Method for manufacturing large-size superconducting magnet laminated iron core

A superconducting magnet, large-scale technology, applied in the direction of superconducting magnet/coil, inductor/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems that cannot truly reflect the accuracy of punching, rolling, scrapping parts, etc., and achieve savings Effects of Human Resources and R&D Funding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: A kind of preparation method of large-scale superconducting magnet laminated core, comprises the following steps:

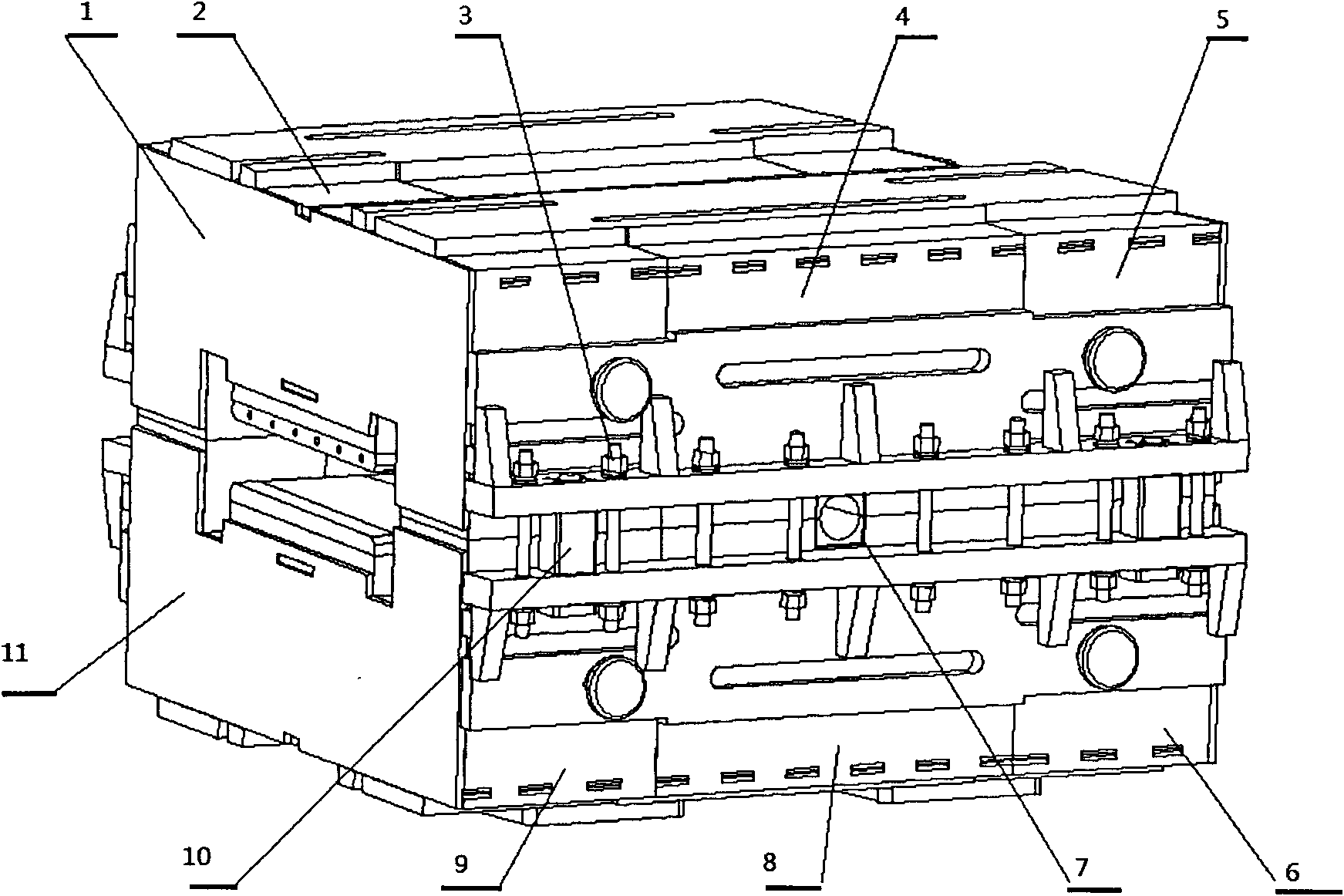

[0027] magnet structure such as figure 1 As shown, the whole magnetic element weighs about 24T, is about 2010mm long, about 2200mm wide, and about 750mm high.

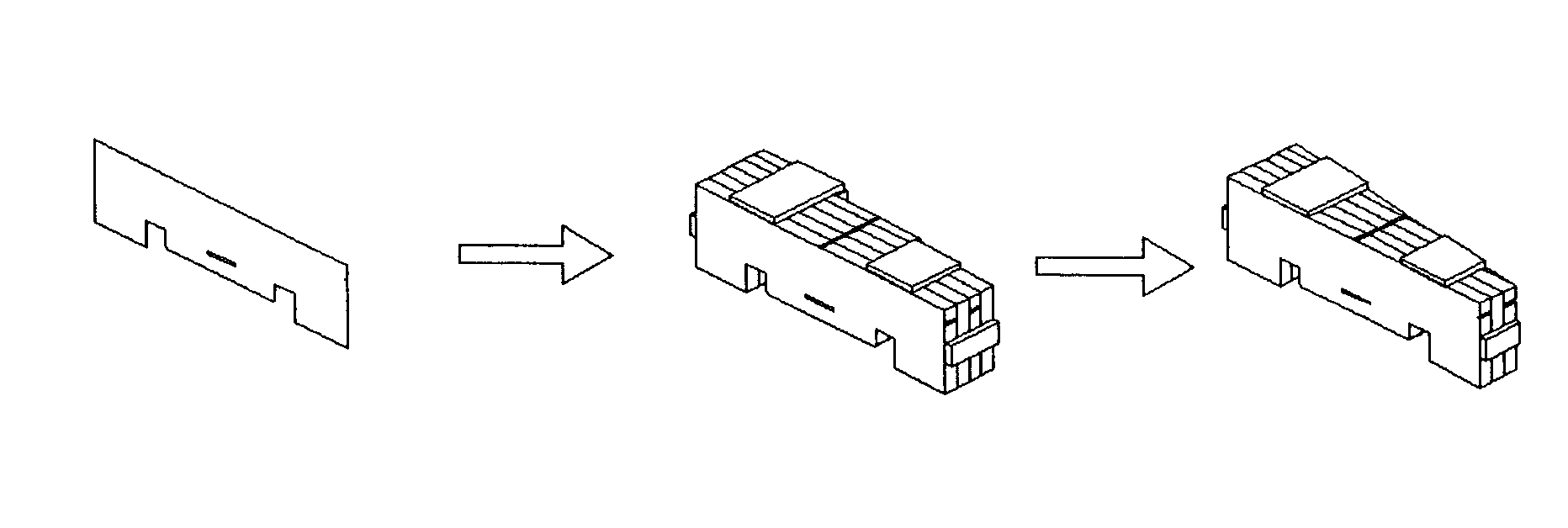

[0028] It is required that the magnetic element is made of laminated 0.5mm silicon steel sheet, the bevel angle at both ends is 15°, and one side is 7.5°. There is a bonded end plate at both ends of the magnet and in the middle, and the middle is laminated with non-glue-coated light sheets and then welded.

[0029] 1. Punch the 0.5mm silicon steel sheet; the punching sheet adopts the 0.5mm silicon steel sheet specified in the national standard, and the silicon steel sheet can choose different grades according to the magnetic field requirements.

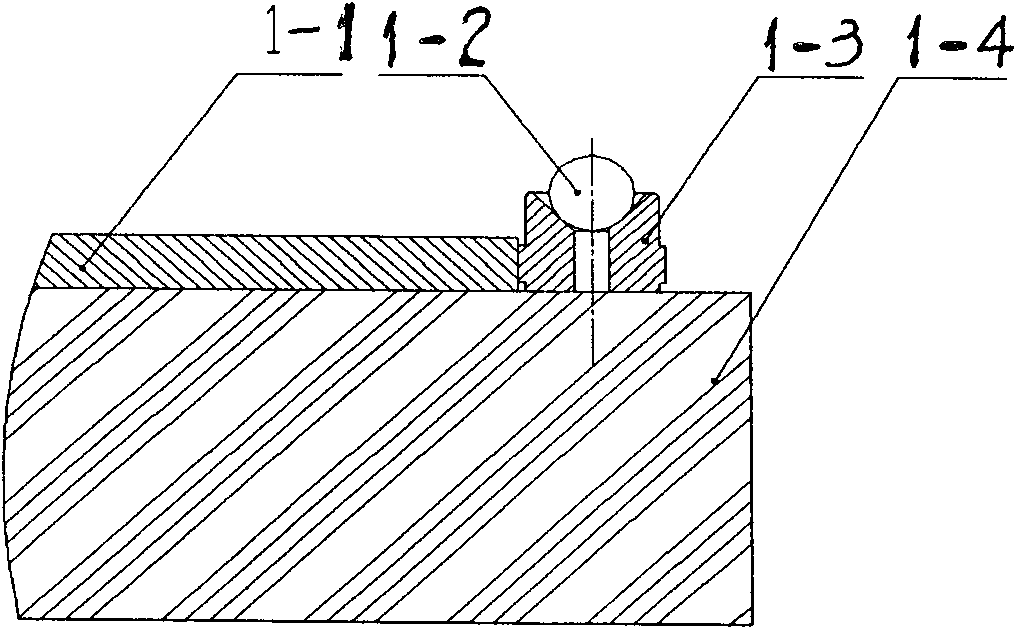

[0030] 2. Detection: see figure 2 , using a laser tracker, press the punching sheet 1-1 on the 00-grade marble platform 1-4, and use the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com