Fluid Magnetic Processor

A processor and fluid technology, applied in the fields of magnetic field/electric field water/sewage treatment, etc., can solve the problems of large damage, cumbersome assembly process of magnetized descaling device, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and through embodiments.

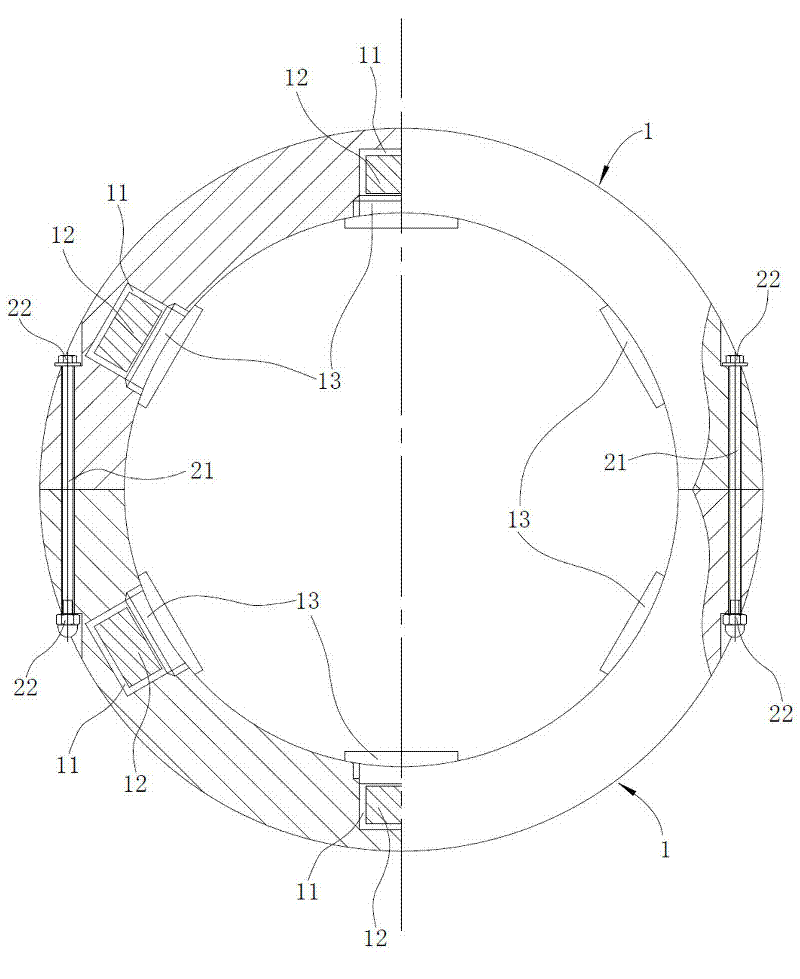

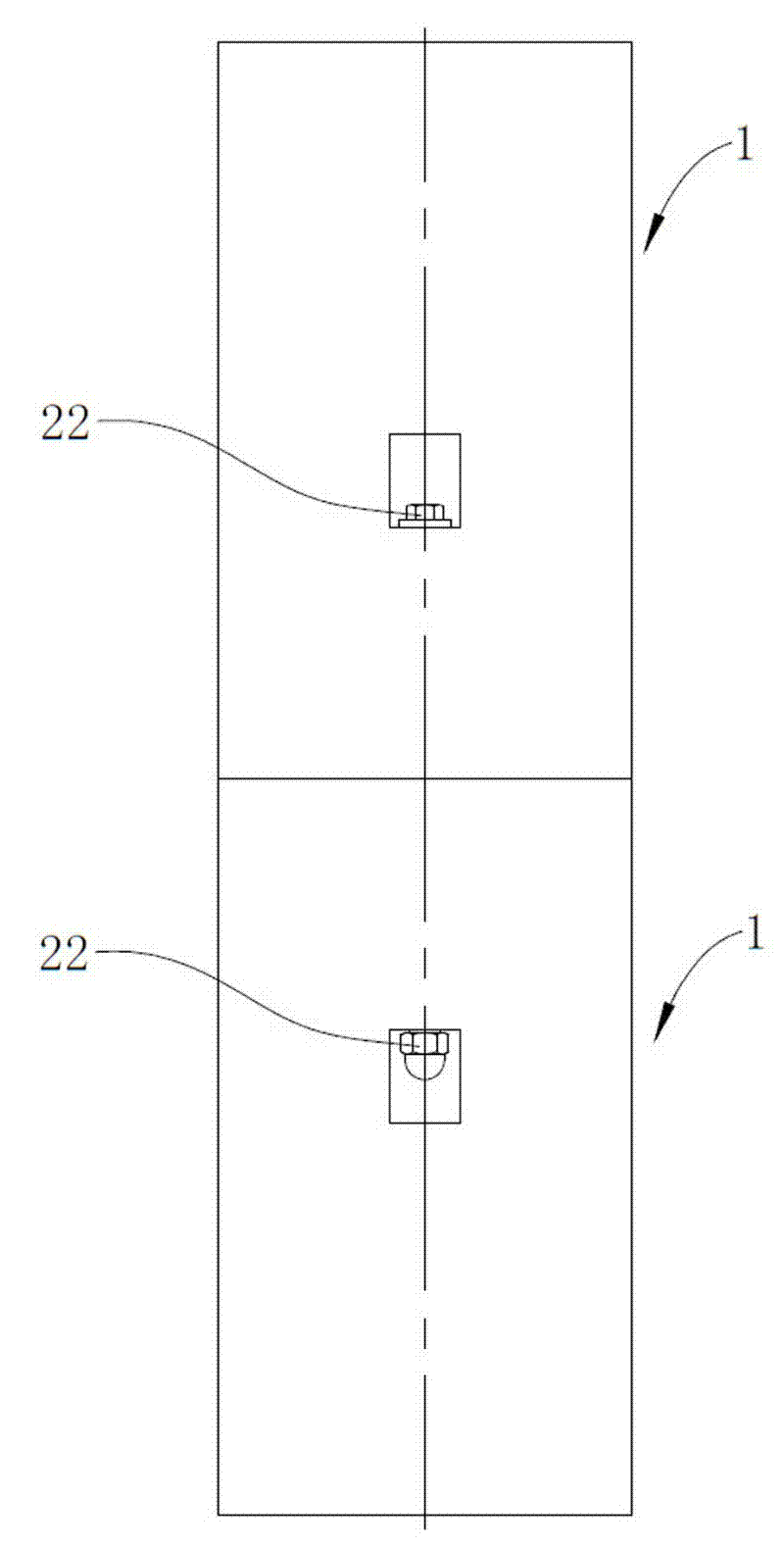

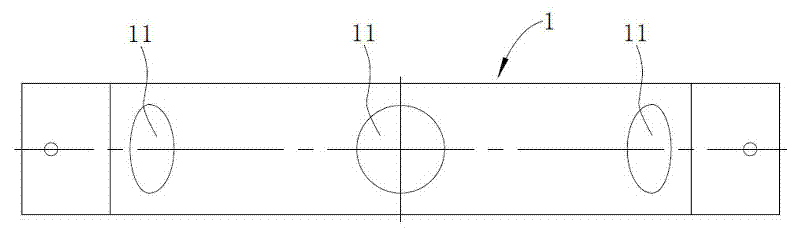

[0021] see figure 1 — image 3 :

[0022] The processor includes two semicircular hoops 1 of the same specifications butted to form a circular ring-shaped body. The material of the two hoops 1 is iron material for magnetic shielding. The opening end face of each hoop 1 A connection hole perpendicular to the end face of the opening is provided at the end face of the opening (the part number of the connection hole is not shown in the drawings), the centerlines of the two connection holes at the joint of the two clamps 1 are in the same line, and every two connection holes at the joint A double-ended screw rod 21 is installed in the center, and two threaded ends of each double-ended screw rod 21 are each screwed with a nut 22 that is in close contact with the corresponding clamp 1, so that the two clamps 1 are detachably connected.

[0023] Thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com