Telescopic cross magnet yoke fluorescent magnetic powder flaw detection machine

A fluorescent magnetic powder, telescopic technology, applied in the direction of material magnetic variables, etc., can solve the problem that the magnetic pole of the crossed yoke cannot be automatically compensated, and achieve stable flaw detection sensitivity, stable effect, and ensure the effect of magnetic field strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

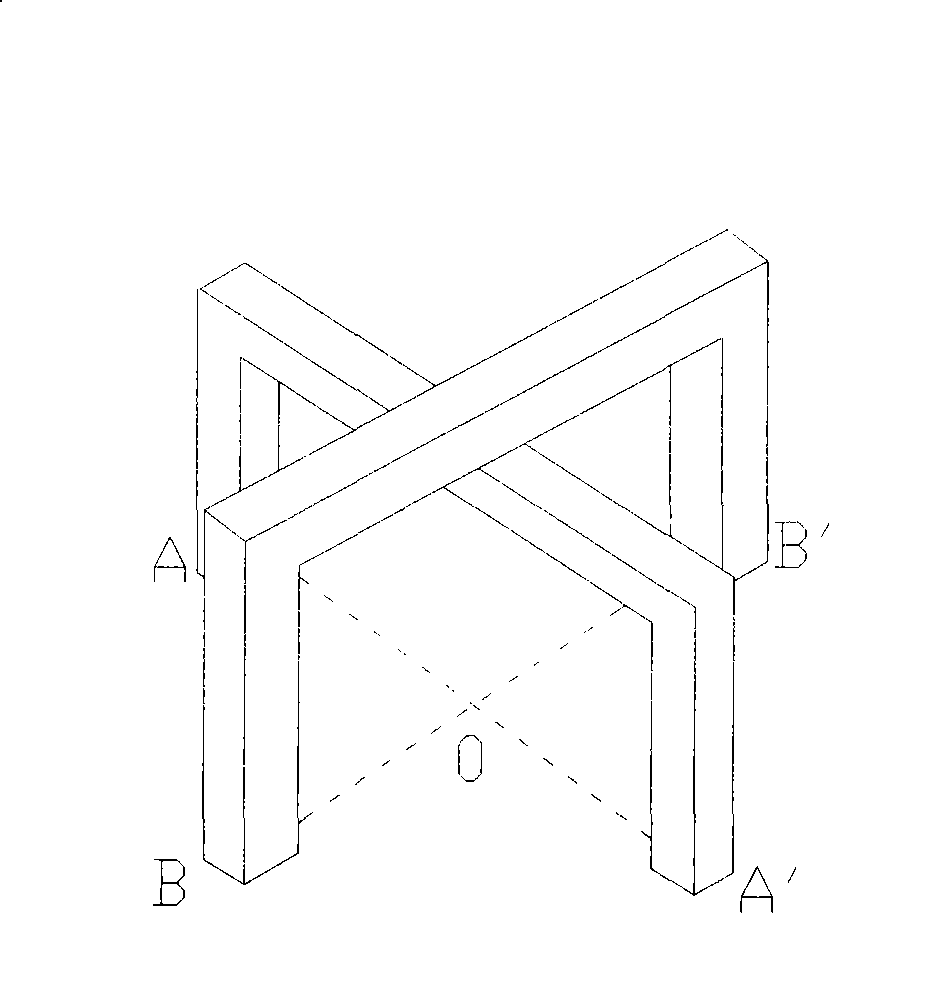

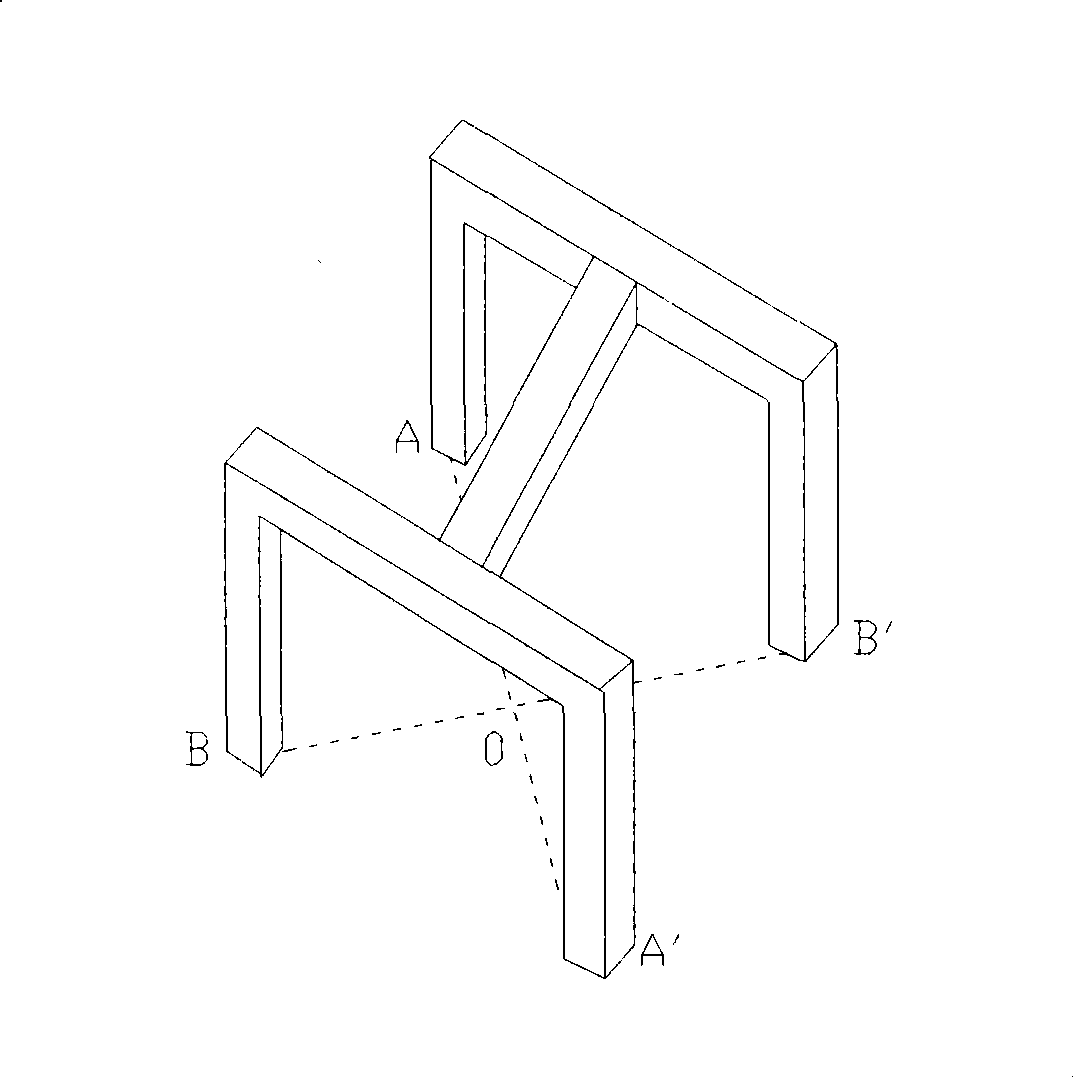

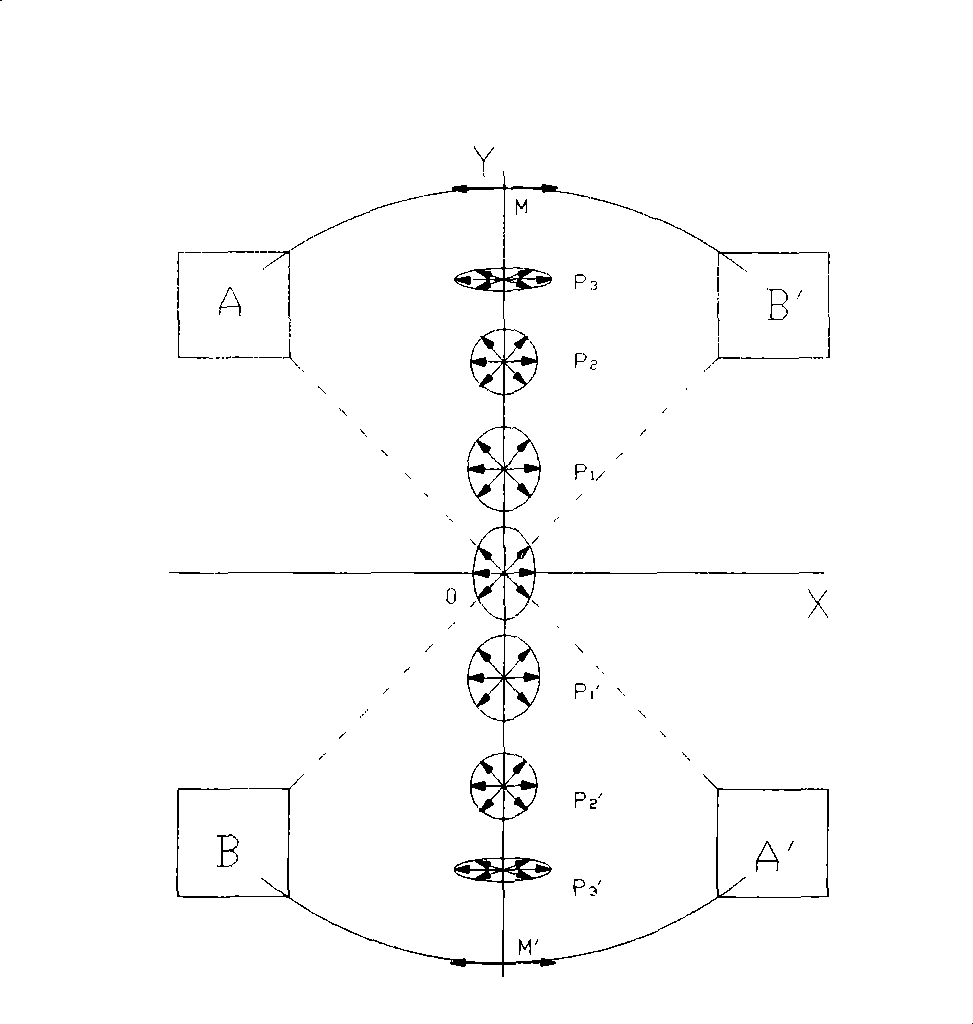

[0046] A telescopic cross yoke fluorescent magnetic particle flaw detector, which is composed of a magnetic suspension liquid spray recovery device 1 and a cross yoke 2, the cross yoke is composed of a fixed yoke 3 and a movable yoke 4, and the cross yoke is connected with the workpiece to be tested The part parallel to the surface forms a fixed yoke, and the part perpendicular to the surface of the workpiece to be measured in the cross yoke forms a movable yoke. The four corners of the fixed yoke are fixedly connected to a sliding sleeve 5, and the sliding sleeve is perpendicular to the plane formed by the fixed yoke. , the movable yoke passes through the sliding sleeve and is slidably connected with the sleeve. The movable yoke is divided into compression spring 6, sliding area 7, magnetizing coil 8 and magnetic pole 9 from top to bottom. The sliding area of the movable yoke can be Sliding up and down in the sliding sleeve, the upper part of the compression spring is provid...

Embodiment 2

[0048] It is basically the same as Embodiment 1, except that a magnetic suspension spraying recovery device 1 is installed at the front end of the crossed yoke in the traveling direction, and an ultraviolet lamp 20 and an image acquisition charge-coupled device 13 are arranged at the rear end of the crossed yoke in the traveling direction. Image Acquisition The distance between the charge-coupled device and the cross yoke is 300mm.

Embodiment 3

[0050] It is basically the same as Embodiment 2, except that the magnetic particle flaw detection machine is also provided with a lead screw that is parallel to the surface 14 of the workpiece to be tested and moves at a uniform speed, and the magnetic suspension spray recovery device 1, the cross yoke 2 and the image acquisition charge coupling The device is loaded on a lead screw. The speed of uniform motion is 1 m / min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com