Device and method for detecting surface magnetic field intensity of permanent magnet

A detection device and detection method technology, applied in the direction of magnetic performance measurement, etc., can solve the problems of limiting the thickness of the hall element and the level of the measuring personnel, the permanent magnet cannot reflect the magnetic field strength on the surface of the permanent magnet, and the difference, so as to achieve convenient and rapid measurement and measurement. Convenience and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

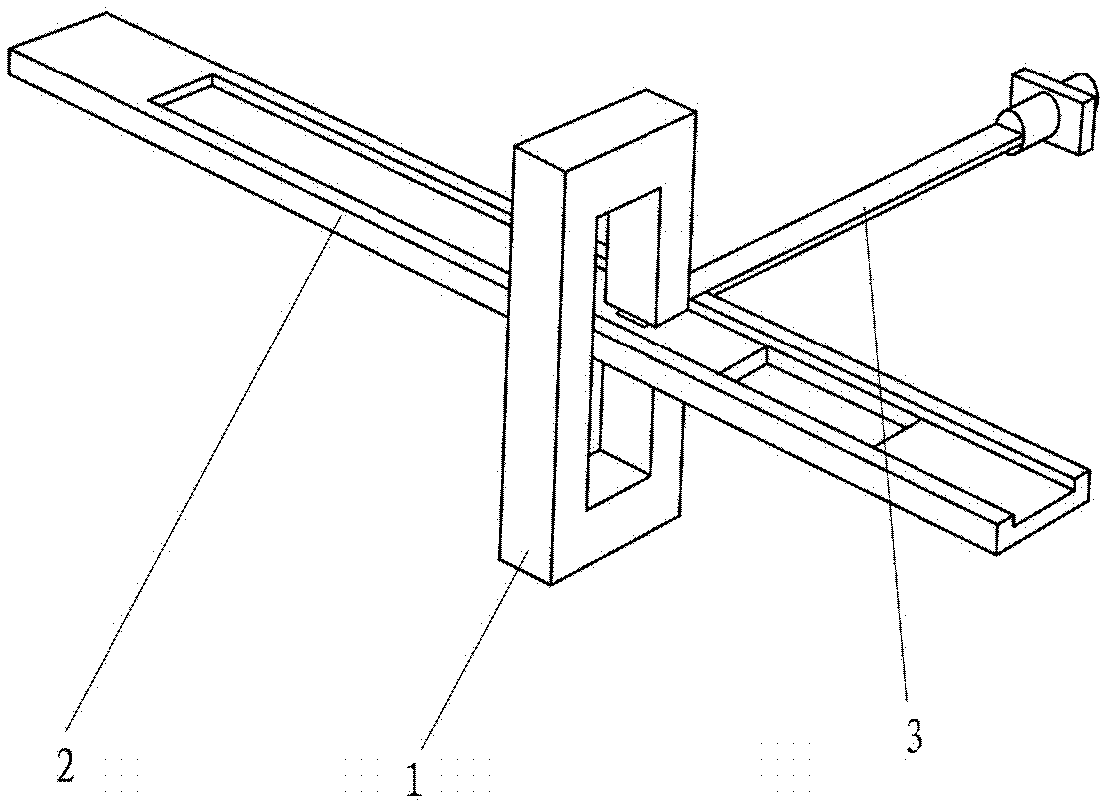

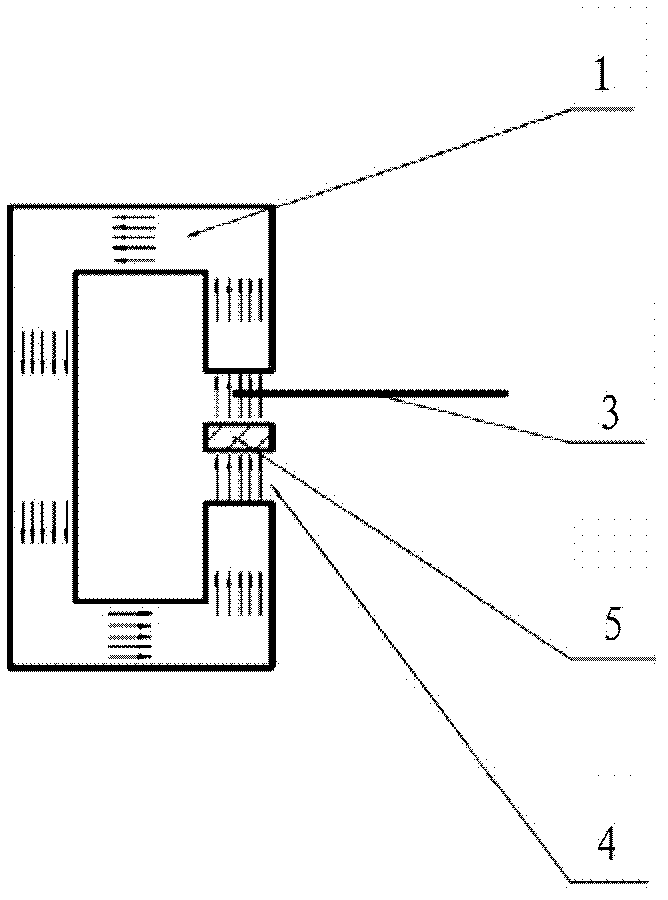

Method used

Image

Examples

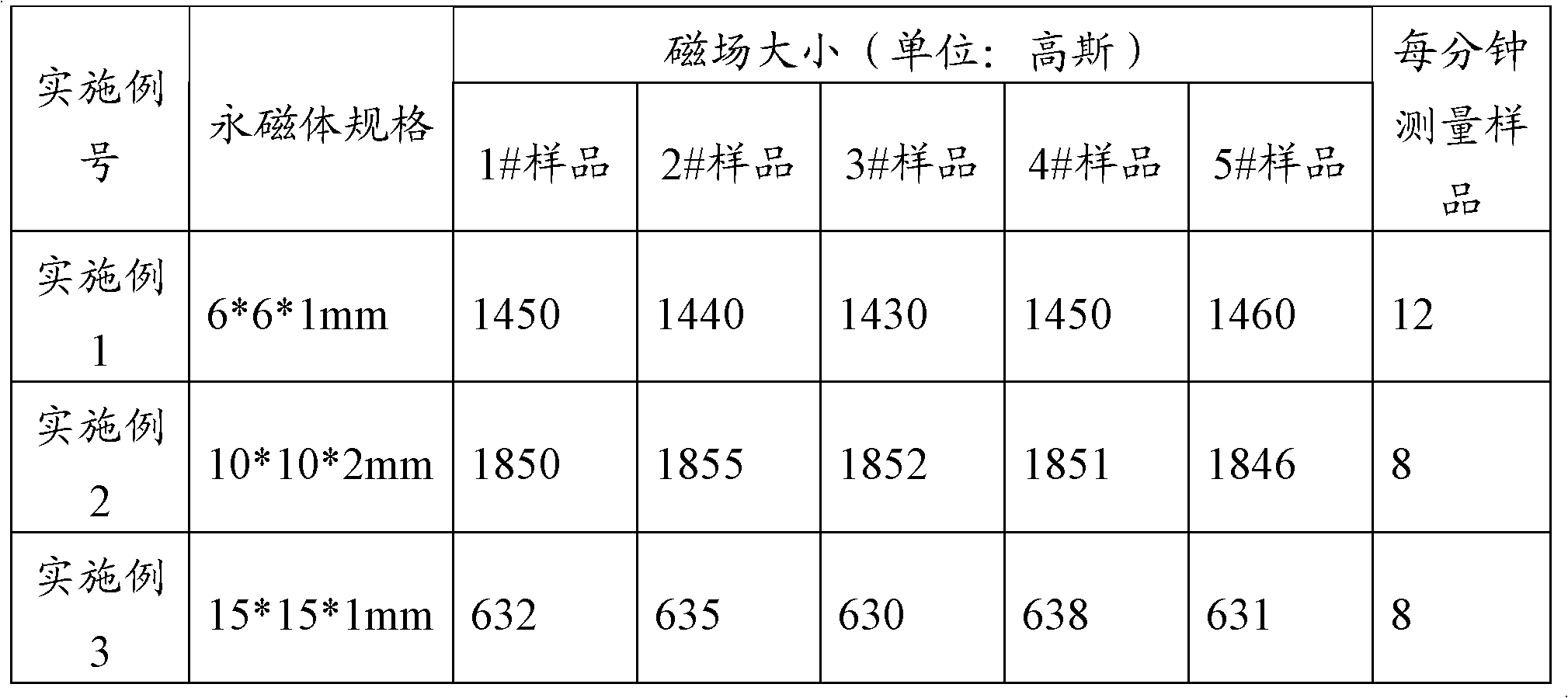

Embodiment 1

[0037] Take a sintered NdFeB permanent magnet workpiece with a size of 6*6*1mm. The surface of the magnet is treated with NiCuNi coating. The magnetic performance grade is N45H. The intensity is about 1450 Gauss, and the number of samples that can be measured per minute using the measuring method according to the present invention is 12 pieces.

Embodiment 2

[0039] Take a 10*10*2mm sintered NdFeB permanent magnet workpiece. The surface of the magnet is treated with Zn coating. The magnetic performance grade is N42H. 1850 Gauss, the number of samples that can be measured per minute using the measuring method according to the present invention is 8 pieces.

Embodiment 3

[0041] Take a 15*15*1mm sintered NdFeB permanent magnet workpiece. The surface of the magnet has been passivated. The magnetic performance grade is N35SH. 632 gauss, using the measuring method according to the present invention, the number of samples that can be measured is 8 pieces per minute.

[0042] The detection results of three embodiments are shown in the table below:

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com