Closed loop current sensor

A current sensor and closed-loop technology, applied in the direction of only measuring current, voltage/current isolation, measuring current/voltage, etc., can solve the problems of large sensor size, high production cost, heavy weight, etc., and achieve small size, low production cost, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

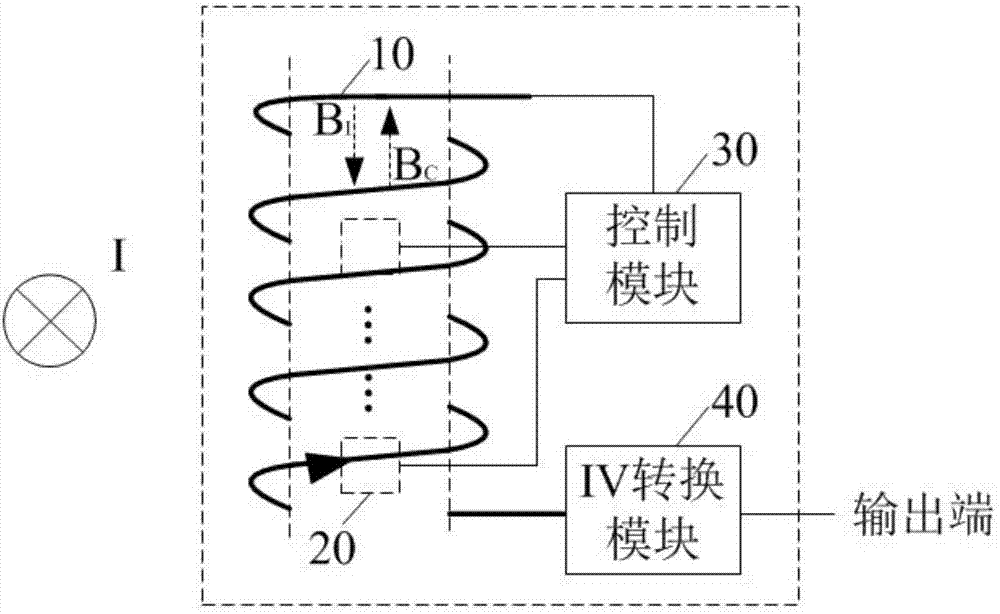

[0031] figure 2 A schematic diagram of a closed-loop current sensor according to an embodiment of the present invention is shown. Such as figure 2 As shown, the closed-loop current sensor includes at least one compensation coil 10 , at least one magnetic sensor chip 20 , a control module 30 and an IV conversion module 40 . figure 2 The "×" on the left side of the center indicates that the wire through which the current to be measured flows is perpendicular to the paper, and the current flows in the direction of penetrating the paper.

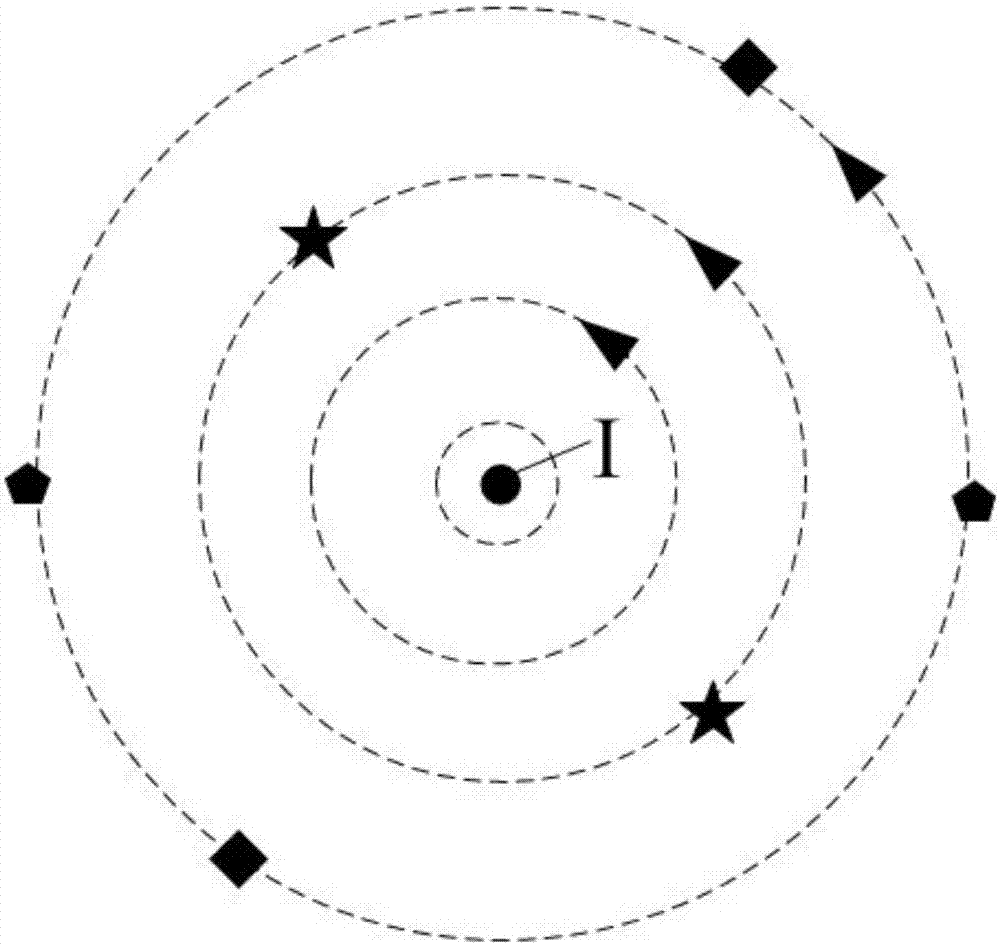

[0032] The compensation coil 10 is arranged at a predetermined position of the wire through which the current to be measured flows, and is used to generate a compensation magnetic field opposite to the magnetic field of the current to be measured. The "predetermined position" refers to the distance and orientation relative to the wire through which the current to be measured flows, image 3 and Figure 4 Several scenarios of predetermined...

Embodiment 2

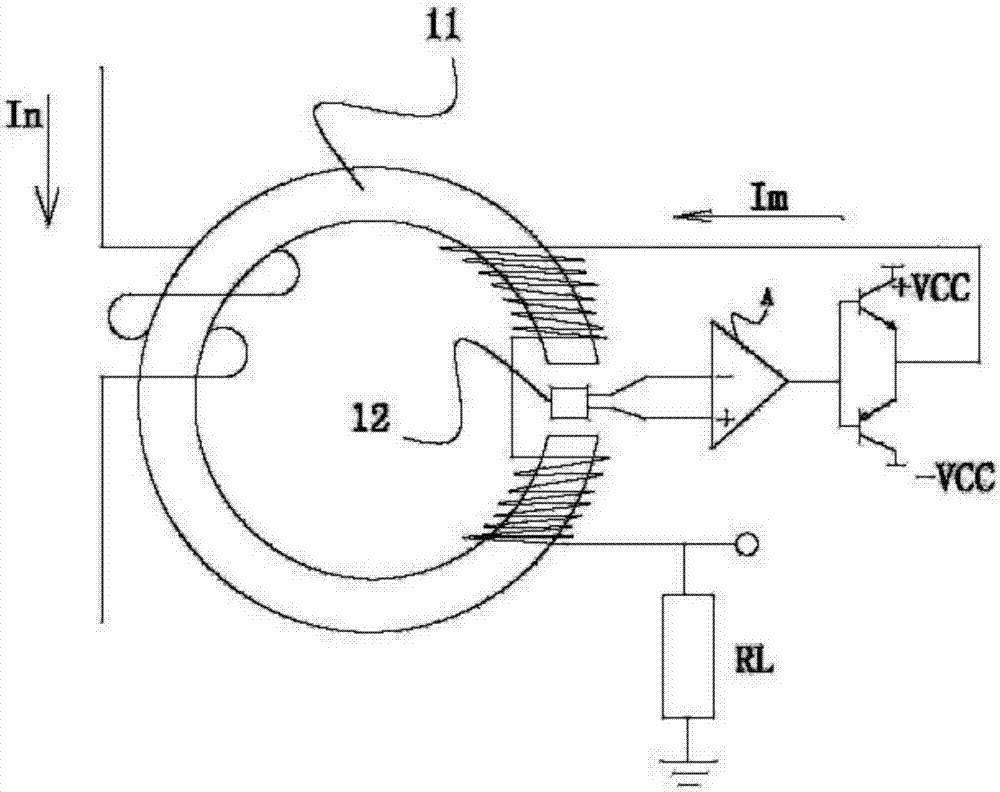

[0040] Figure 5 A schematic diagram of another closed-loop current sensor according to an embodiment of the present invention is shown. Such as Figure 5 As shown, the difference from Embodiment 1 is that the closed-loop current sensor includes at least two compensation coils 11 and 12 , two magnetic sensor chips 21 and 22 , a control module 30 , and an IV conversion module 40 .

[0041] The magnetic sensor chip 21 is arranged in the lumen of the compensation coil 11 , and the magnetic sensor chip 22 is arranged in the lumen of the compensation coil 12 . The wire through which the current to be measured flows is arranged between the two compensation coils 21 and 22 .

[0042] Figure 5 The "×" in means that the current to be measured flows through the wire perpendicular to the paper, and the current flows in the direction of penetrating the paper, B I1 and B I2 Indicates the magnetic field of the current to be measured, B C1 and B C2 Indicates the magnetic field of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com