High-energy beam additive manufacturing forming device and forming method

A technology of additive molding and additive manufacturing, which is applied in the direction of additive manufacturing, additive processing, and energy efficiency improvement. It can solve problems such as residual stress, microscopic crack spheroidization, reduced additive molding control effect, and difficult tissue control. Achieve the effects of improving laying efficiency, improving control effect, and improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

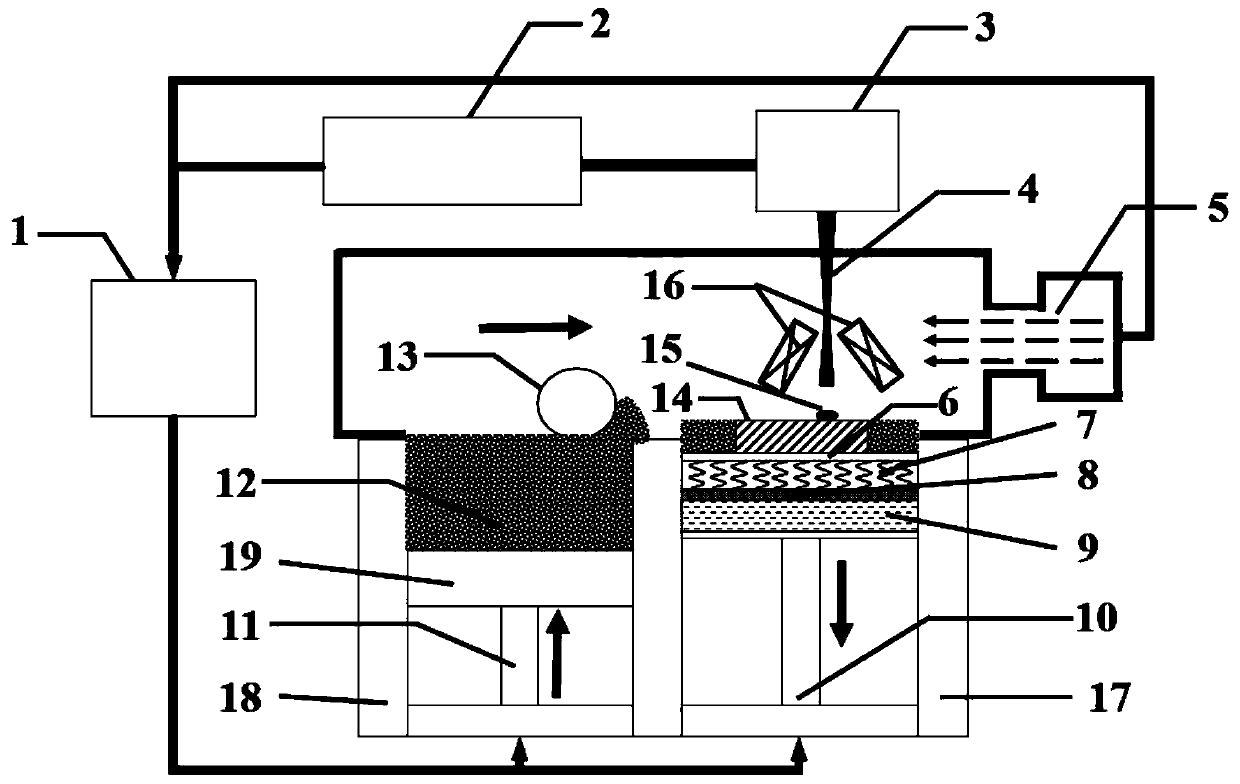

[0037] Such as Figure 1-Figure 3 As shown, the present embodiment provides a magnetic field unit for auxiliary additive molding, including a first magnetic field generating device 7, the first magnetic field generating device 7 includes an induction coil 20 arranged below the molten pool 15, and the magnetic flux generated by the induction coil 20 The induction line can pass through the molten pool 15 , and at any moment, the molten pool 15 formed by the melting of the material 12 to be processed is located in the area where the induction coil 20 emits concentrated magnetic induction lines.

[0038] Before additive molding, the induction coil 20 is connected to a DC power supply or an AC power supply to generate a steady magnetic field or an alternating magnetic field, and the middle part of the induction coil 20 generates clustered magnetic lines, which are drawn from the bottom of the molding surface of the molten pool 15 through. When performing additive molding, the mate...

Embodiment 2

[0040] Such as Figure 1-Figure 3 As shown, this embodiment provides a magnetic field unit for auxiliary additive molding. On the basis of Embodiment 1, the magnetic field unit for auxiliary additive molding in this embodiment also has the following characteristics:

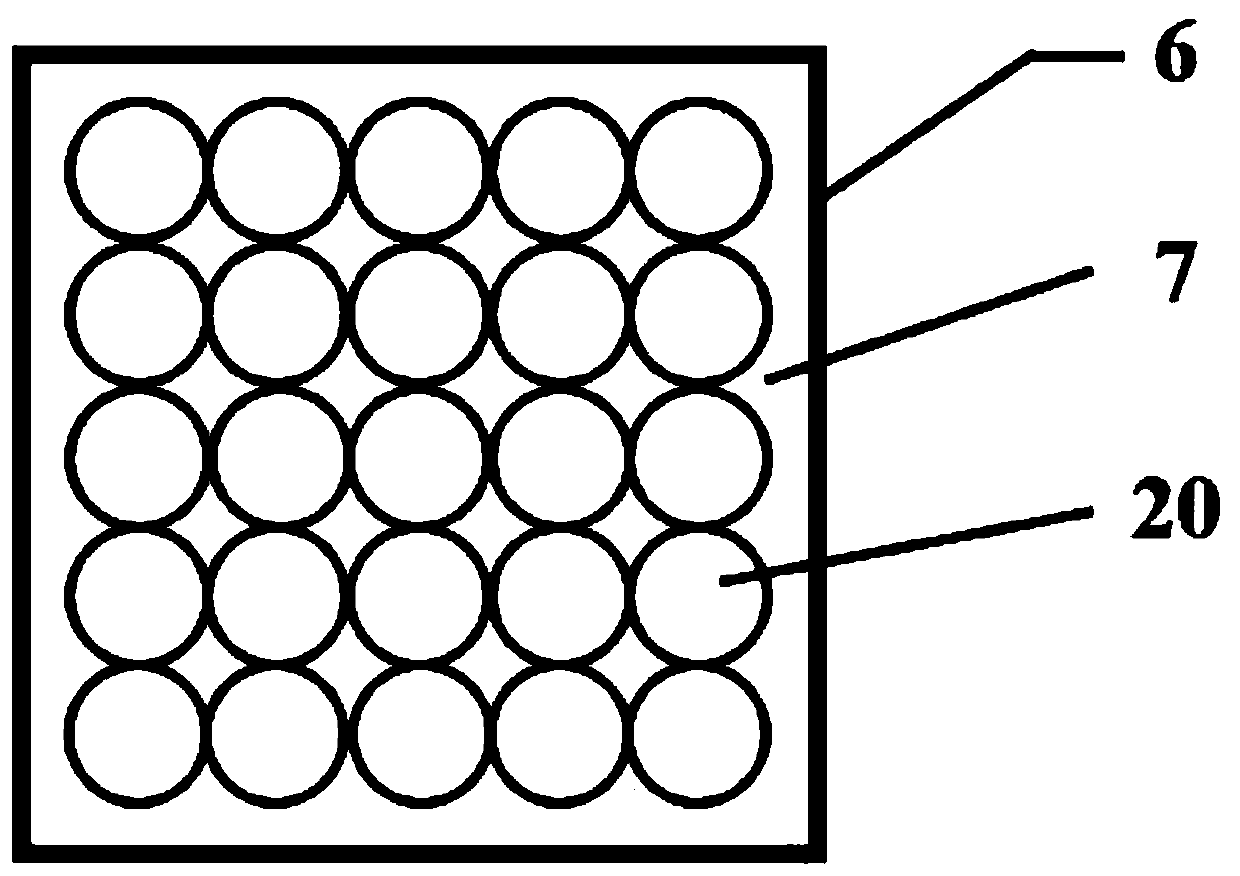

[0041] In order to make the magnetic field where the molten pool 15 is located uniform, the induction coil 20 arranged below the molten pool 15 is perpendicular to the surface where the molten pool 15 is located, so that the clustered magnetic lines generated by the induction coil 20 can all penetrate from the bottom of the molten pool 15, and the induction coil 20 The number of settings can be one or more. When the number of induction coils 20 is set to one, the forming range of the molten pool 15 is located within the inner diameter of the induction coil 20. When the number of induction coils 20 is set to multiple, more Each induction coil 20 is arranged in an array along the transverse direction and the longit...

Embodiment 3

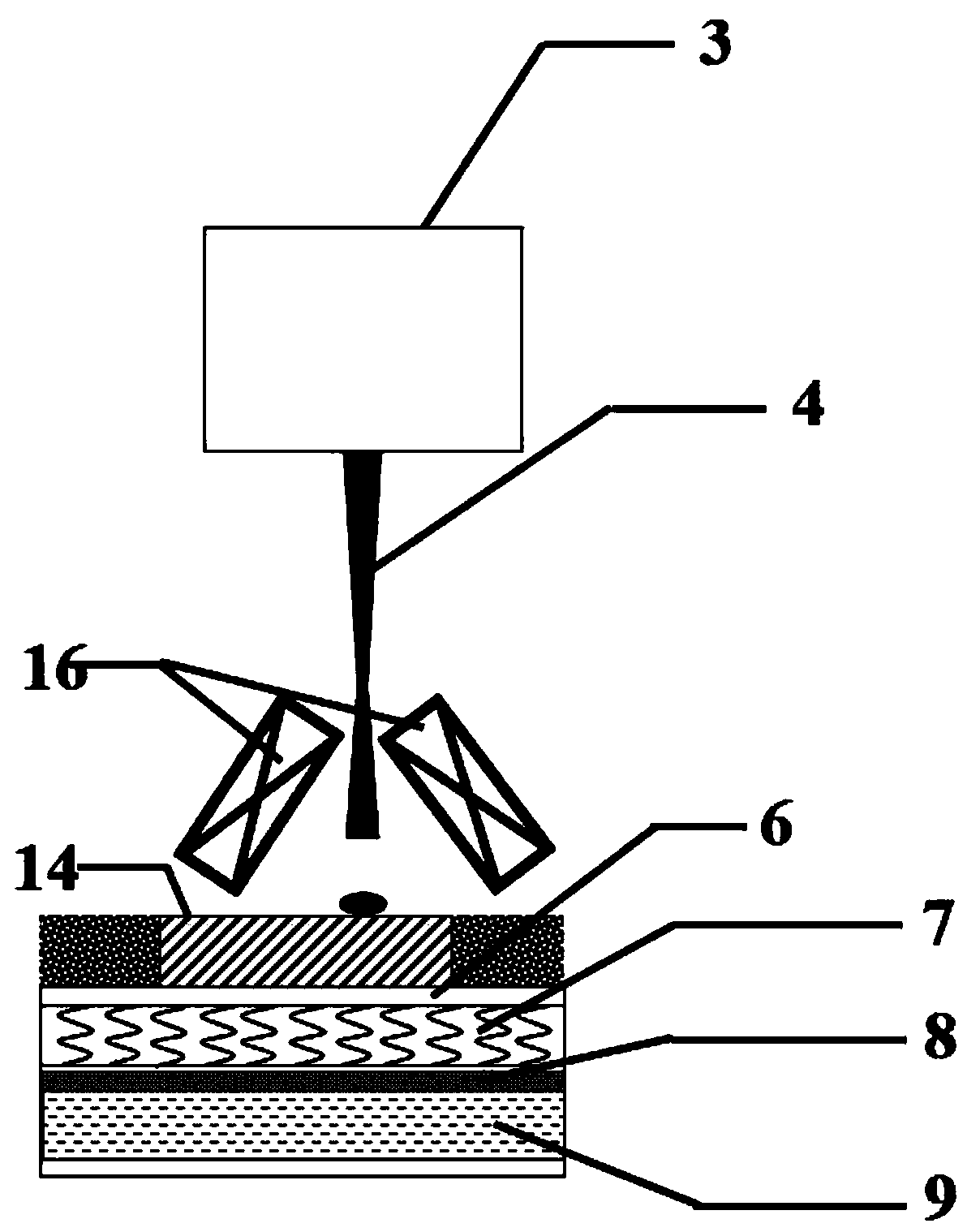

[0044] Such as Figure 1-Figure 3 As shown, this embodiment provides a high-energy beam additive manufacturing forming device. On the basis of Embodiment 2, the high-energy beam additive manufacturing forming device of this embodiment also has the following characteristics:

[0045] The device for high-energy beam additive manufacturing molding includes a magnetic field unit for auxiliary additive molding, a molding base 6, and a high-energy beam generating device; the molding base 6 is a hollow box-shaped structure, and the upper surface of the molding base 6 is used for additive molding. The molding surface is flat, and the second magnetic field generating device 16 is arranged above the molding surface. In the molding base 6, a first magnetic field generating device 7 and a water cooling device 9 for cooling the first magnetic field generating device 7 are sequentially arranged from top to bottom. The heat dissipation layer 8 , the insulating heat dissipation layer 8 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com