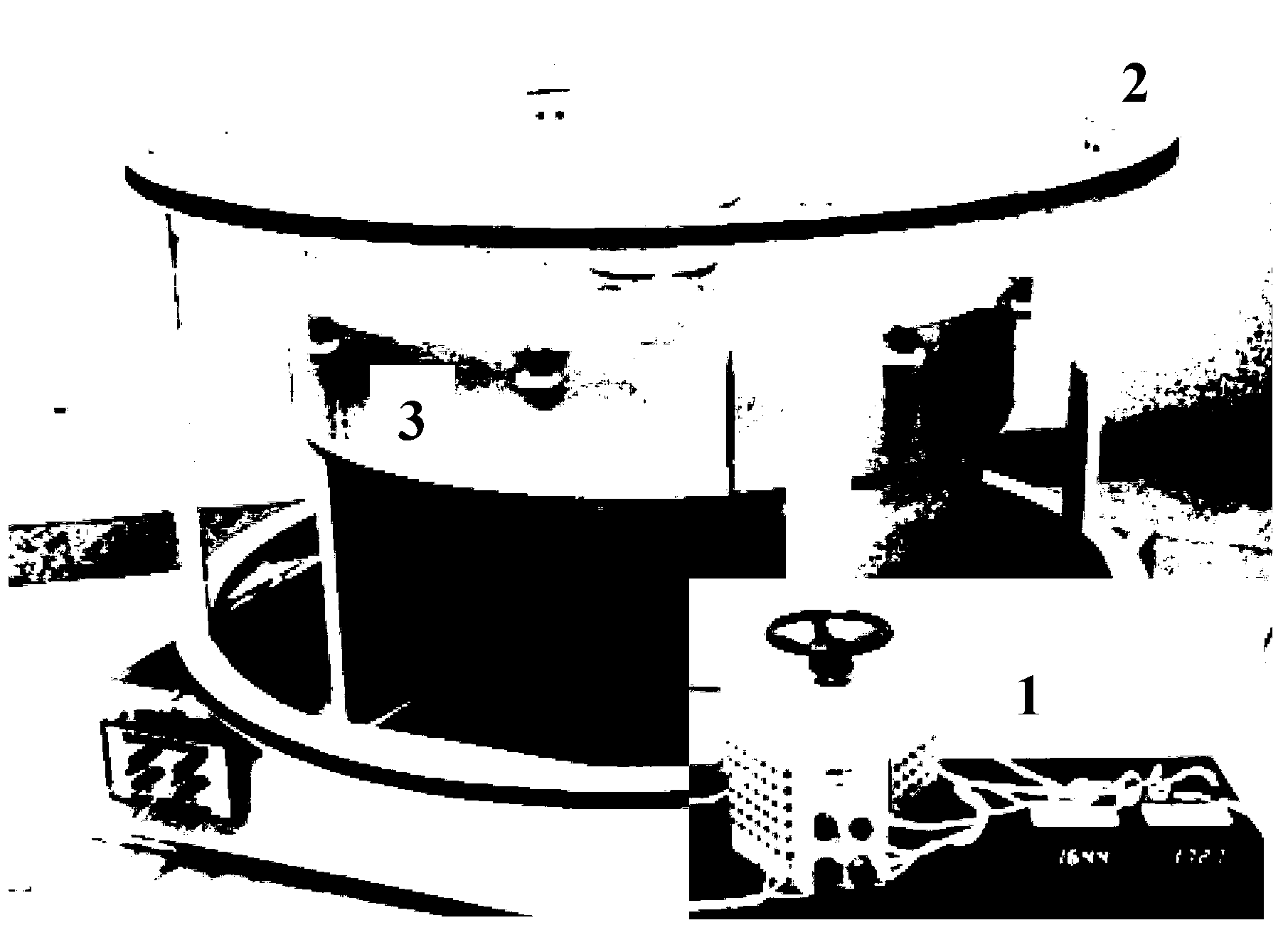

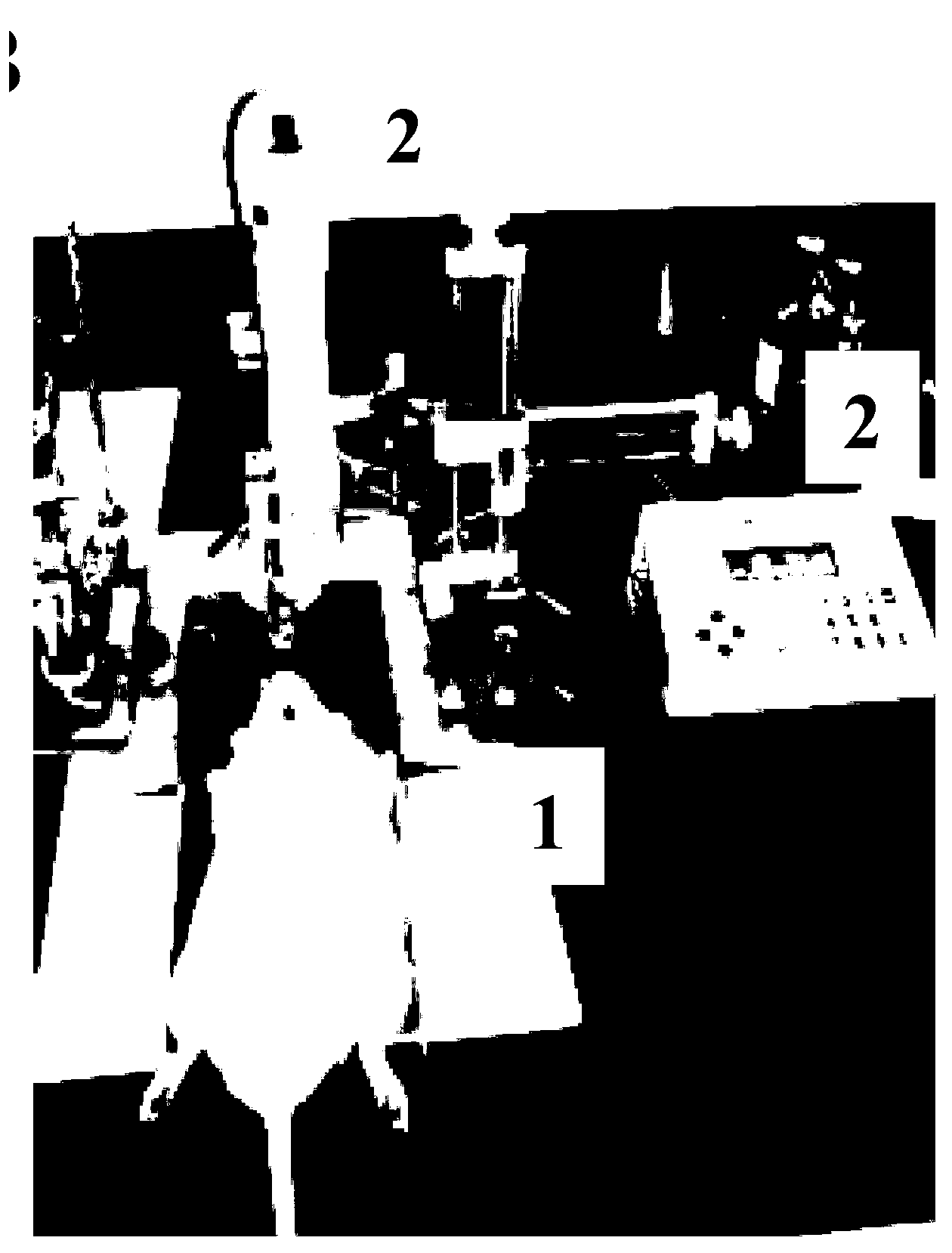

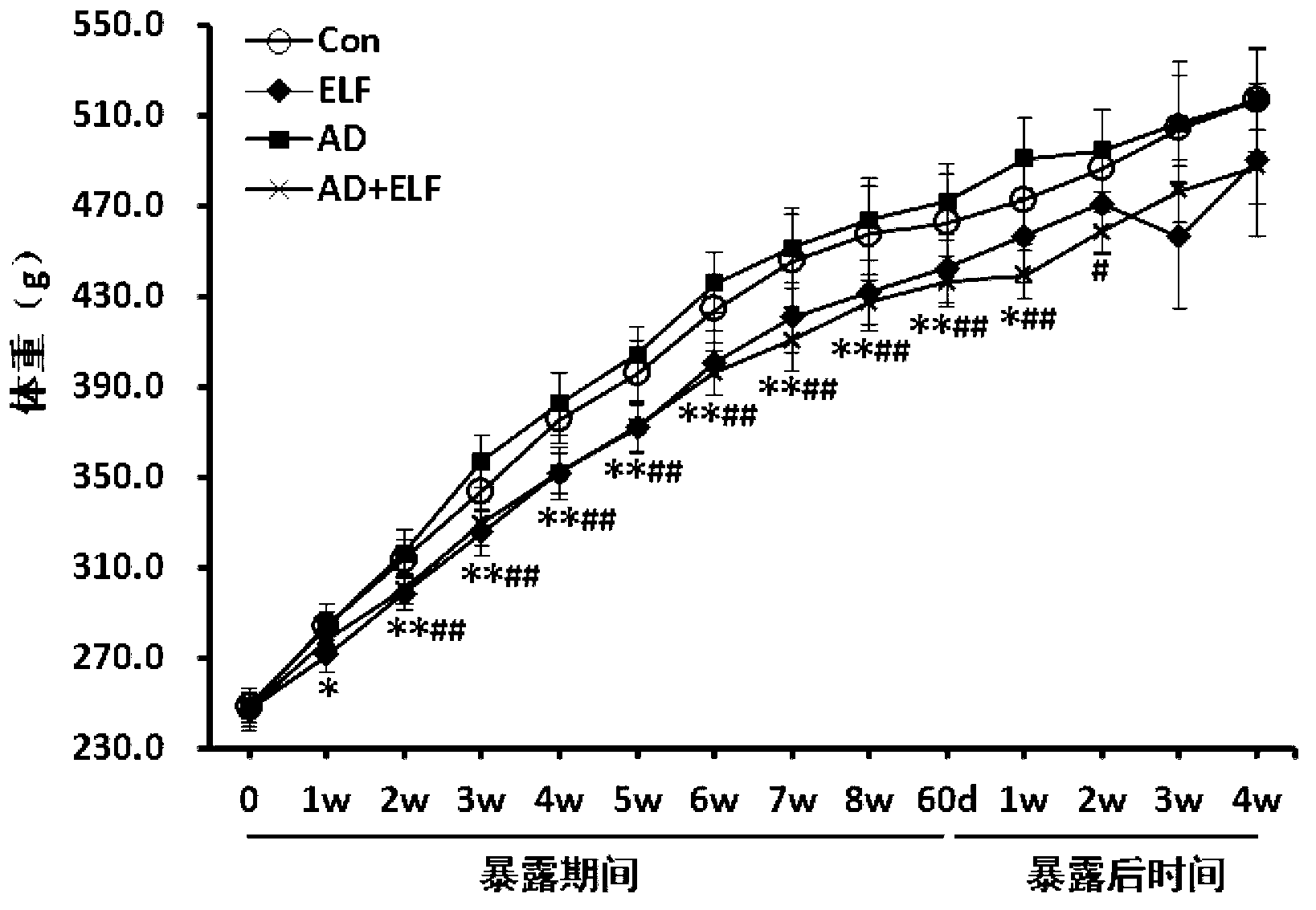

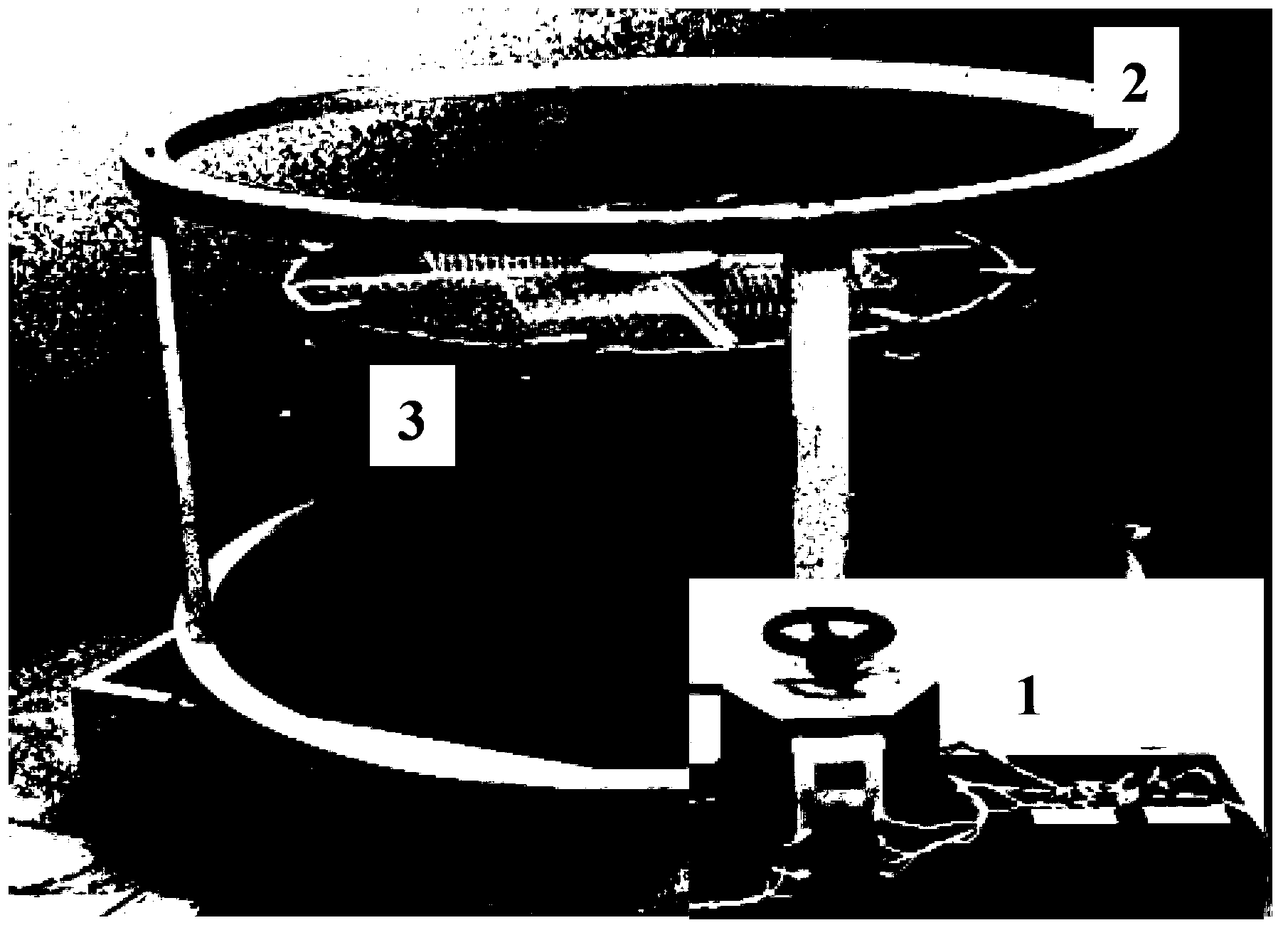

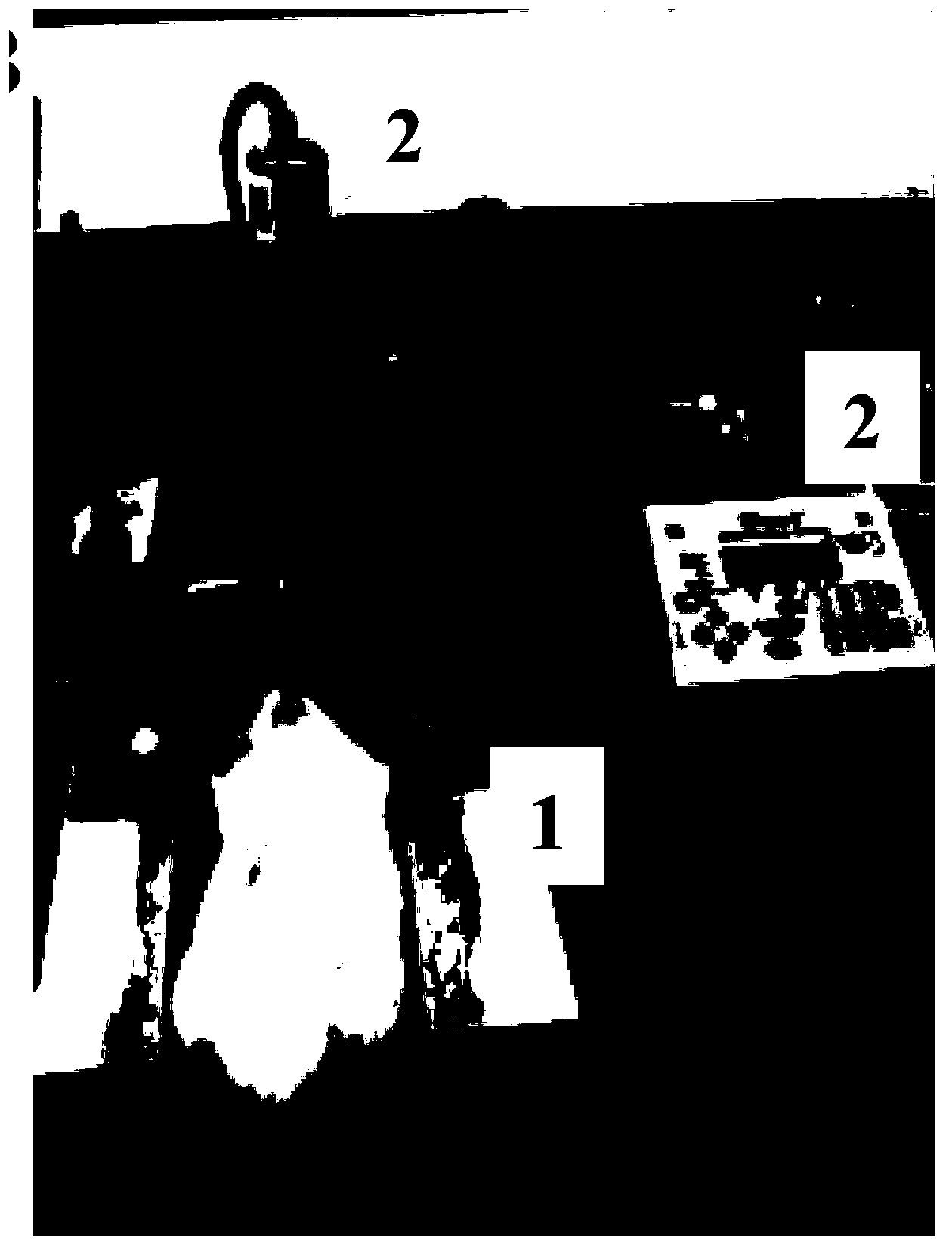

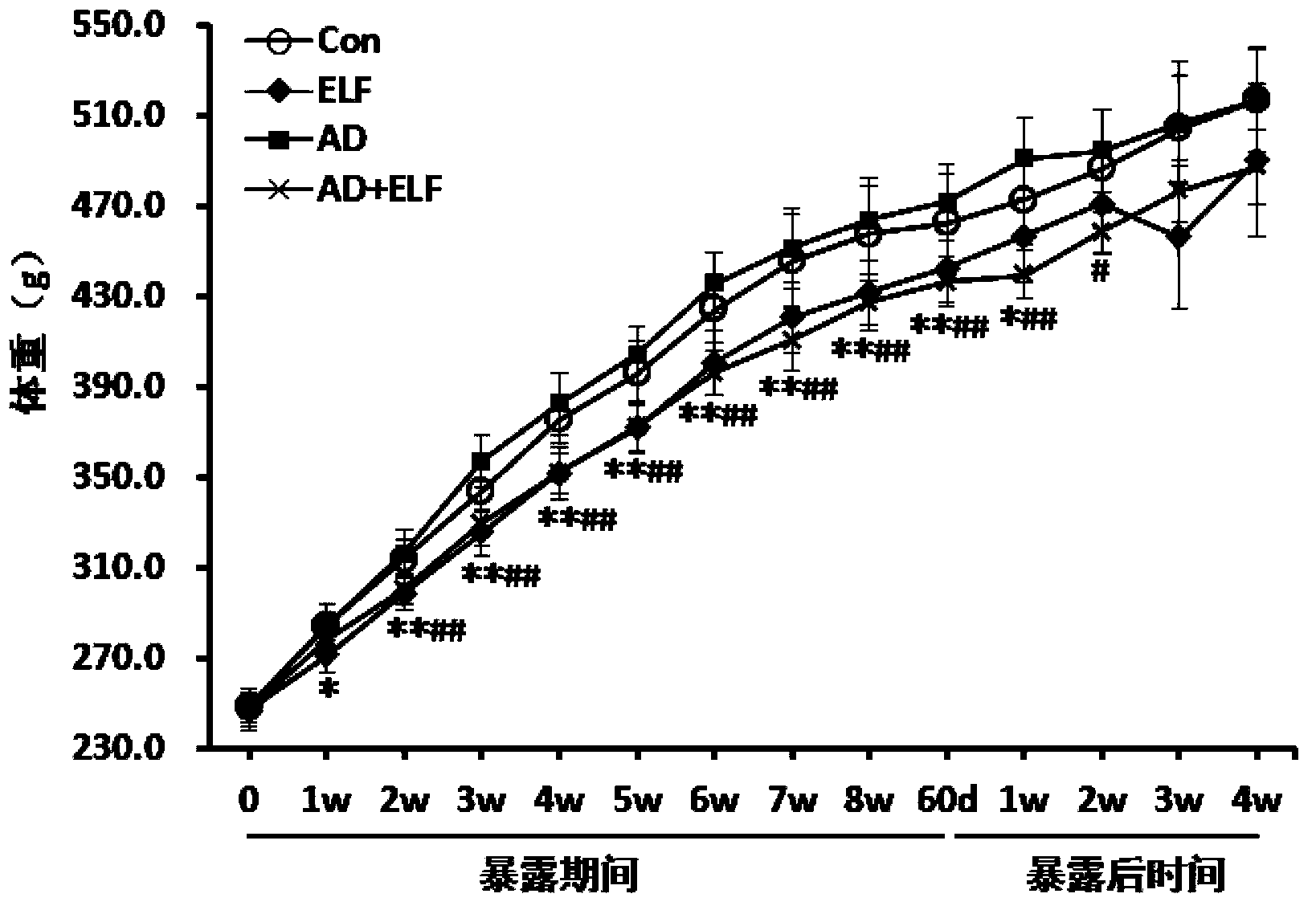

Method for establishing animal model of Alzheimer's disease

The invention provides a method for establishing an animal model of an Alzheimer's disease. The method includes feeding a rat for at least 60 days under the condition of exposing to a power-frequency magnetic field; feeding the rat with drug D of galactose and beta of amyloid protein liquid during the process of feeding, and accordingly obtaining the animal model of the Alzheimer's disease. Thus, the method can be a useful supplement of a single-factor-induced animal model of the Alzheimer's disease. According to an embodiment of the method, characteristic pathological changes of the animal of the Alzheimer's disease can be expressed; the method has a characteristic of learning and memory impairment, is consistent with the environmental requirements of long-time and lasting exposure to the power-frequency magnetic field, and has the advantages of stable performance, good reproducibility, and low cost.

Owner:INST OF RADIATION MEDICINE ACAD OF MILITARY MEDICAL SCI OF THE PLA

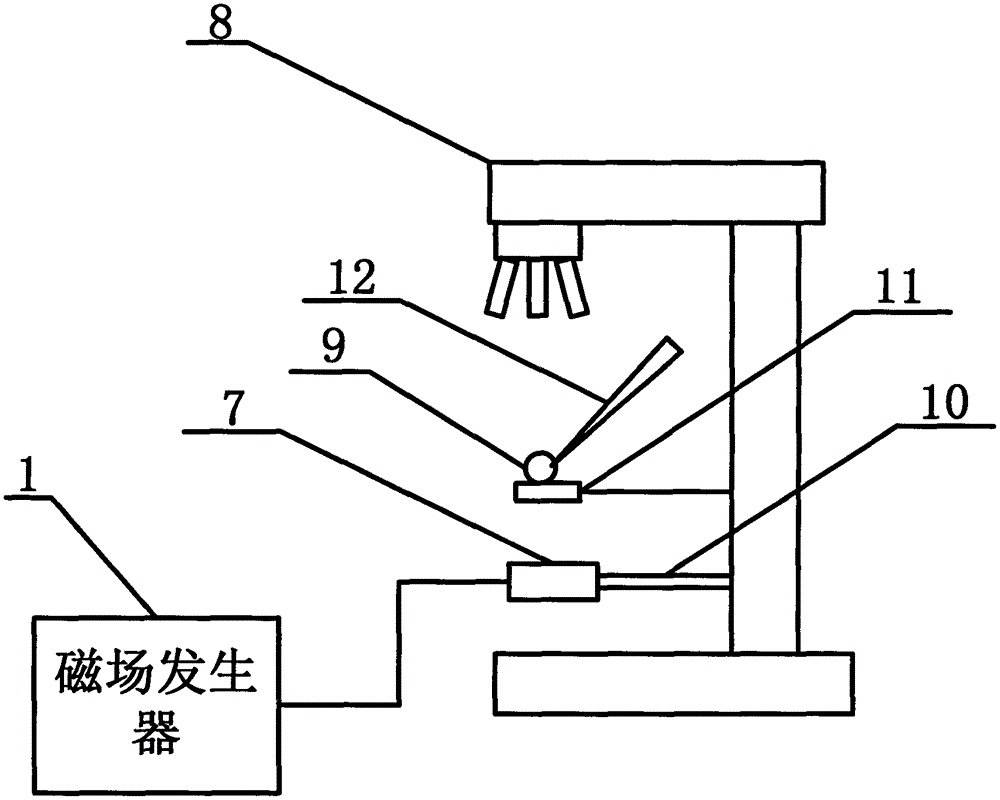

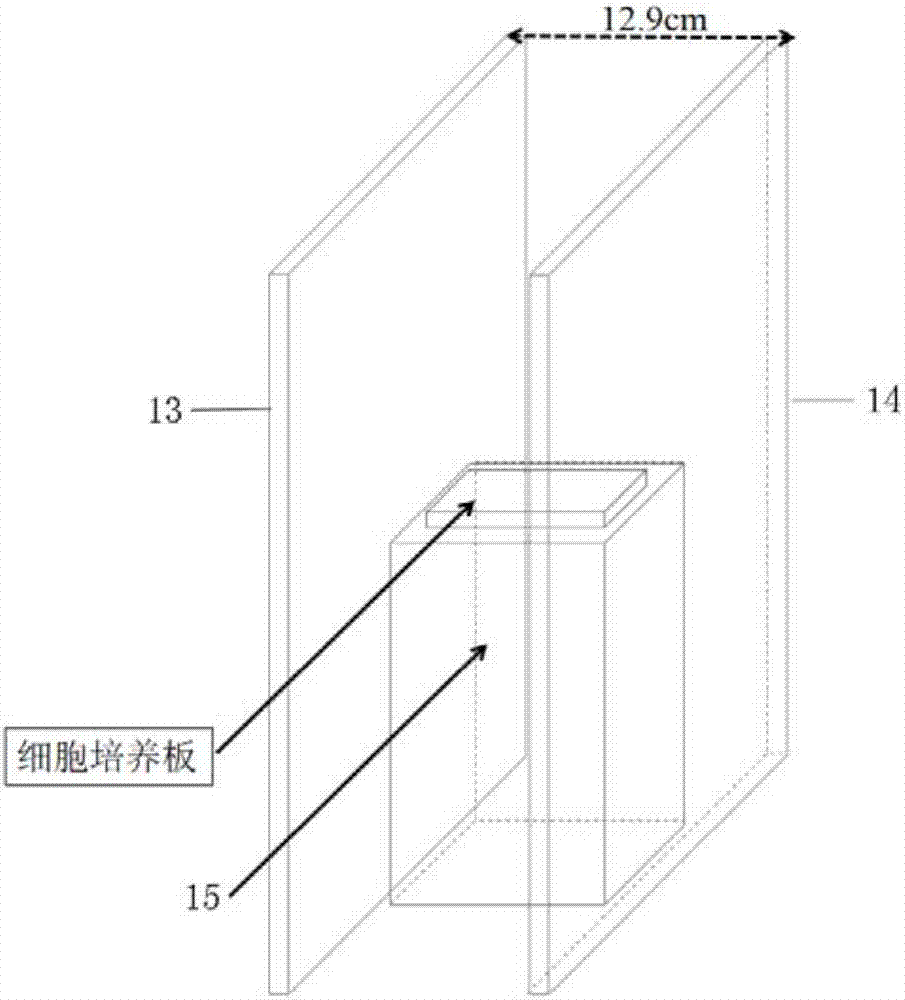

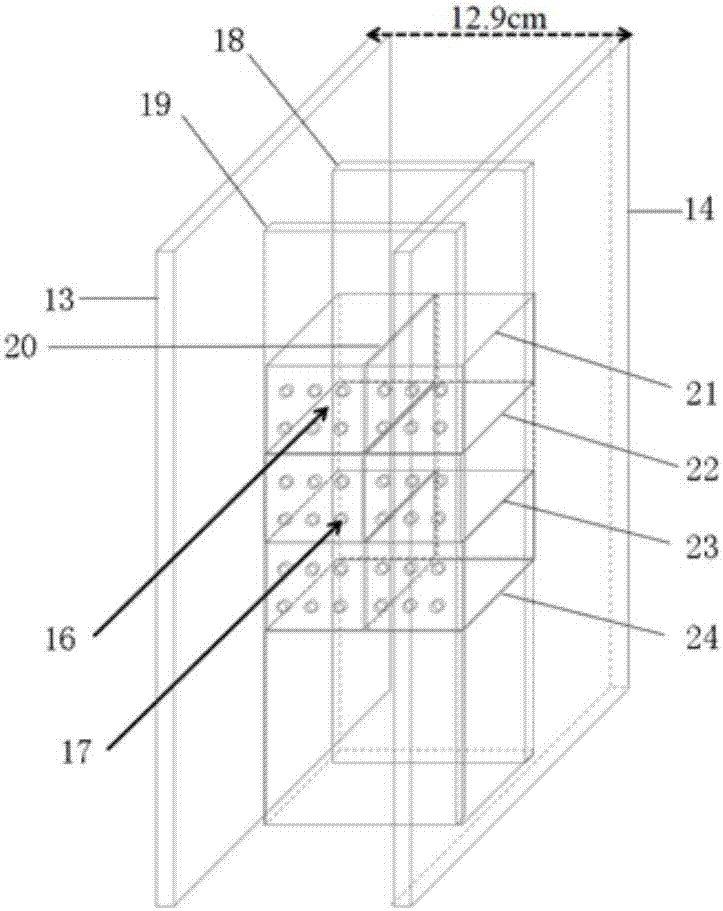

Low-frequency magnetic field generator for cell experiment researches

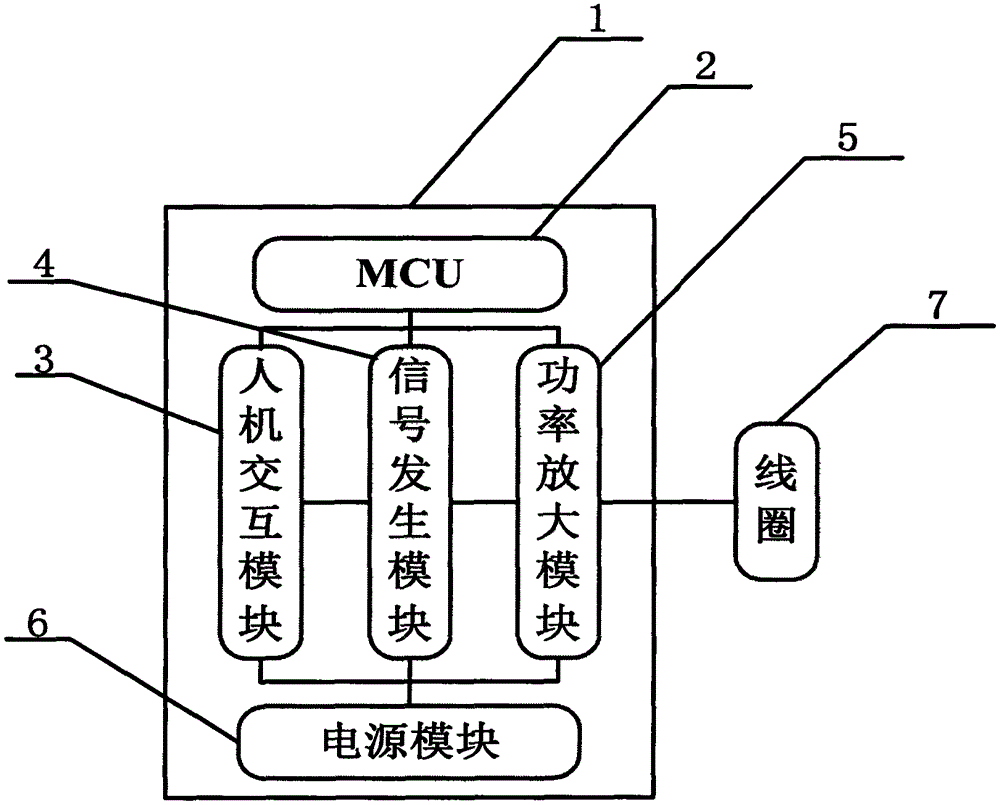

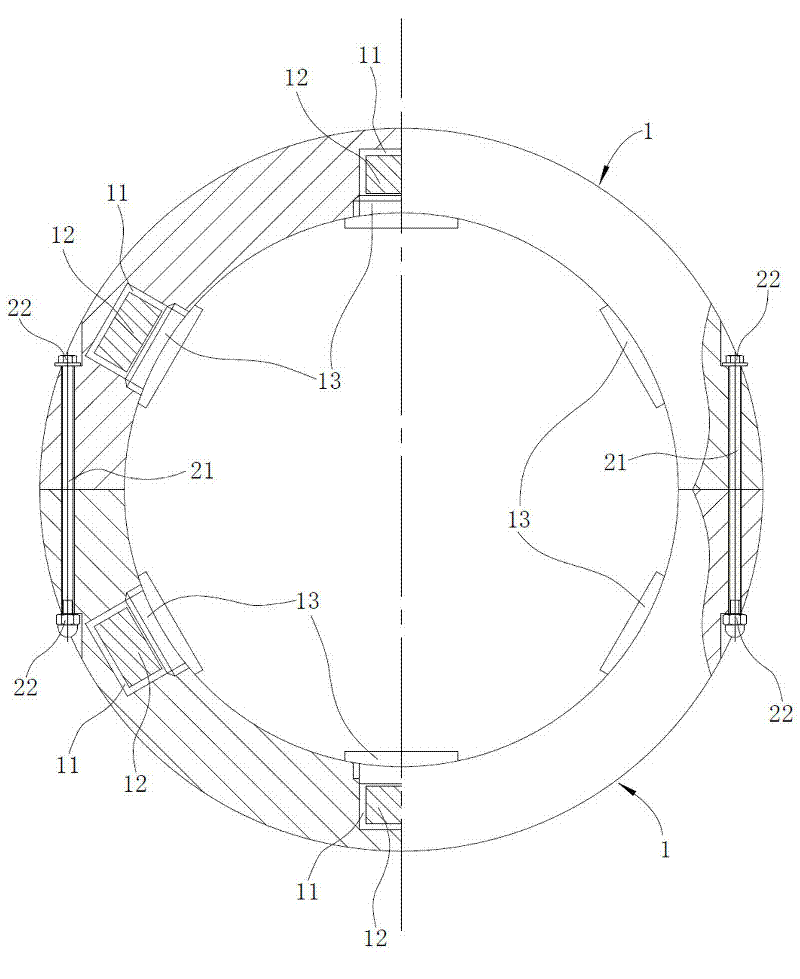

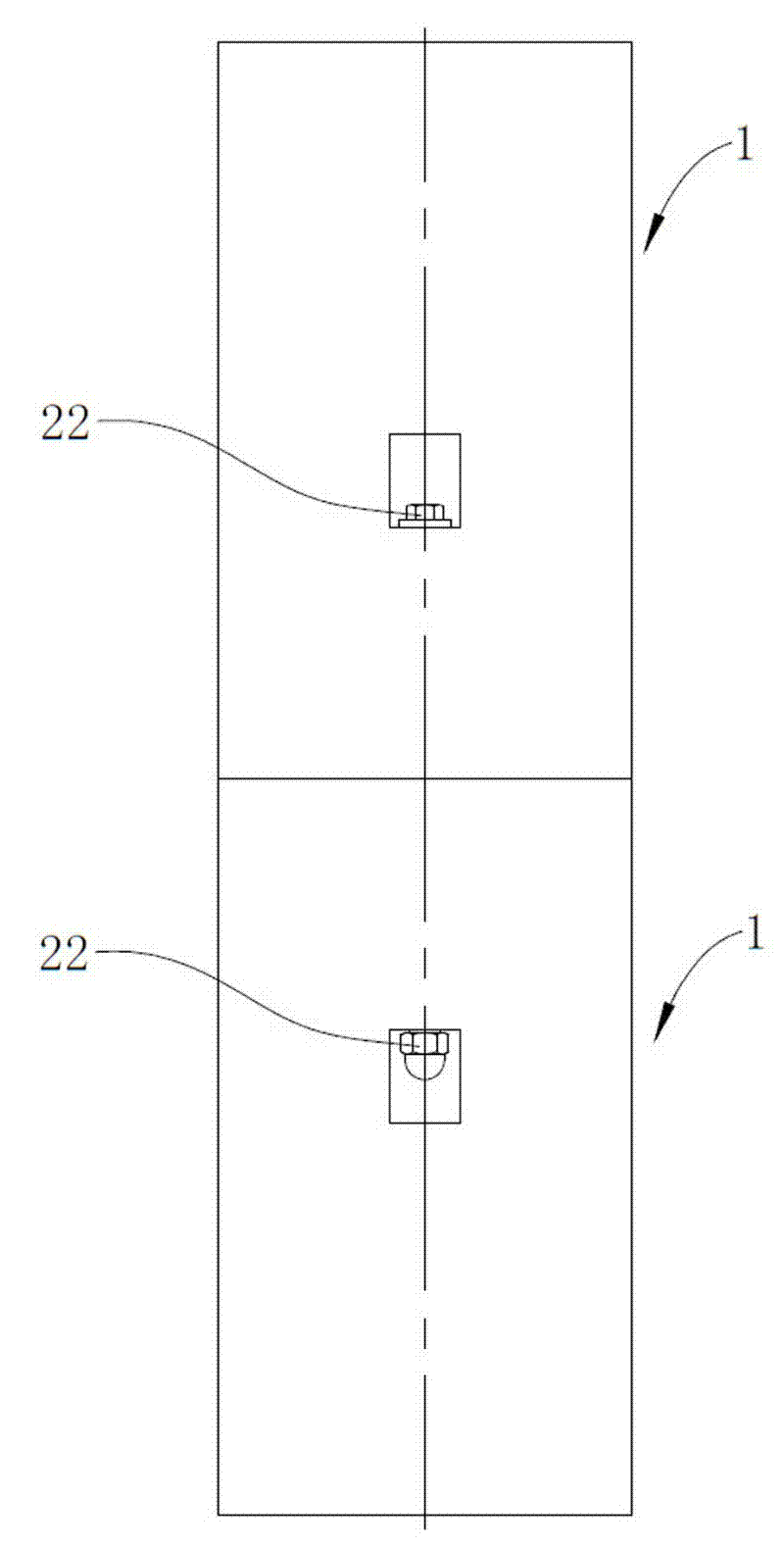

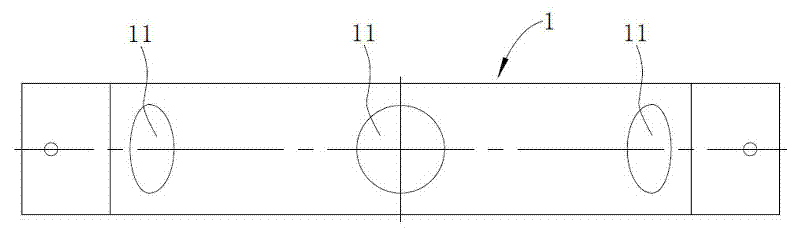

InactiveCN105675855ASimple structureAchieve magnetic stimulationMaterial analysisHuman–computer interactionPatch clamp

The invention relates to a low-frequency magnetic field generator used for cell experiment research. Its basic components include: a magnetic field generator part, a coil part and a patch clamp recording part. The magnetic field generator part mainly includes: MCU, human-computer interaction module, Signal generation module, power amplification module, power supply module, human-computer interaction module to realize the input and display of user commands, MCU as the core to realize the generation of signals and the control of various parameters, etc., the coil is fixed on the patch clamp microscope through a movable plastic arm On the mirror arm, the user selects the waveform, intensity and duty cycle of the signal through the human-computer interaction part, and the single-chip microcomputer controls the signal generation part to output the corresponding signal according to the selected parameters, and then sends it to the power amplifier circuit to output a large current to drive the diaphragm The coil on the clamp generates the magnetic field expected by the user, stimulates and records the electrophysiological properties of the cells through the patch clamp electrodes.

Owner:TIANJIN POLYTECHNIC UNIV

Fluid Magnetic Processor

InactiveCN102267749AFirmly connectedEasy to removeWater/sewage treatment by magnetic/electric fieldsCooling towerNuclear engineering

A fluid magnetic processor, which includes a ring-shaped body formed by butt joints of at least two clamps, and a flexible connection between every two adjacent clamps, and a number of permanent magnetic cores are buried inside each clamp, and the permanent The direction of the magnetic force line of the magnetic core is the radial direction of the ring-shaped body, and the material of the two hoops is a metal material for magnetic shielding. The processor has the advantages of convenient disassembly and assembly on the water delivery pipe and better magnetic treatment effect. Generally, this processor can be directly installed on the fluid inlet of the equipment and / or non-magnetic pipes (such as PE pipes, PPR pipes, stainless steel pipes, etc.) for anti-scale, descale, sterilization, anti-rust , Anticorrosion, etc. The processor can be used alone according to the equipment structure and equipment working conditions, or can be connected in series or combined on the water delivery pipe. The processor has a wide range of applications, including: various industrial cooling water systems that are prone to bacteria, algae and scale; air conditioning, refrigeration circulating water systems; various heat exchange and cooling tower systems; swimming pool systems, etc.

Owner:孙靖坤

Anti-disturbance loudspeaker

ActiveCN110149581AEffective simulationSmall distortionElectrical transducersLoudspeakersEngineeringSound production

The invention relates to an anti-disturbance loudspeaker, which comprises a shell, a permanent magnet ring, a core column, a voice coil, a paper cone and a protective cover. The guide column and the core column are coaxially arranged. Permanent magnet strips are arranged on the cylindrical surface of the guide column at equal intervals. A guide cylinder is connected between the voice coil and thepaper cone, a guide ring is arranged on the inner wall of the guide cylinder, permanent magnets are arranged on the guide ring at equal intervals, and the permanent magnets and the permanent magnets repel each other in a homopolar mode and are matched in position. The guide column also comprises a magnetism isolating ring which is close to the joint of the voice coil and the guide cylinder. The protective cover comprises a plate body and a flexible film, the plate body is arranged at the end of the guide column, and the flexible film is connected between the plate body and the guide cylinder.The loudspeaker is novel in structure and unique in principle, disturbance of parts to vibration of the paper cone can be effectively reduced, the sound production effect of the paper cone is guaranteed, the sound quality of the loudspeaker is effectively improved, and meanwhile the service life of the loudspeaker is prolonged.

Owner:泓硕电子科技(咸宁)有限公司

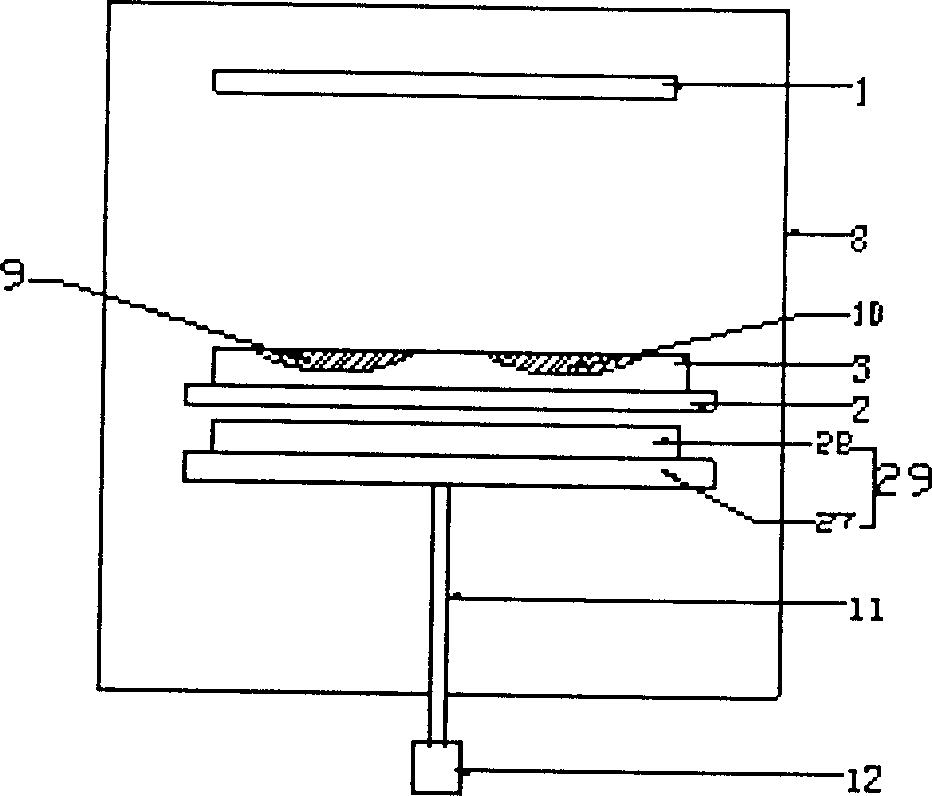

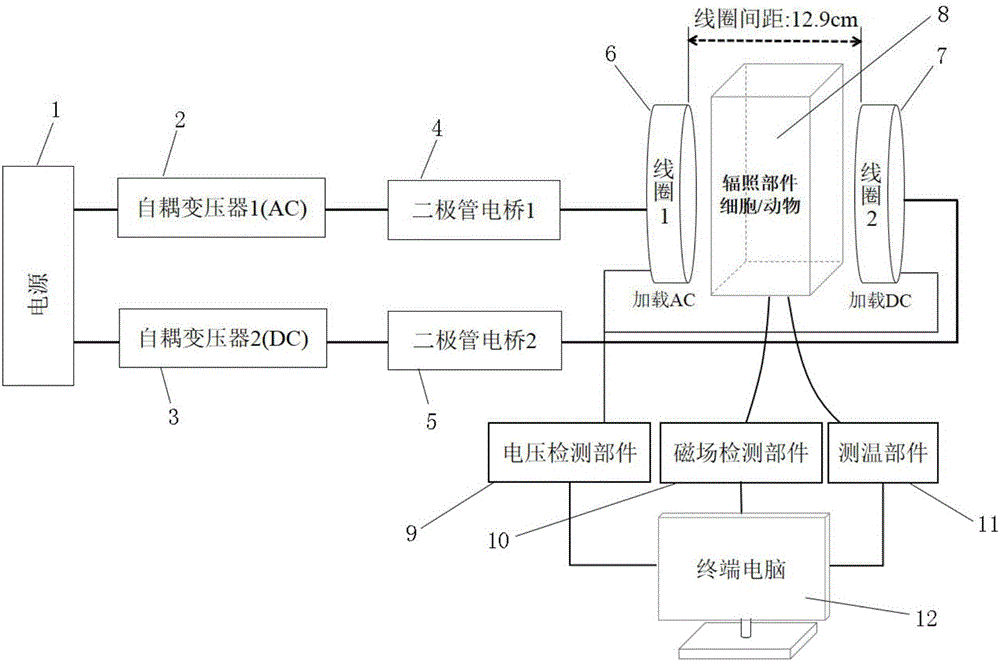

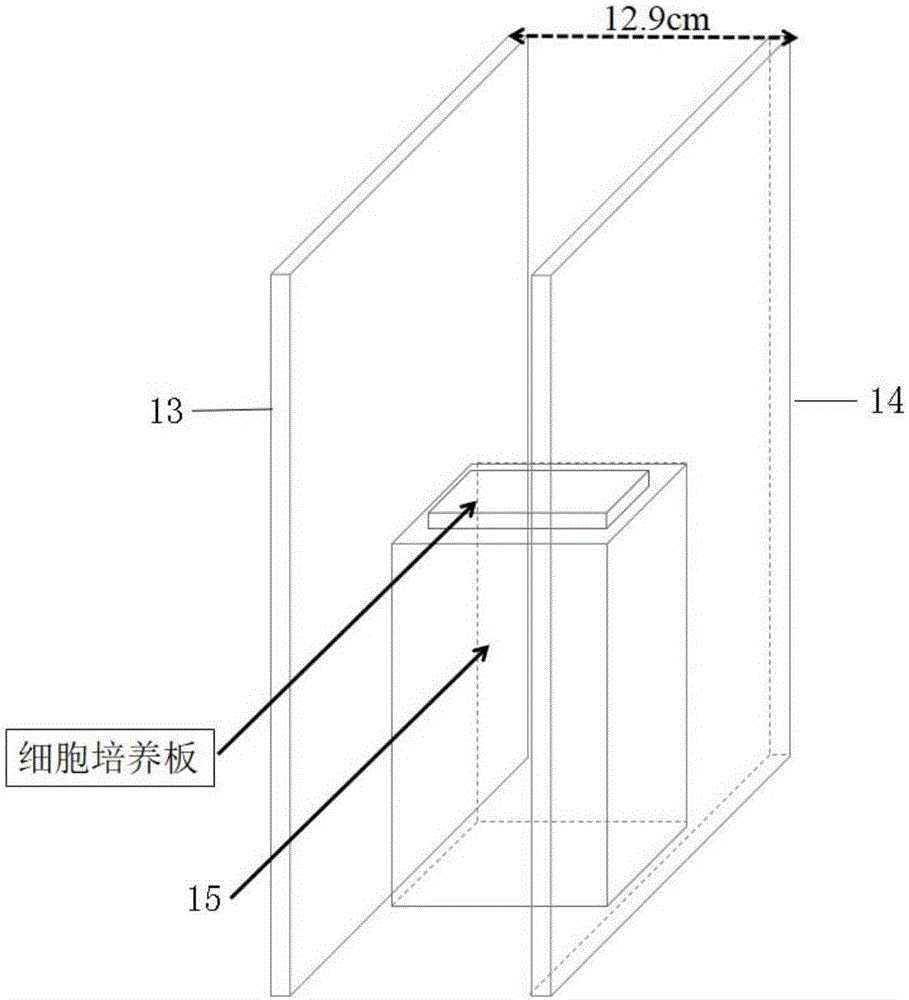

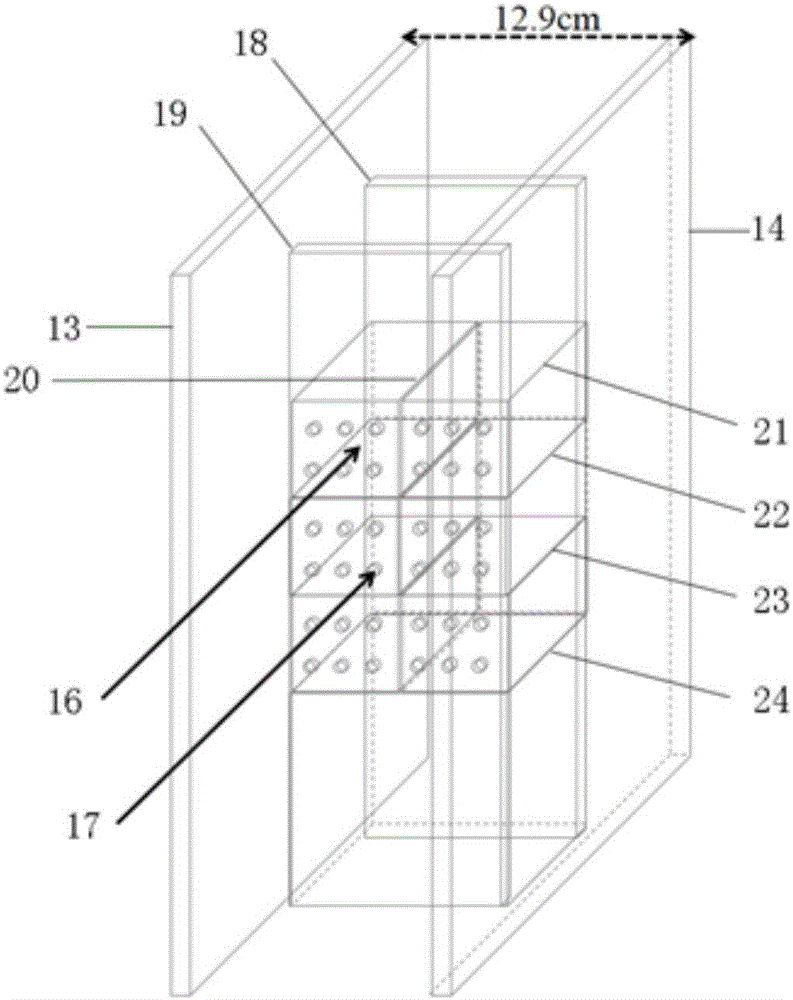

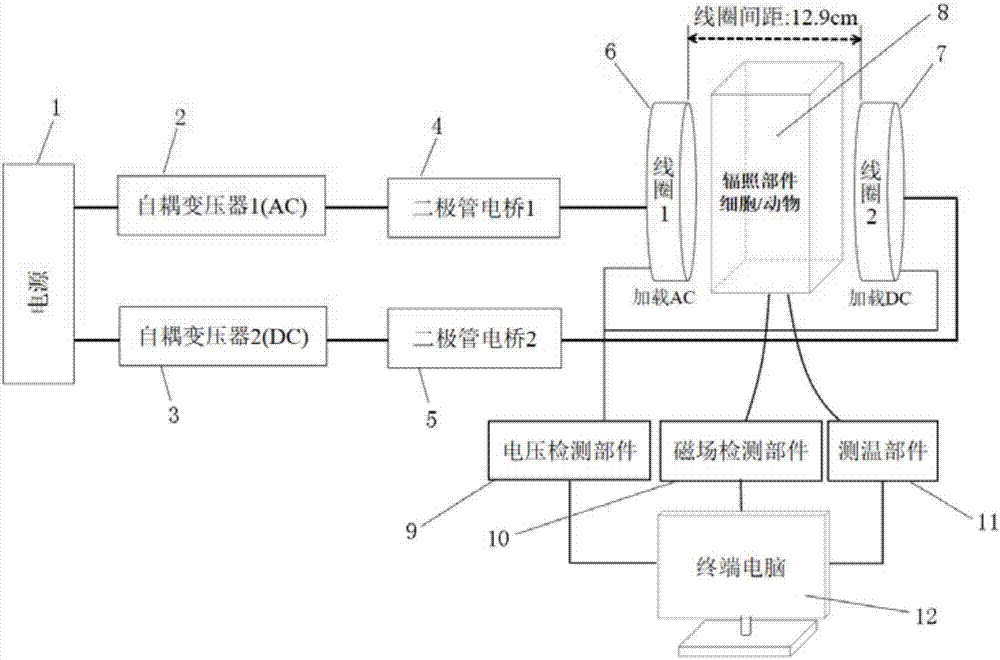

Power frequency electromagnetic field generating device having tumor inhibiting effect and loading method

PendingCN106621050ASignificant inhibitory effect in vitro and in vivoGrowth inhibitionElectrotherapyMagnetotherapy using coils/electromagnetsExtensibilitySide effect

The invention provides a power frequency electromagnetic field generating device having a tumor inhibiting effect. The power frequency electromagnetic field generating device is composed of a power frequency power supply, two auto-transformers, two diode bridges, two groups of coils, a radiation part, a voltage detection part, a magnetic field detection part, a temperature measuring part and a terminal computer. According to the device, on the basis of the power frequency 50 / 60Hz power supply, voltage is continuously changed by virtue of the DC and AC auto-transformers, so that superposed static and alternating electromagnetic fields are generated in the radiation part. A loading method of the electromagnetic fields having the tumor inhibiting effect has a certain extensibility, the frequency is within a range of 30-300Hz, the intensity ratio of the static electromagnetic field to the alternating electromagnetic field is at 0.5-2.5 and total intensity is 1-10mT. The invention provides the special power frequency electromagnetic field generating device and the loading method; the generating device is reasonable in design, capable of acting on organisms, noninvasive and low in toxic and side effects, and the generating device has the obvious inhibiting effect on a plurality of tumors; and due to the action of the magnetic fields, the content of superoxide radicals in cells can be increased, and autophagy is promoted.

Owner:ZHEJIANG UNIV +2

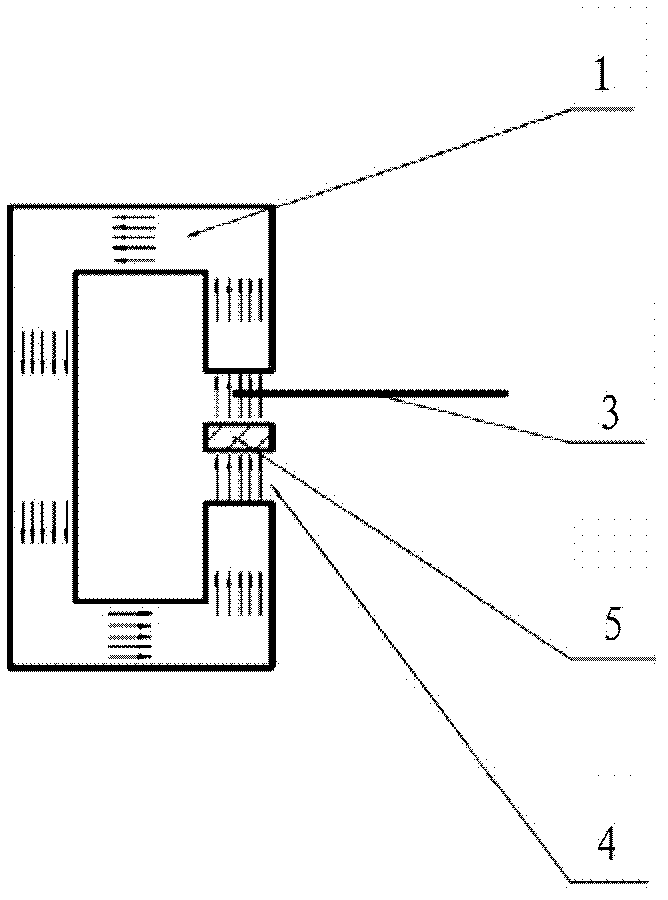

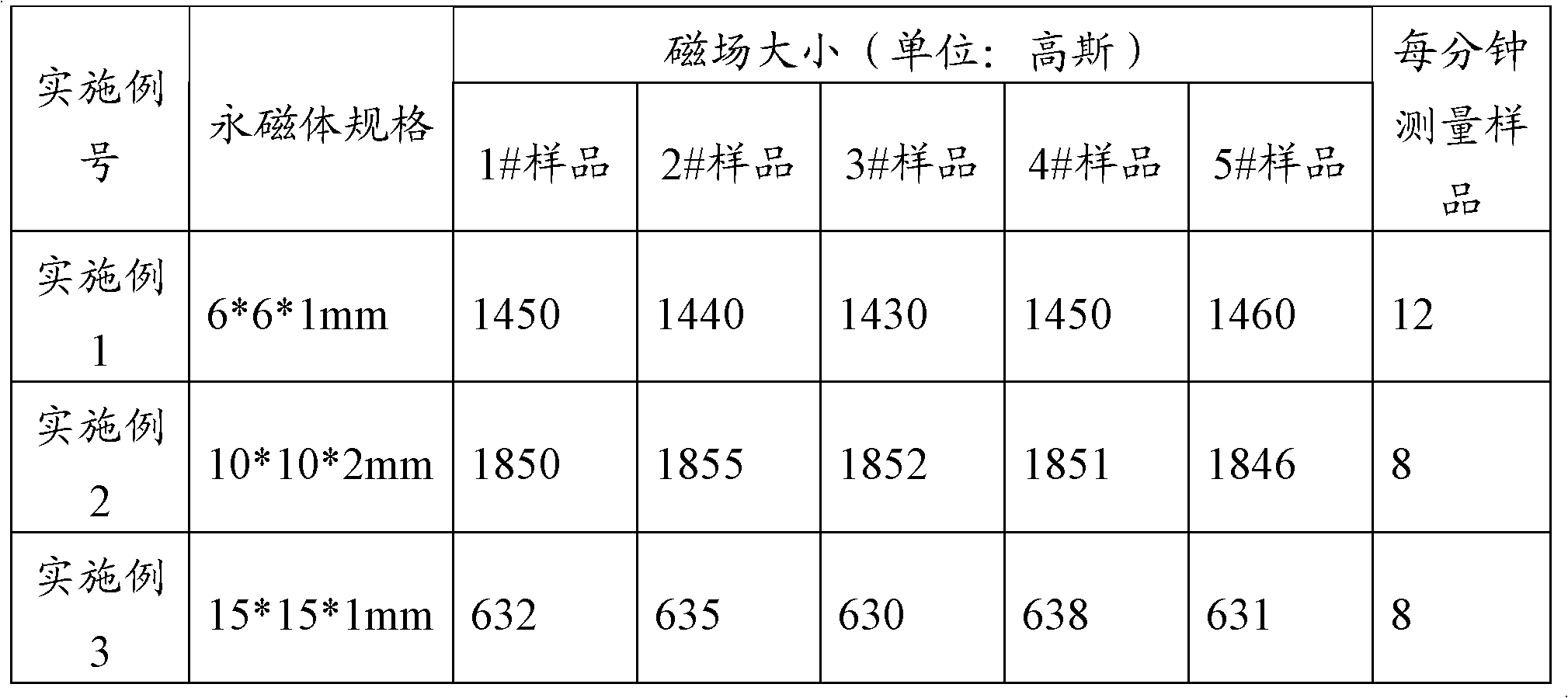

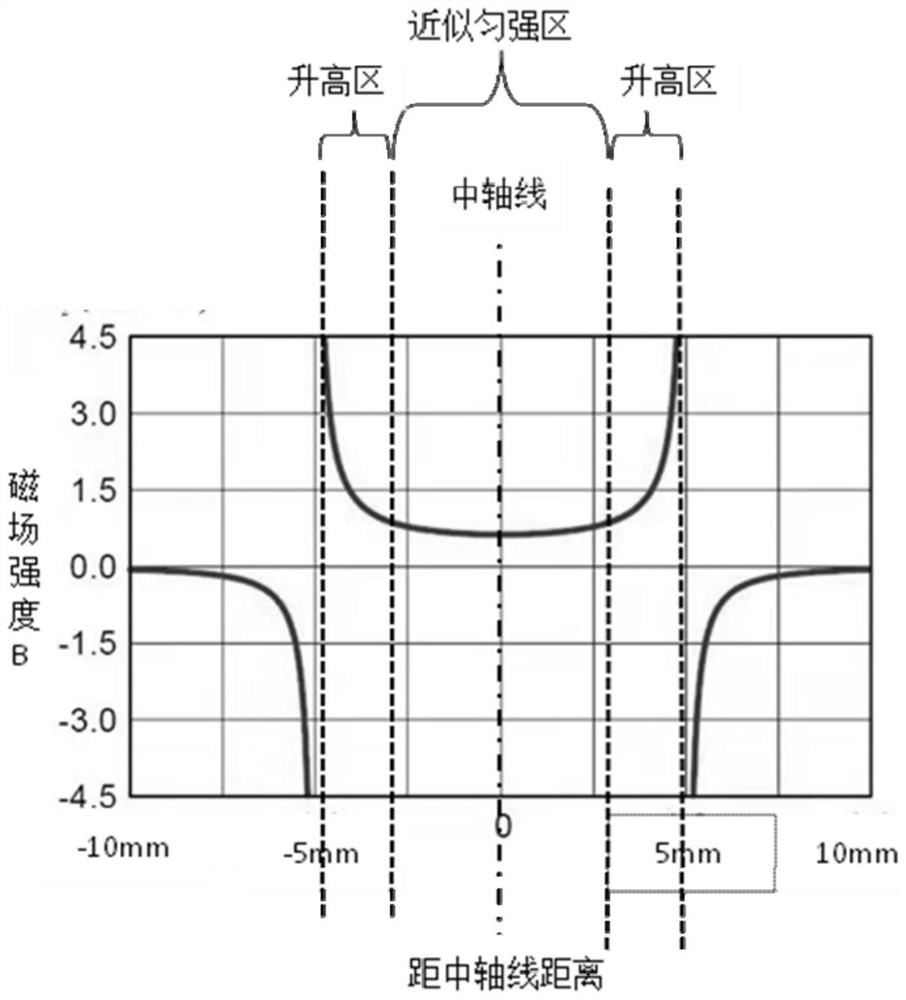

Device and method for detecting surface magnetic field intensity of permanent magnet

InactiveCN102435964AEasy to measureImprove efficiencyMagnetic property measurementsPhysicsMagnetic field magnitude

The invention provides a device and a method for detecting the surface magnetic field intensity of a permanent magnet. The device comprises a C-shaped soft magnetic material part, a conveying track and a Hall probe, wherein the permanent magnet is conveyed to an opening of the C-shaped soft magnetic material part through the conveying track; and the Hall probe is arranged in an air gap which is formed between the detected permanent magnet and the C-shaped soft magnetic material part. The method comprises the following steps of: placing the permanent magnet at the opening of the C-shaped soft magnetic material part to form the air gap between the permanent magnet and the C-shaped soft magnetic material part; and forming a uniform magnetic field in the air gap, and measuring the intensity of the magnetic field by using the Hall probe. By adoption of the device and the method, the surface magnetic field intensity of the permanent magnet can be conveniently and quickly measured, and measurement data is approximate to the actual operating state of the permanent magnet. The invention has the advantages of convenience for measurement, high efficiency and high accuracy, and can be applied to detection of the magnetic induction intensity of batched products.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

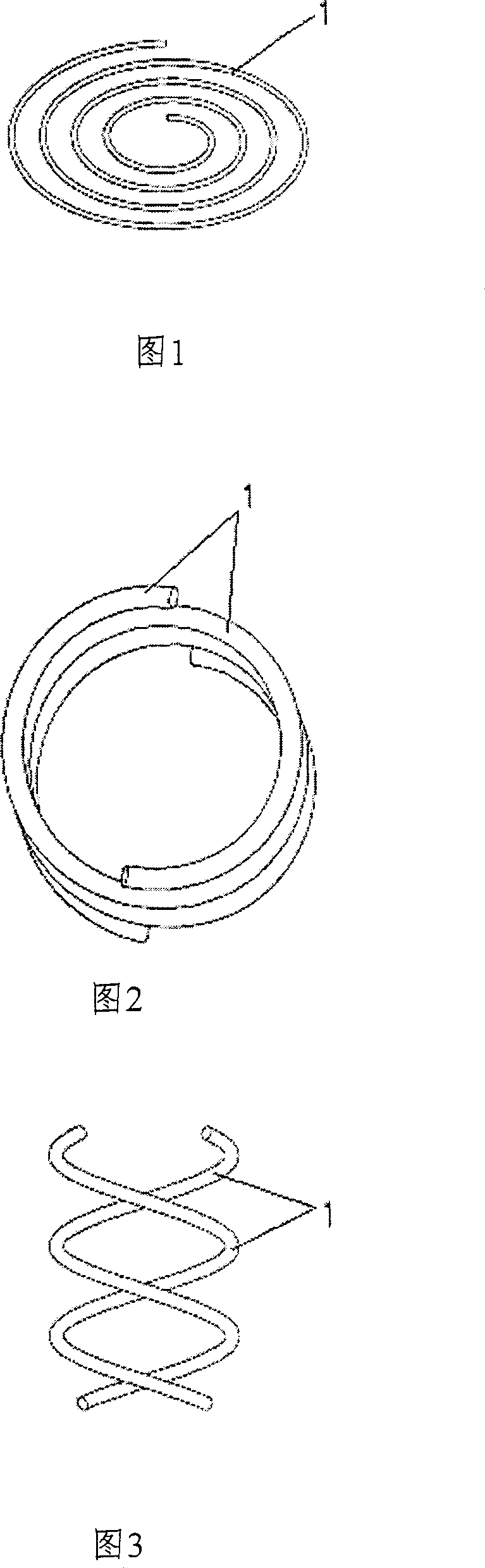

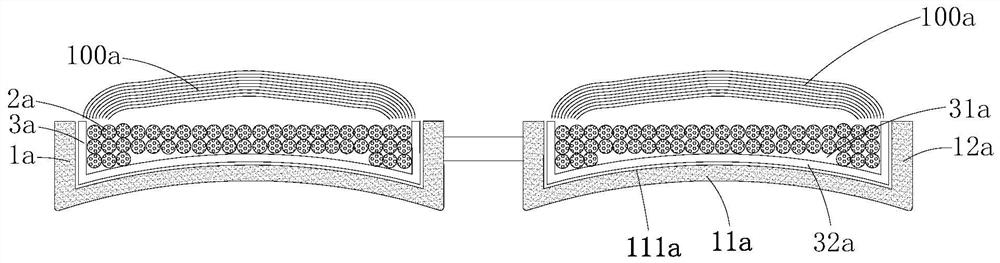

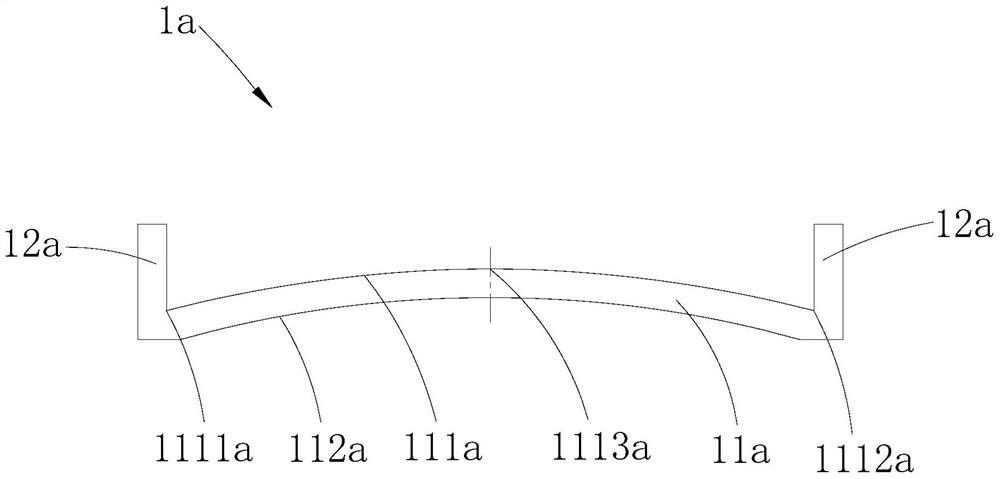

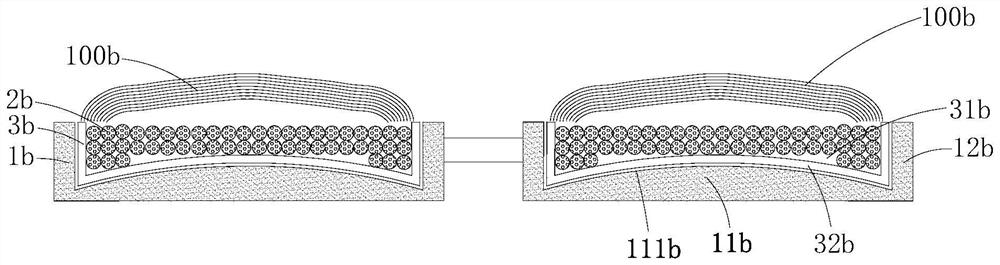

Electromagnetic heating type aerosol delivery appliance and magnetic particle uniform heating type aerosol delivery system

PendingCN113995175AUniform electromagnetic heatingUniform magnetic fieldCigar manufactureMagnetic heatingEngineering

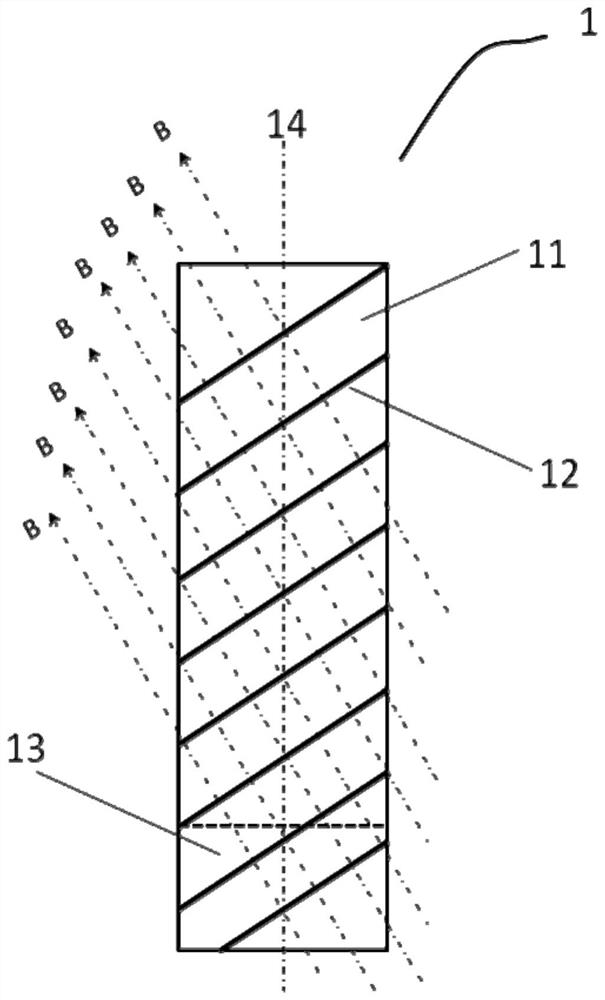

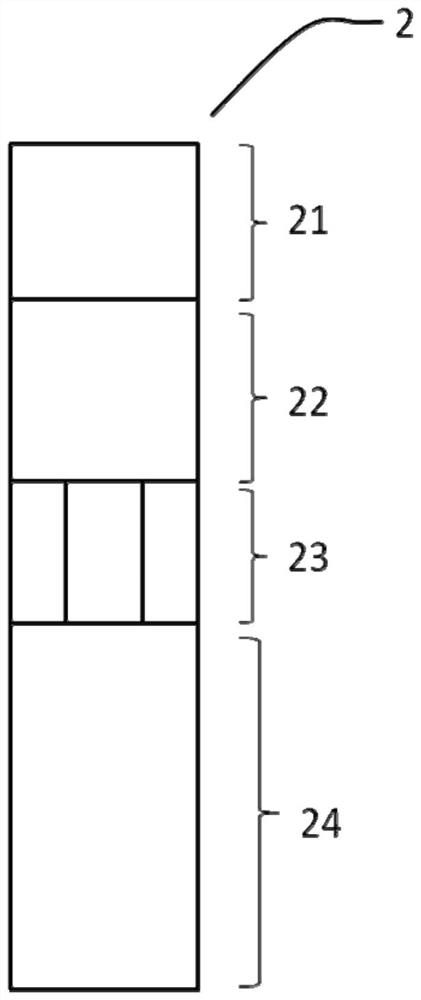

The invention discloses an electromagnetic heating type aerosol delivery appliance, which comprises a cylindrical aerosol generating product containing cavity (1) and a magnet exciting coil (2) surrounding the outer wall of the containing cavity, and the included angle between a winding wire of the magnet exciting coil (2) and the central axis of the aerosol generating product containing cavity (1) is 20-70 degrees. According to the invention, a coil inclined winding mode is adopted, compared with a coil vertical winding mode, the magnetic field intensity in the aerosol generating product containing cavity can be more uniform, the electromagnetic heating type aerosol delivery appliance is particularly suitable for being used in cooperation with a magnetic particle uniform heating type aerosol generating product, and more uniform electromagnetic heating is achieved.

Owner:CHINA TOBACCO YUNNAN IND

Quasi-ideal iron core and electromagnetic conversion device using same

InactiveCN103680839ALow magnetic saturationLow Electromagnetic Conversion EfficiencyTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresForce linesSuperconducting Coils

The invention relates to a quasi-ideal iron core, an electromagnetic conversion device using the same, and a method for producing the iron core and relates to the technical field of electromagnetism. Iron cores in prior art are of rectangular or annular frame structures, iron yoke portions coat coils or coils are bared in external space, magnetic leakage and electromagnetic vortex are large, the magnetic saturation value is low, and electromagnetic conversion efficiency is low. The quasi-ideal iron core is an equal magnetic flux section three-dimensional axisymmetric body or rotation body, an iron yoke coats and surrounds a coil without an air gap, a magnetic circuit is in smooth transition, and all magnetic force lines generated by the coil are directly incorporated into magnetic flux of the iron core, so that magnetic leakage and electromagnetic vortex of the iron core are furthest reduced, electromagnetic conversion efficiency and magnetic saturation values are high, high magnetic field intensity can be achieved by matching a superconducting coil with the iron core, and meanwhile, a production process for the equal magnetic flux section air-gap-free quasi-ideal iron core is disclosed; the iron core can be widely applied to occasions where equal electromagnetism generated by general and ultra-strong magnetic fields is converted.

Owner:杜臣

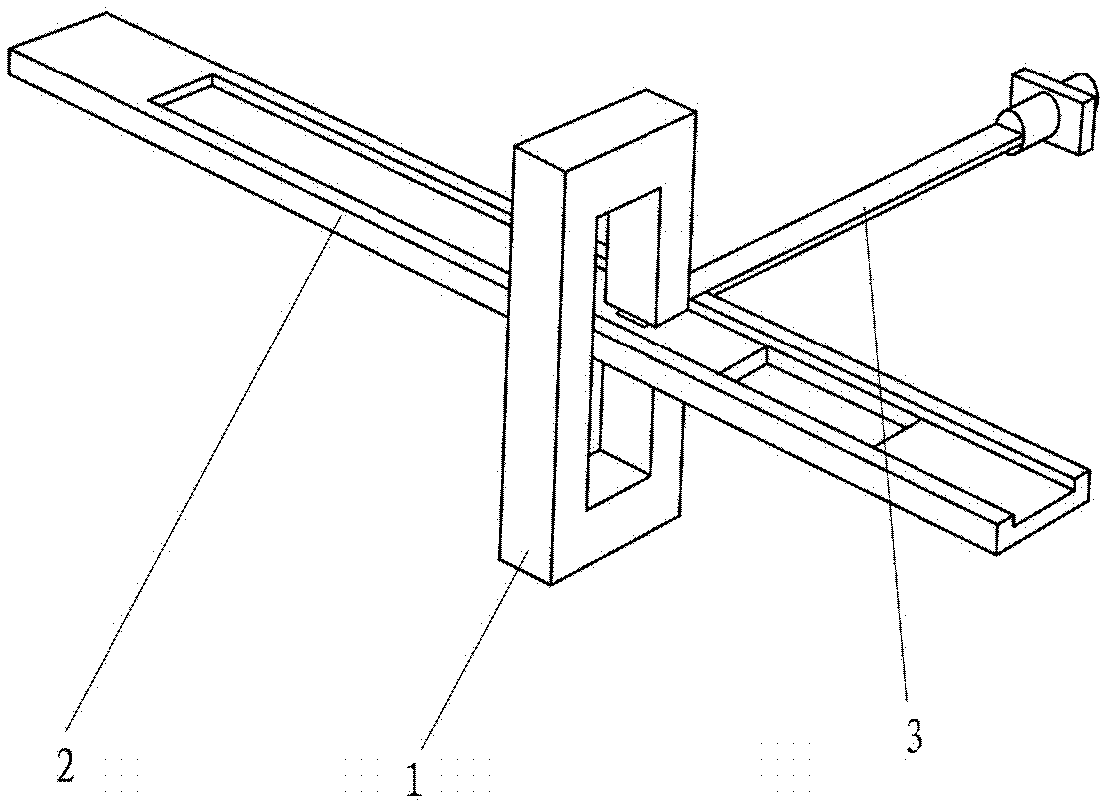

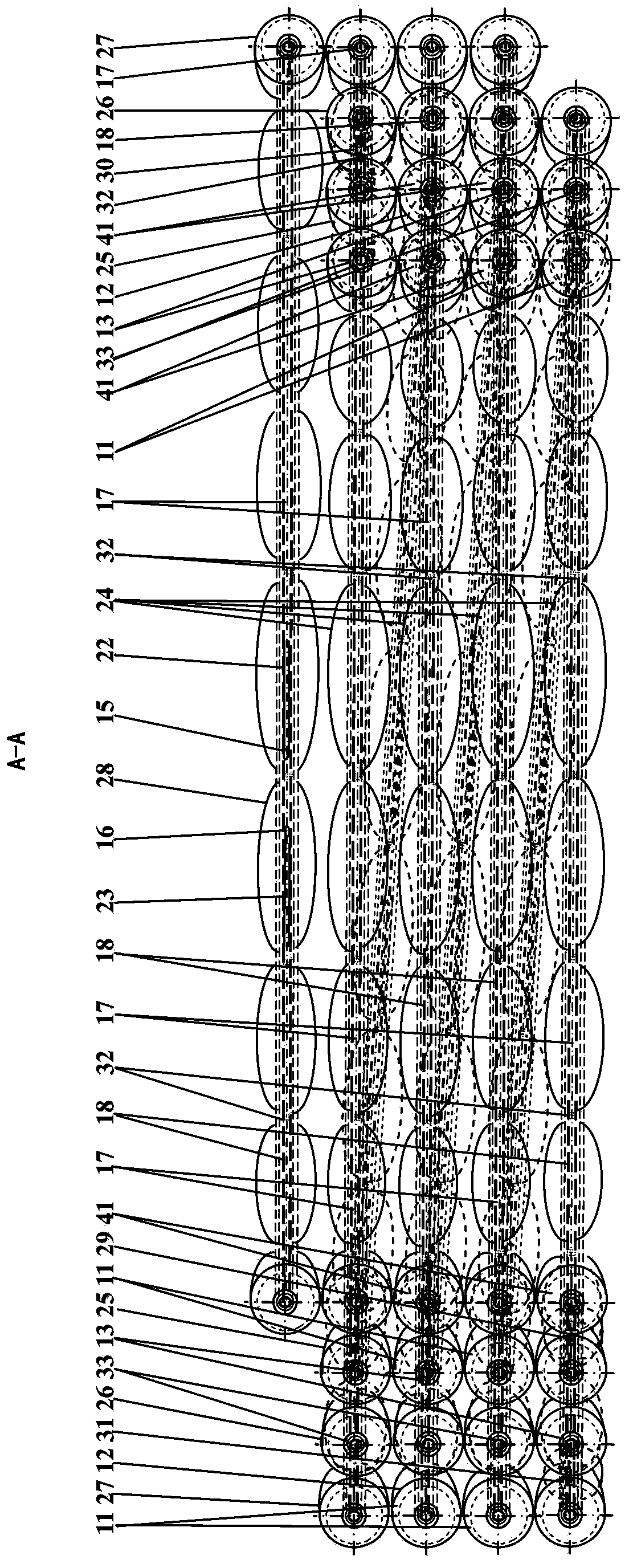

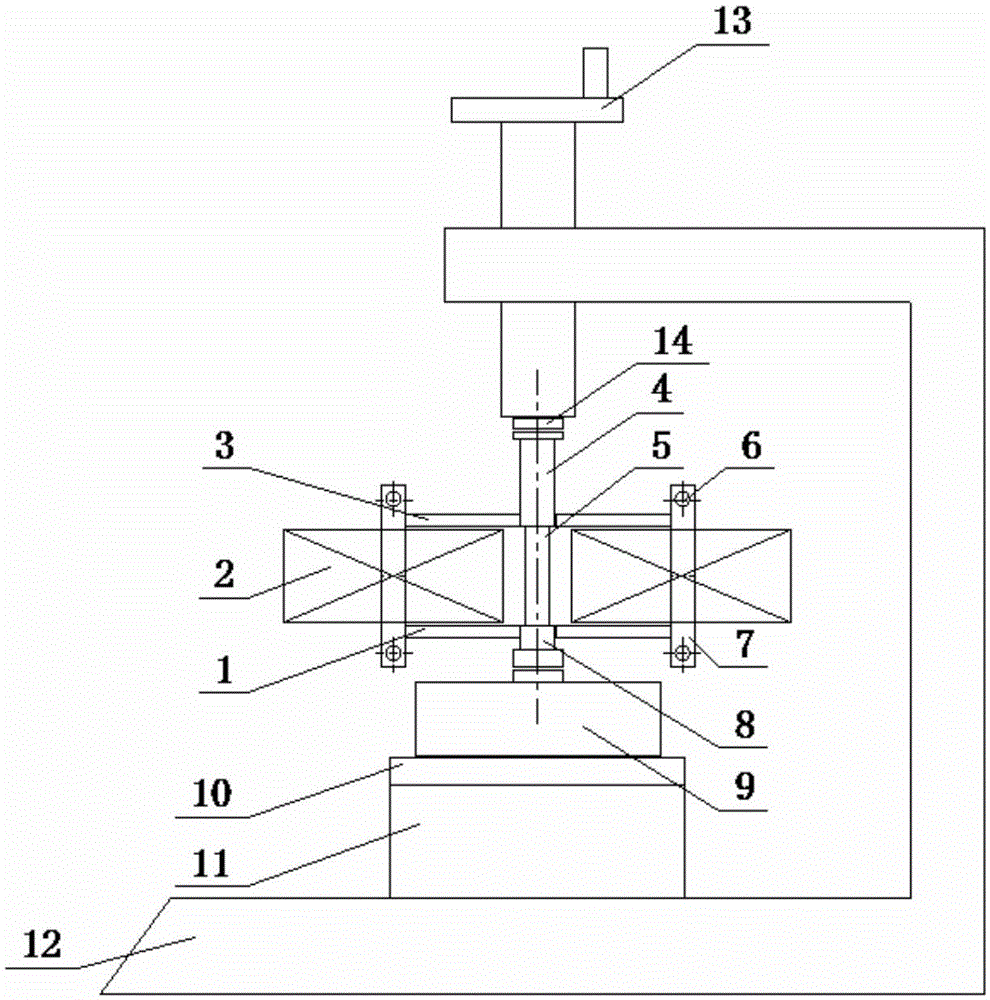

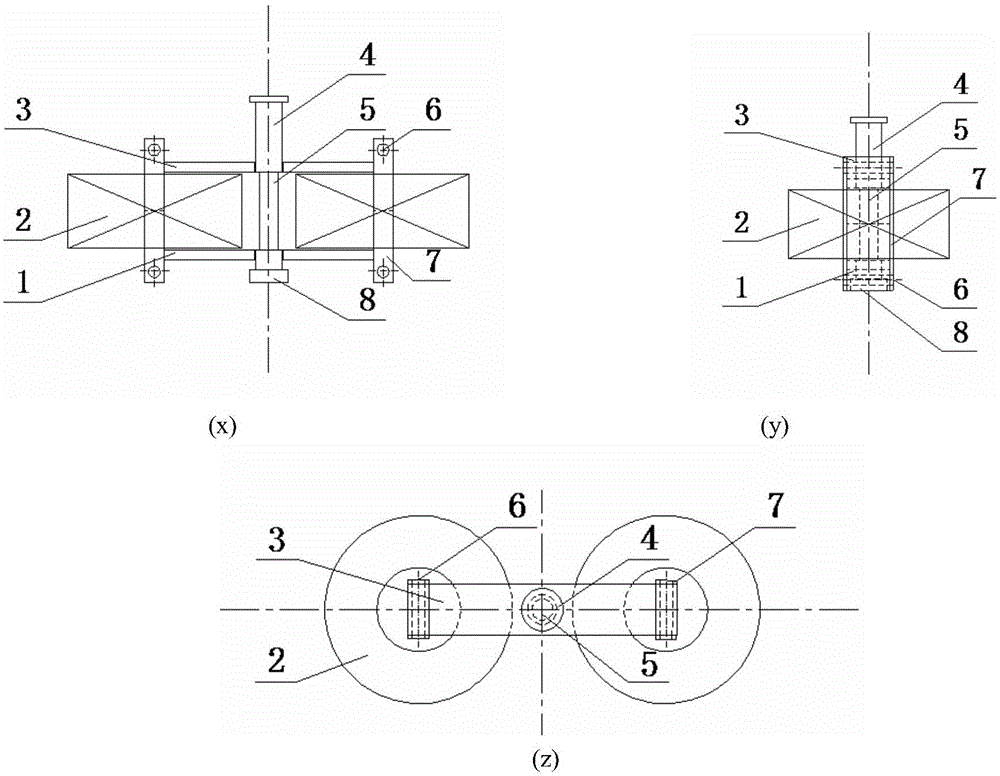

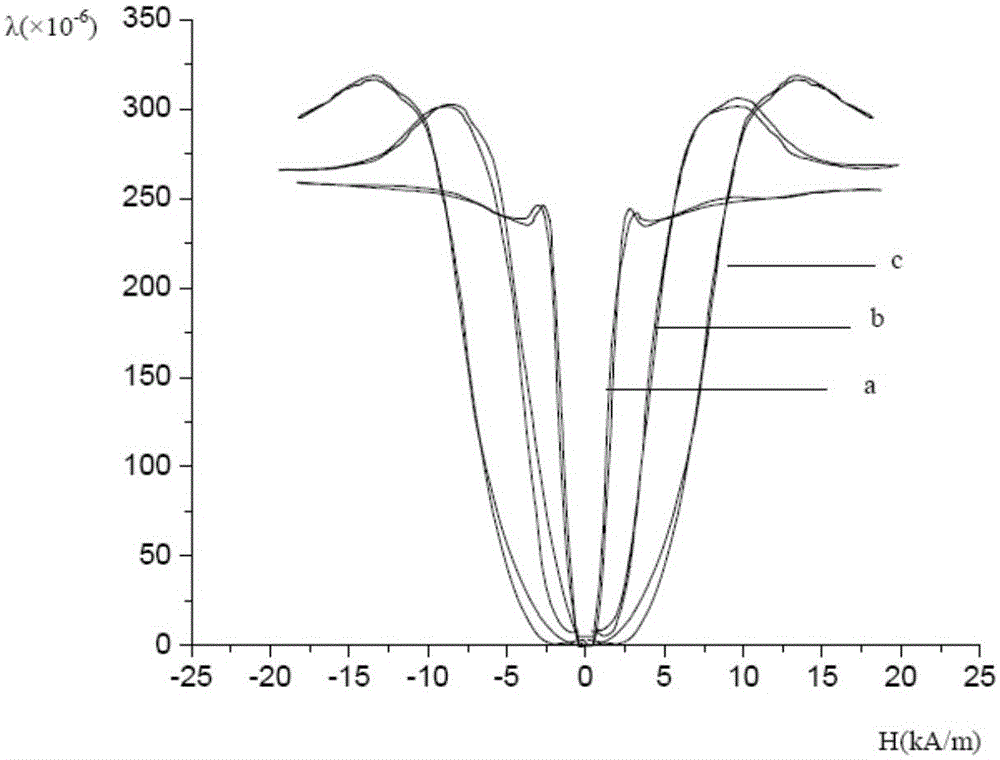

A magnetostrictive material magnetic characteristic tester

ActiveCN103558569BUniform magnetic field strengthEasy to operateMagnetostrictive property measurementsInverse magnetostrictive effectTester device

The invention relates to a tester for the magnetic property of a magnetostriction material. The tester comprises a main measurement component, a standard force sensor, a stress applying device and a permanent magnet. The main measurement component is composed of an upper loop module, a lower loop module, an upper pole head, a lower pole head, a left exciting coil, a right exciting coil and the magnetostriction material to be tested. The overall structure of the main measurement component is in bilateral symmetry. Through the application of the main measurement component and the stress applying device, the device can test the property of the positive magnetostriction effect and the property of the converse magnetostriction effect, can carry out a magnetic property test under the condition of dynamic excitation, and is simple in structure and high in flexibility.

Owner:HEBEI UNIV OF TECH

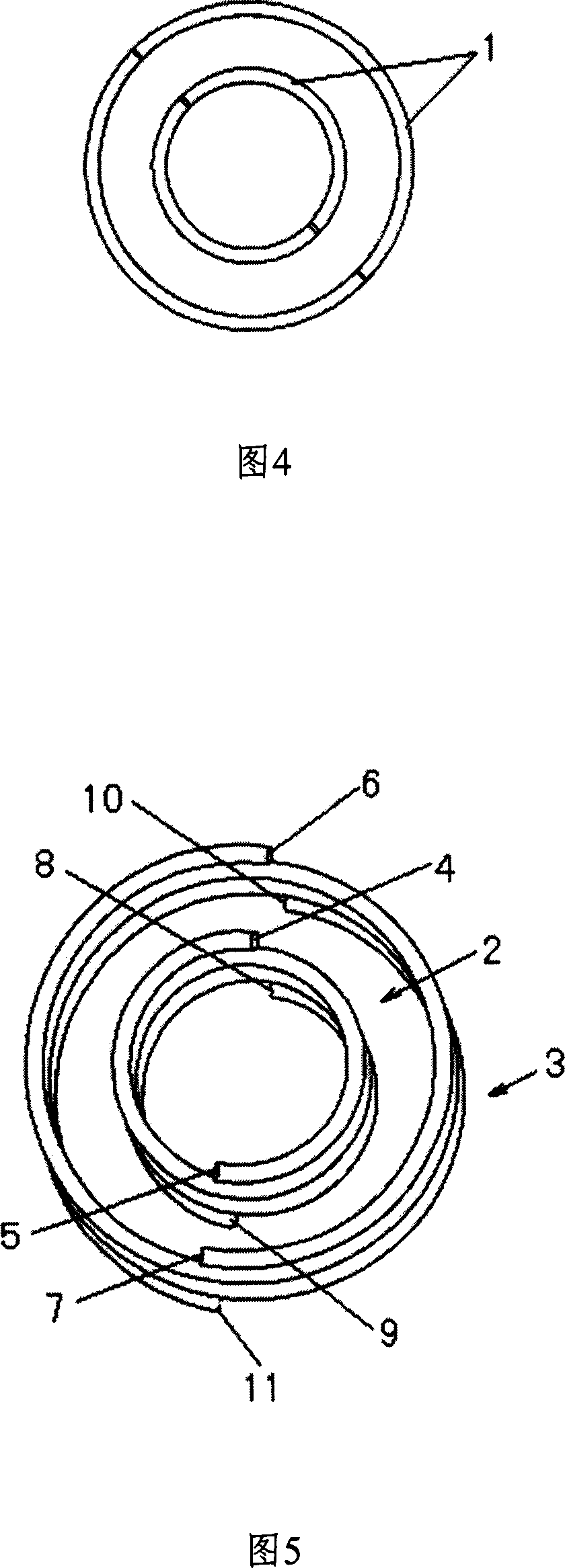

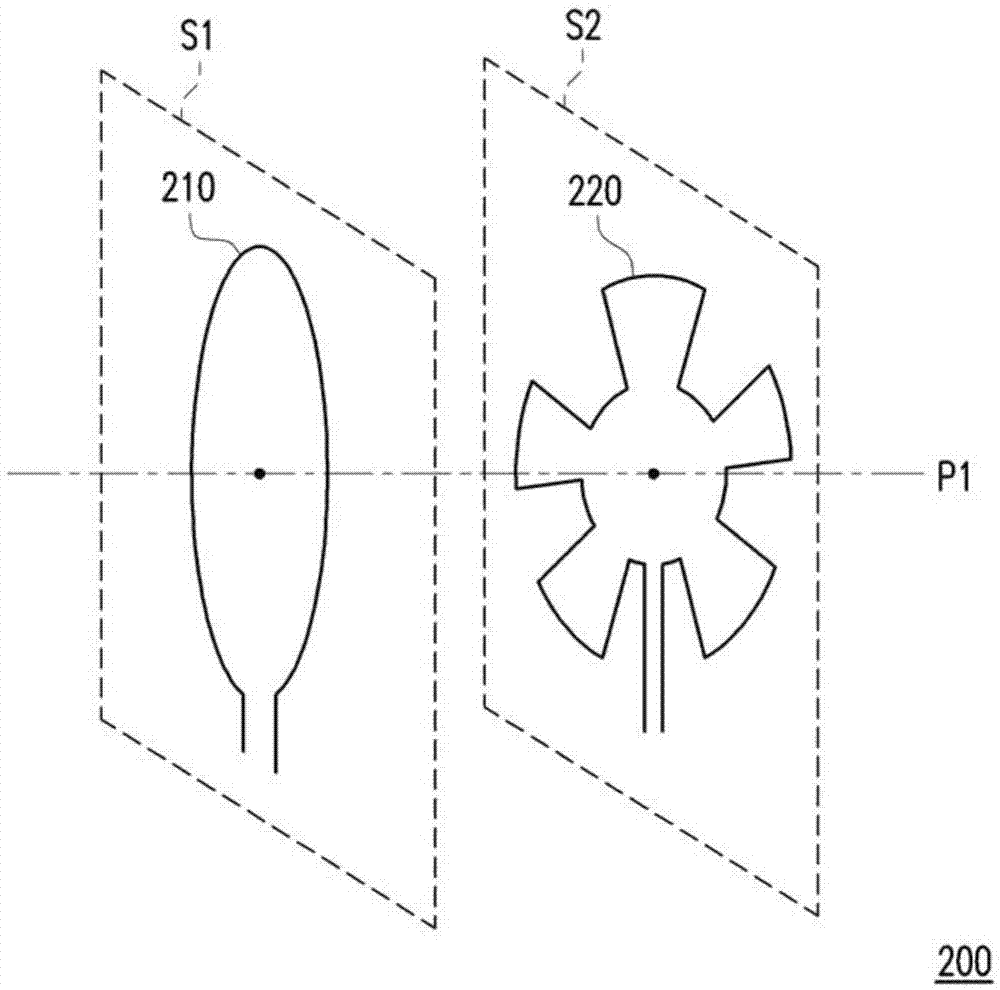

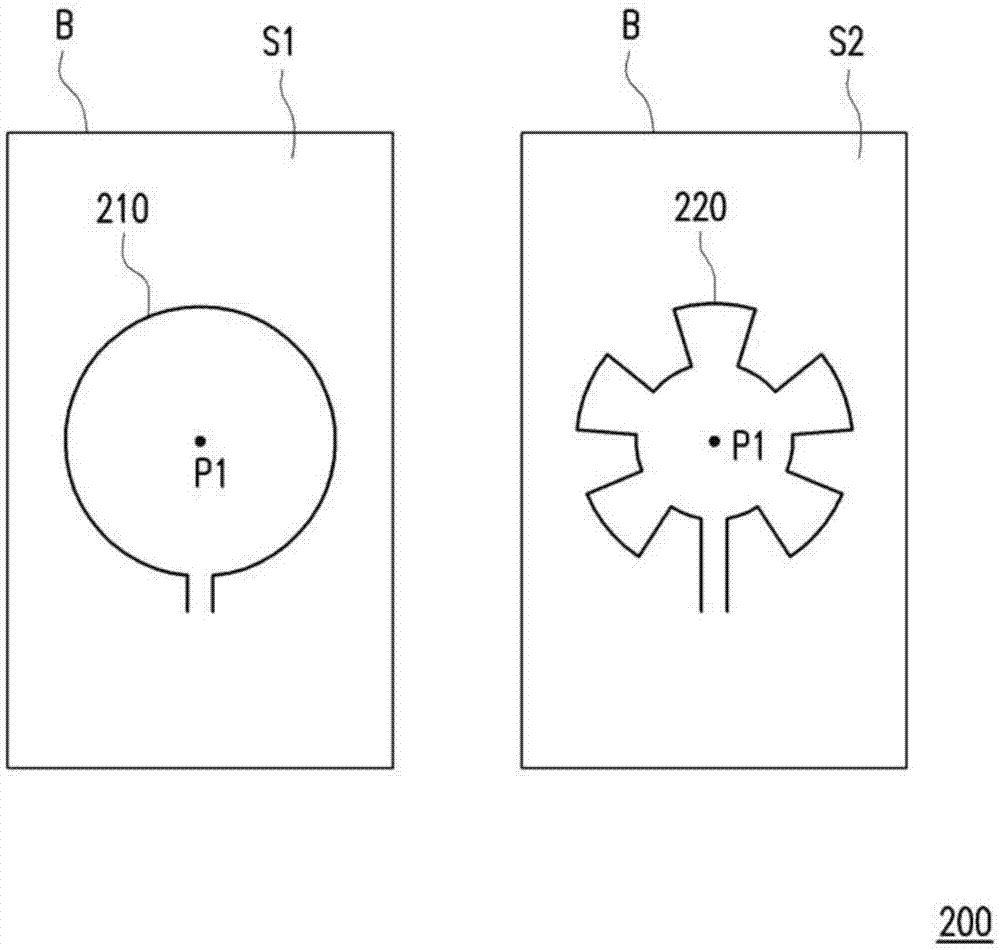

Coil assembly and wireless power transmission system

InactiveCN106899087AImprove transmission efficiencyUniform magnetic field strengthTransformersCircuit arrangementsElectric power transmissionSingle loop

A coil assembly and a wireless power transmission system are provided. The coil assembly includes a first coil and a second coil. The first coil is disposed on a first plane. The second coil is disposed on a second plane. The second coil is coupled to the first coil. The second coil includes a plurality of bending section, and the bending sections are connected by a plurality of connection lines to form a single loop.

Owner:IND TECH RES INST

Method for combining power-frequency electromagnetic field generating device with platinum-based drugs

InactiveCN106902464AImprove anti-tumor effectReduce distractionsHeavy metal active ingredientsElectrotherapySide effectCombined method

The invention provides a method for combining a power-frequency electromagnetic field generating device with platinum-based drugs. A power-frequency electromagnetic field generating device is constructed and a power supply with a power frequency is 50 / 60Hz is employed; voltages are changed continuously by direct-current and an alternating-current autotransformers, so that within a superimposed static and alternating electromagnetic field is generated inside an irradiation component and the average loaded magnetic field intensity is 5.5 milli tesla; the total irradiation time of an irradiated object on the irradiation component each day is 60 to 120 mins; and platinum-based drugs are applied on the irradiated object on the irradiation component. The device is designed reasonably; with a unique power frequency and simultaneous loading of static and alternating electromagnetic fields, the intensity of the magnetic field generated by the device is uniform, the height is controllable, and implementation becomes convenient. The interference on the irradiated object is low and no trauma is caused. Experiments in vivo and vitro demonstrates that curative effects of independent usage of the platinum-based chemotherapeutic drug and the magnetic field can be enhanced and several kinds of tumours can be suppressed obviously based on combined usage of the oncotherapy electromagnetic field and the platinum-based chemotherapeutic drug; the dosage of cis-platinum can be reduced; and the toxic and side effects can be reduced.

Owner:ZHEJIANG UNIV +2

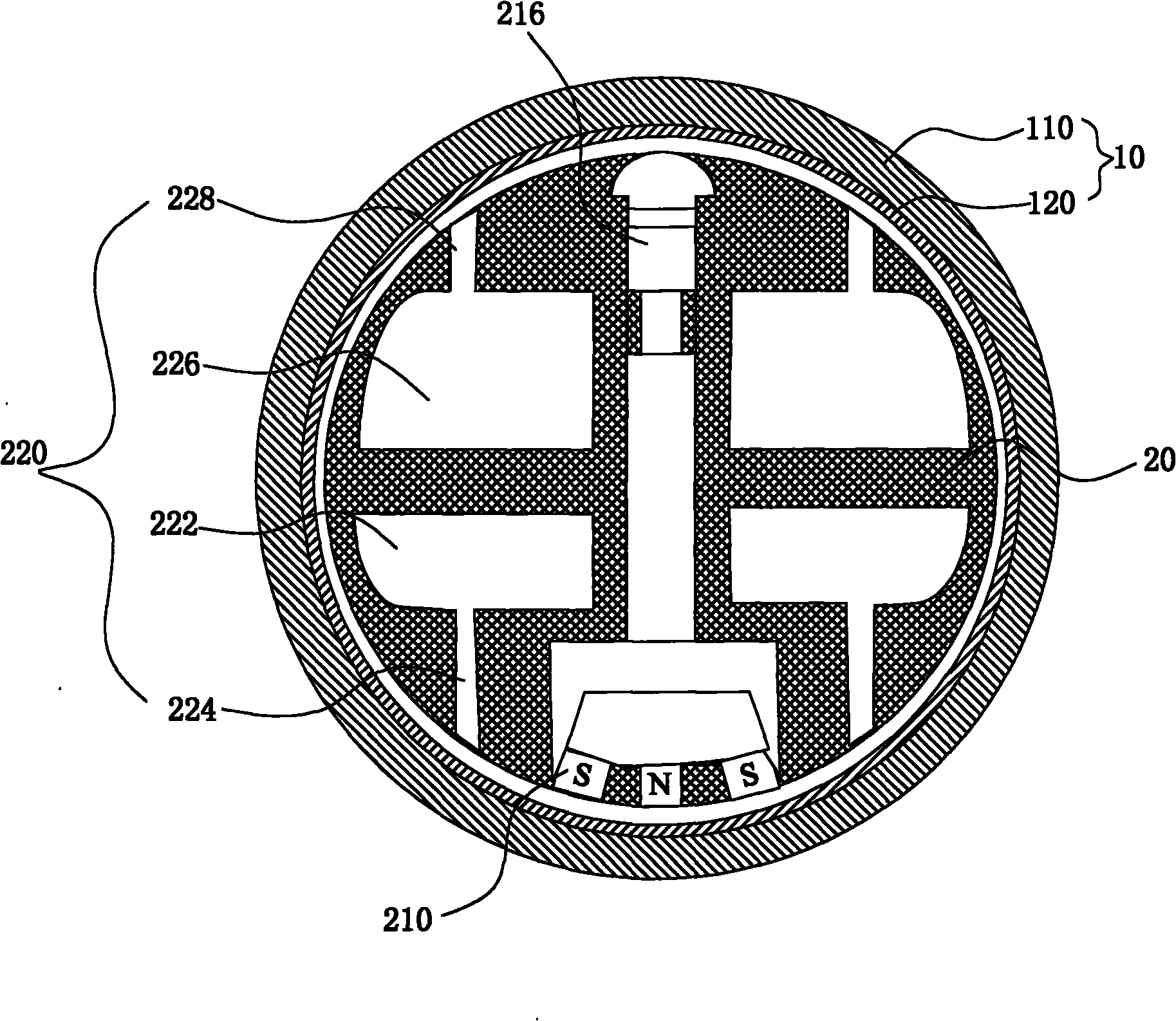

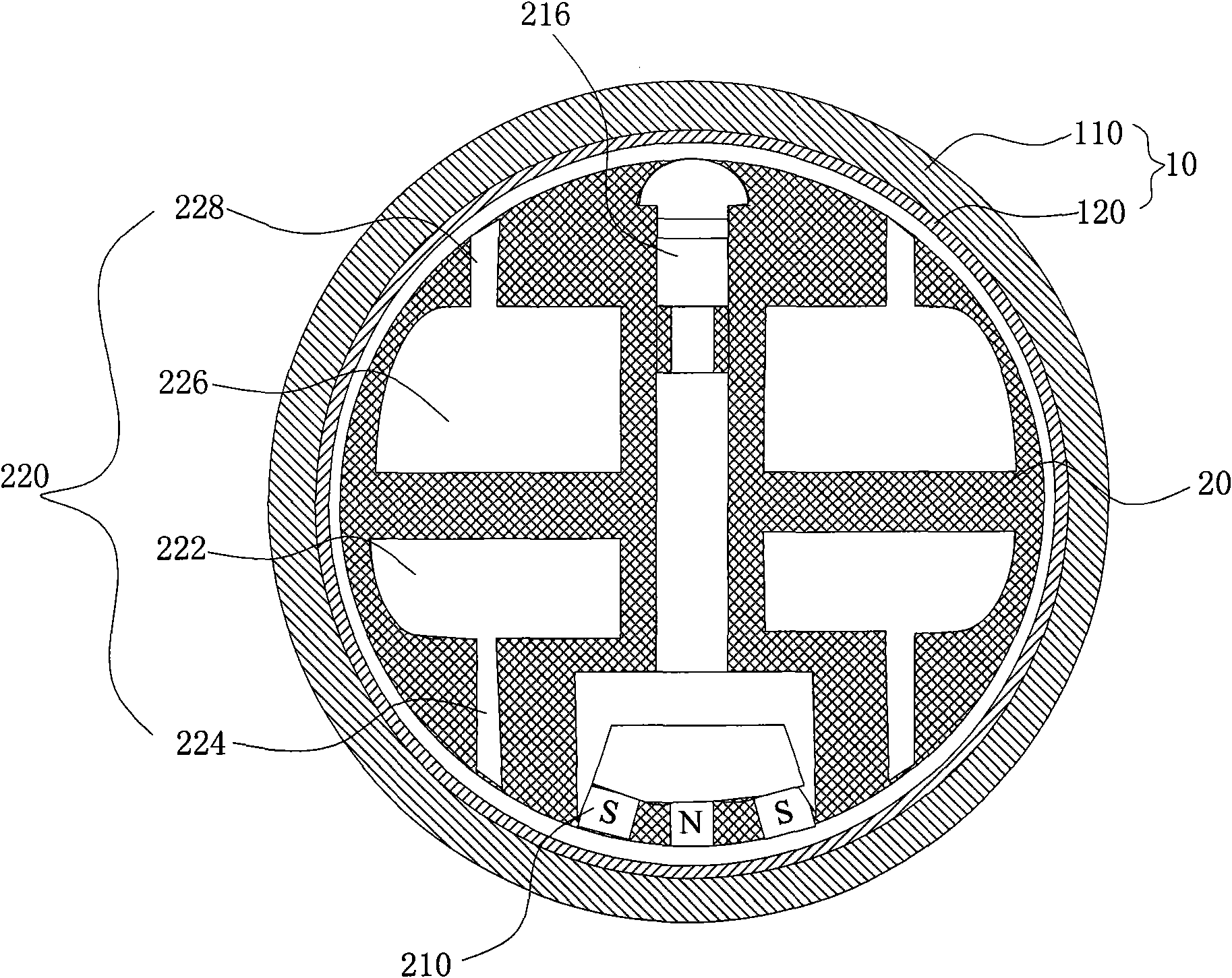

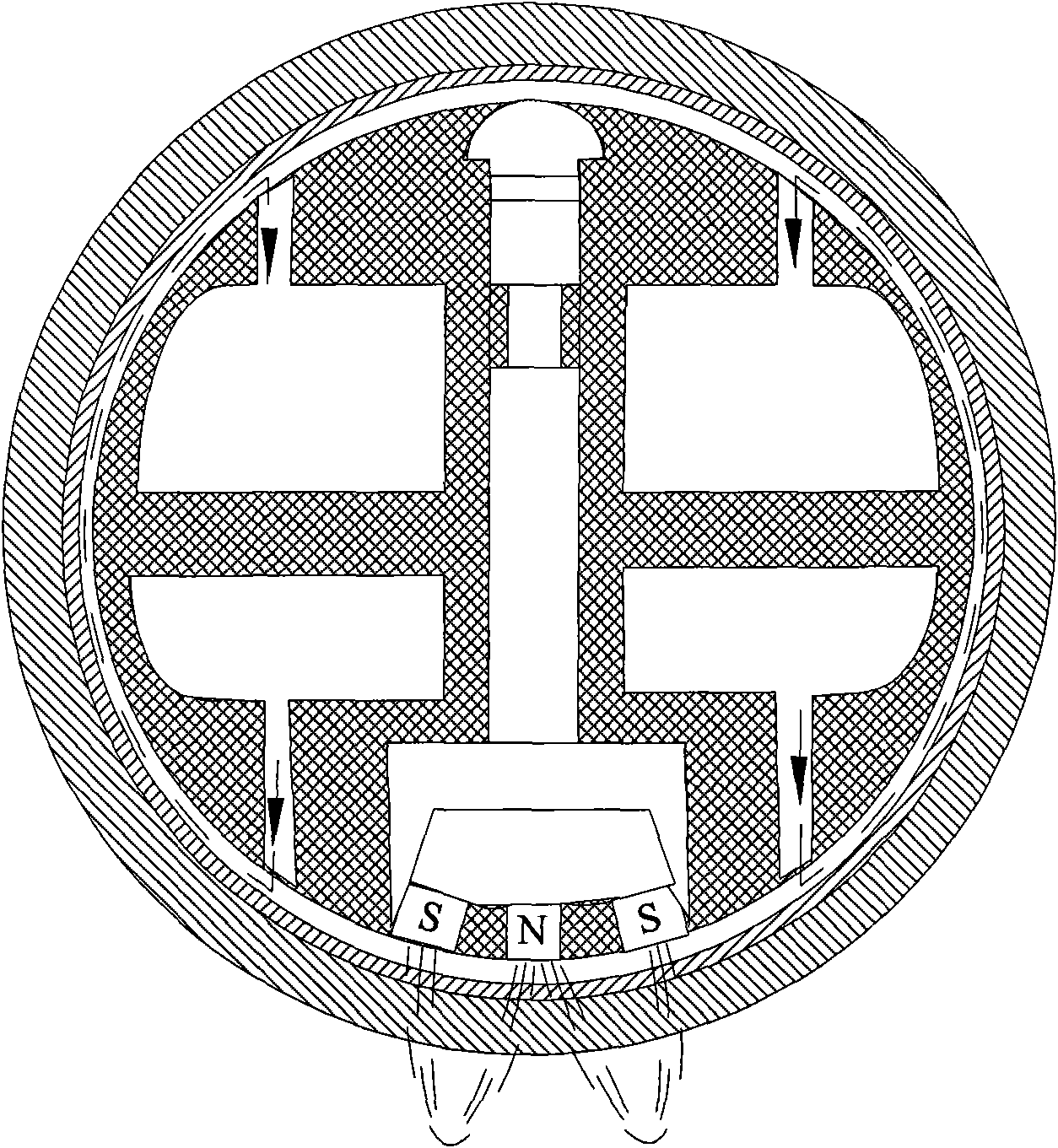

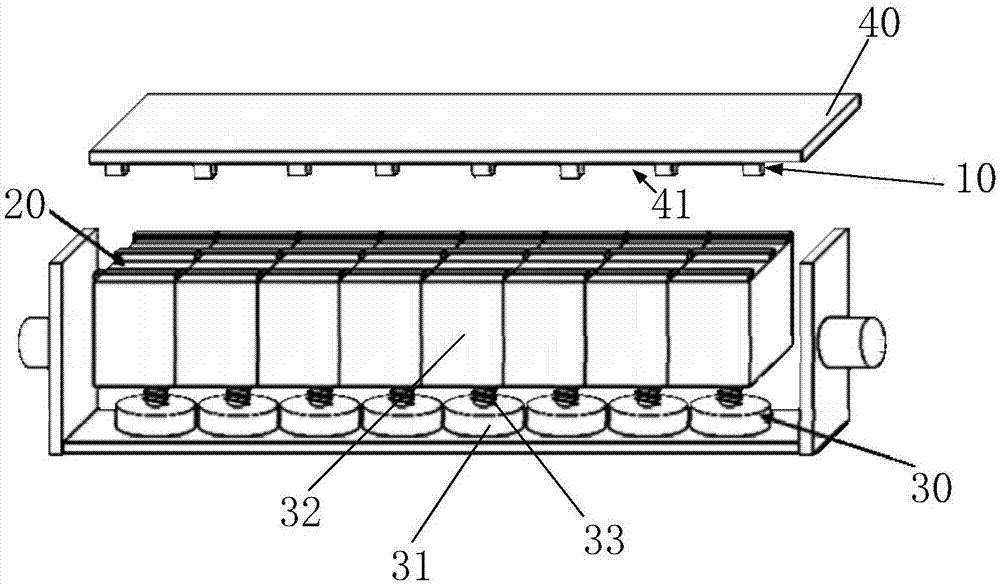

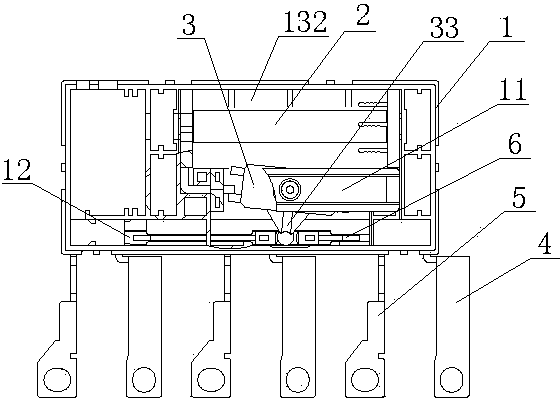

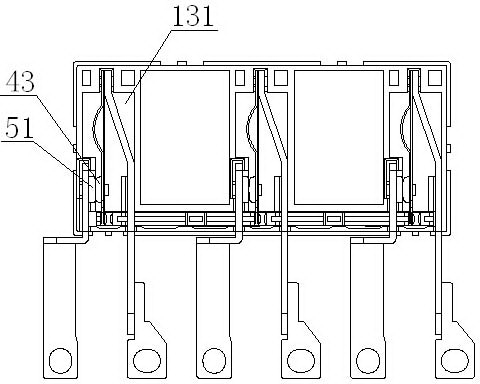

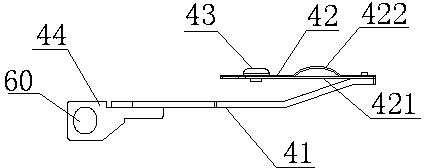

Magnetic latching relay

ActiveCN104051190AUniform magnetic field strengthSame degree of influenceElectromagnetic relay detailsEngineeringMechanical engineering

The invention relates to a magnetic latching relay. A magnetic latching relay in the prior art easily causes a demagnetization phenomenon and is not compact in structure. The magnetic latching relay comprises a base, a yoke iron assembly, a magnetic steel assembly, a moving spring assembly, a static spring assembly and a pushing piece and is characterized in that an installing groove for installing the pushing piece is formed in the base, the length of the installing groove is larger than the pushing piece, a clamping groove is formed in the pushing piece, and a moving spring movable piece of the moving spring assembly is clamped into the clamping groove. A shifting rod for shifting the pushing piece in a reciprocating mode is arranged on the magnetic steel assembly, a limiting groove is formed in the pushing piece, and the shifting rod is clamped in the limiting groove. The pushing piece is parallel to an irony core, a moving spring terminal lug is arranged on the moving spring assembly, a static spring terminal lug is arranged on the static spring assembly, and the moving spring terminal lug and the static spring terminal lug are perpendicular to the irony core. The magnetic latching relay is simple in structure, reasonable in design, compact in structure and good in performance.

Owner:HAIYAN ZHONGXIN ELECTRONICS

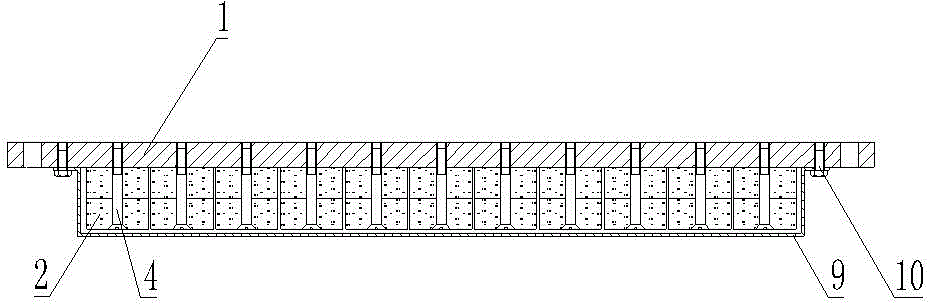

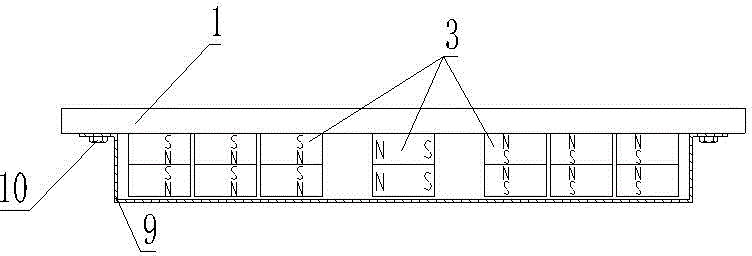

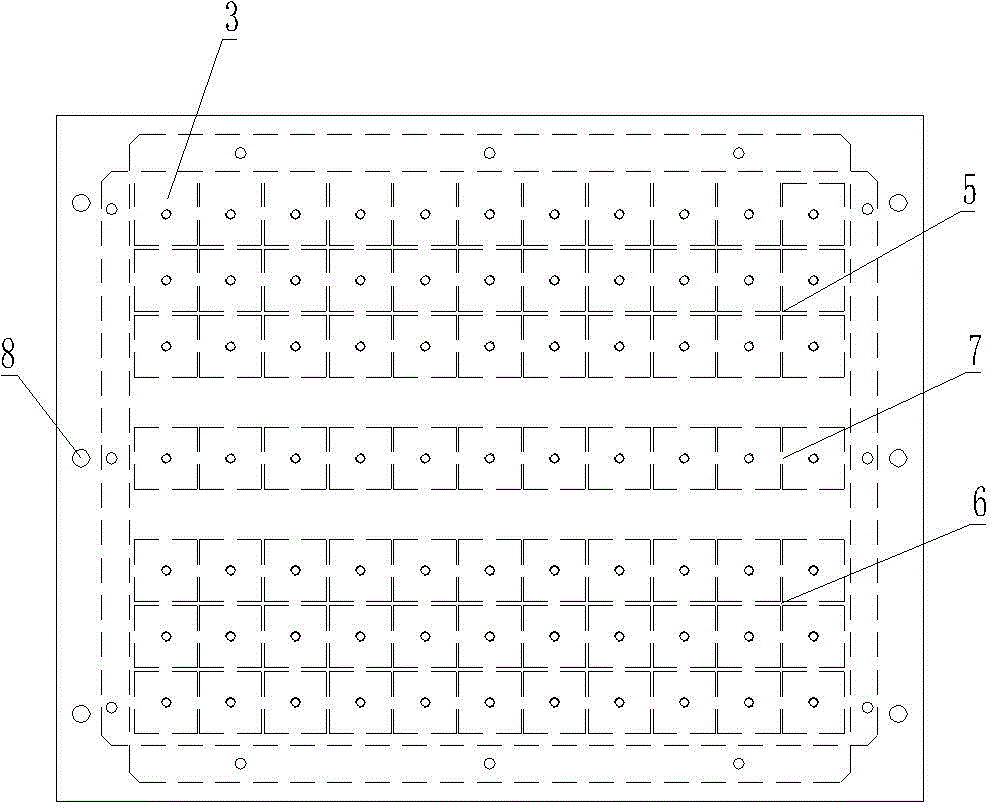

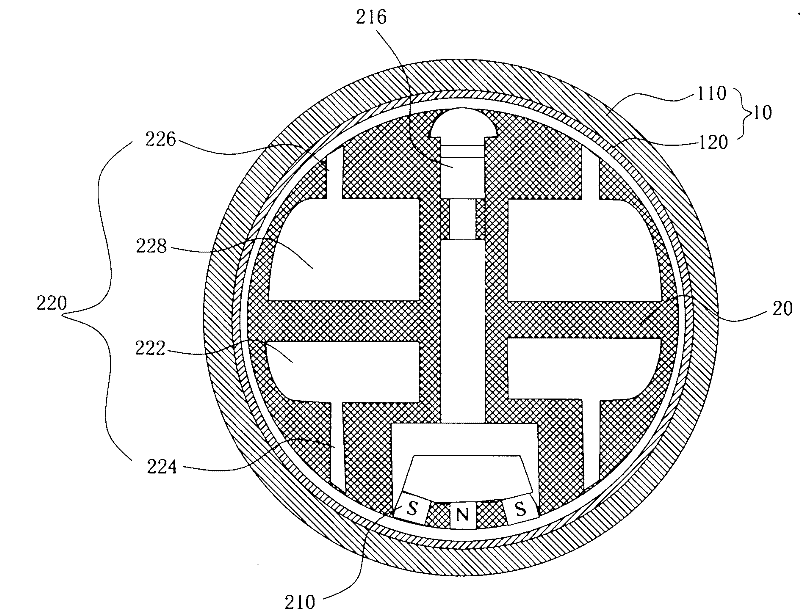

Magnetic system of magnetic separator

InactiveCN104588204AGuaranteed magnetic field strengthIncrease the magnetic field strengthMagnetic separationMagnetic separatorMagnet

The invention provides a magnetic system of a magnetic separator, and the magnetic system is simple in structure and good in property of separating magnetic substances. The magnetic system of the magnetic separator comprises a magnet yoke plate and magnets, the magnet yoke plate is provided with magnet lattices, the magnets are fixed in the magnet lattices through screws, the magnetic system is characterized in that the magnet lattice comprises a front magnet lattice and a rear magnet lattice, a middle partition is formed between the front magnet lattice and the rear magnet lattice, the S pole of the magnet in the front magnet lattice is upward fixed in the magnet lattice, and the N pole of the magnet in the rear magnet lattice is upward fixed in the magnet lattice, and the magnet in the middle partition is horizontally arranged on the magnet yoke plate with the N pole facing the front magnet lattice and the S pole facing the rear magnet lattice.

Owner:WUXI KANGHUI MACHINE BUILDING

Method for establishing animal model of Alzheimer's disease

InactiveCN103314926BLarge space for magnetic fieldUniform magnetic field strengthAnimal husbandryDiseaseAmyloid

The invention provides a method for establishing an animal model of an Alzheimer's disease. The method includes feeding a rat for at least 60 days under the condition of exposing to a power-frequency magnetic field; feeding the rat with drug D of galactose and beta of amyloid protein liquid during the process of feeding, and accordingly obtaining the animal model of the Alzheimer's disease. Thus, the method can be a useful supplement of a single-factor-induced animal model of the Alzheimer's disease. According to an embodiment of the method, characteristic pathological changes of the animal of the Alzheimer's disease can be expressed; the method has a characteristic of learning and memory impairment, is consistent with the environmental requirements of long-time and lasting exposure to the power-frequency magnetic field, and has the advantages of stable performance, good reproducibility, and low cost.

Owner:INST OF RADIATION MEDICINE ACAD OF MILITARY MEDICAL SCI OF THE PLA

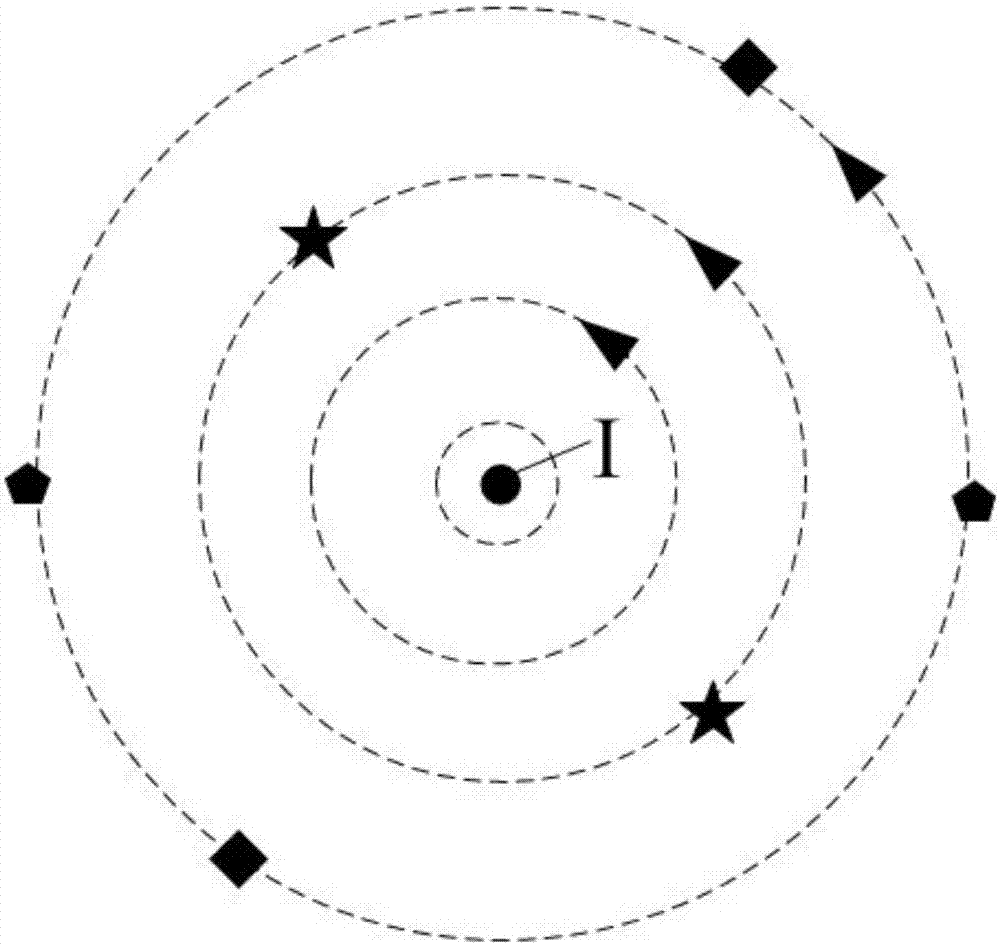

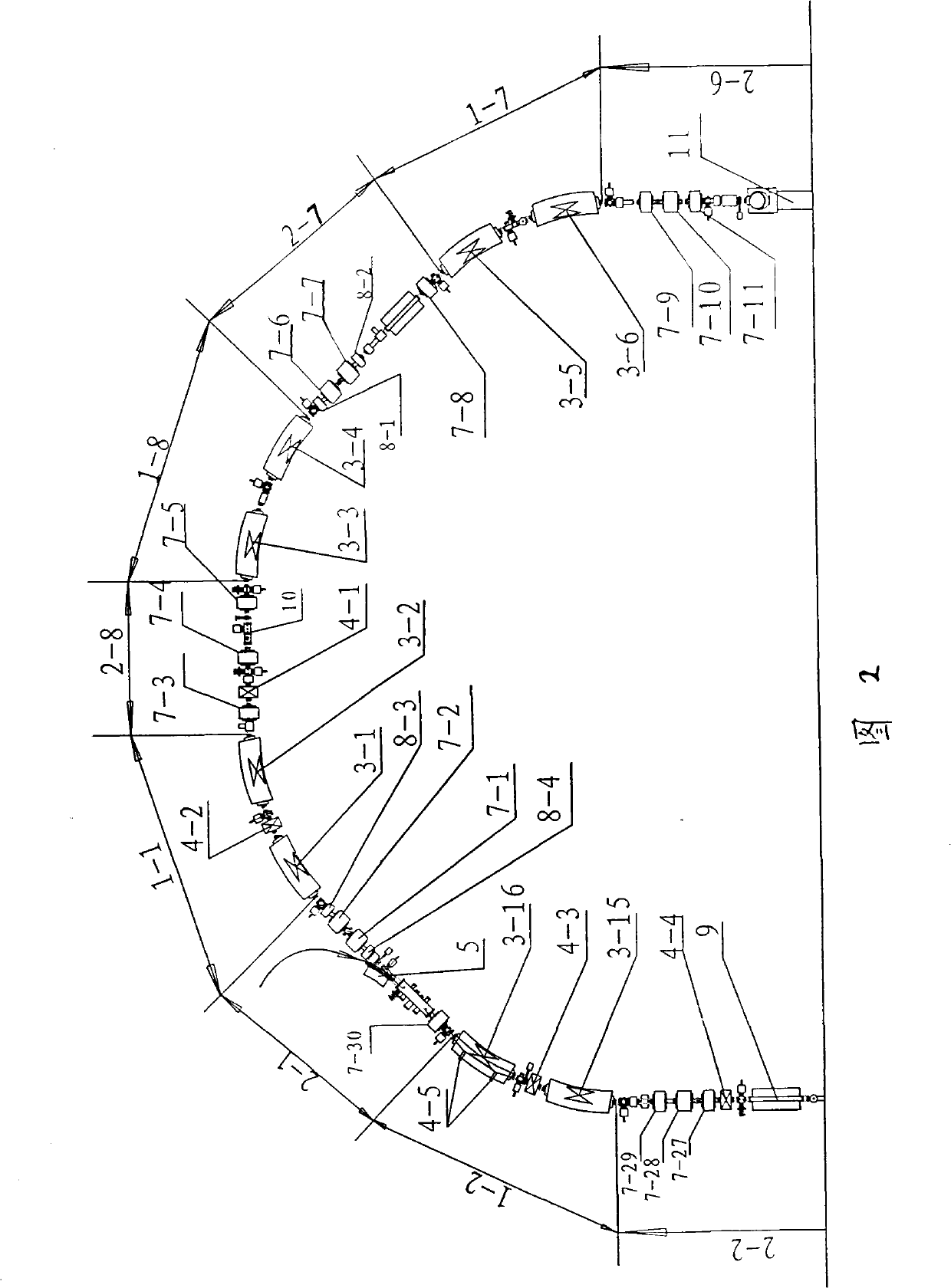

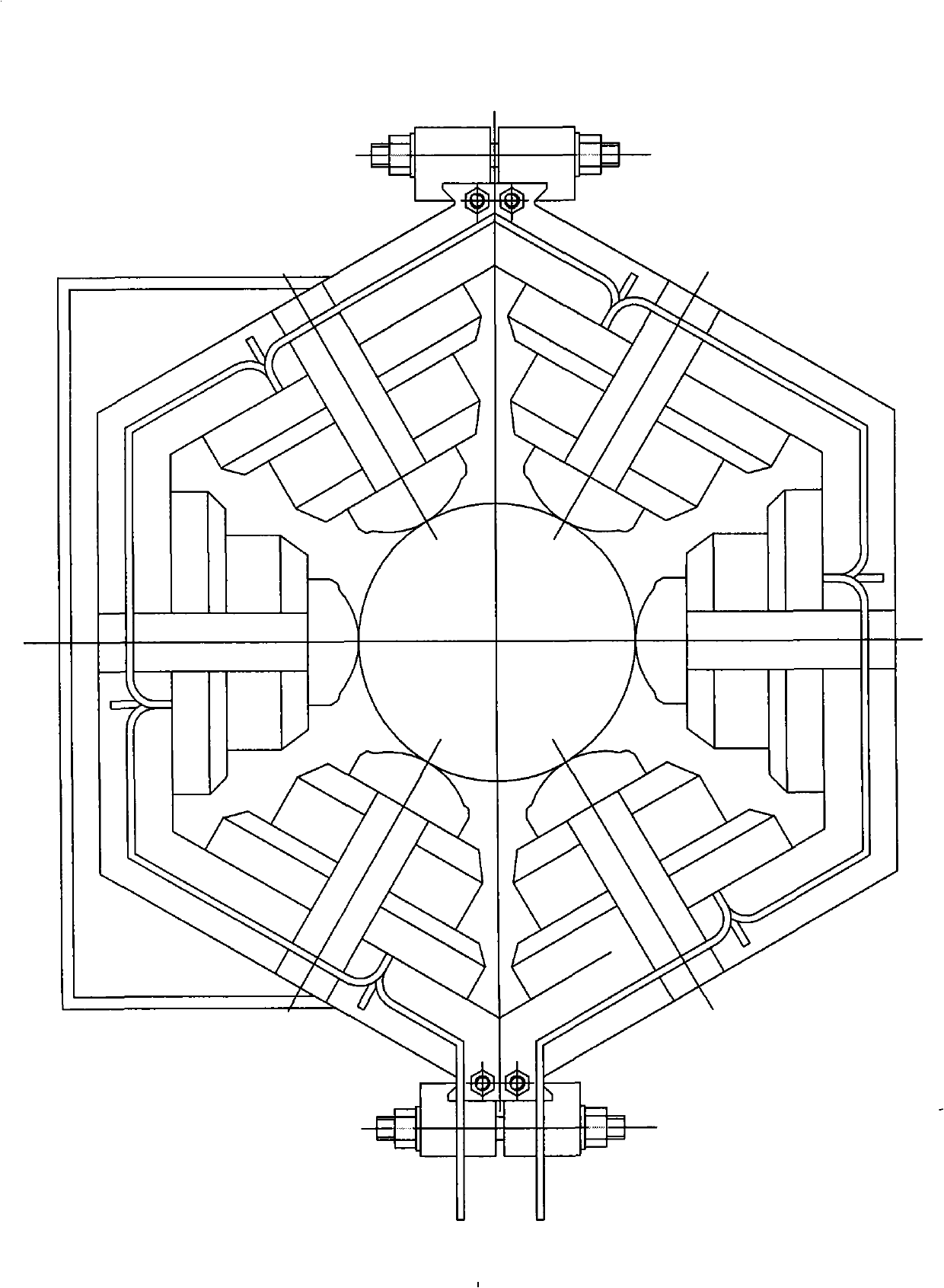

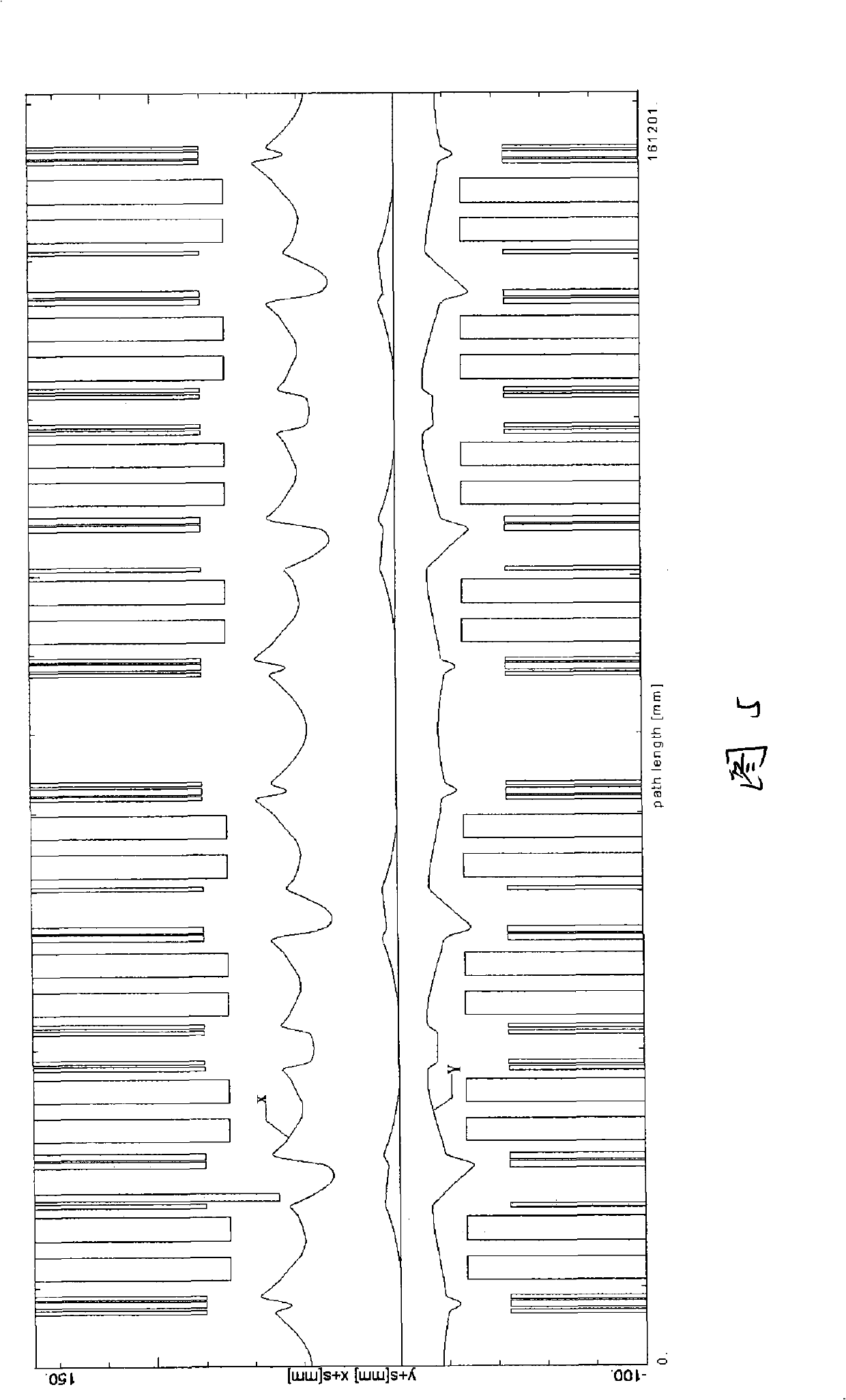

Accelerator used for cancer therapy with protons-heavy ion beams

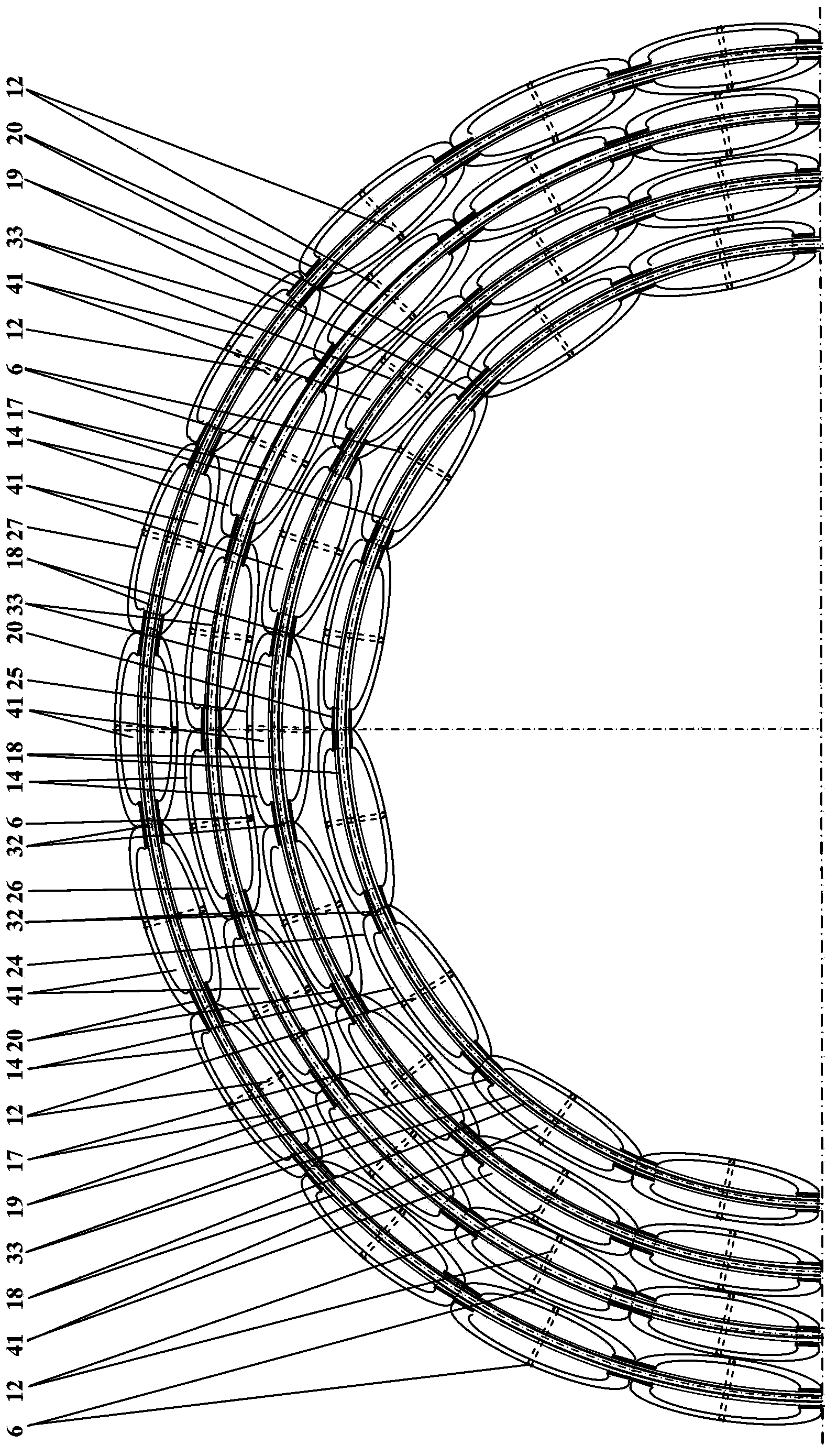

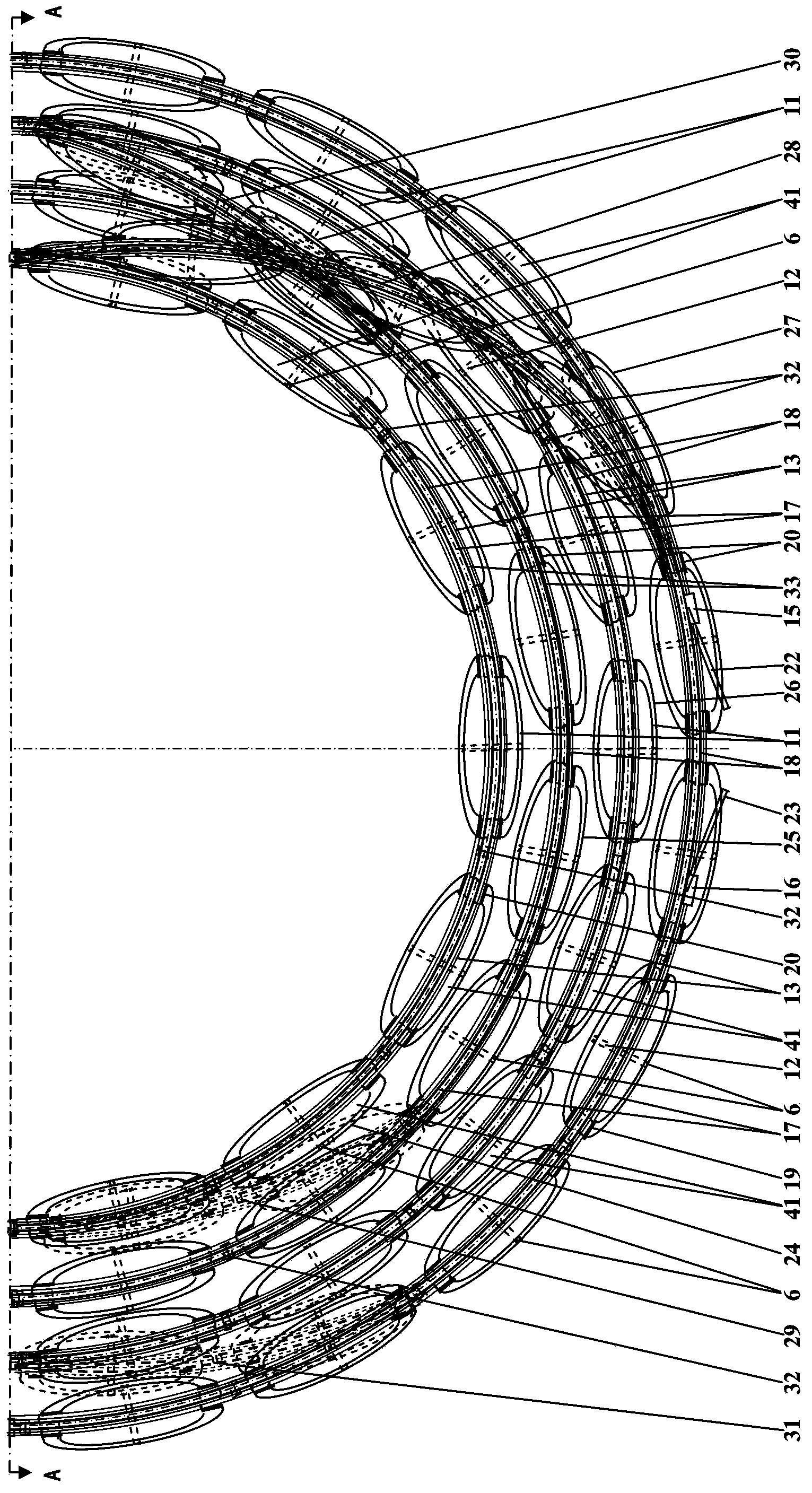

ActiveCN101631420BFulfillment requirementsTo achieve the requirements of the beam current parametersMagnetic resonance acceleratorsRadiation therapyMass numberSynchrotron

The invention relates to an accelerator which combines a cyclotron and a synchrotron and is used for cancer therapy with protons-heavy ion beams, comprising an ion source E and the synchrotron C. The accelerator is characterized in that the synchrotron C comprises a septum magnet implanting device (5), a septum magnet extracting device (6), a radio-frequency accelerating device (9), eight bendingsections of the synchrotron (1-1 to 1-8) and eight straight sections of the synchrotron (2-1 to 2-8), which are connected by an ion beam transmission line F; the ion beam implantation end of the synchrotron C is provided with a sector focusing cyclotron A or / and a separated sector focusing cyclotron B. By adopting the method of combining the cyclotron and the synchrotron, a set of accelerator devices required by cancer therapy with protons and heavy ion beams is set up to realize the requirements of clinical therapy on beam parameters; the mass numbers of the protons and the heavy ions are less than or equal to 40; the protons and heavy ion beams have wide energy range from 10MeV / u to 400MeV / u and high flux (the ion number provided by each pulse is up to 10<7-10> magnitude).

Owner:INST OF MODERN PHYSICS CHINESE ACADEMY OF SCI

Magnetron sputtering plating film cathode device

ActiveCN101812667BUniform cooling effectSmall changes in magnetic field strengthVacuum evaporation coatingSputtering coatingSputteringCooling effect

The invention relates to a magnetron sputtering plating film cathode device which comprises a target barrel and a magnetic rod tubing, wherein the magnetic rod tubing is arranged in the target barrel. The target barrel comprises a target inner barrel and a spattering target which covers the outside surface of the target inner barrel. A magnet of a spattering magnetic field is arranged in the magnetic rod tubing, and a cooling water passage is arranged in the magnetic rod tubing. The cooling water passage comprises a water inlet passage, a plurality of water inlet holes and water return holes and a water return passage, wherein the water inlet holes and the water return holes are distributed around the magnetic field area in the length direction of the magnetic rod tubing. By arranging thewater outlet holes on the surface near the spattering area of the magnetic rod tubing, the cooling water can be uniformly sprayed to the target inner barrel from the water inlet passage through the water outlet holes. Compared with the traditional single-end water inlet cooling, the cooling effect of the cooling water in the length direction is uniform, the magnetic field strength of the cathode magnetic rod tubing has little change in length direction during rotation, and the temperature difference of the spattering target in the length direction is small, thereby obviously improving the uniformity of the plating film.

Owner:CSG HOLDING

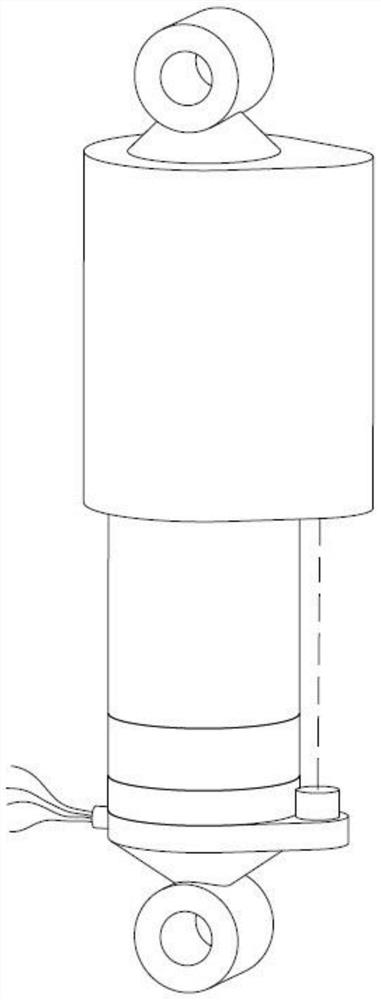

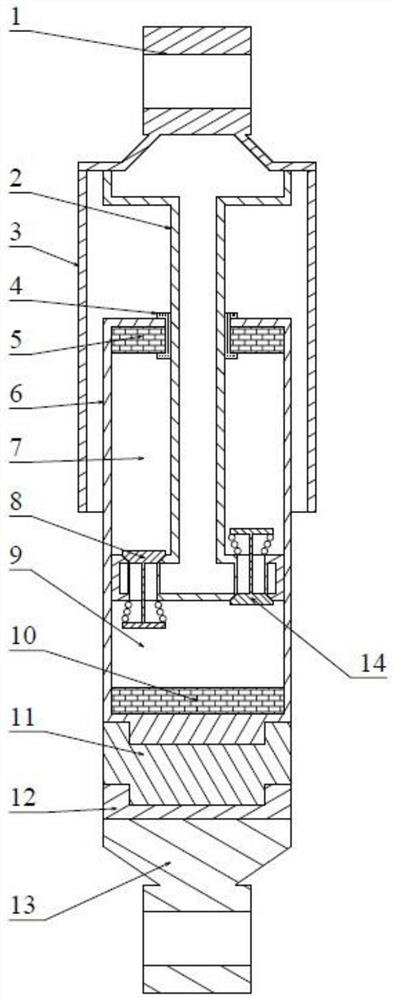

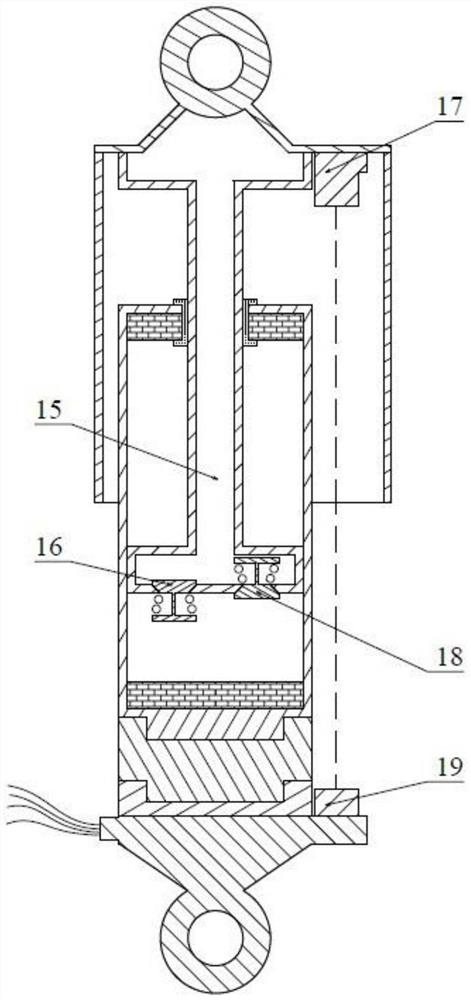

Electric control variable damping shock absorber for vehicle debugging

PendingCN114110075AEasy to determine damping characteristicsAccurate collectionSpringsNon-rotating vibration suppressionInlet valveElectric control

The invention relates to an electric control variable damping shock absorber for vehicle debugging, which comprises an upper lifting lug, a piston assembly, a dust cover, an oil seal, an upper magnet exciting coil, an oil cylinder barrel, an upper oil cavity, an oil inlet valve, a lower oil cavity, a lower magnet exciting coil, a transition cylinder barrel, a pressure sensor, a lower lifting lug, an oil return valve, an oil storage cavity, a compression valve, a speed sensor transmitting end, a compensation valve and a speed sensor receiving end, the shock absorber is used for being arranged on an automobile suspension or the upper position and the lower position of the suspension, the non-stop damping force can be adjusted according to the smoothness performance condition of an automobile, and the driving smoothness of the whole automobile is improved.

Owner:SHAANXI AUTOMOBILE GROUP

Induction Cooker Magnetic Strip, Induction Cooker Coil Disk and Induction Cooker

ActiveCN106162974BSimple structureUniform magnetic field strengthDomestic stoves or rangesCoil arrangementsEngineeringCondensed matter physics

The invention is suitable for the field of household electrical appliances, and discloses an induction cooker magnetic strip, an induction cooker coil disc and an induction cooker, wherein the induction cooker magnetic strip includes a magnetic strip body located under the coil, and the magnetic strip body has a top magnetic surface facing the coil and a bottom facing away from the coil. Magnetic surface, the top magnetic surface is a convex arc surface facing away from the bottom magnetic surface, and the top magnetic surface has an inner end close to the center of the coil disk of the induction cooker, an outer end away from the center of the coil disk of the induction cooker, and an inner end located between the inner end and the outer end. The middle part, and the inner end and the outer end are in the same height plane. In the present invention, by setting the top magnetic surface of the magnetic strip of the induction cooker as a convex arc surface facing away from the bottom magnetic surface, it is beneficial to equalize the magnetic field strength in the inner, outer and middle regions of the coil disk of the induction cooker. When working, the temperature in the middle area, inner area and outer area of the coil plate of the induction cooker is close to the same, which improves the uniformity of the heating energy distribution of the induction cooker, and realizes the effect of equivalent heating energy everywhere at the bottom of the pot.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

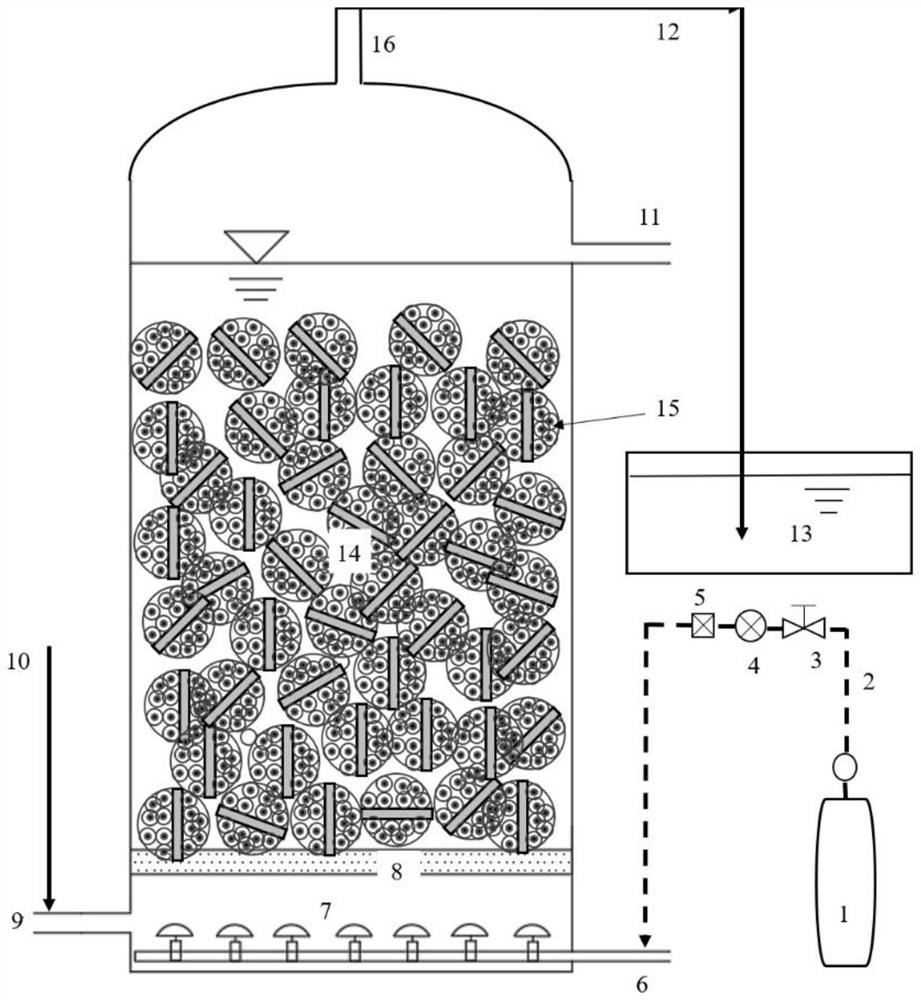

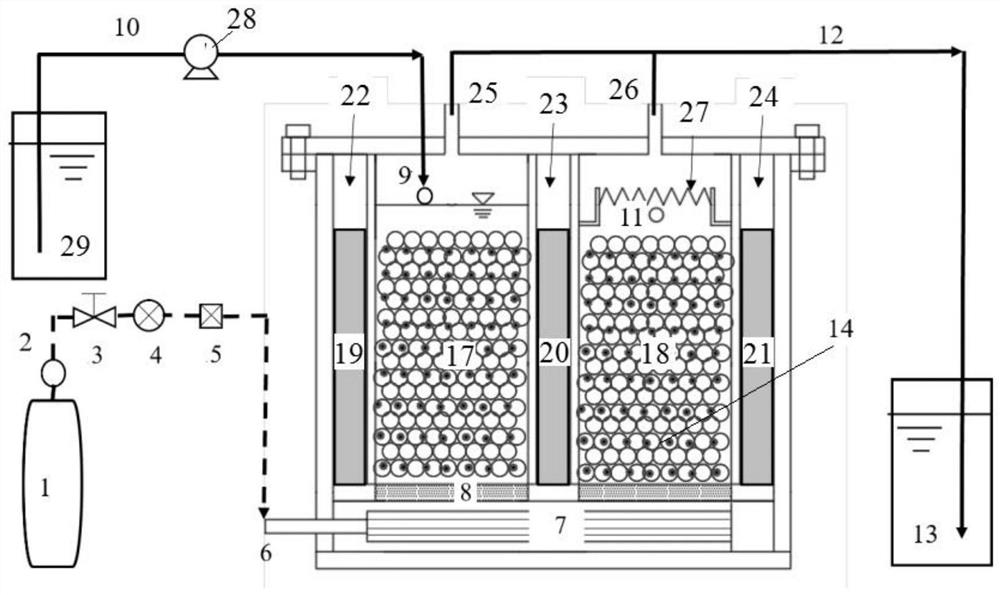

Device and method for enhancing iron autotrophic denitrification coupling carbon capture

PendingCN114573102AIncrease consumption rateImprove removal rateWater contaminantsTreatment with anaerobic digestion processesEnvironmental chemistryGas supply

The invention relates to the technical field of wastewater denitrification and carbon emission reduction, in particular to a device and a method for enhancing iron autotrophic denitrification coupled carbon capture. The invention provides a device for enhancing iron autotrophic denitrification coupled carbon capture. The device comprises a water inlet device, a carbon dioxide supply system, a low-intensity magnetic field reactor and an adsorption liquid pool, the water inlet device is connected with a water inlet of the low-intensity magnetic field reactor; the carbon dioxide gas supply system is connected with a gas inlet of the low-intensity magnetic field reactor; the low-intensity magnetic field reactor is connected with the adsorption liquid pool through an exhaust port; the low-intensity magnetic field reactor comprises an iron-based carrier. The device can synchronously realize the purposes of denitrification and carbon emission reduction in the wastewater.

Owner:BEIJING JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com