Induction Cooker Magnetic Strip, Induction Cooker Coil Disk and Induction Cooker

A technology of an induction cooker and a coil disc, applied in the field of induction cookers, can solve the problems of uneven heating energy distribution of the induction cooker, and achieve the effects of ensuring consistency, optimizing structure, and improving uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

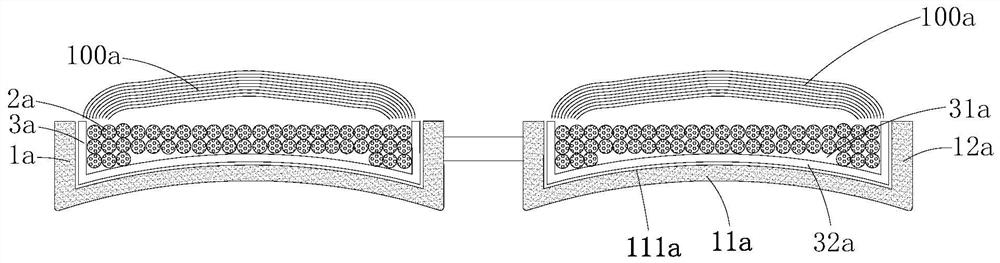

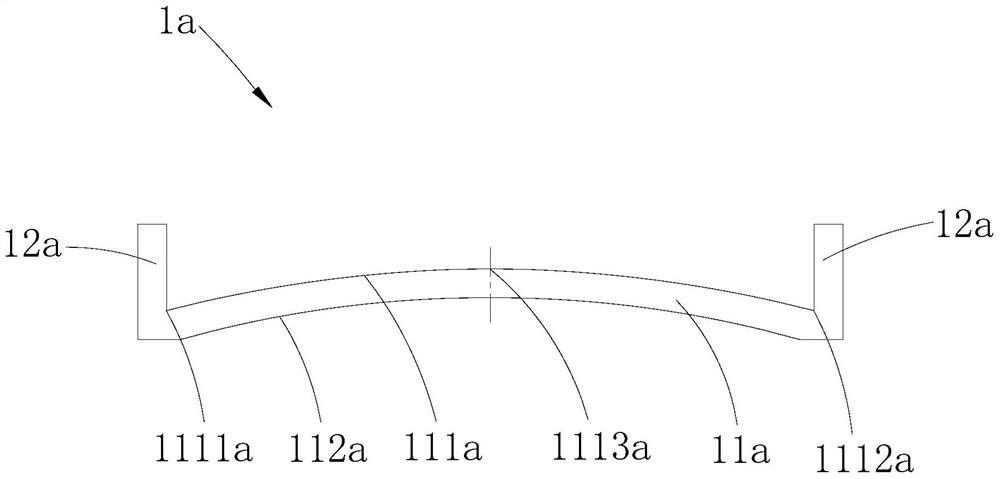

[0027] Such as figure 1 and figure 2 As shown, the electromagnetic cooker magnetic strip 1a provided by Embodiment 1 of the present invention includes a magnetic strip body 11a located below the coil 2a. The magnetic strip body 11a has a top magnetic surface 111a facing the coil 2a and a bottom magnetic surface 112a facing away from the coil 2a. The top magnetic surface 111a is a convex arc surface facing away from the bottom magnetic surface 112a, that is, the top magnetic surface 111a is a convex arc surface away from the bottom magnetic surface 112a. In this embodiment, by setting the top magnetic surface 111a of the electromagnetic cooker magnetic strip 1a as a convex arc surface facing away from the bottom magnetic surface 112a, the structure of the electromagnetic cooker magnetic strip 1a can be effectively optimized, and the peripheral area of the electromagnetic cooker coil disk can be effectively optimized. The magnetic field strength, the magnetic field strength ...

Embodiment 2

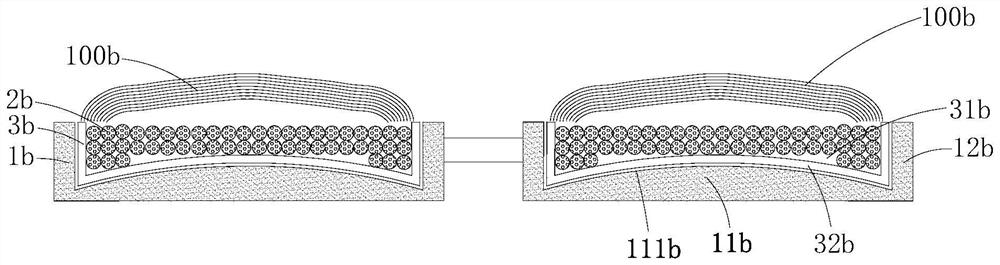

[0041] Such as image 3 and Figure 4 As shown, the induction cooker magnetic strip 1b, the induction cooker coil plate and the induction cooker provided in this embodiment are the same as the first embodiment: it also includes a magnetic strip body 11b located below the coil 2b, and the magnetic strip body 11b also has a The top magnetic surface 111b and the bottom magnetic surface 112b facing away from the coil 2b, the top magnetic surface 111b is also a convex arc surface facing away from the bottom magnetic surface 112b, and the inner end 1111b and the outer end 1112b of the top magnetic surface 111b are also upward Pins 12b protrude, and the disk body 3b is also provided with a slot 31b for accommodating the coil 2b and an arc-shaped partition 32b between the coil 2b and the magnetic strip body 11b. The difference from Embodiment 1 is that the bottom magnetic surface 112a in Embodiment 1 is an arc-shaped surface; while the bottom magnetic surface 112b in this embodiment ...

Embodiment 3

[0044] Such as Figure 5 As shown, the induction cooker magnetic strip 1c, the induction cooker coil plate and the induction cooker provided in this embodiment are the same as the first embodiment: it also includes a magnetic strip body 11c located below the coil, and the magnetic strip body 11c also has a top magnet facing the coil. The surface 111c and the bottom magnetic surface 112c facing away from the coil, the top magnetic surface 111c is also a convex arc surface facing away from the bottom magnetic surface 112c, and the bottom magnetic surface 112c is also an arc surface. The difference from the first embodiment is that the inner end 1111a and the outer end 1112a of the top magnetic surface 111a in the first embodiment are provided with pins 12a protruding upward; and the inner end 1111c and The outer end 1112c has no protruding pins, that is, the main difference between this embodiment and the first embodiment is the setting method of the pins. However, using the set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com