Miniaturized magnetron structure

A magnetron and tube core technology, applied in the field of household microwave oven magnetron, can solve the problems of avoiding the use of ferrite magnetic rings, low temperature resistant permanent magnet materials, reducing the diameter and thickness of ferrite magnetic rings, etc. Achieve the effect of miniaturization design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

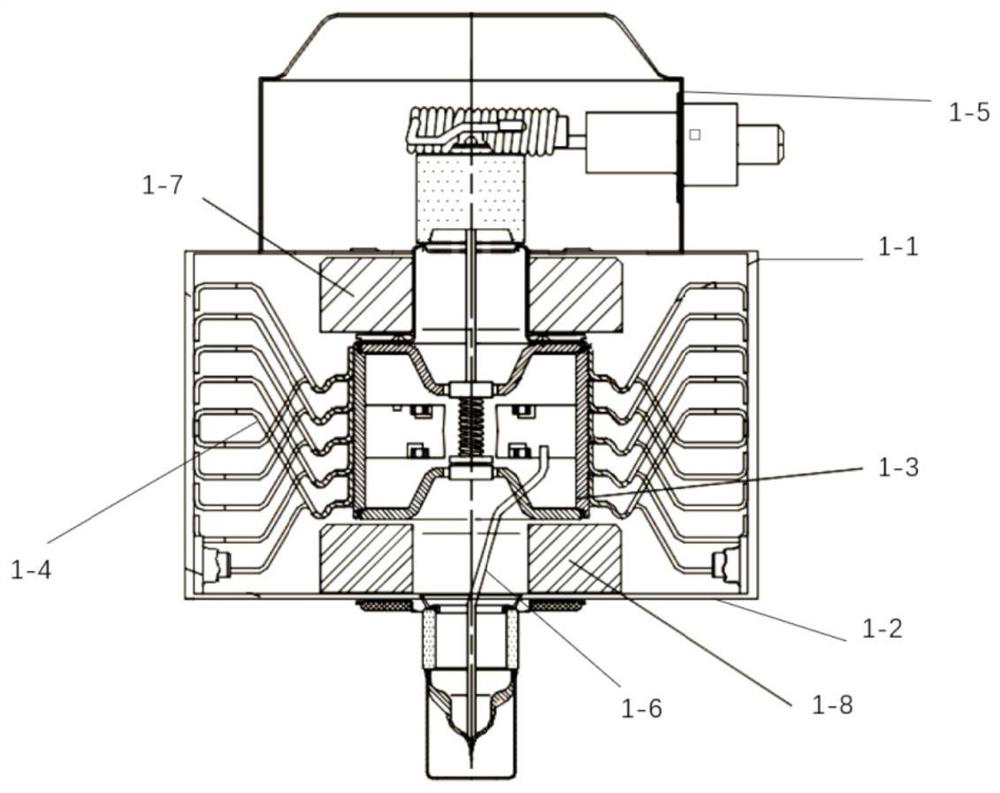

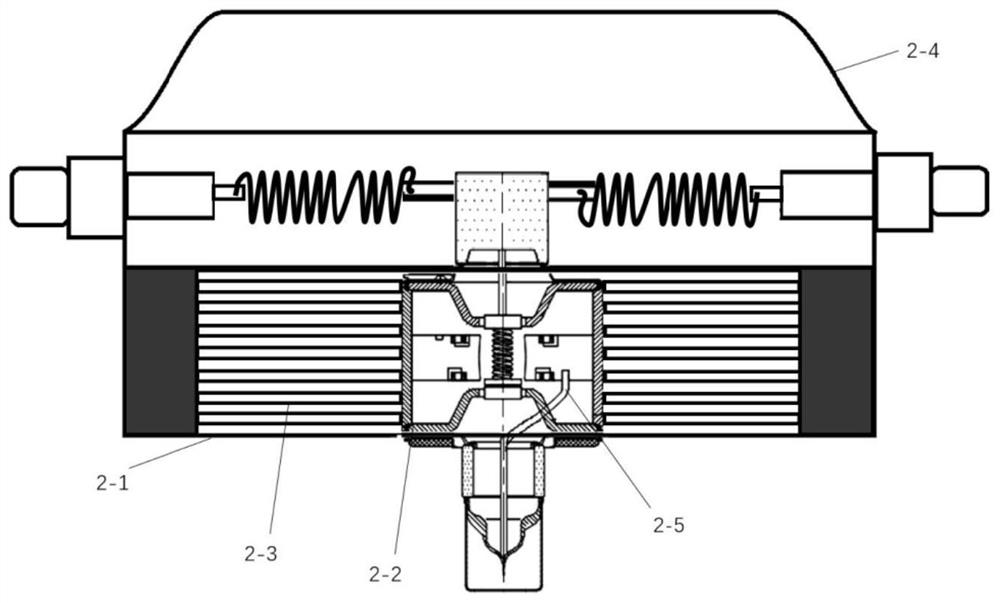

[0026] This embodiment provides a miniaturized magnetron structure, its structure is as follows image 3 As shown, it specifically includes: a bracket 2-1, a tube core 2-2, a heat dissipation blade 2-3, a filter assembly 2-4 and an antenna 2-5, wherein the tube core is installed in the center position of the bracket, and the heat dissipation The blades are arranged around the die, the filtering component is arranged on the support and connected to the die, and the antenna is arranged under the support and connected to the die;

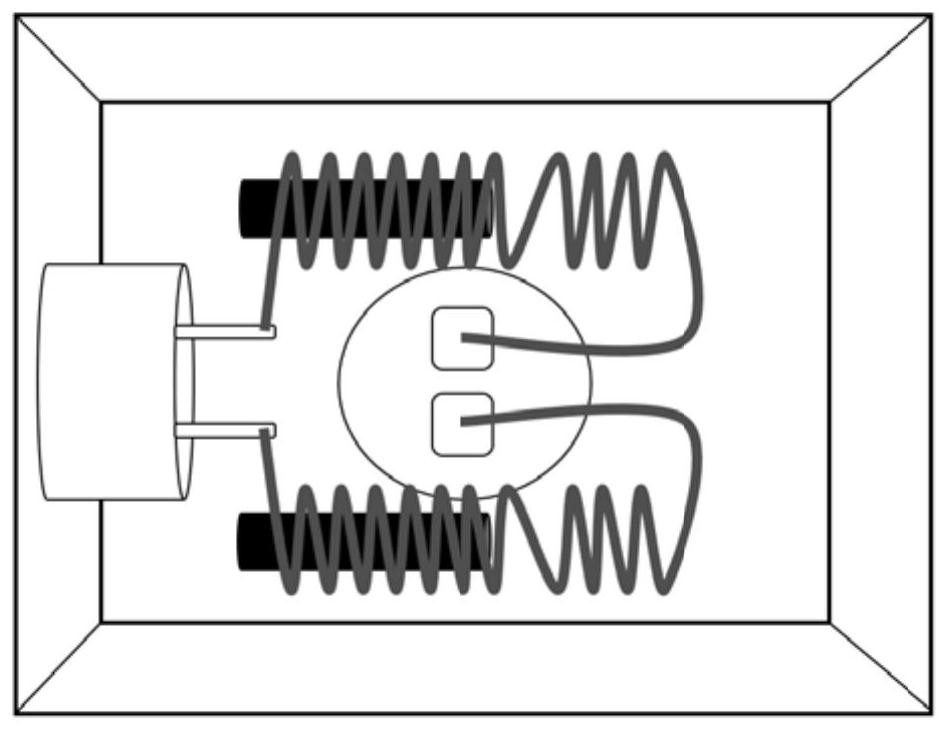

[0027] The support 2-1 is in the shape of a cuboid, such as Figure 4 As shown; surrounded by the top plate 2-1-1, the bottom plate 2-1-2, and the permanent magnet 2-1-3 fixedly supported between the top plate and the bottom plate, the permanent magnet is located in the short distance between the top plate and the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com