Patents

Literature

159results about "Transit-tube leading-in arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

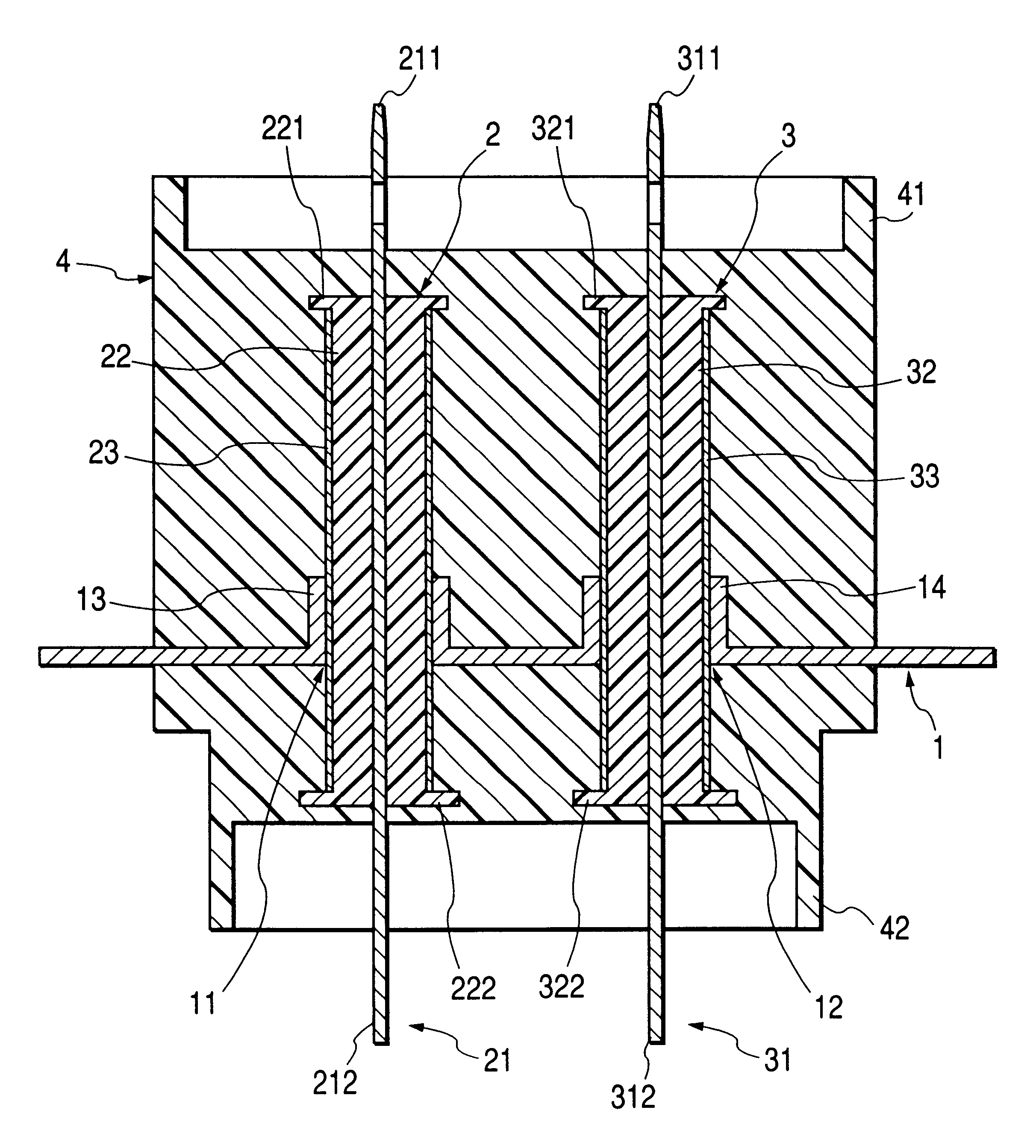

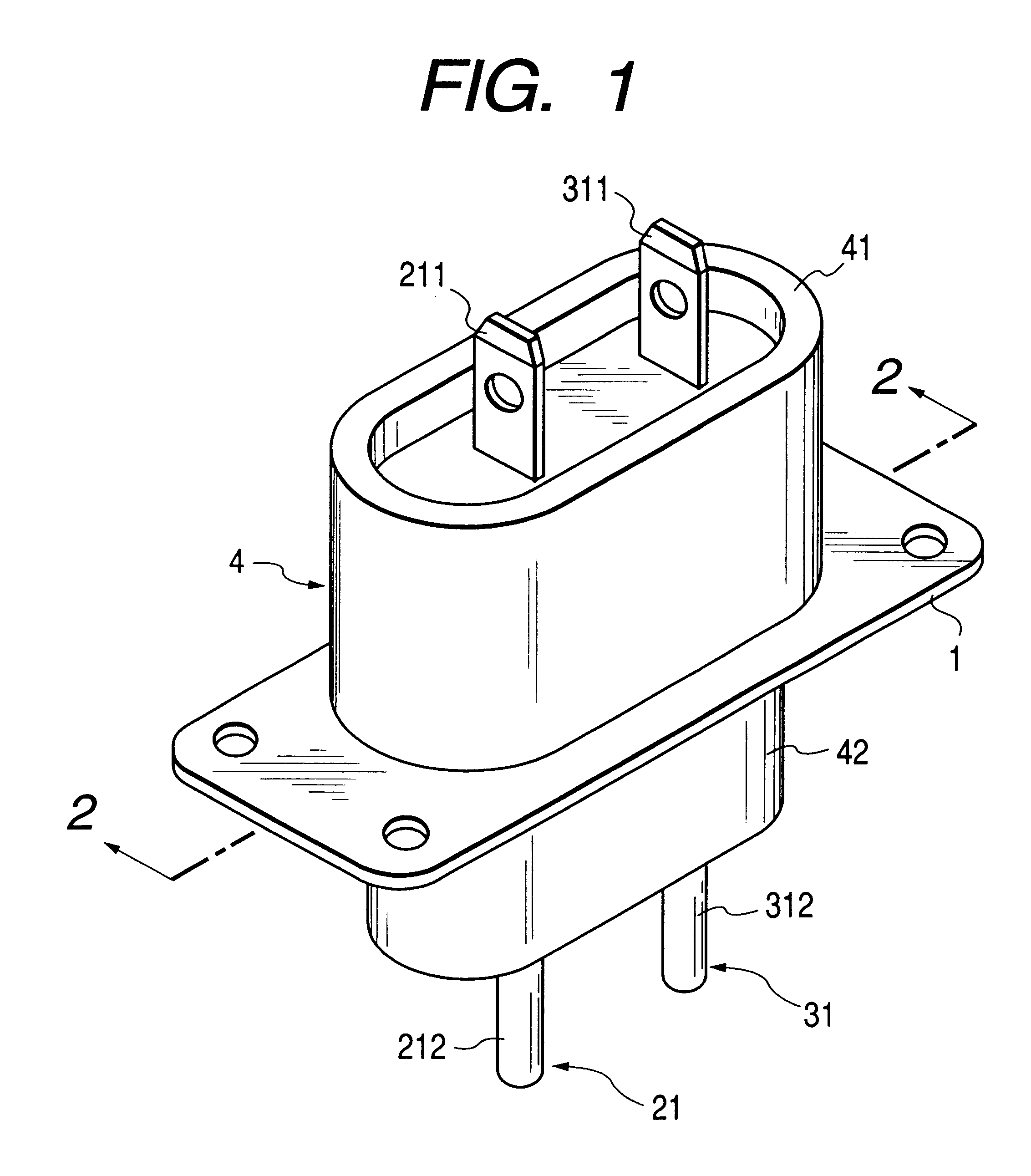

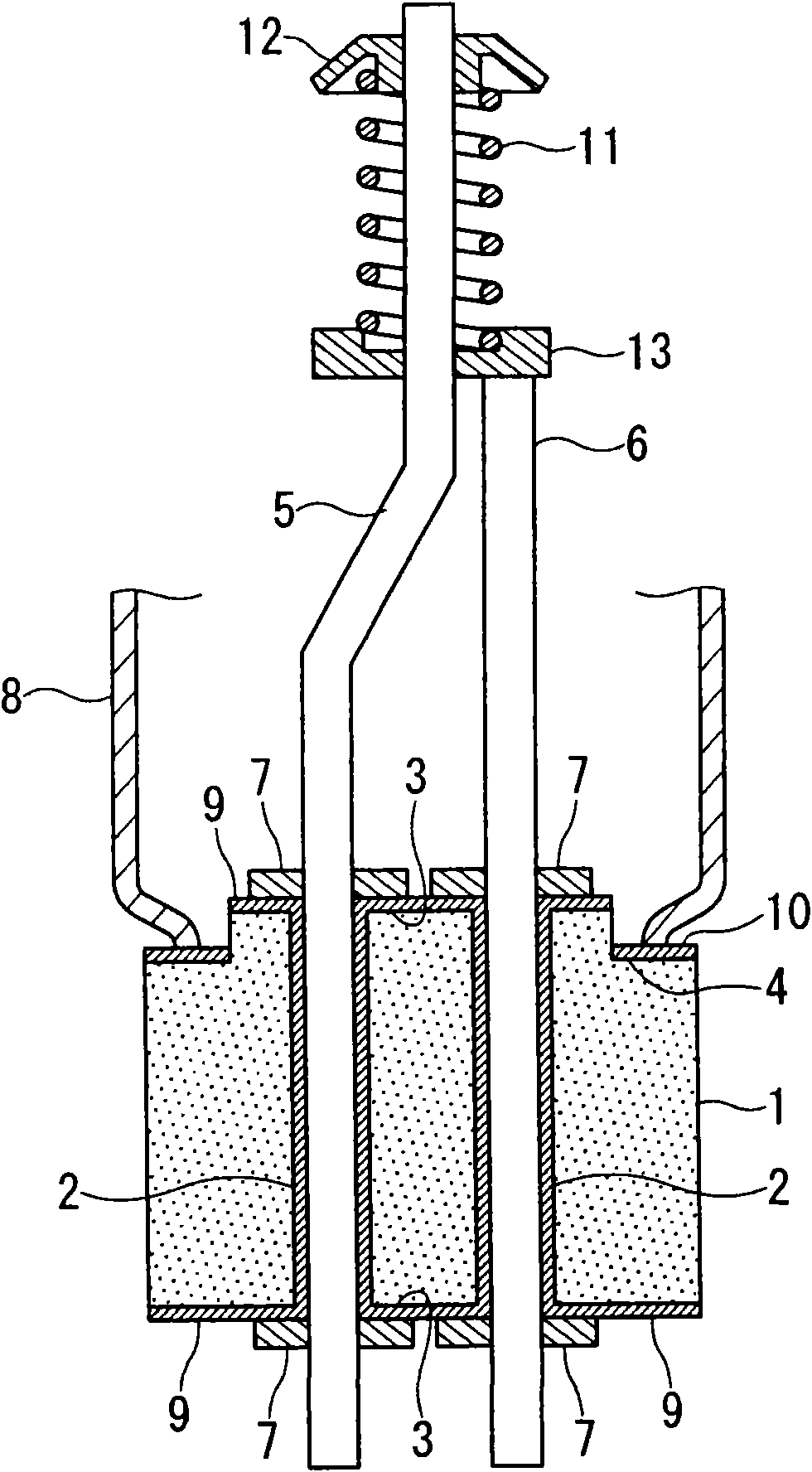

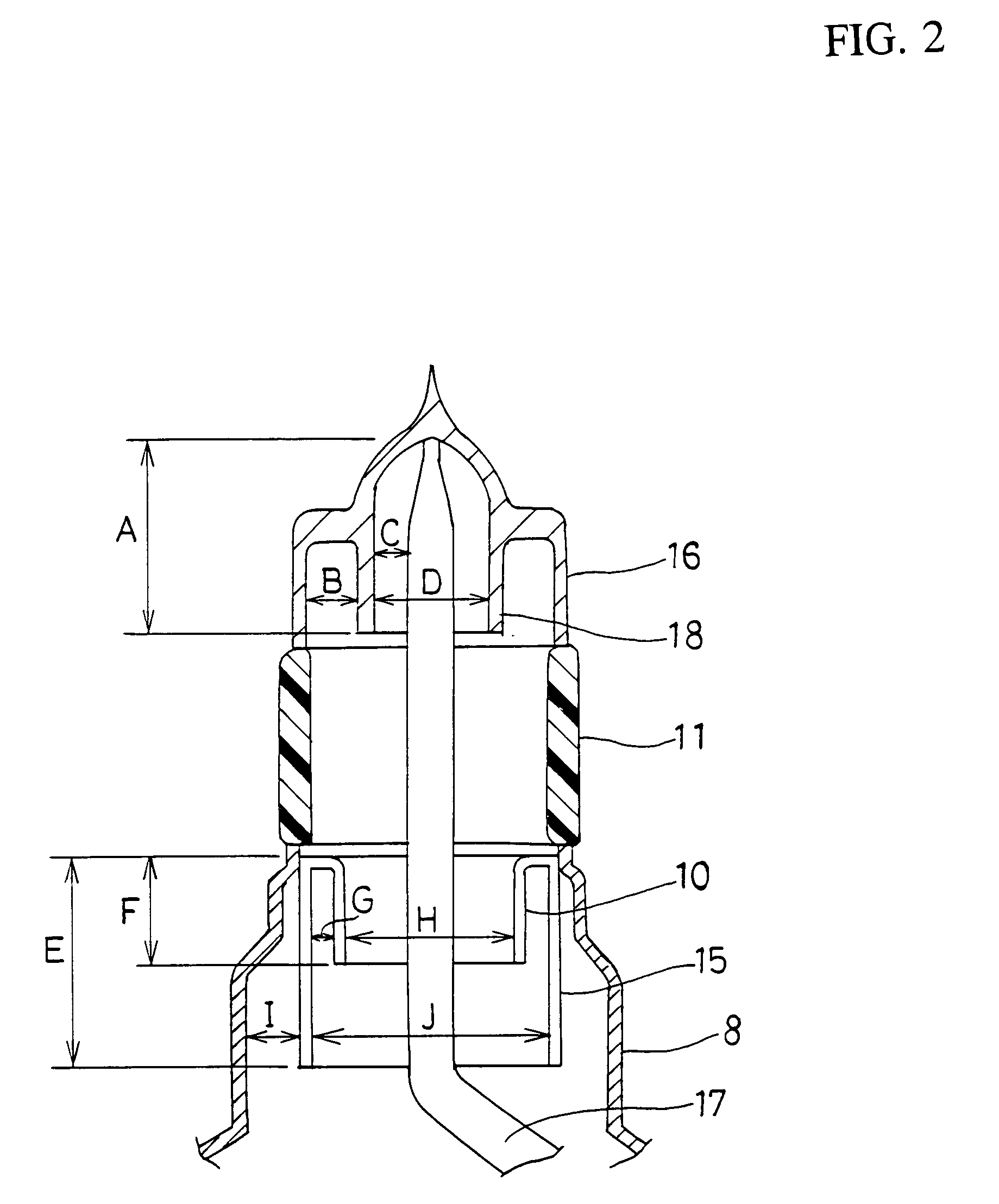

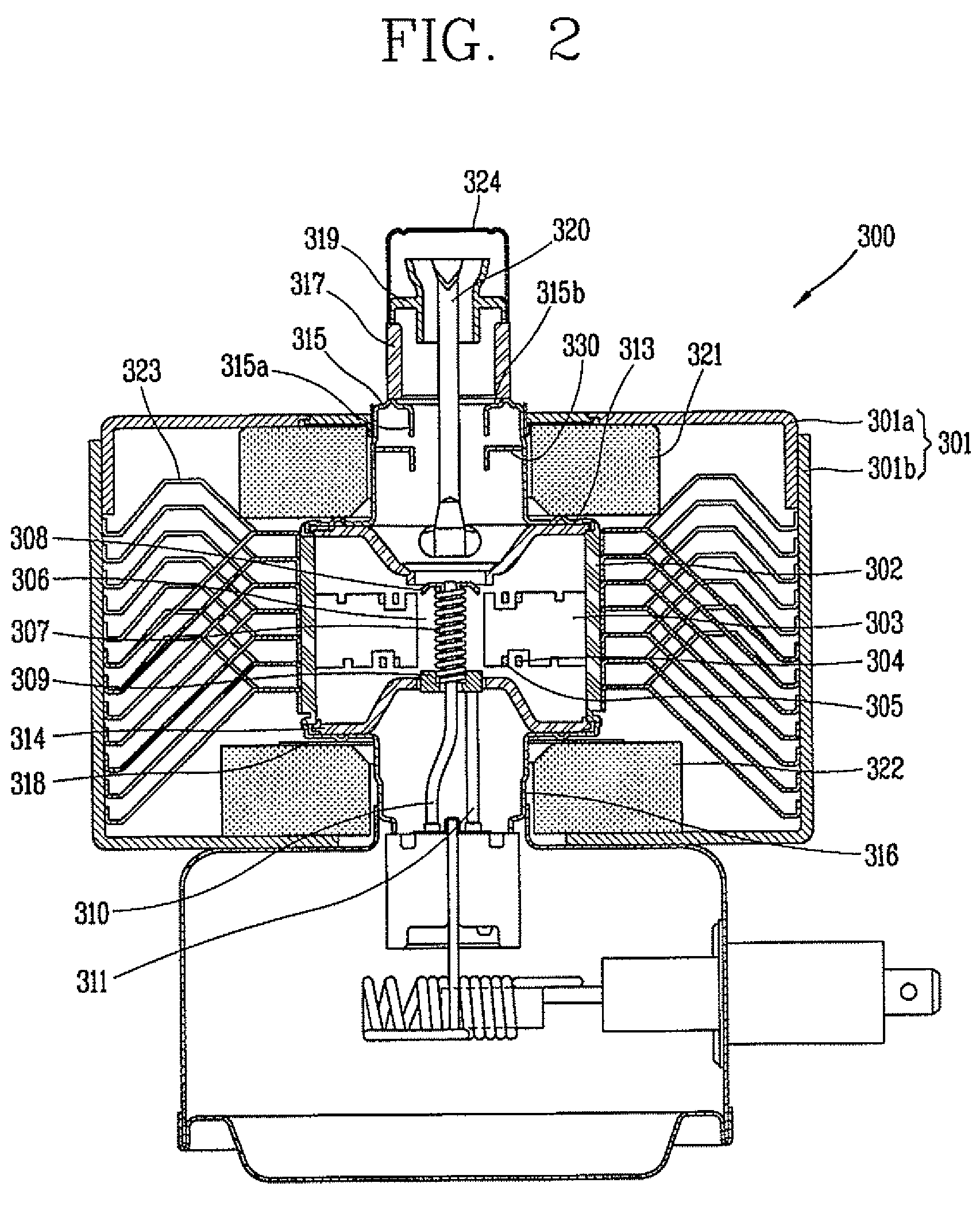

High-voltage feedthrough capacitor

InactiveUS6510038B1Increase capacitanceImprove filtering effectAnti-noise capacitorsTransit-tube leading-in arrangementsElectrical conductorEngineering

In a high-voltage feedthrough capacitor, a grounding member has two through-holes spaced away from each other. Feedthrough capacitors each has one central conductor, a dielectric layer, and an electrode. The periphery of the central conductor is respectively covered with the dielectric layer, and the surface of the dielectric layer is respectively covered with the electrode. The feedthrough capacitor extends respectively through the through-hole, and has been fitted to the grounding member. The electrode has been bonded to the grounding member. An armoring insulator covers the peripheries of the feedthrough capacitors and the periphery of the grounding member.

Owner:TDK CORPARATION

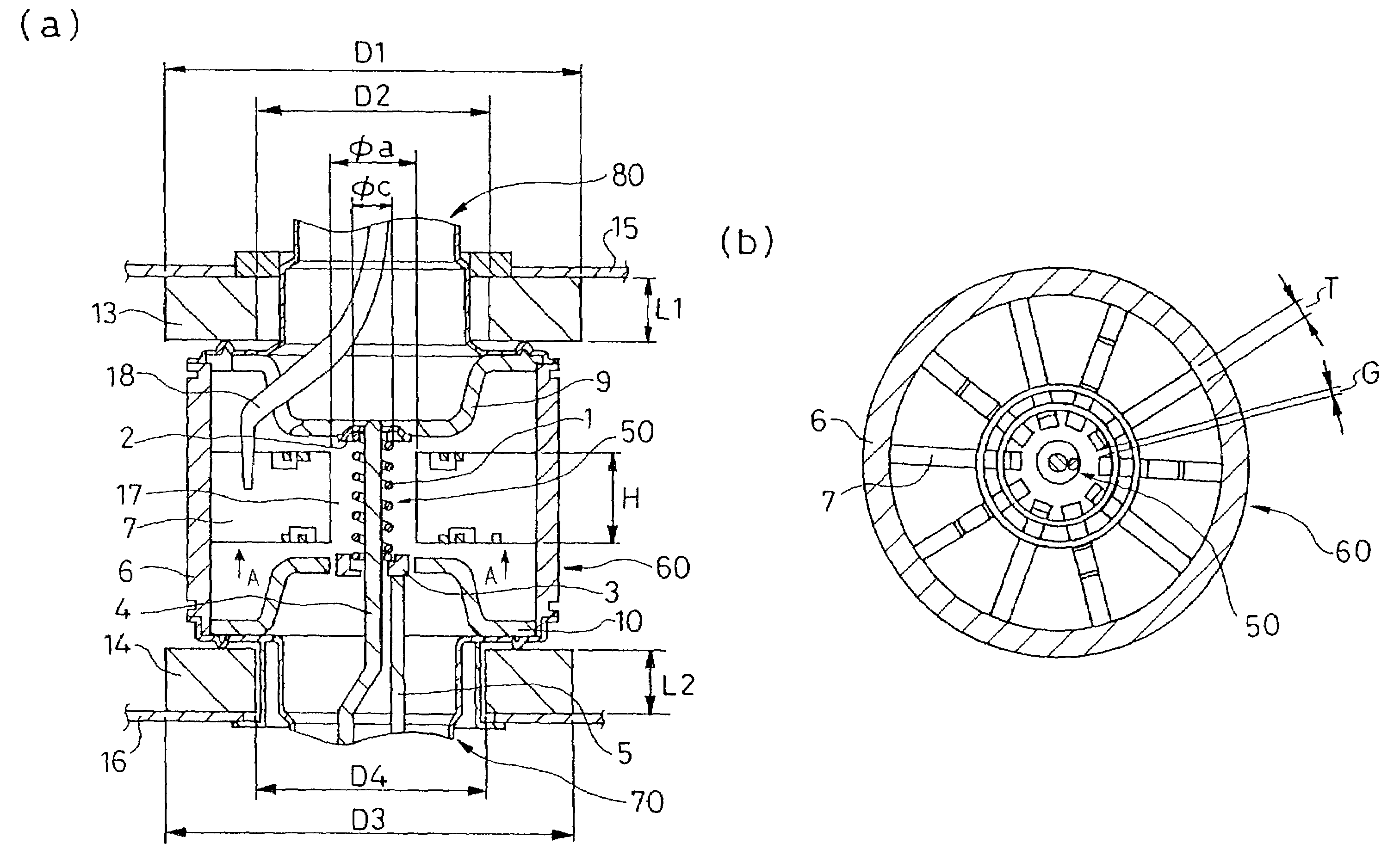

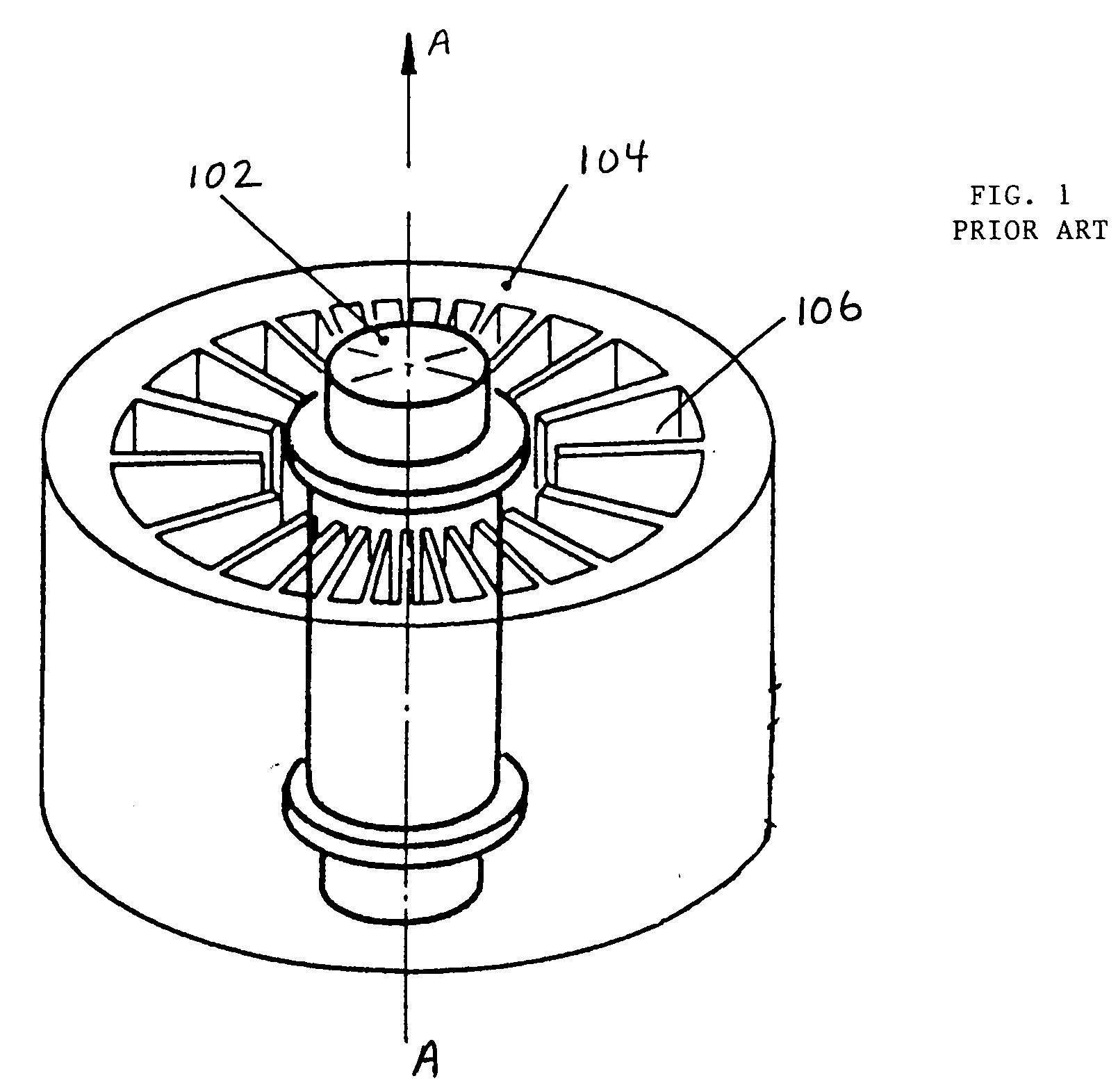

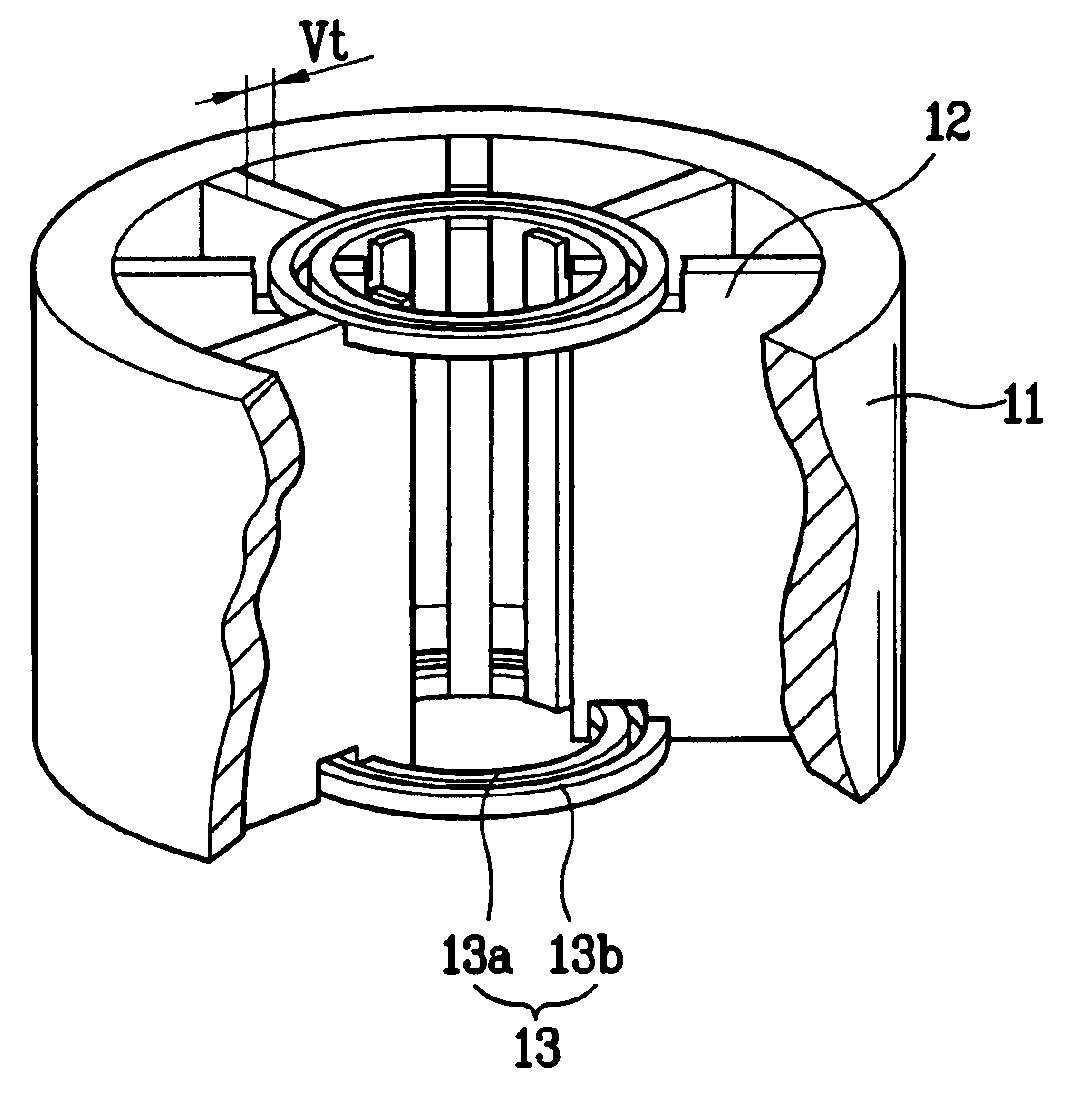

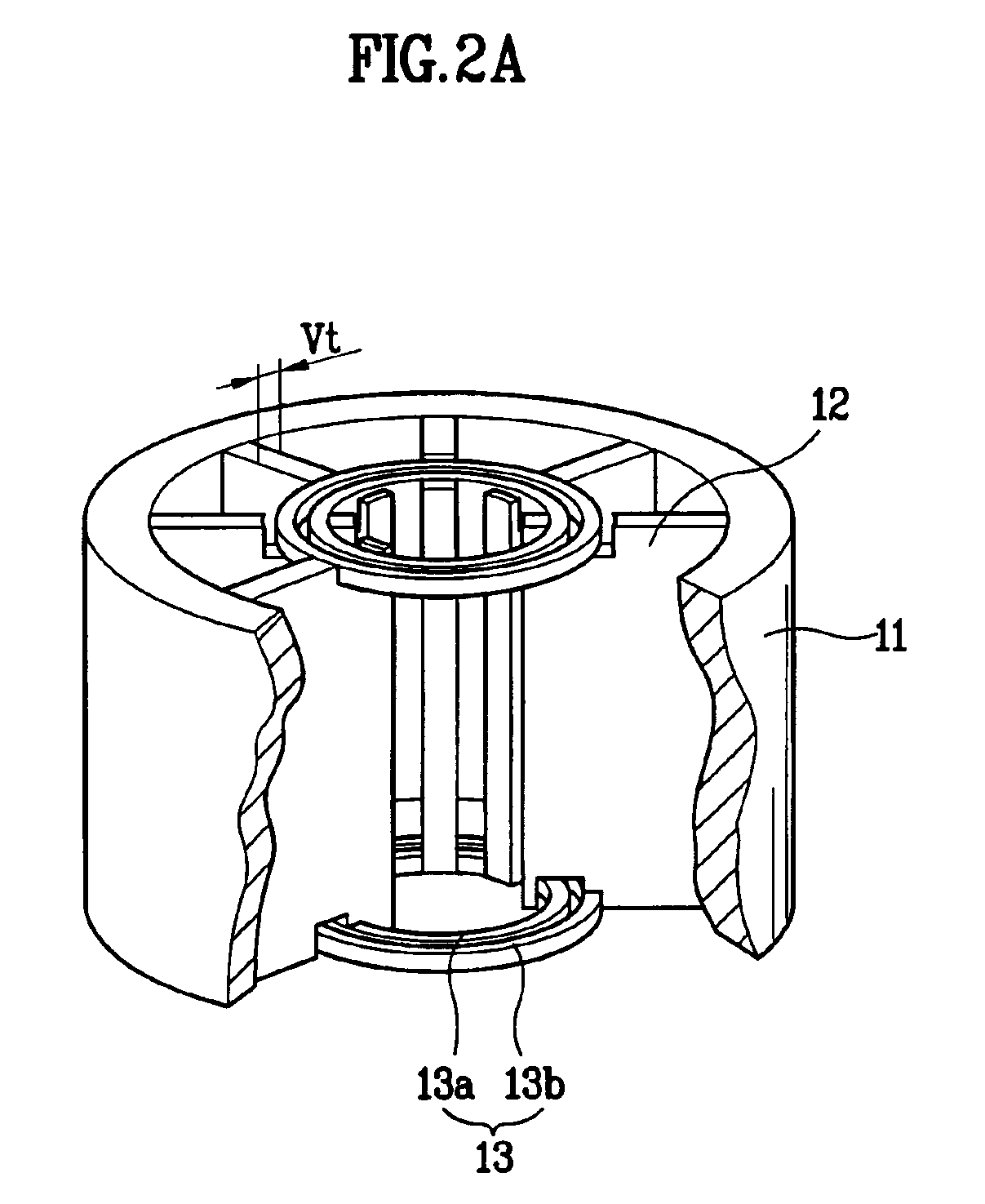

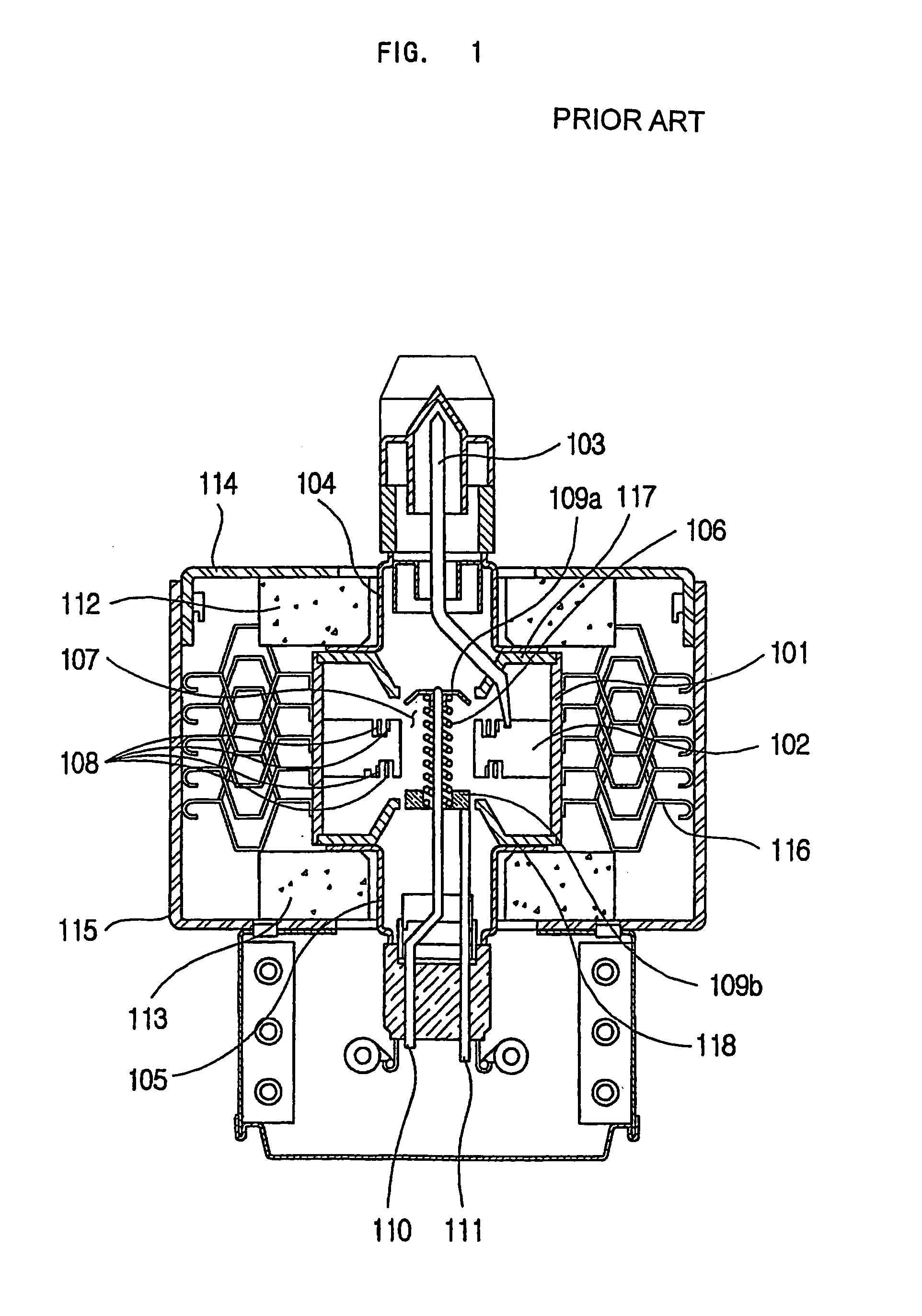

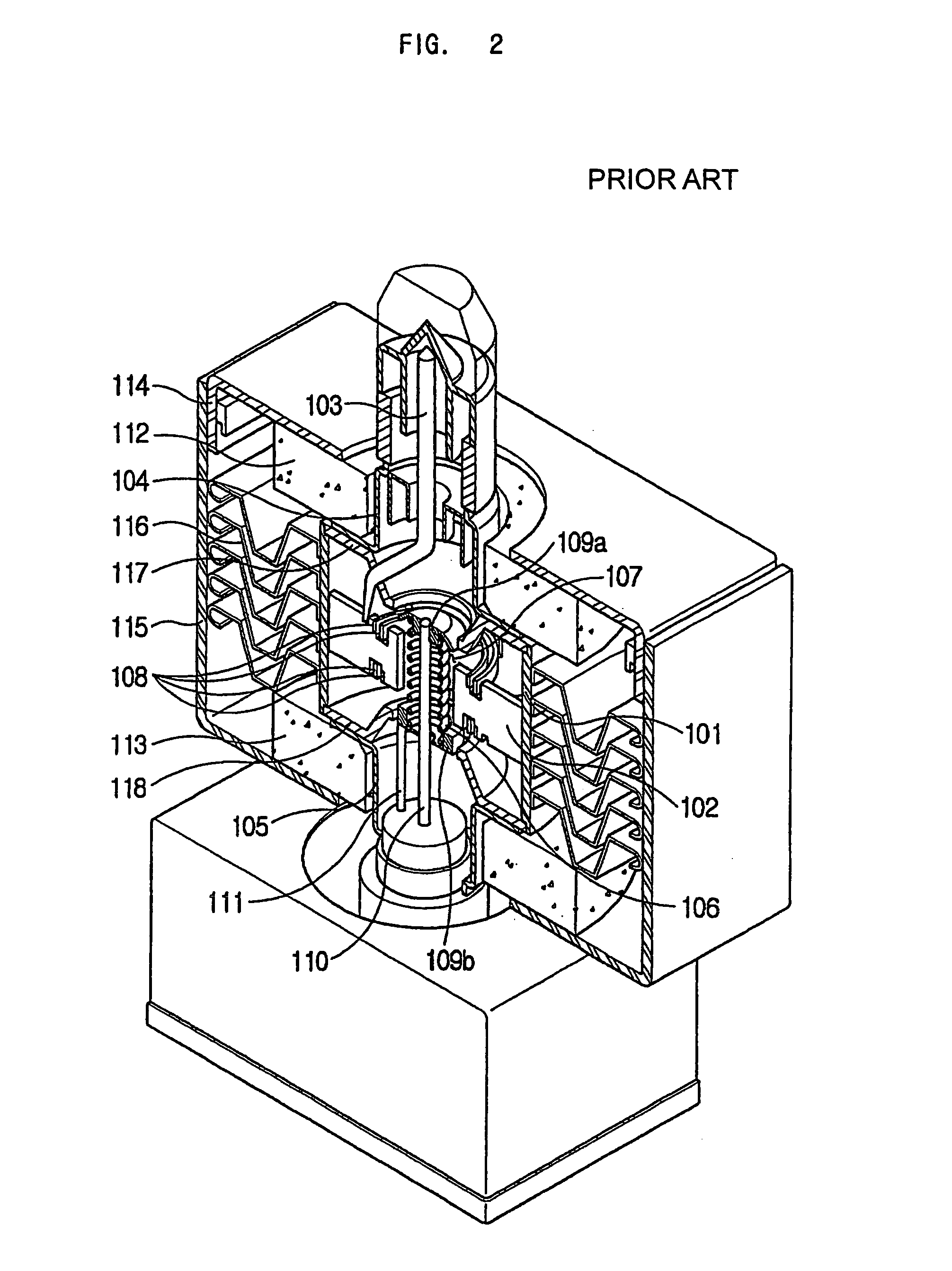

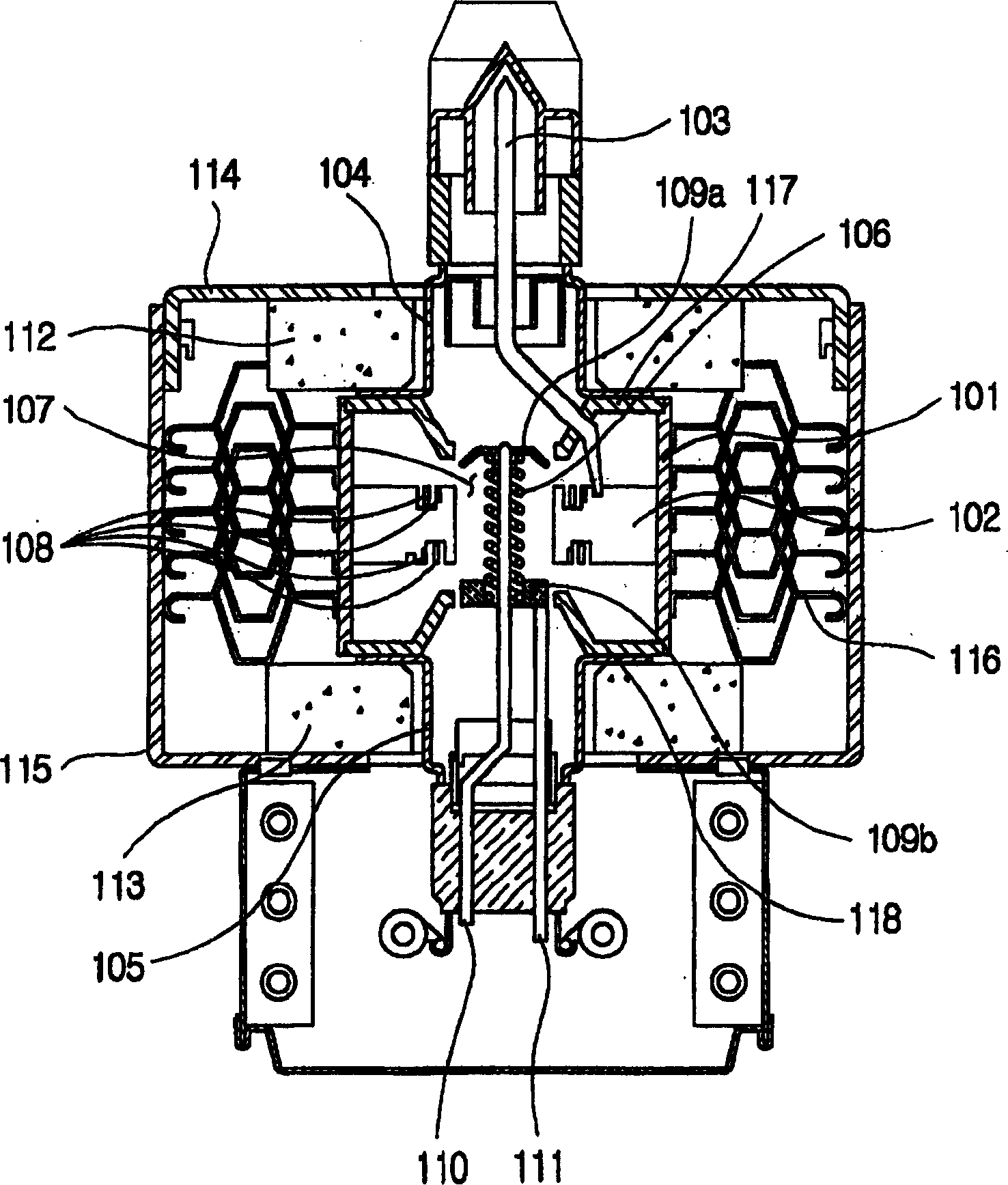

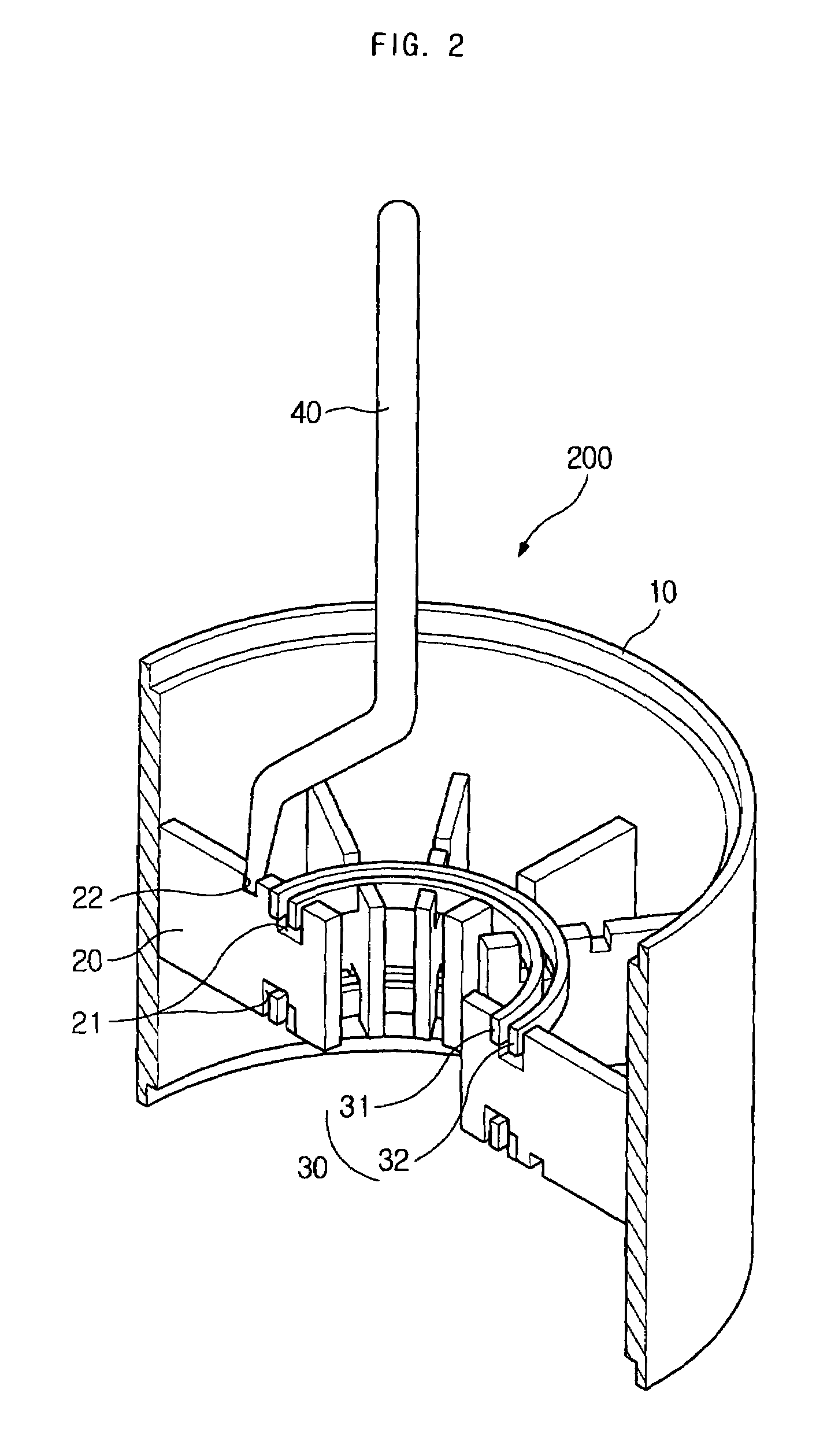

Magnetron

InactiveUS7023137B2Improve electronic efficiencyImprove oscillation efficiencyCellsTransit-tube leading-in arrangementsMicrowaveMagnetic poles

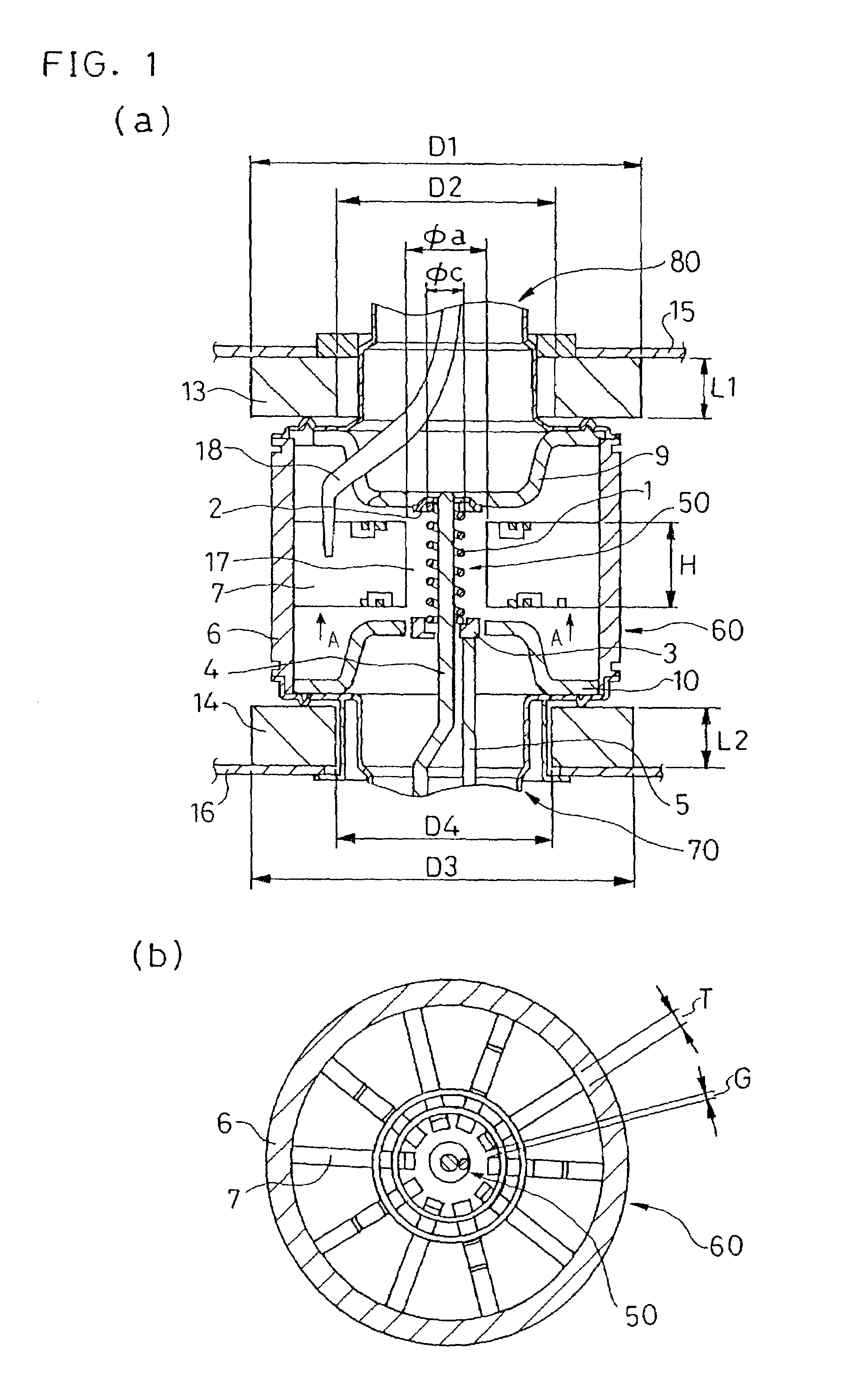

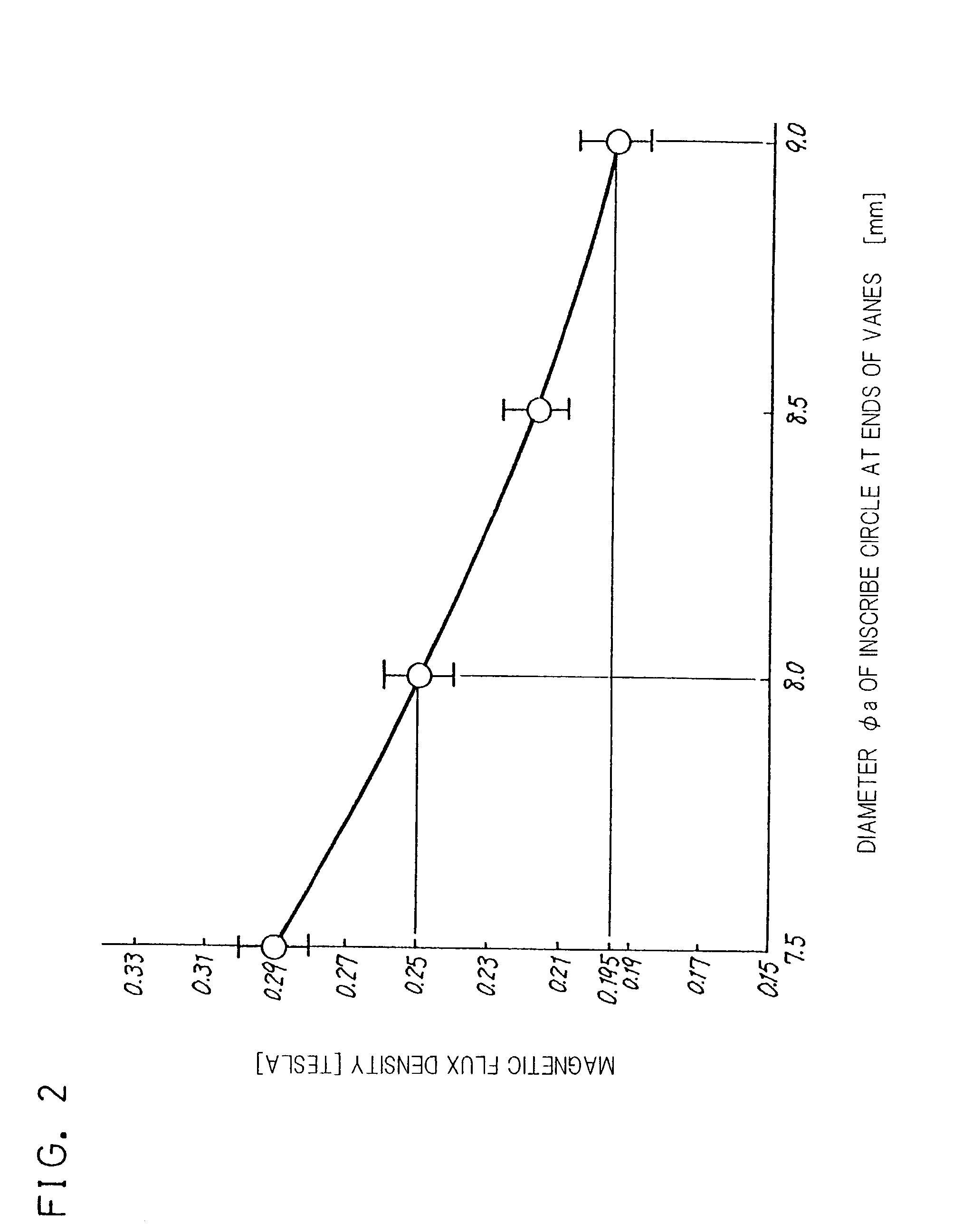

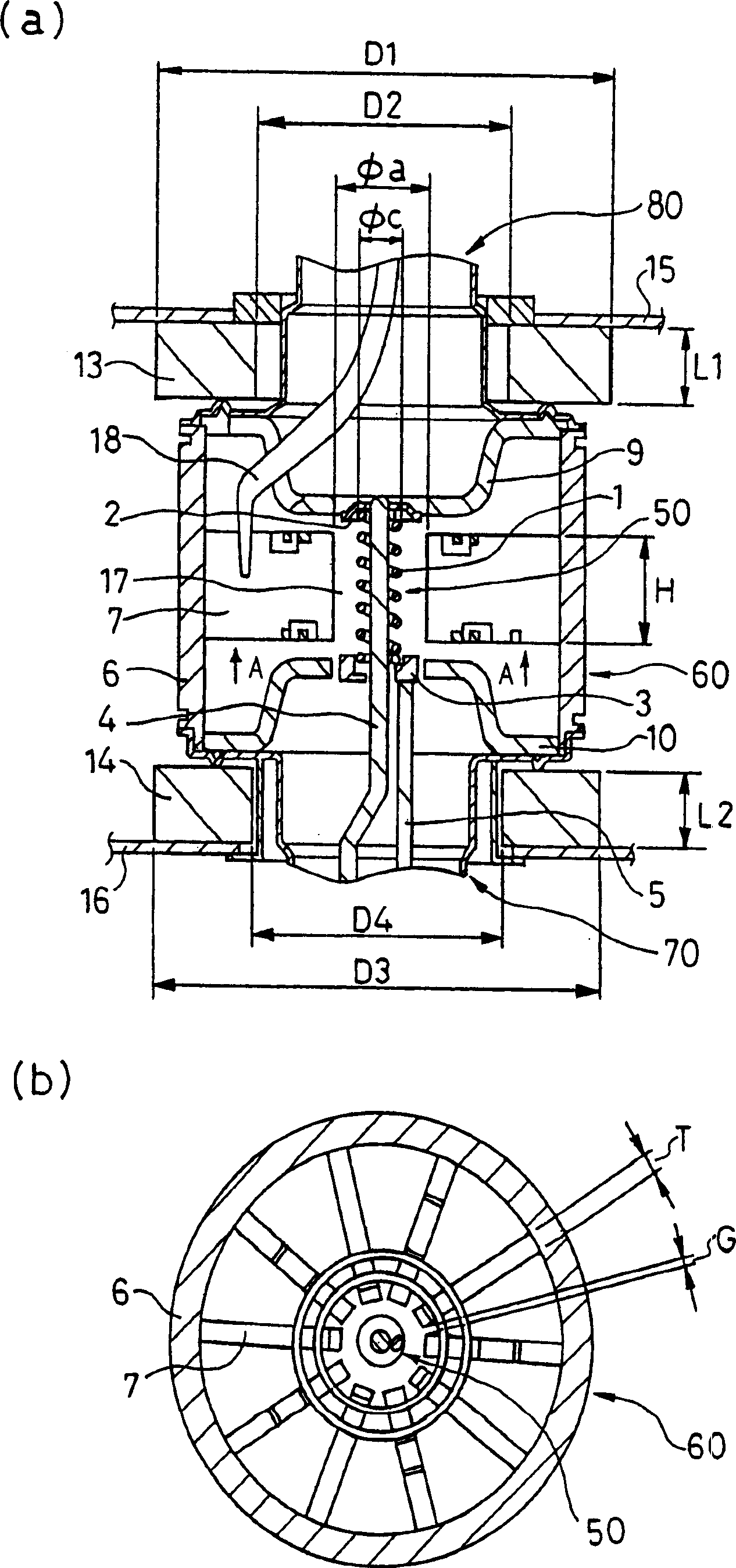

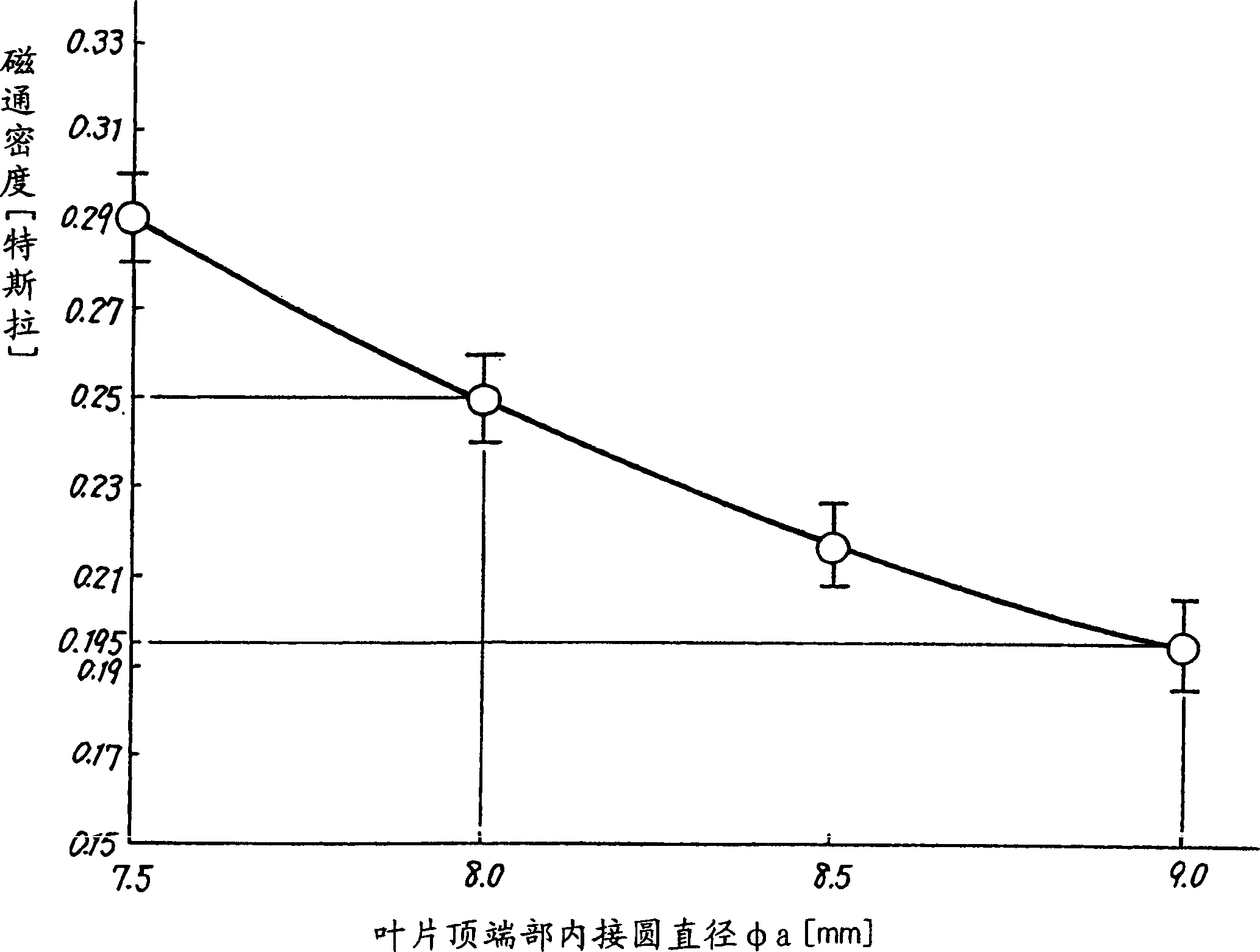

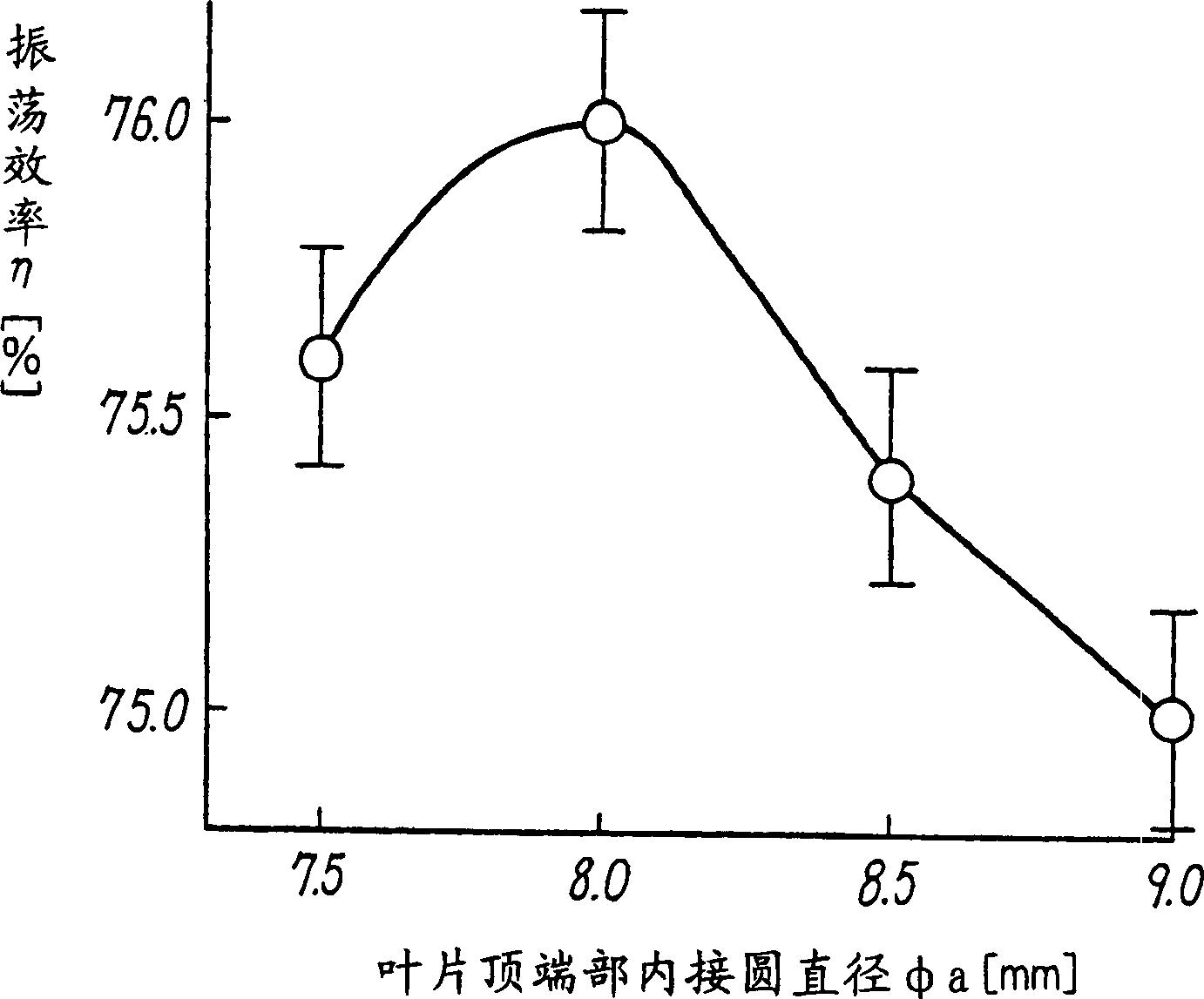

A magnetron comprising an anode portion having an anode cylinder and vanes, a cathode portion having a coil-shaped filament, magnetic poles disposed at the upper and lower ends of the filament, ring-shaped permanent magnets made of a Sr ferrite magnet containing La—Co, an input portion and an output portion. The diameter φa of the inscribed circle at the ends of the vanes constituting the anode portion is in the range of 7.5 to 8.5 mm, and the outside diameter φc of the coil-shaped filament 1 constituting the cathode portion is in the range of 3.4 to 3.6 mm.

Owner:PANASONIC CORP

Magnetron

InactiveCN1404093AImprove electronic efficiencyImprove oscillation efficiencyTransit-tube leading-in arrangementsVacuum evaporation coatingMagnetic polesOptoelectronics

A magnetron comprising an anode portion having an anode cylinder and vanes, a cathode portion having a coil-shaped filament, magnetic poles disposed at the upper and lower ends of the filament, ring-shaped permanent magnets made of a Sr ferrite magnet containing La-Co, an input portion and an output portion. The diameter phia of the inscribed circle at the ends of the vanes constituting the anode portion is in the range of 7.5 to 8.5 mm, and the outside diameter phic of the coil-shaped filament 1 constituting the cathode portion is in the range of 3.4 to 3.6 mm.

Owner:PANASONIC CORP

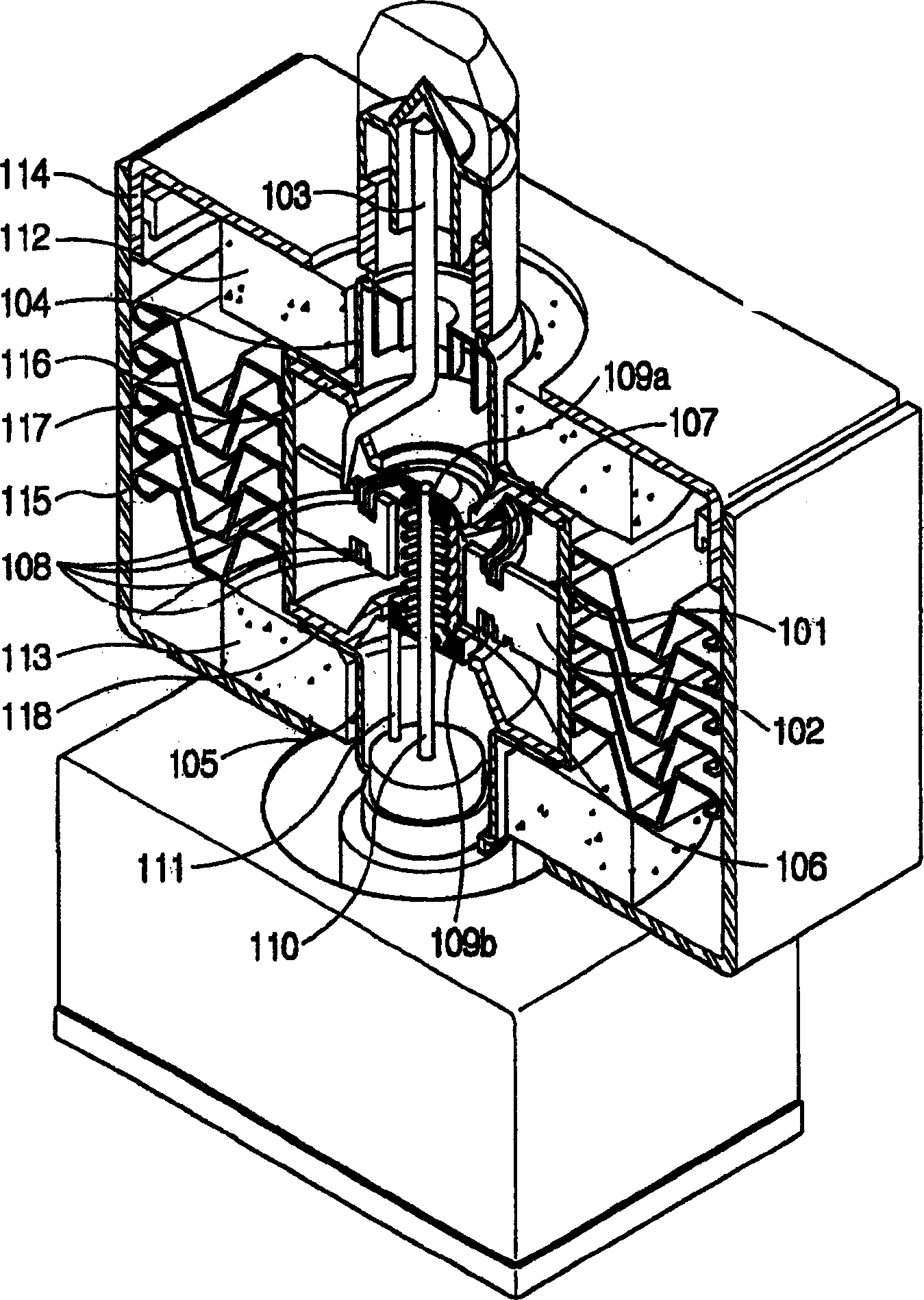

Magnetron

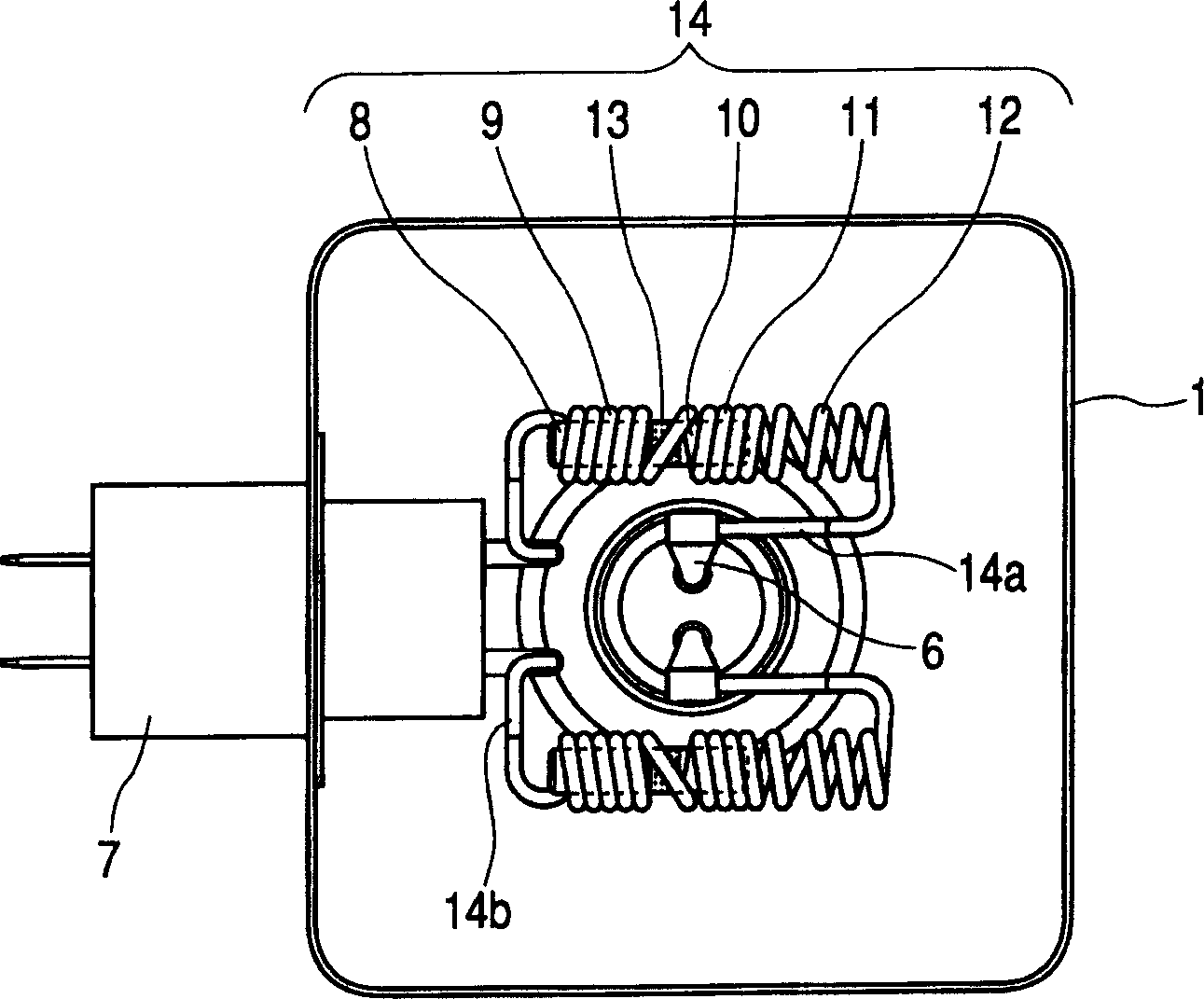

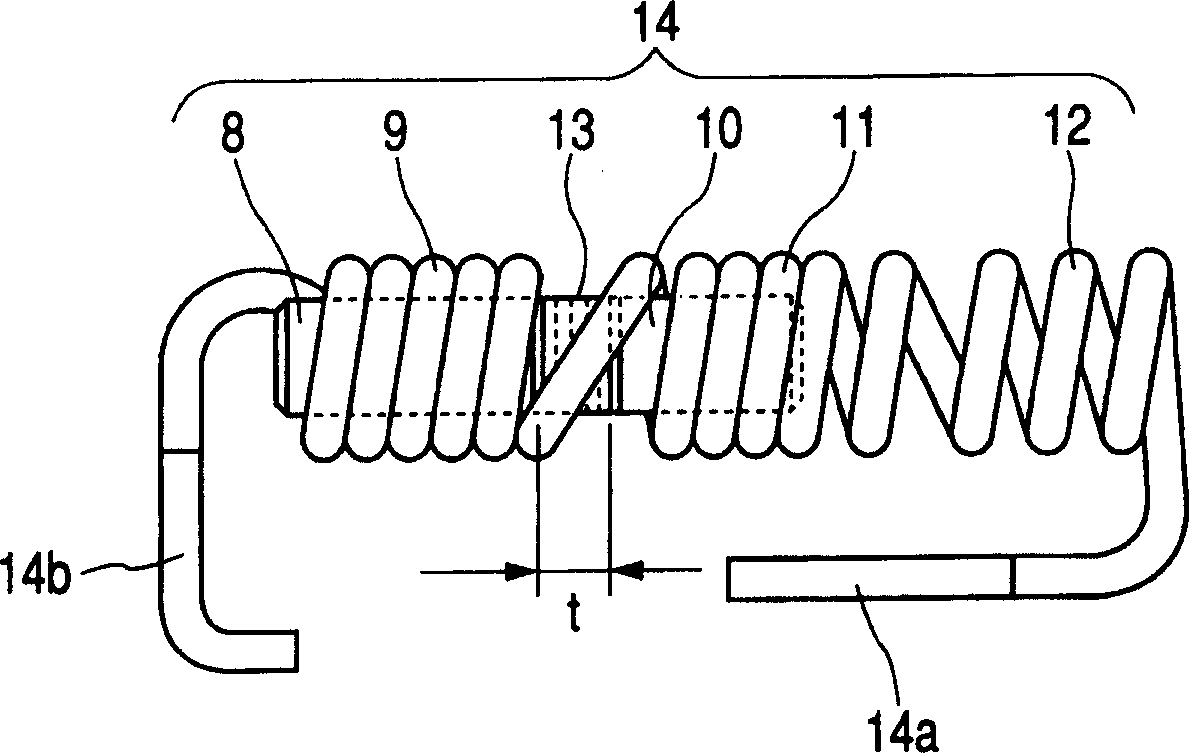

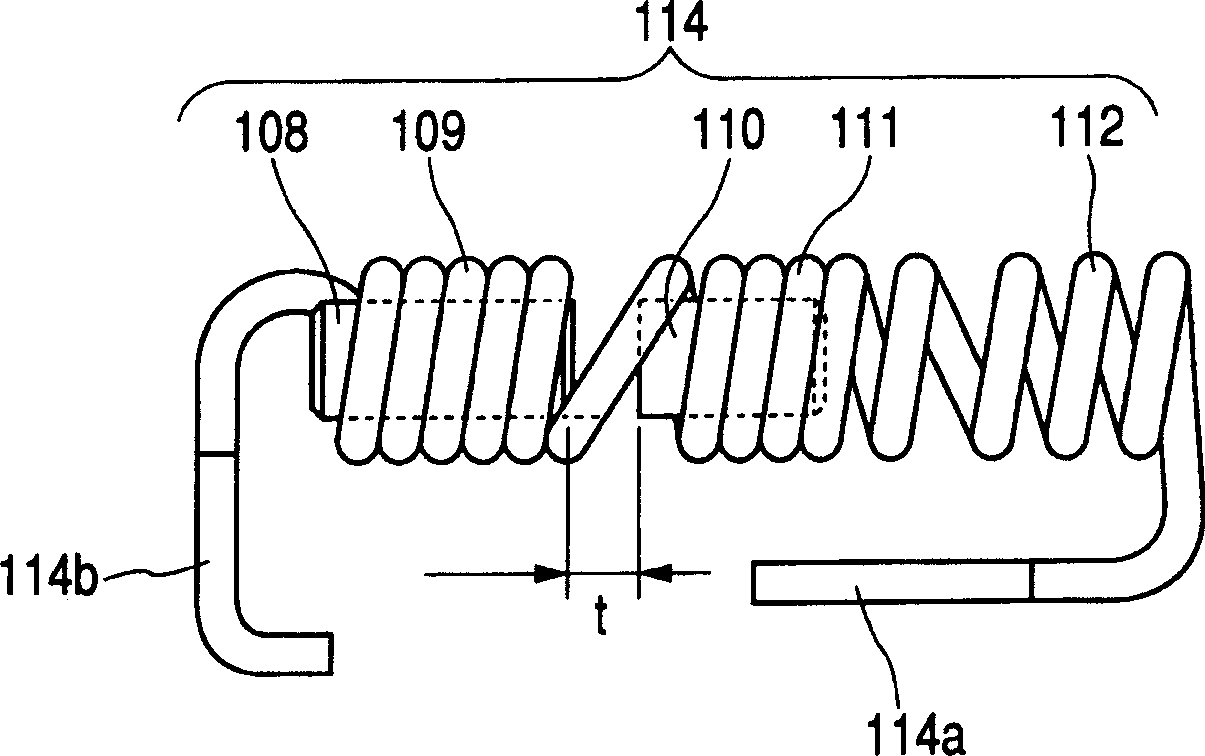

InactiveCN1577700APrevent slap noiseInfluence of dielectric constant characteristicsTransit-tube leading-in arrangementsMagnetronsAir coreInductor

A magnetron that includes a choke coil which is connected at one end to a cathode terminal and at the other end to a capacitor to form an LC circuit. The choke coil is made up of a first core type inductor, a second core type inductor and an air-core inductor, connected to the cathode terminal, all of which are connected in series and where the first and second core type inductors are separated by a 1 mm to 6 mm gap. The first and second core type inductors have a bar like, high-frequency absorbing member located within their respective windings.

Owner:PANASONIC CORP

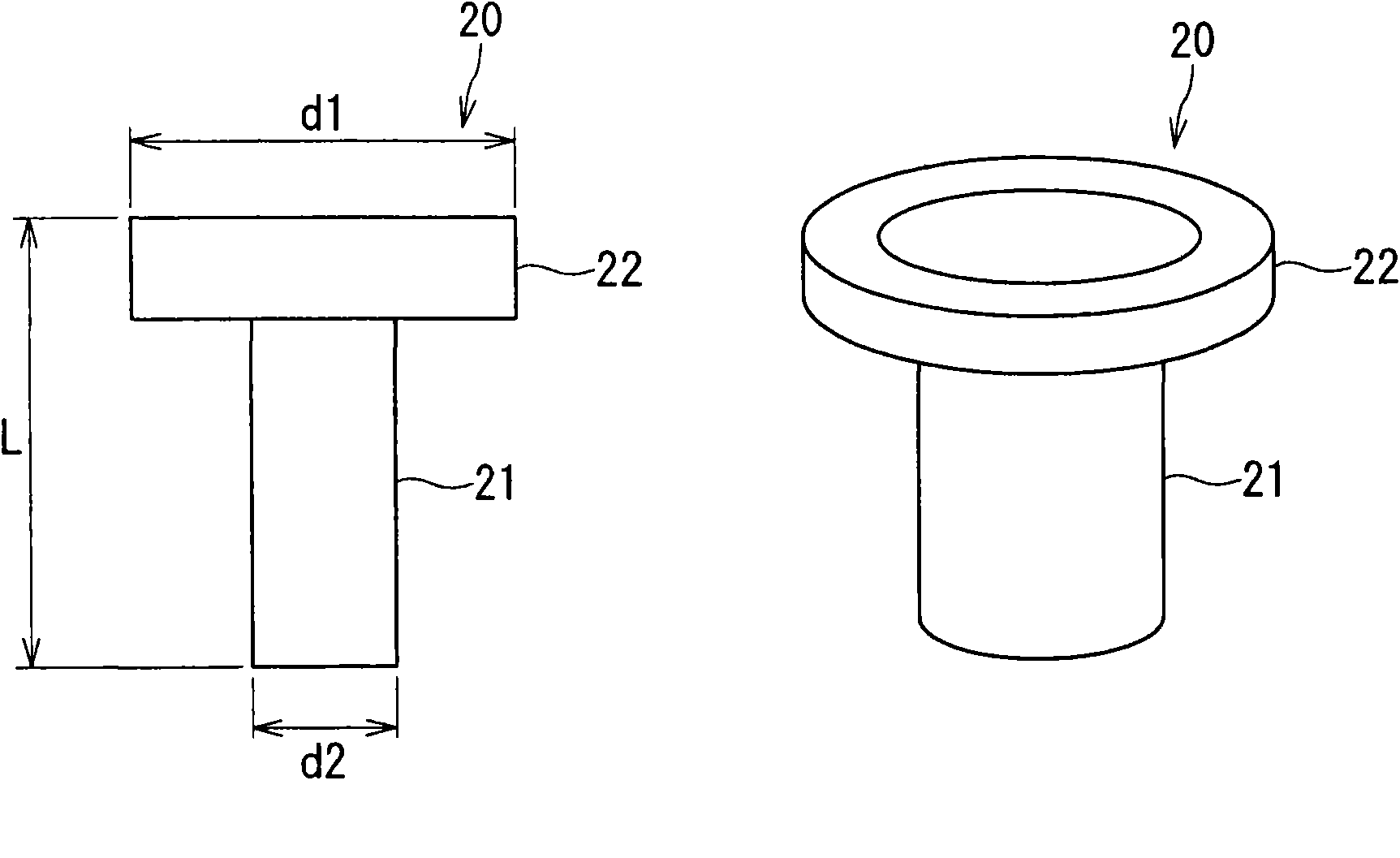

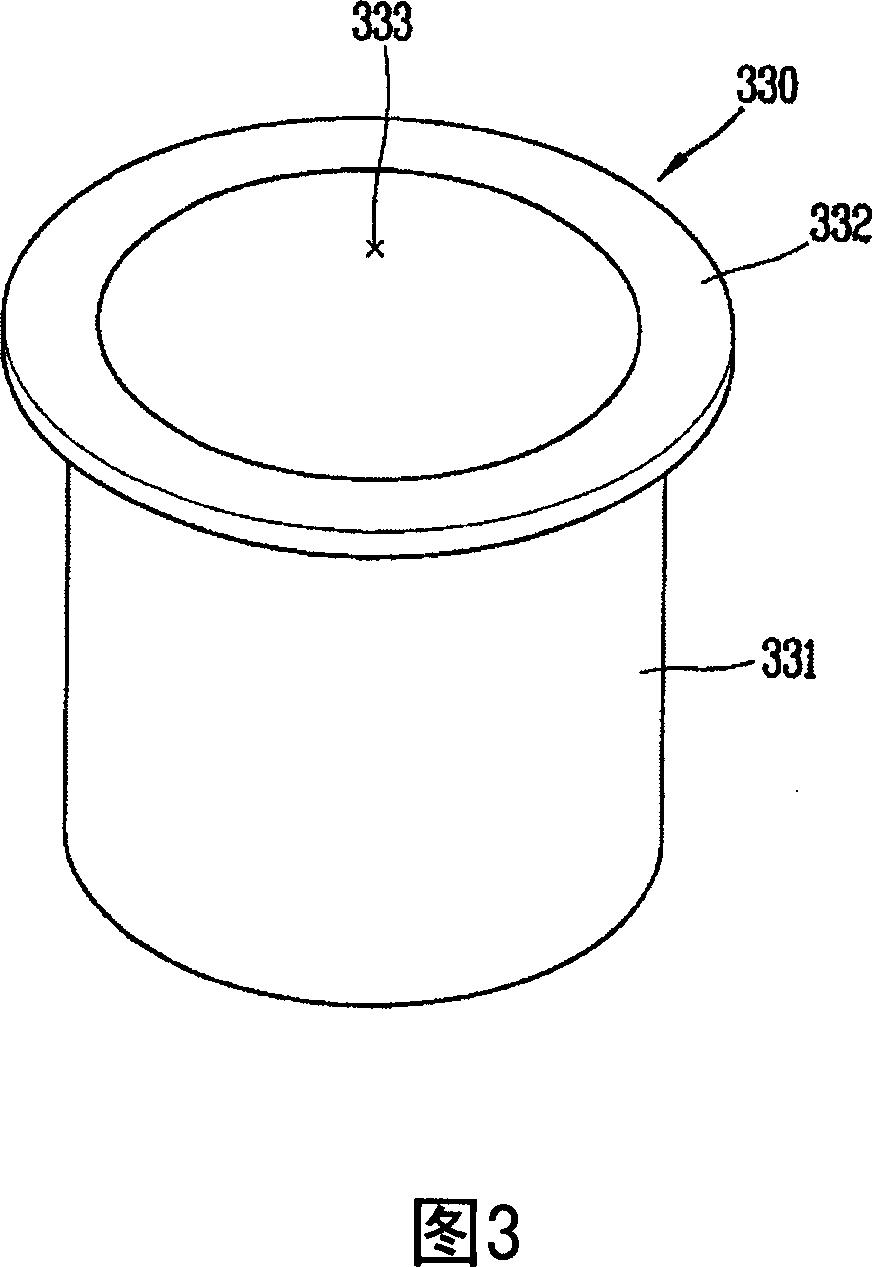

Ceramic part for magnetron, magnetron employing the same, and process for producing ceramic part for magnetron

ActiveCN101652829AImprove joint strengthImprove reliabilityTransit-tube vessels/containersTransit-tube leading-in arrangementsAdhesion strengthGrain boundary

A ceramic part for magnetrons which has a metallic layer having improved adhesion strength. The ceramic part for magnetrons comprises a ceramic main body part (1) comprising an alumina sinter and Mo-Mn metallic layers (9 and 10) disposed by metallization on the surface of part of the ceramic main body part, wherein the ceramic main body part is an alumina sinter having an Mn-containing grain boundary phase and has an Mn-rich phase at the interface between the ceramic main body part and the Mo-Mn metallic layers.

Owner:KK TOSHIBA +1

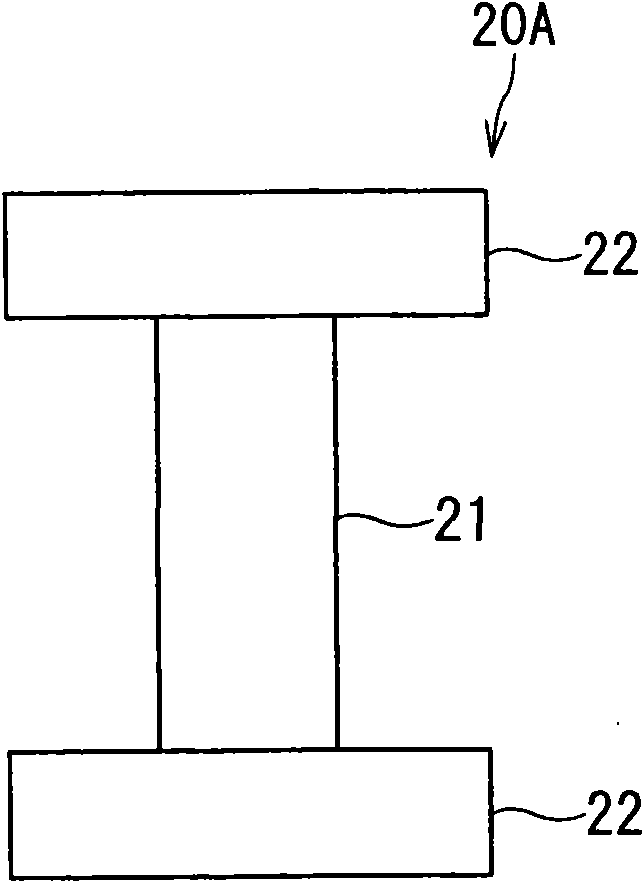

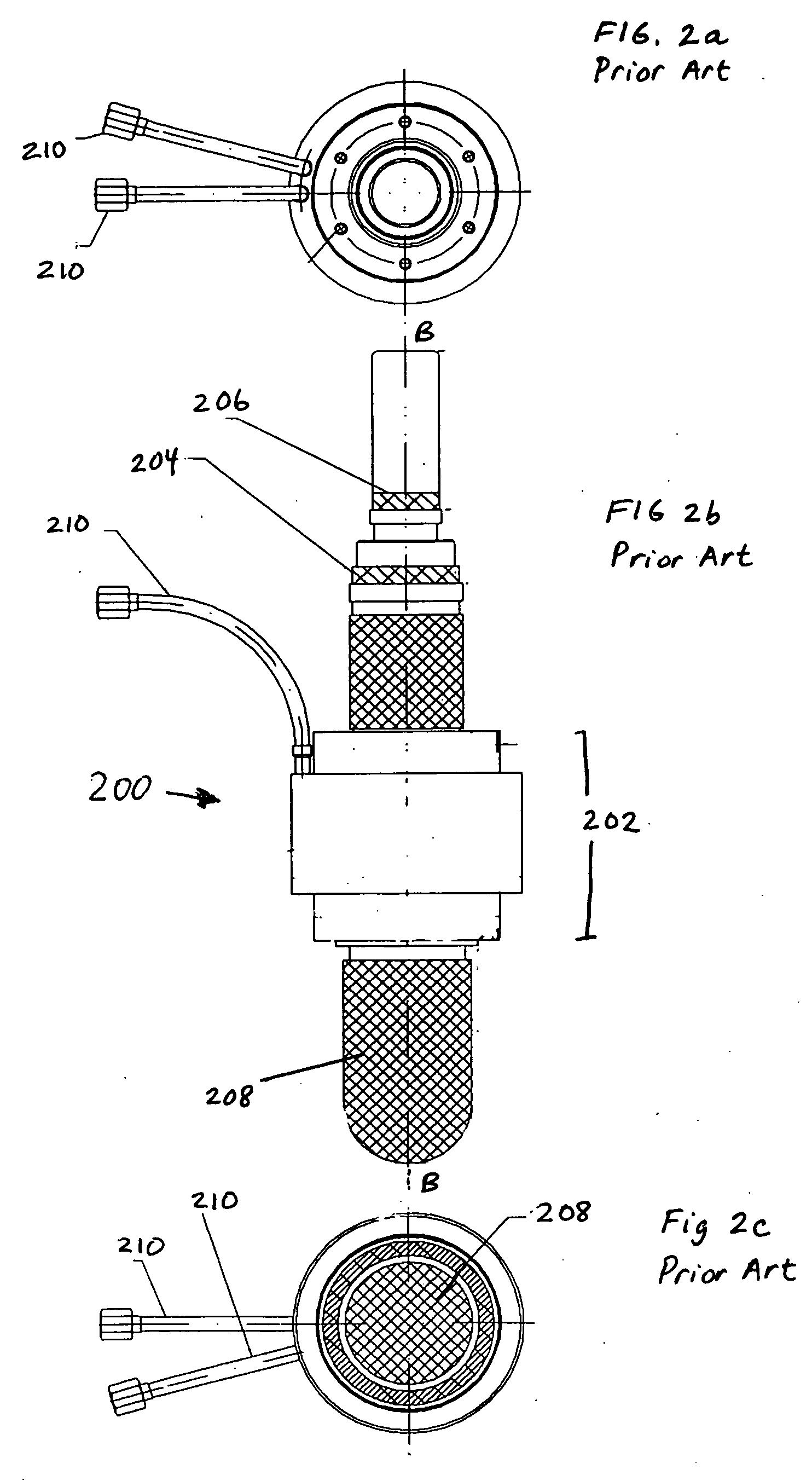

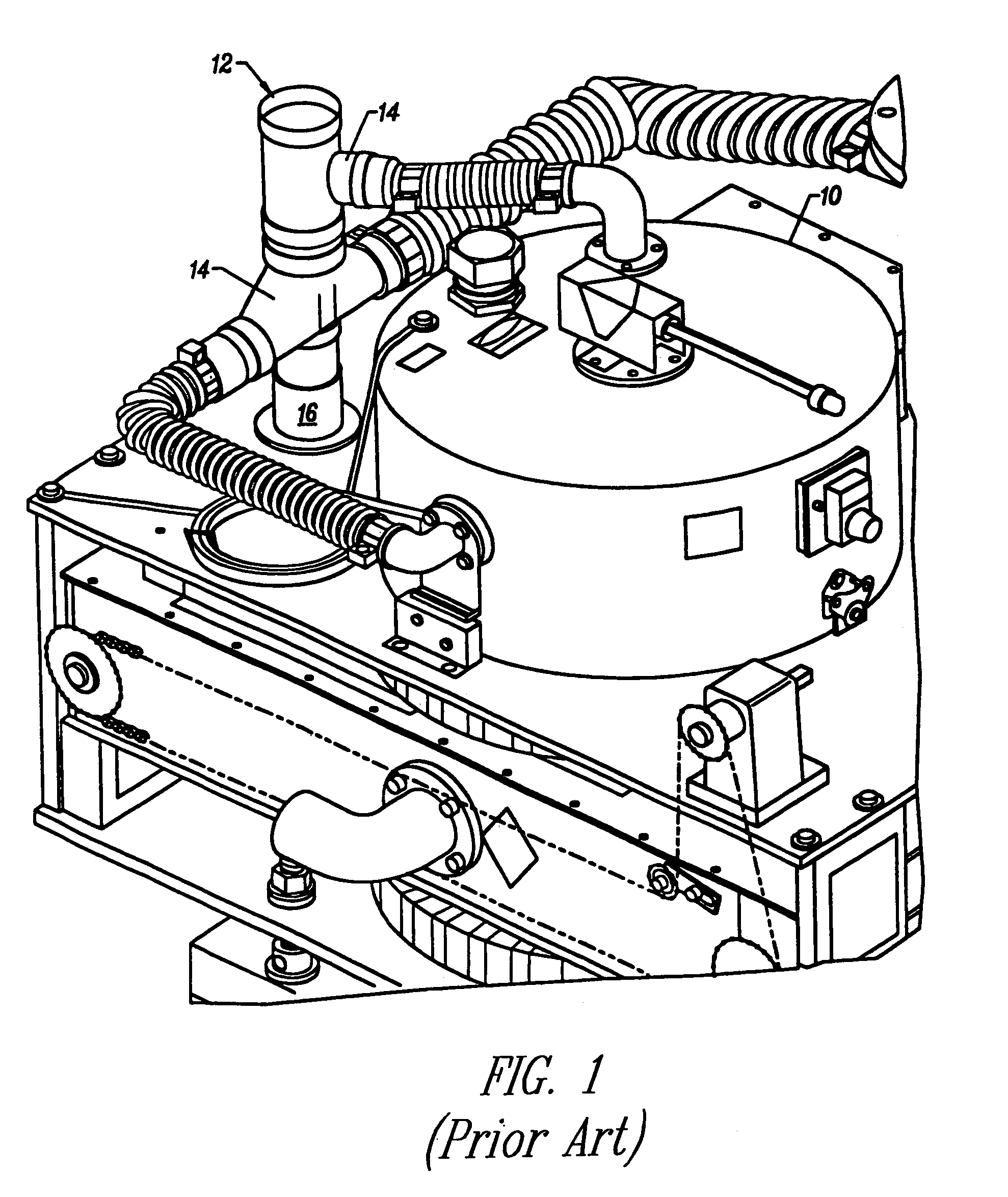

Insulated RF suppressor for industrial magnetrons

InactiveUS20050230387A1High voltageLow failure rateTransit-tube leading-in arrangementsMicrowave heatingElectricityIron powder

A radio-frequency (RF) radiation suppressor component for use with magnetrons that reduces spurious leakage radiation by absorbing RF radiation, that seats a metal ring connector fixture for making electrical contact to the cathode of the magnetron, and that exhibits improved tolerance of higher operating voltages. An insulated RF suppressor component is comprised of an insulating sleeve member and an outer shell cladding layer made of molded composite iron powder / epoxy resin material that absorbs part of the RF radiation and thus acts as an absorber to reduce magnetron radiation leakage. The insulating sleeve end has a ridged groove indentation to seat a metal clamping ring that contacts the magnetron cathode and provides a terminal connection for the cathode voltage bias and filament heating circuit leads. Testing of prototypes indicates significant improvement in permissible operating voltages and comparable RF suppression compared to conventional RF suppressor components currently in use.

Owner:BURLE TECH LLC

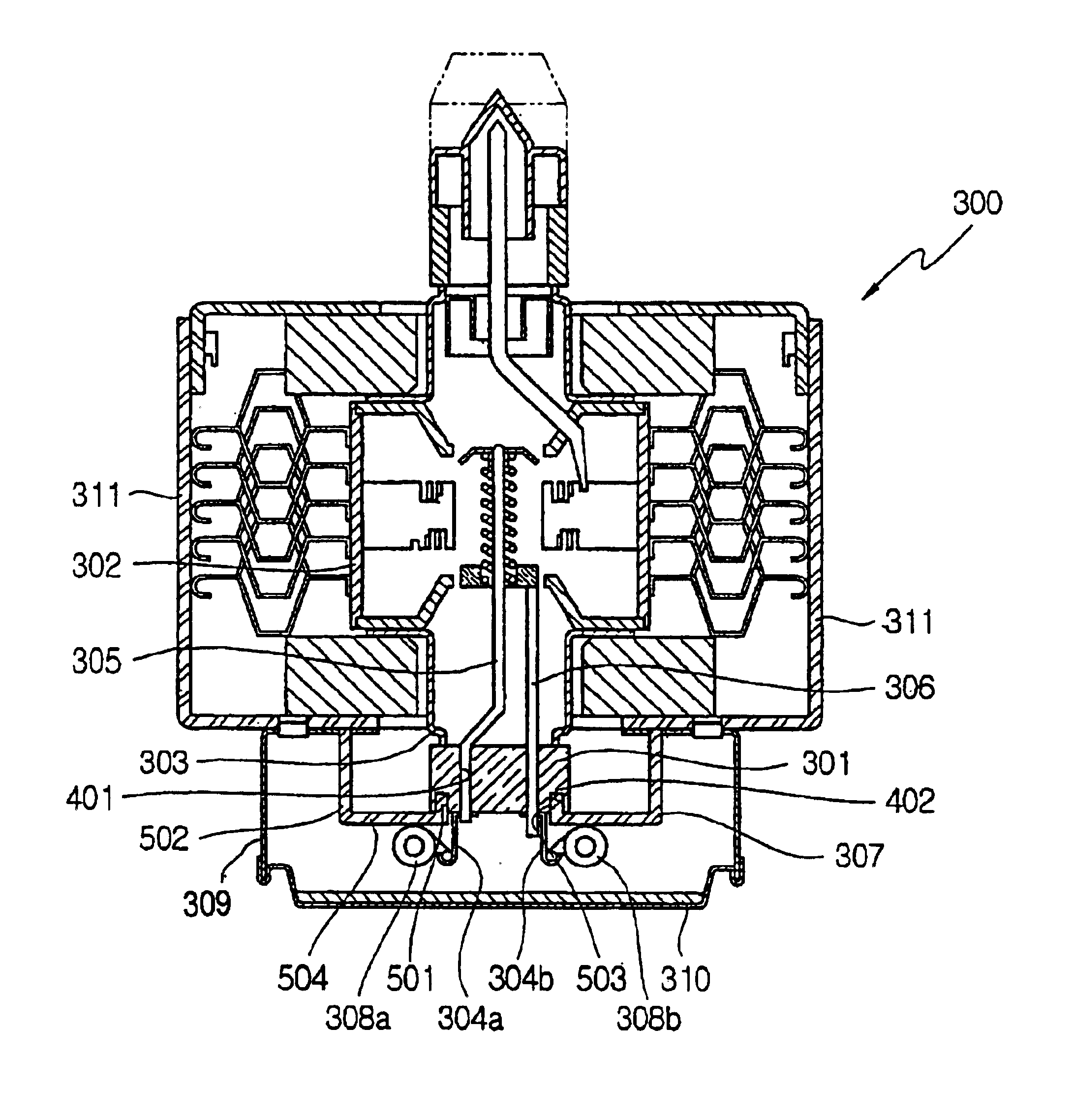

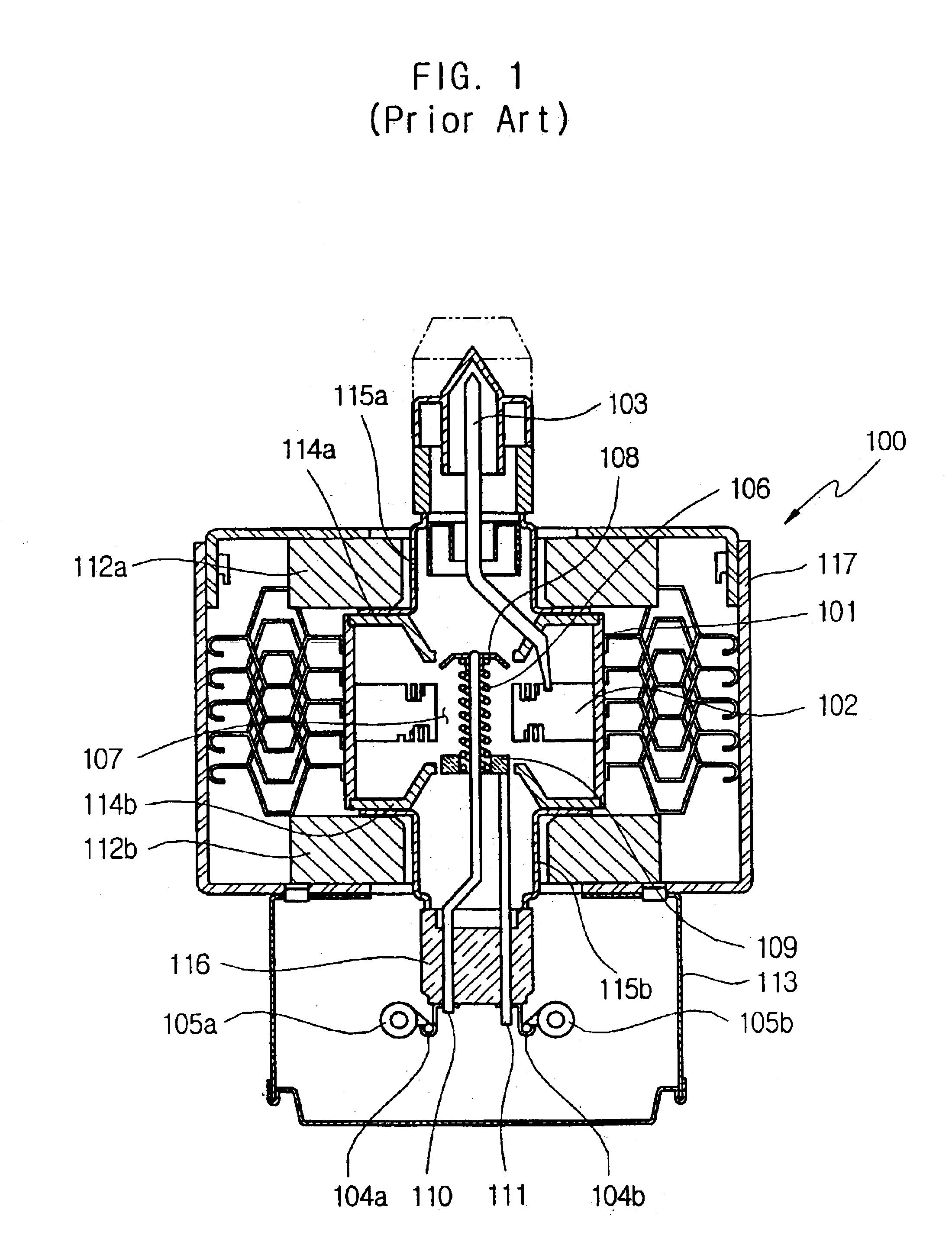

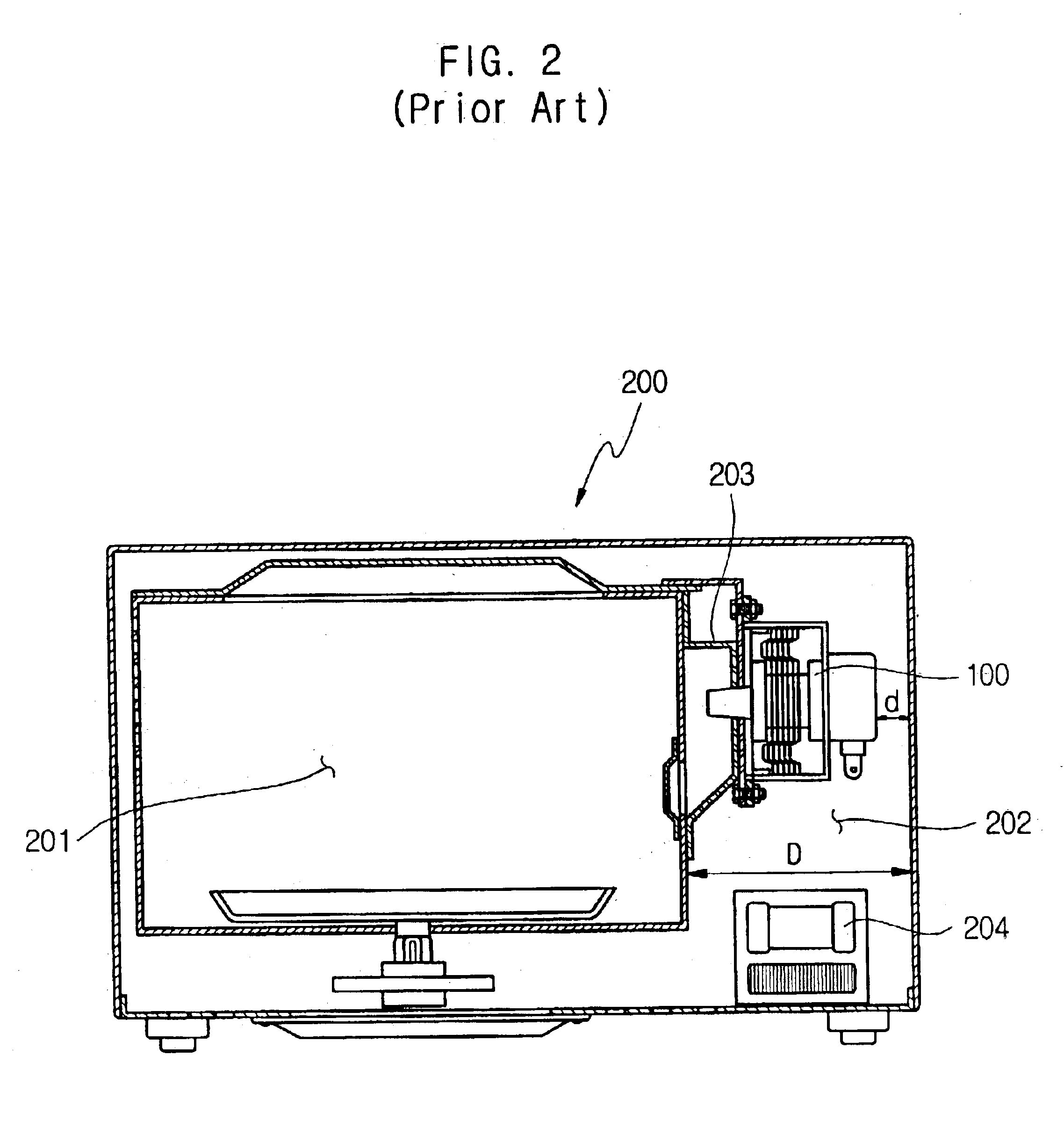

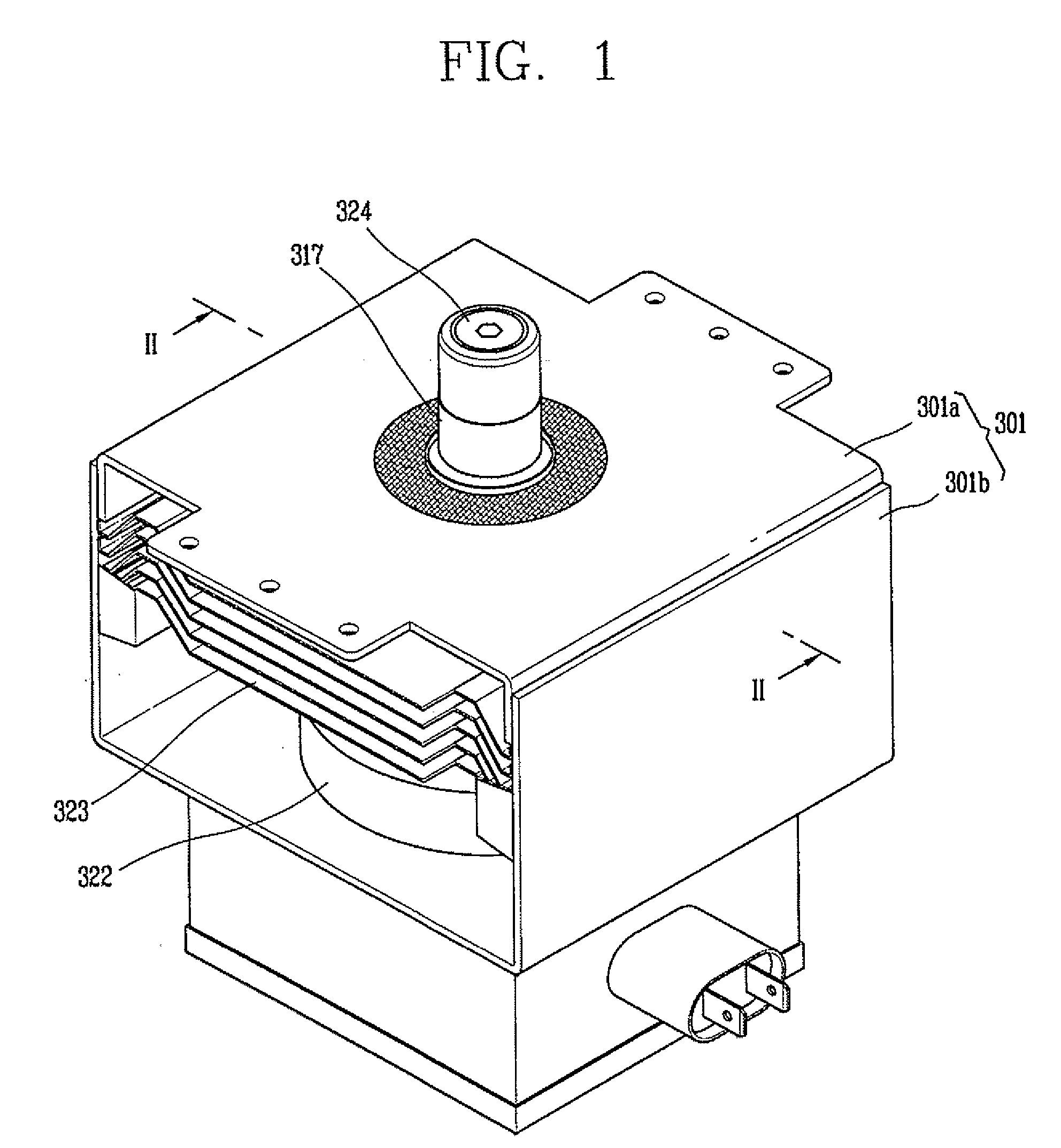

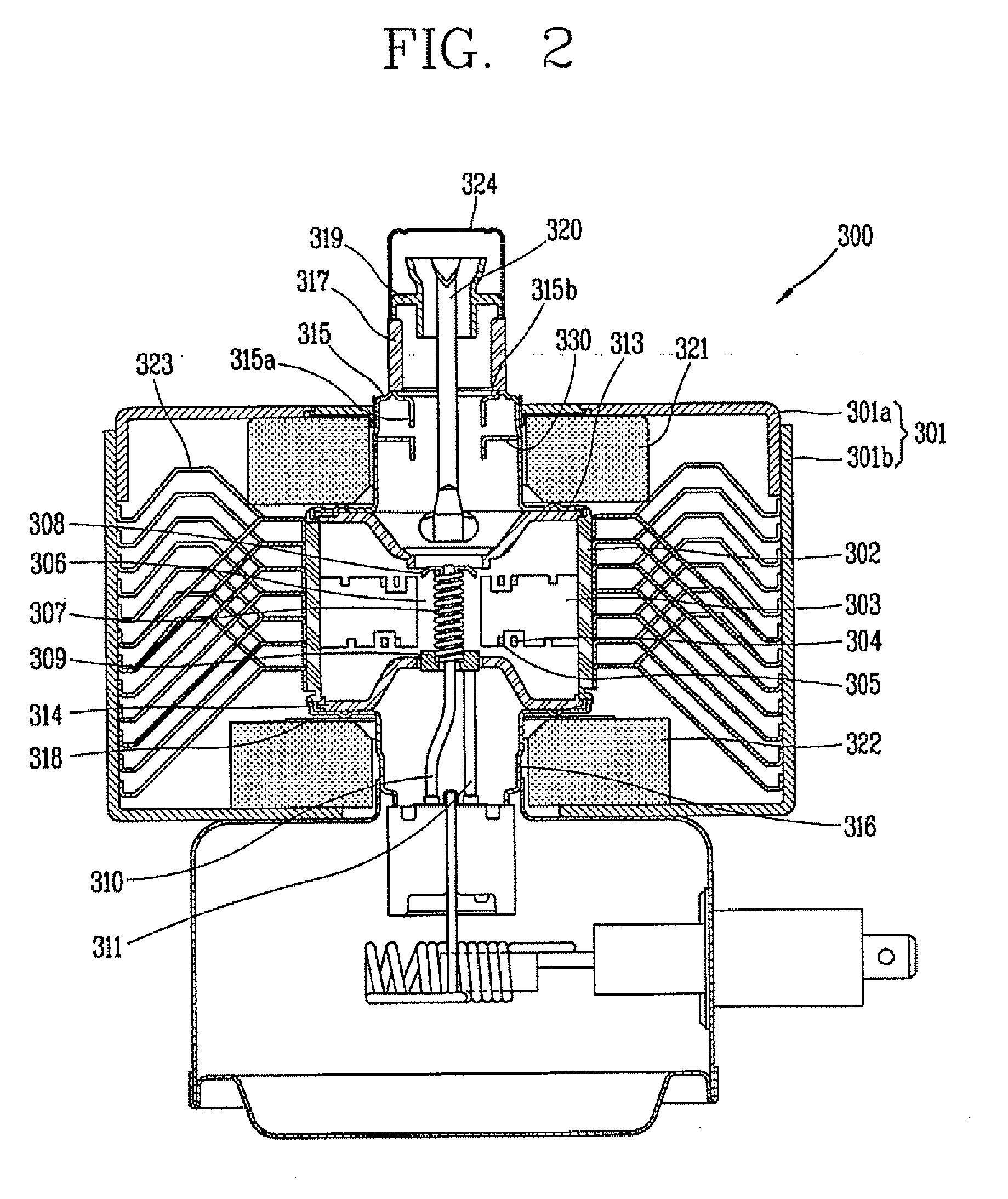

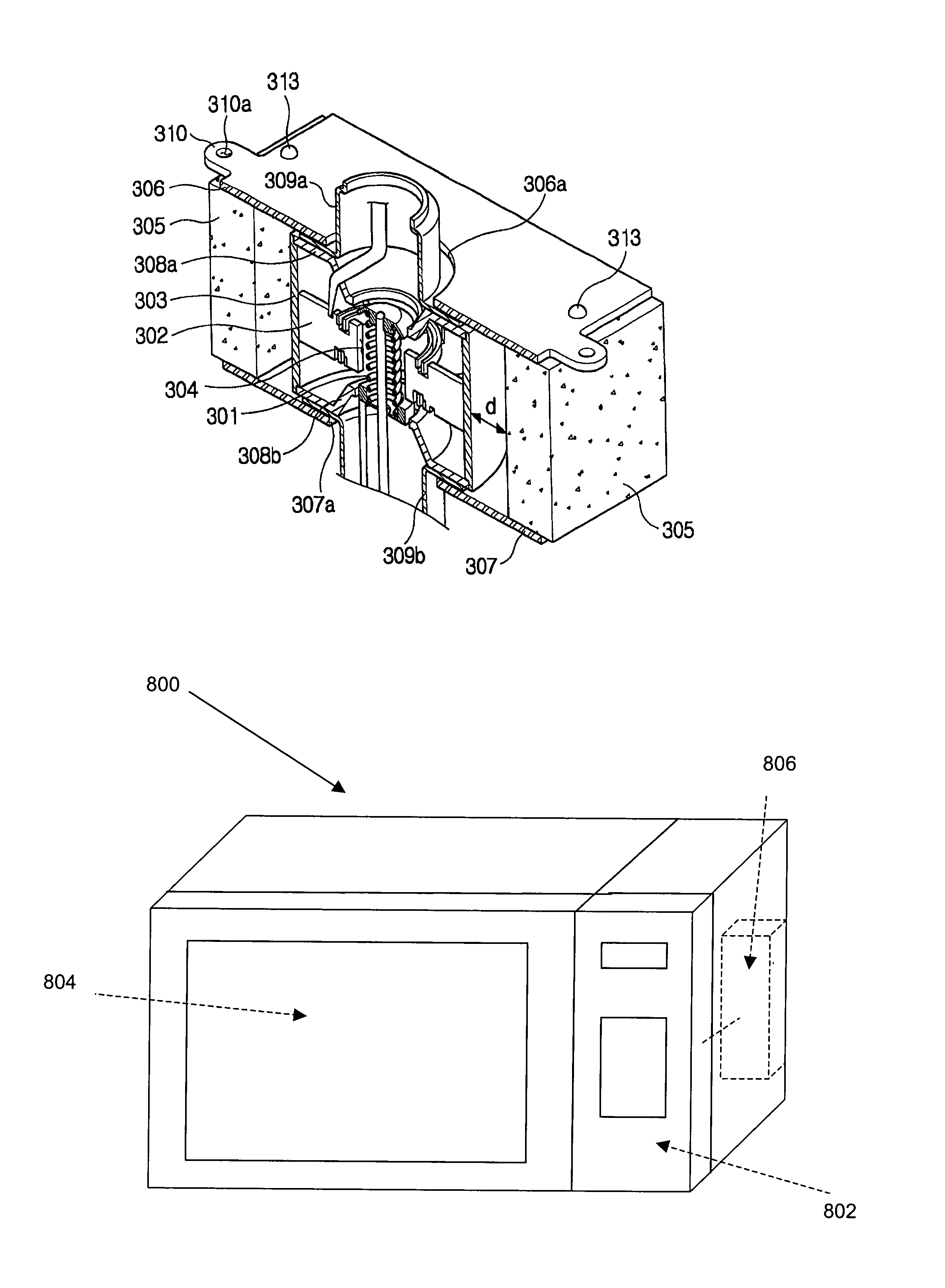

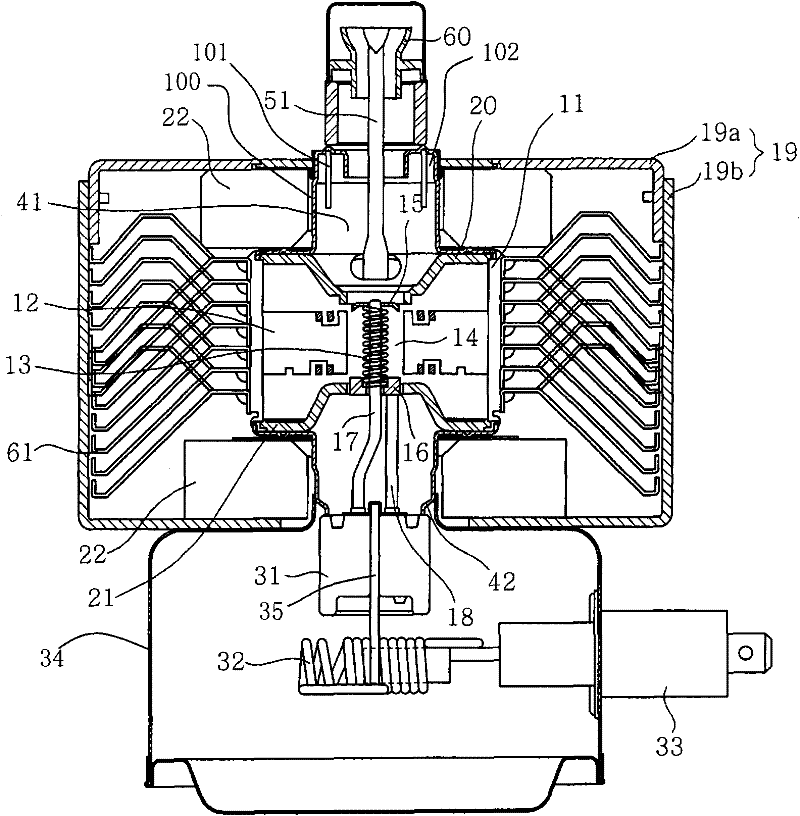

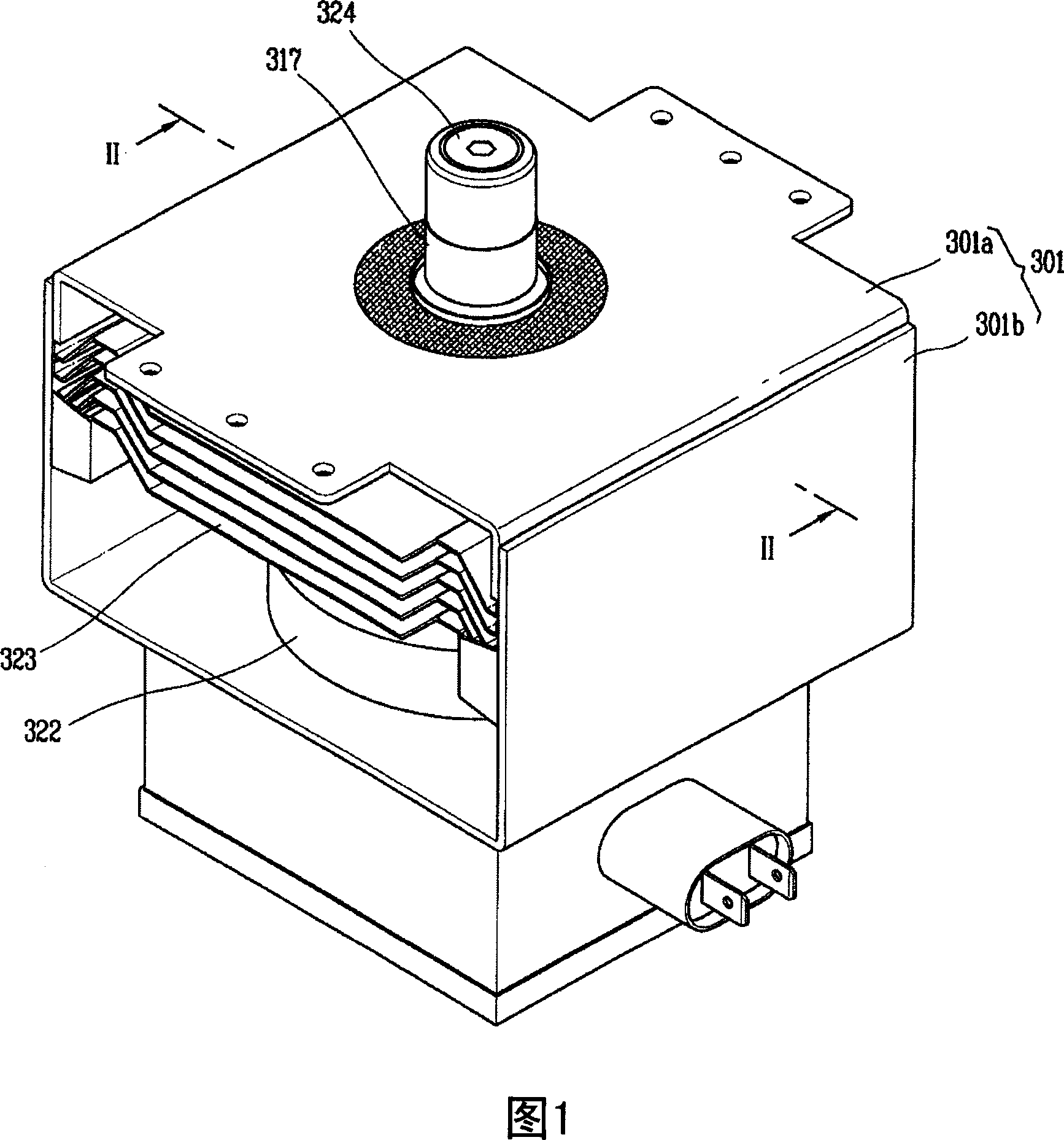

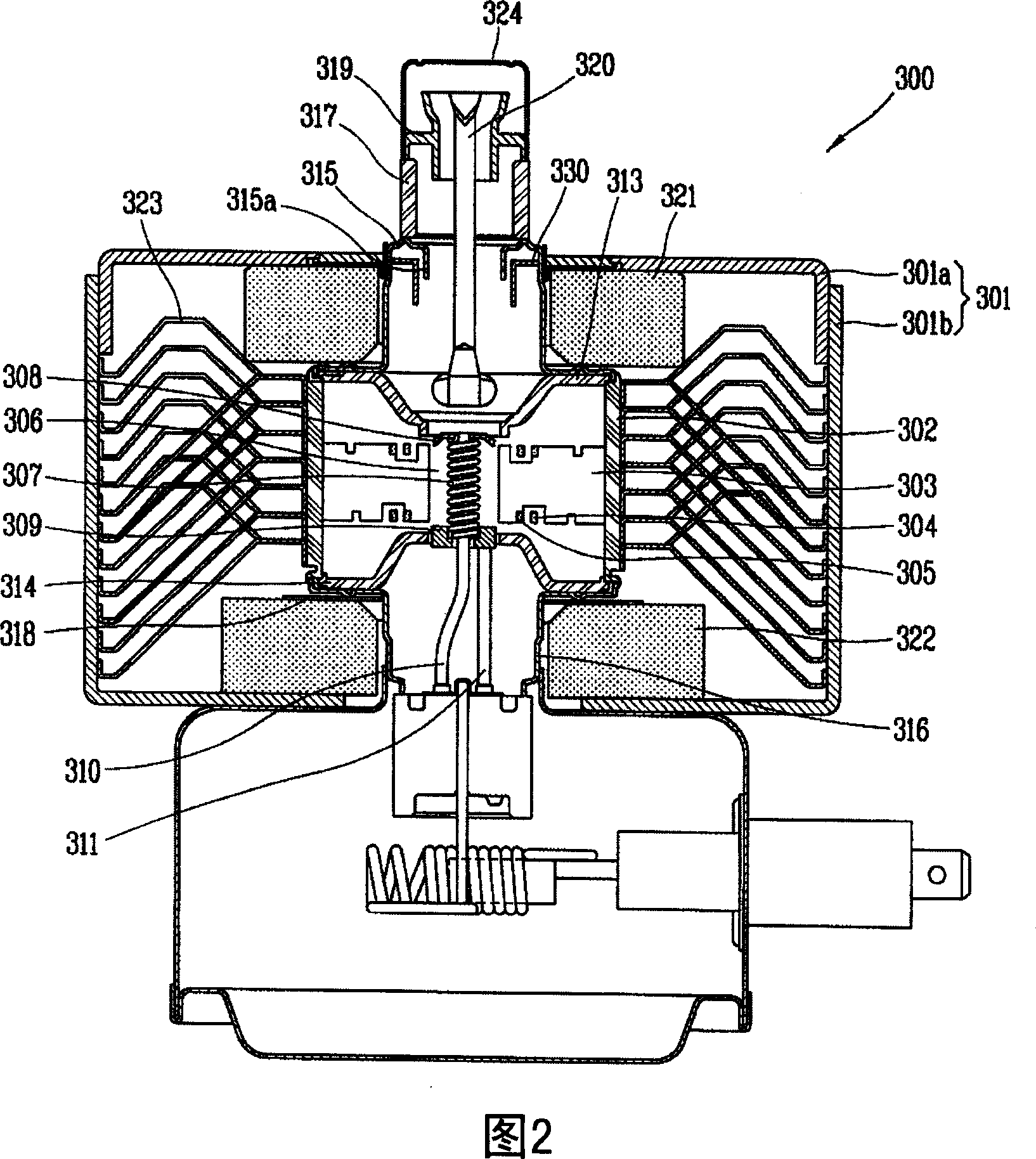

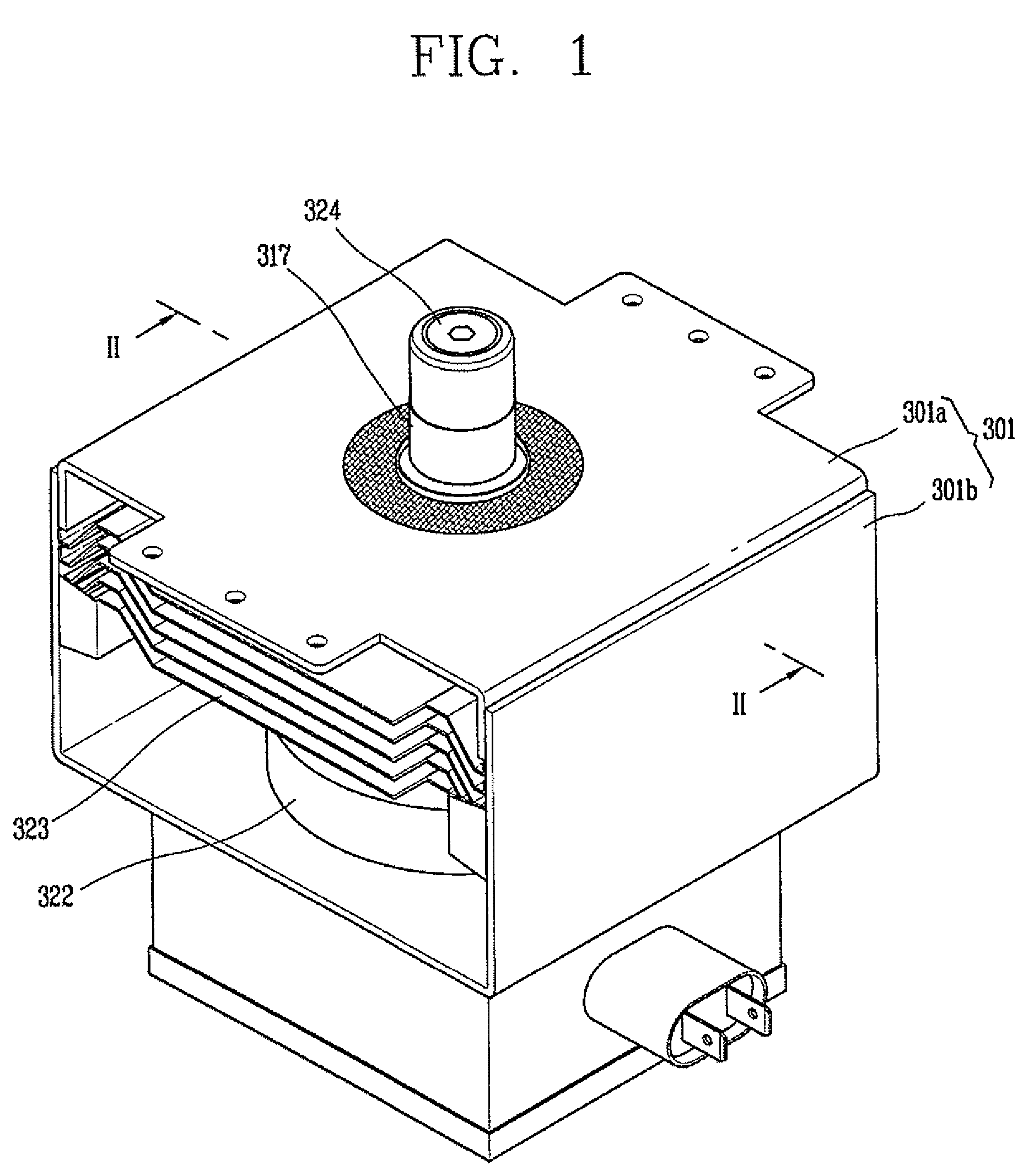

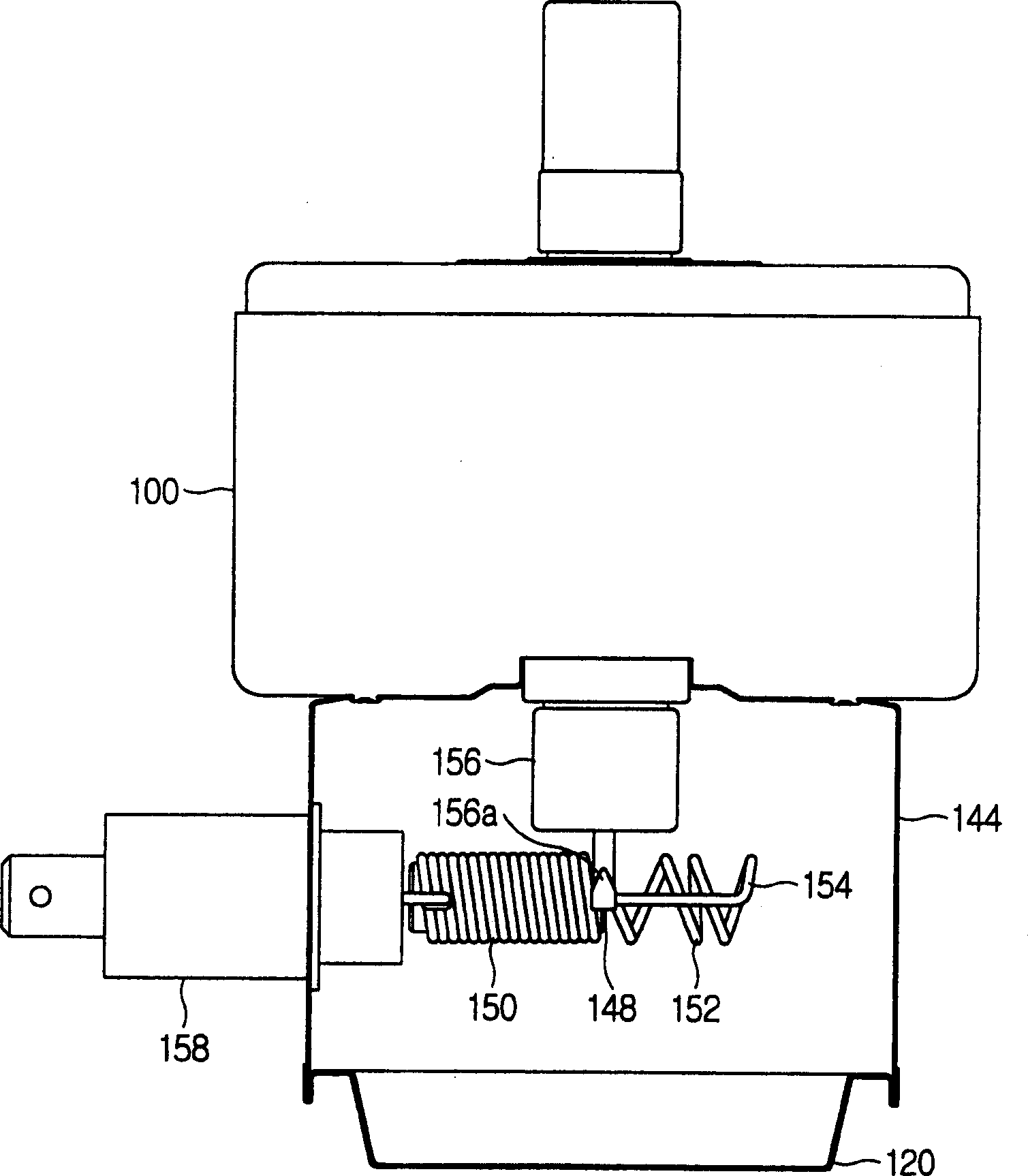

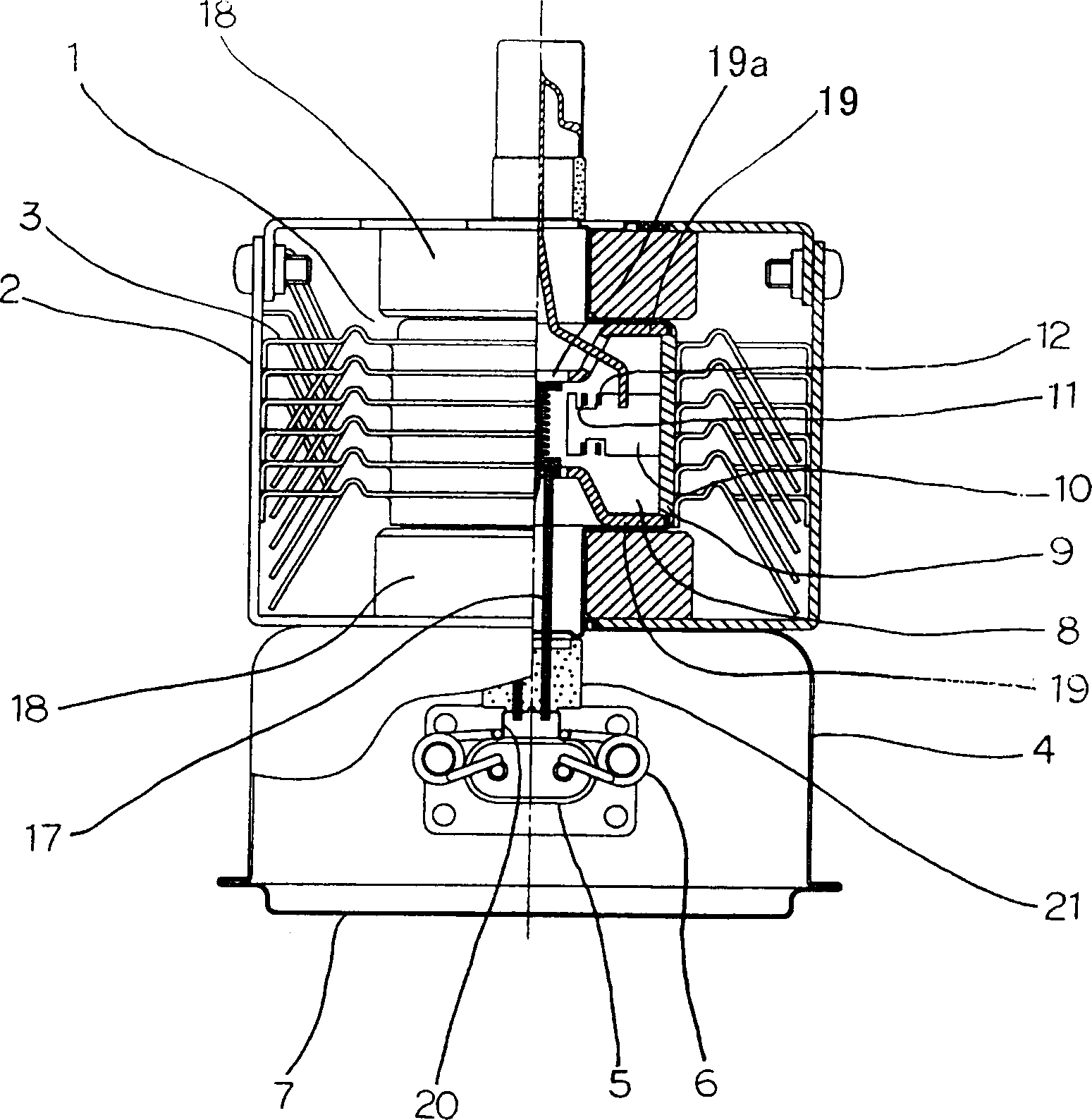

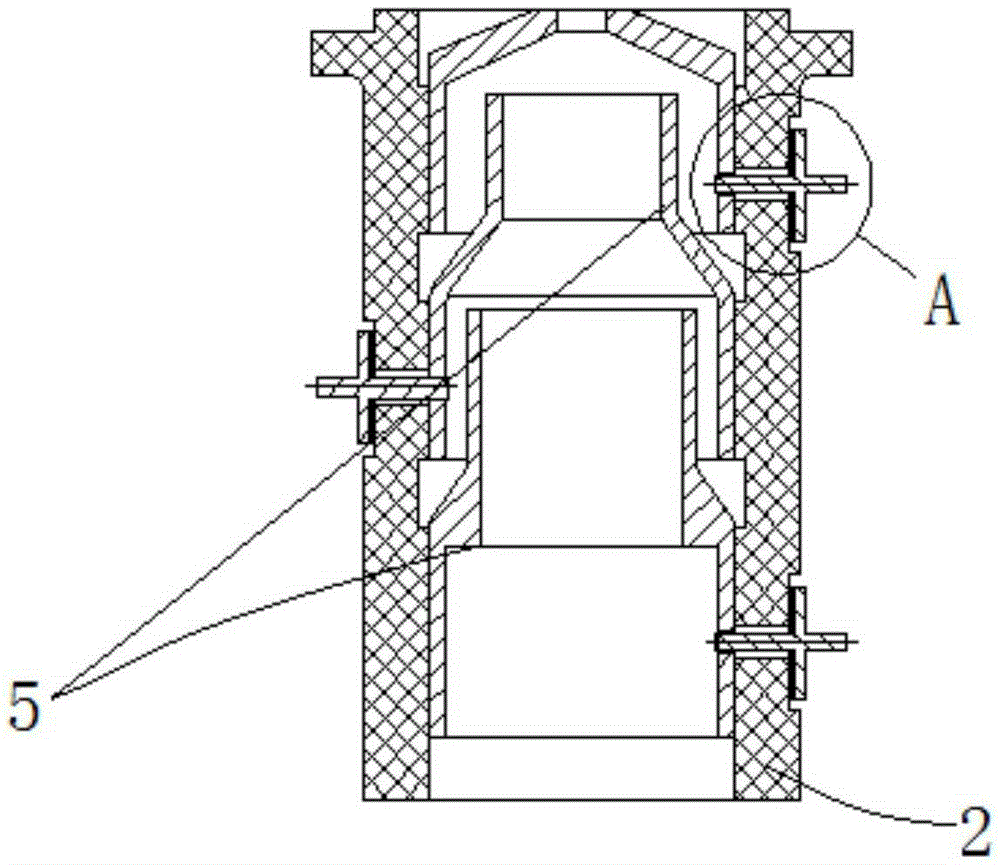

Magnetron for microwave ovens

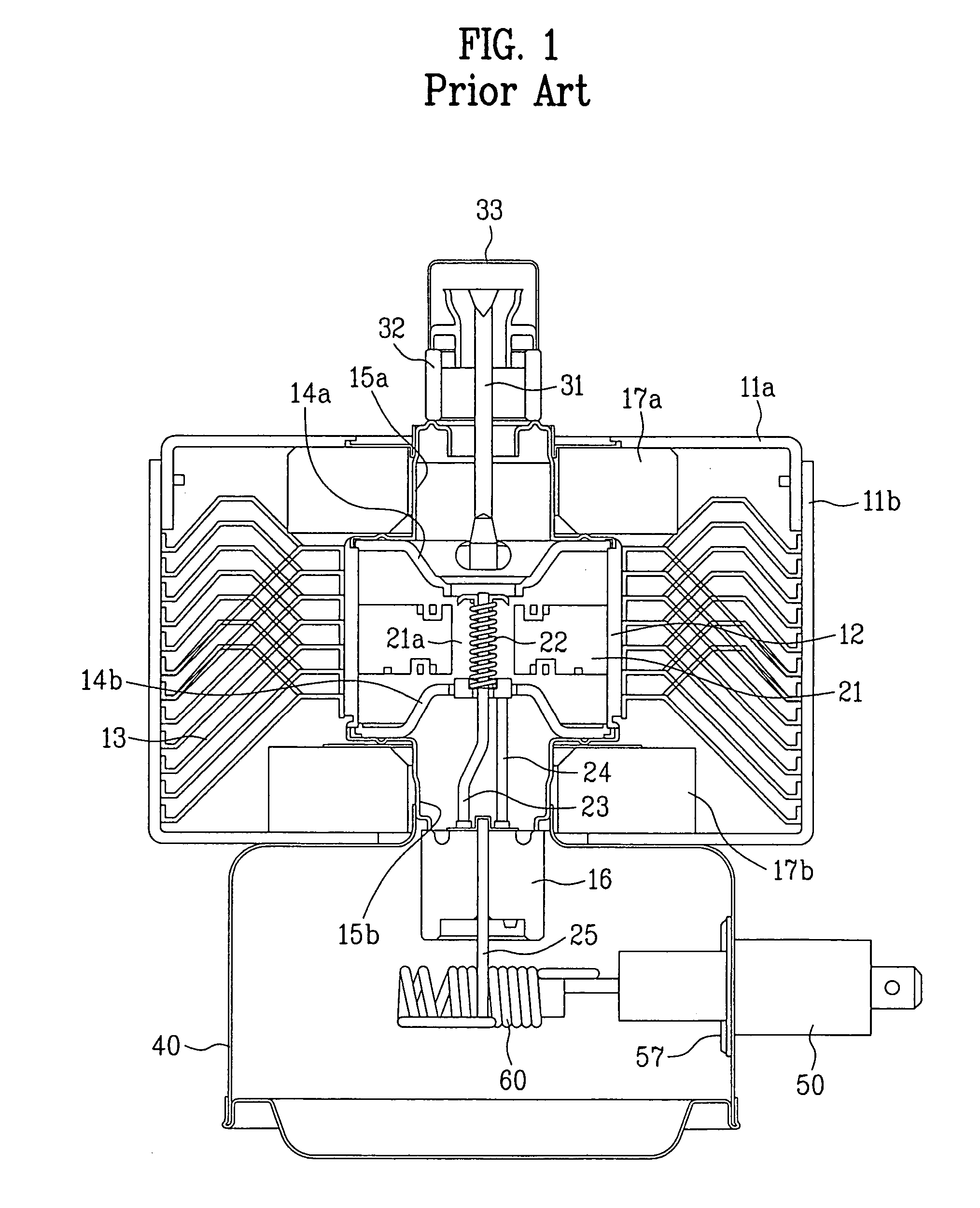

InactiveUS6847023B2Reduce the overall heightReduce insulation distanceTransit-tube leading-in arrangementsMicrowave heatingMicrowave ovenMiniaturization

A magnetron for microwave ovens including a second insulator interposed between a connection part and a bottom of a yoke to form a relatively lengthened insulation distance, or a molded insulating plate attached to a bottom of the filter box to reduce a distance between the connection part and a bottom of the filter box. In the magnetron, an entire height of the magnetron is reduced, so that a miniaturization of the magnetron can be implemented and a design of a product including the magnetron, such as a microwave oven, can be freely carried out, thus allowing an appearance of the product to be variously designed.

Owner:SAMSUNG ELECTRONICS CO LTD

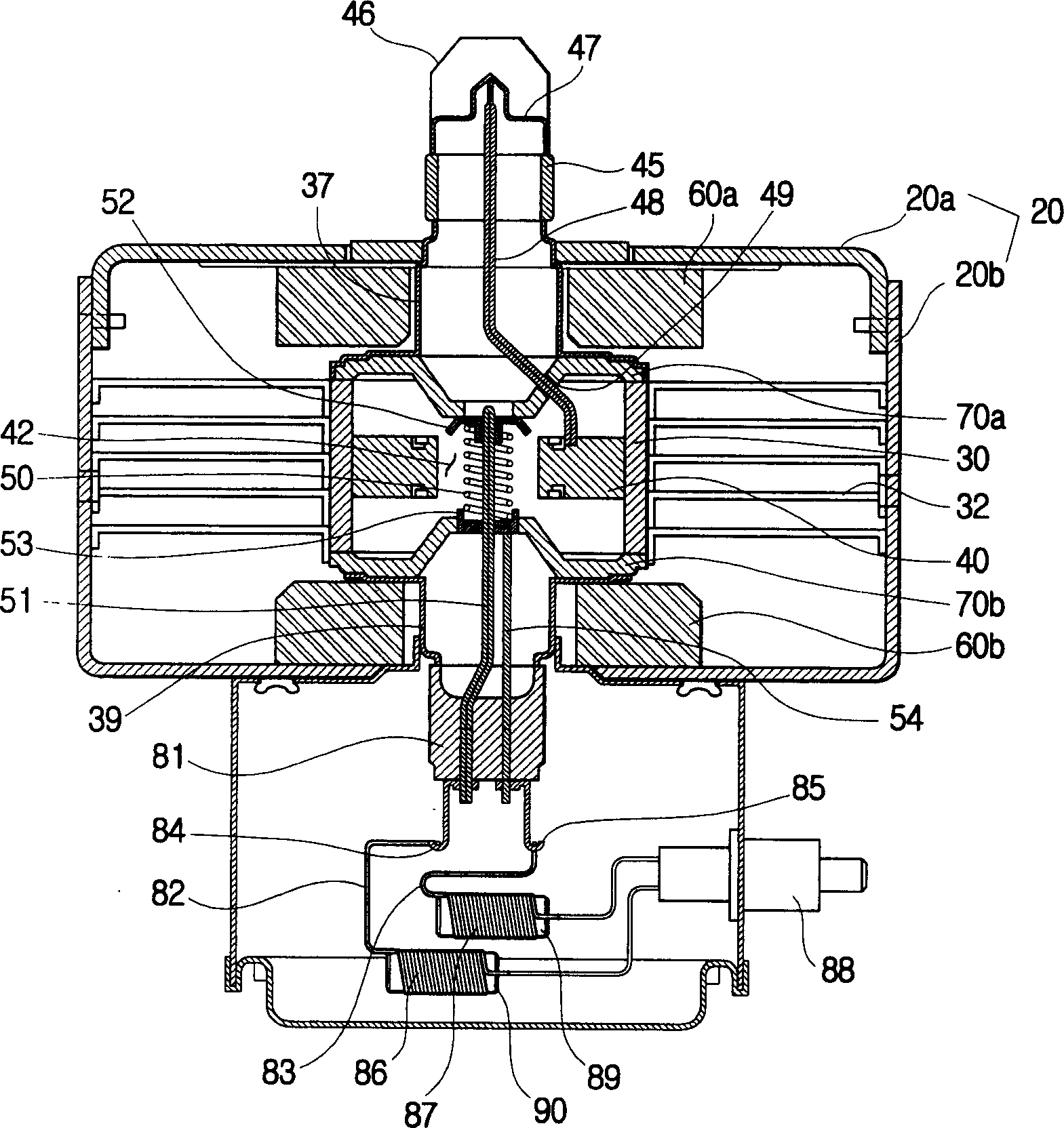

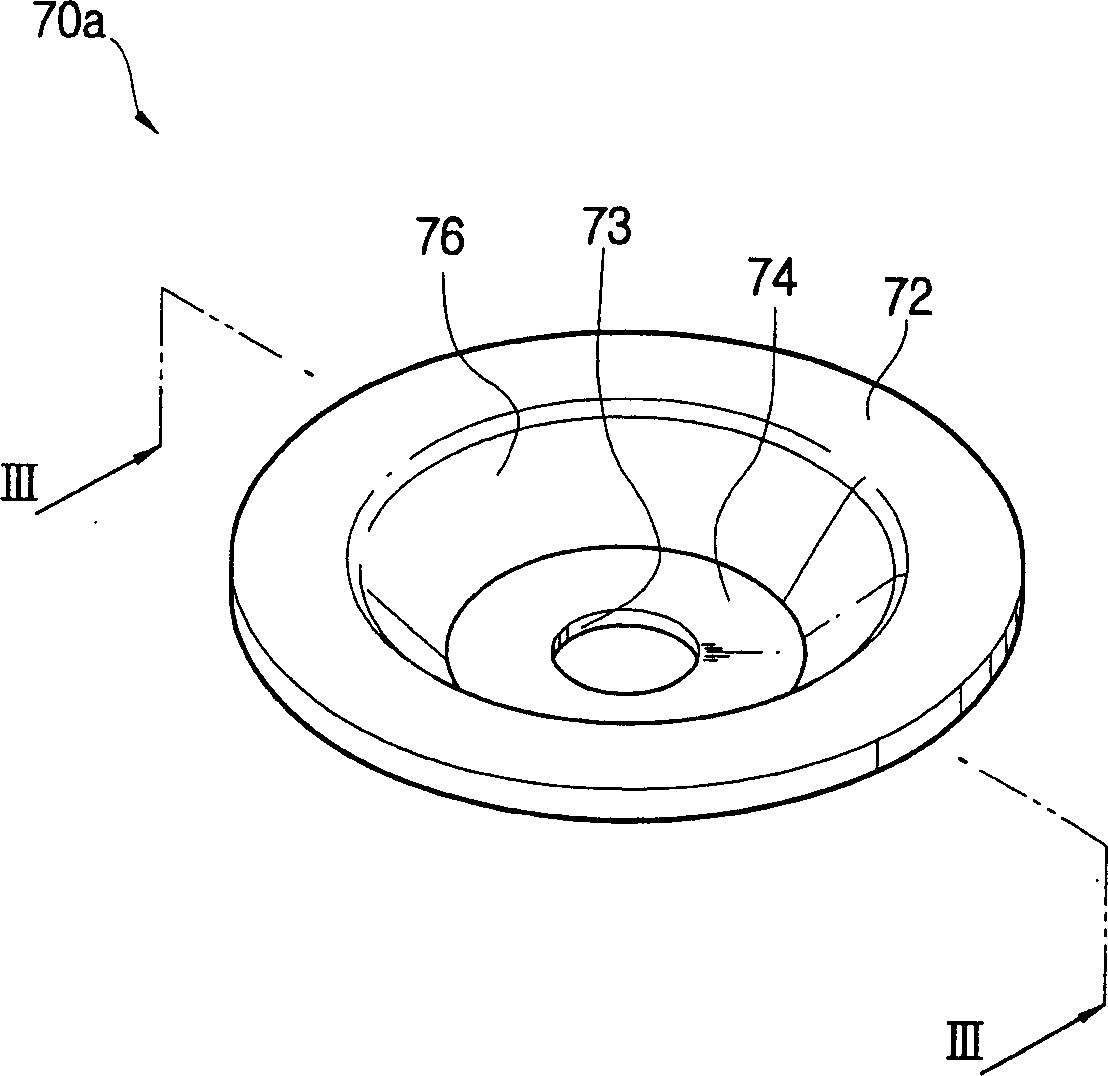

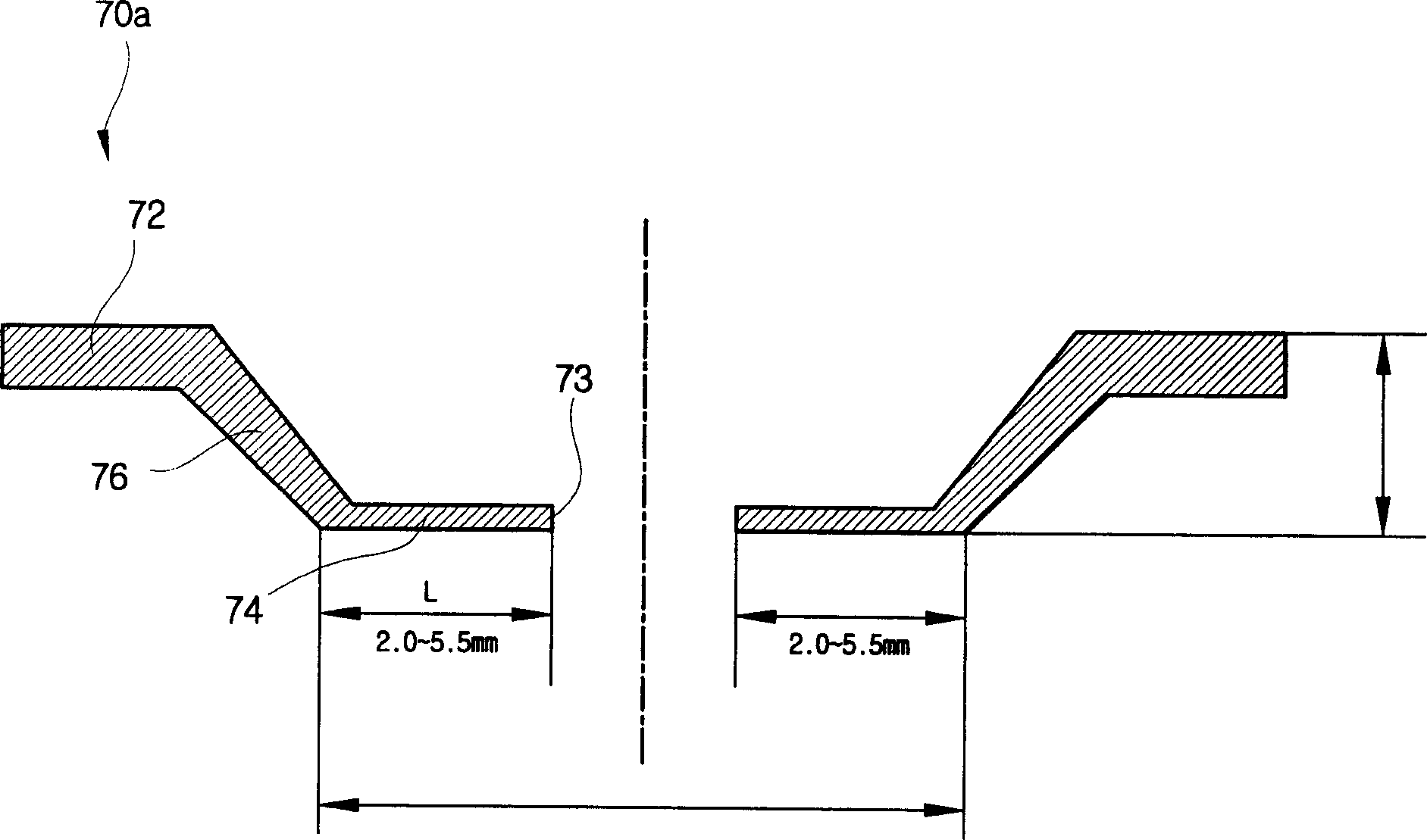

Magnetron for microwave oven

A magnetron for a microwave oven includes a yoke, an anode cylindrical body installed inside the yoke, a plurality of veins mounted inside the anode cylindrical body, a filament installed in a center of the veins, and an upper magnet and a lower magnet respectively mounted on an upper side and a lower side of the anode cylindrical body. The magnetron also includes an upper pole piece and a lower pole piece respectively installed between the anode cylindrical body and the upper and lower magnets. A length (L) from an external tip of a central part of the upper pole piece to an internal tip thereof, on which a hollow part is formed, is adjusted to suppress harmonics in the magnetron. Thus, generation of the harmonics may be effectively attenuated, and an output of a microwave may be enhanced by preventing power consumption of the magnetron which may be large due to interrupting harmonics.

Owner:SAMSUNG ELECTRONICS CO LTD

Anode and magnetron therewith

InactiveUS6960283B2Reduce material costsSimplify the manufacturing processCellsTransit-tube leading-in arrangementsElectrical connectionMetallurgy

Anode with a 2450 MHz resonance frequency, and magnetron therewith, the anode including a cylindrical anode body with an inside diameter in a range of 32.5 to 34.0 mm, a total of ten vanes fitted to an inside circumferential surface of the anode body in a radial direction, and an inner strap and an outer strap provided to both of an upper surface and a lower surface of each vane, a distance of the inner strap and the outer strap being in a range of 0.8 to 1.2 mm, and each of the inner strap and outer strap being in contact with every second vanes for electrical connection of the vanes alternately. The anode body and the vanes are formed as one unit for simplification of a fabrication process.

Owner:LG ELECTRONICS INC

Magnetron

InactiveUS20070139125A1Transit-tube leading-in arrangementsPulse automatic controlRadio frequency energyEngineering

A magnetron is provided including a yoke having an internal space, a first magnet provided at one end of the internal space, a second magnet provided at a second end of the internal space, the second magnet being axially spaced from the first magnet. Further, an anode cylinder that generates radio frequency energy may be provided axially between the first and second magnets, a first pole piece and a second pole piece may be provided proximate first and second openings of the anode cylinder, respectively. Additionally, the magnetron may also include a seal that intercepts external leakage, the seal may have an inward protrusion extending axially towards the anode cylinder; and a choke filter that intercepts external leakage provided proximate the seal.

Owner:LG ELECTRONICS INC

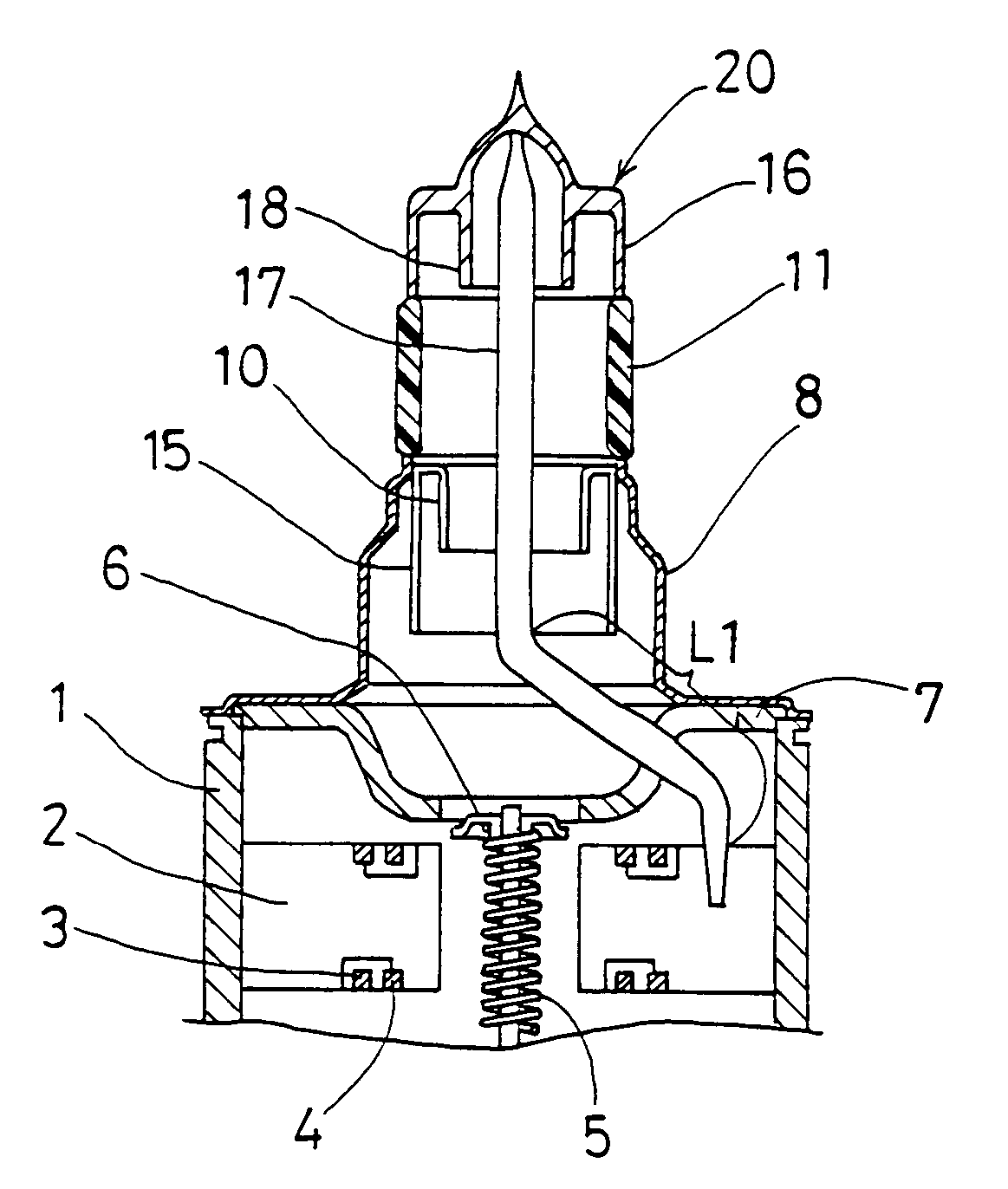

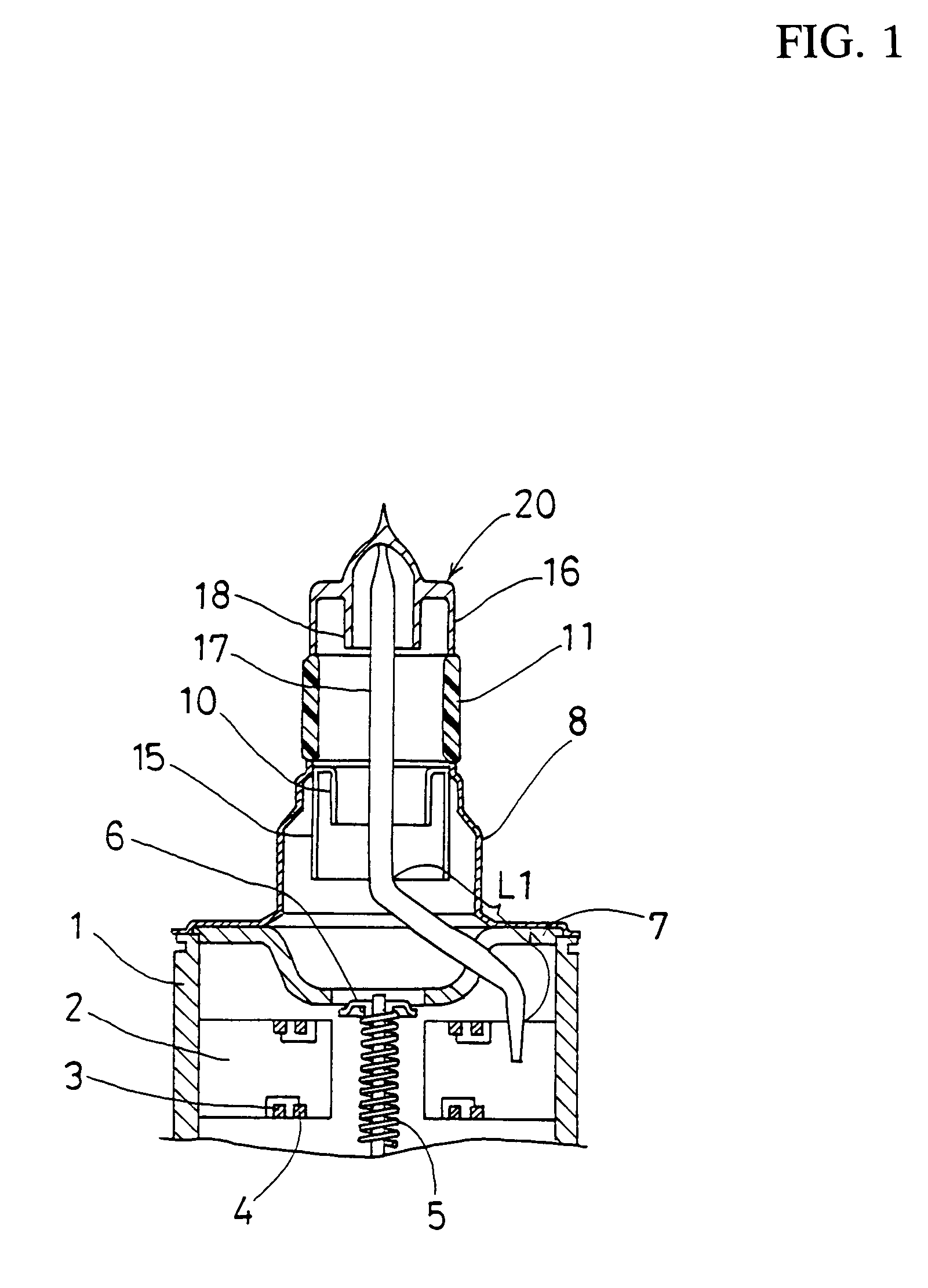

Magnetron

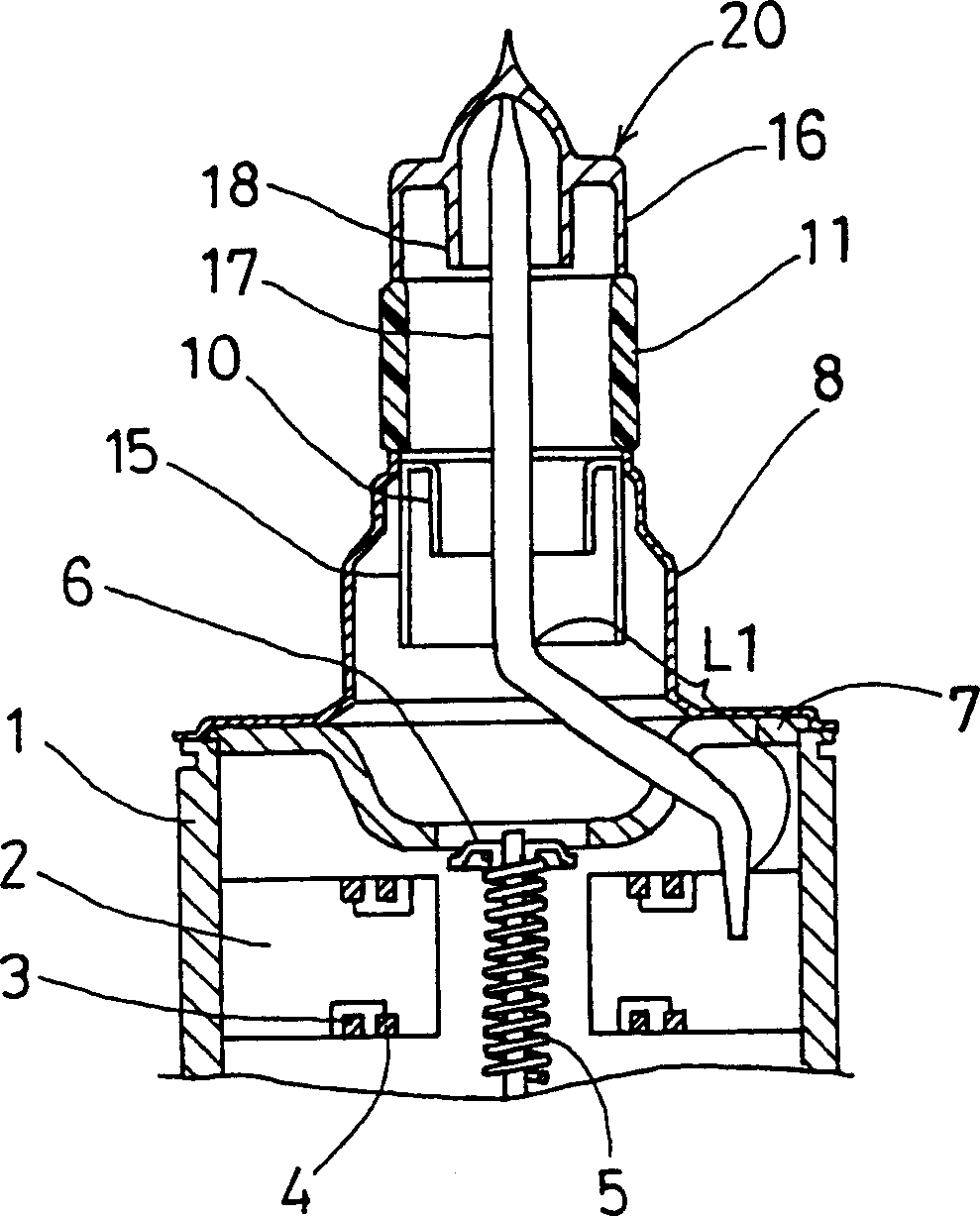

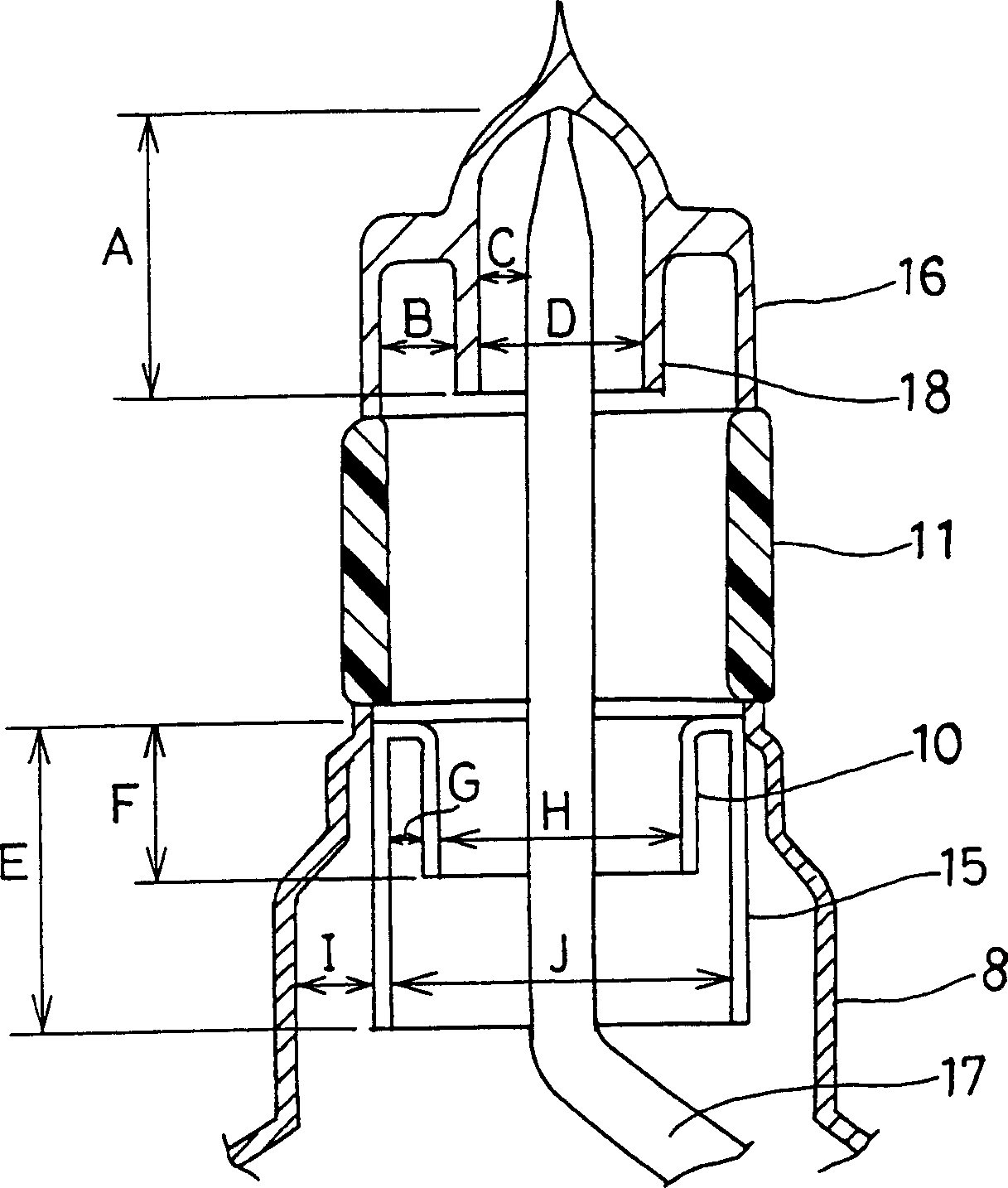

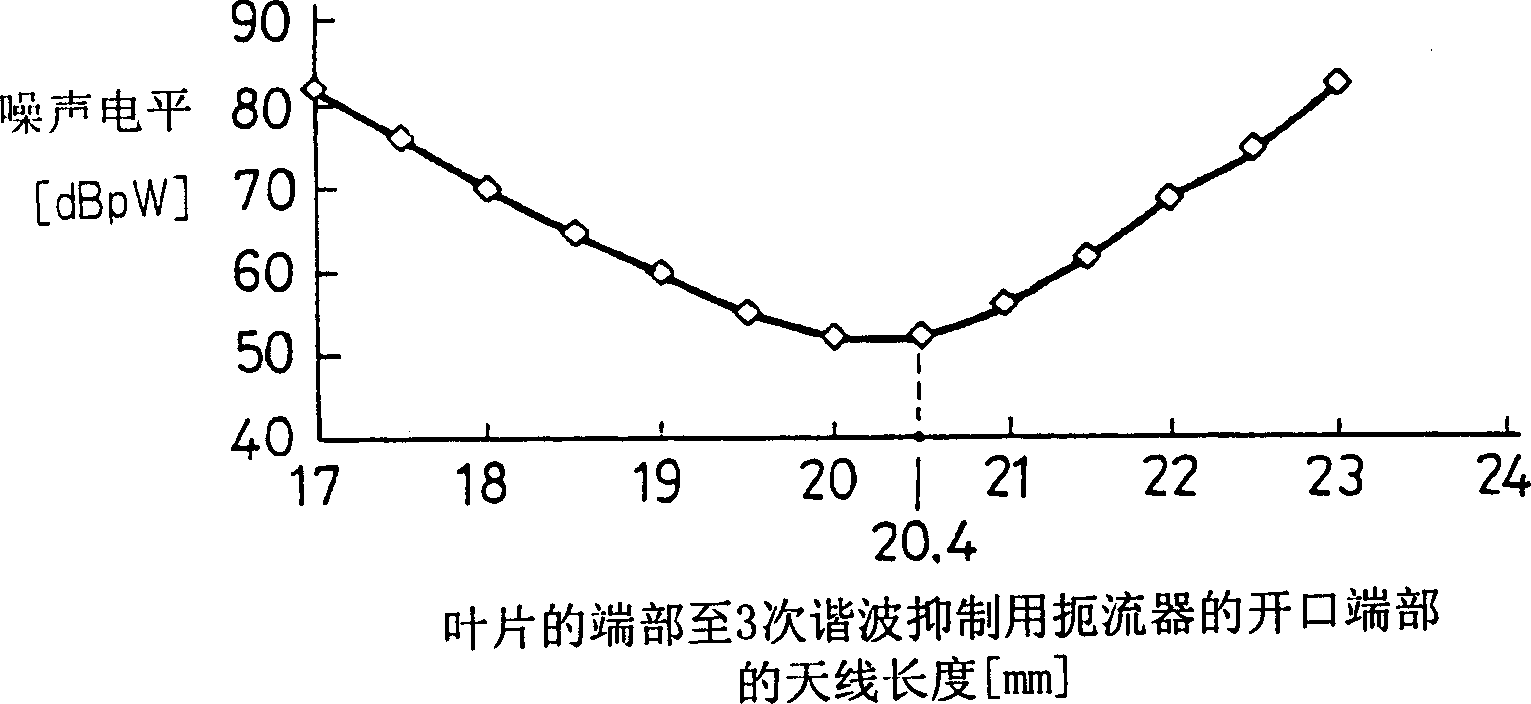

ActiveUS7148627B2Reduce noise levelSecurely lowering noise levelTransit-tube leading-in arrangementsMulti-cavity magnetronsMicrowaveMagnetic poles

A magnetron is configured so that an antenna lead 17 connected to a desired position of an anode segment 2 passes through a magnetic pole piece 7 and a metal cylinder 8 so as not to make contact therewith and is connected to the output portion of the magnetron, and so that the electrical length L1 of this antenna lead 17 between the opening end of a third harmonic restraint choke 15 and the connection portion of the anode segment 2 is 1 / 2 of the wavelength (λ) of the third harmonic, thereby restraining the third harmonic and the side bands of the third harmonic.

Owner:PANASONIC CORP

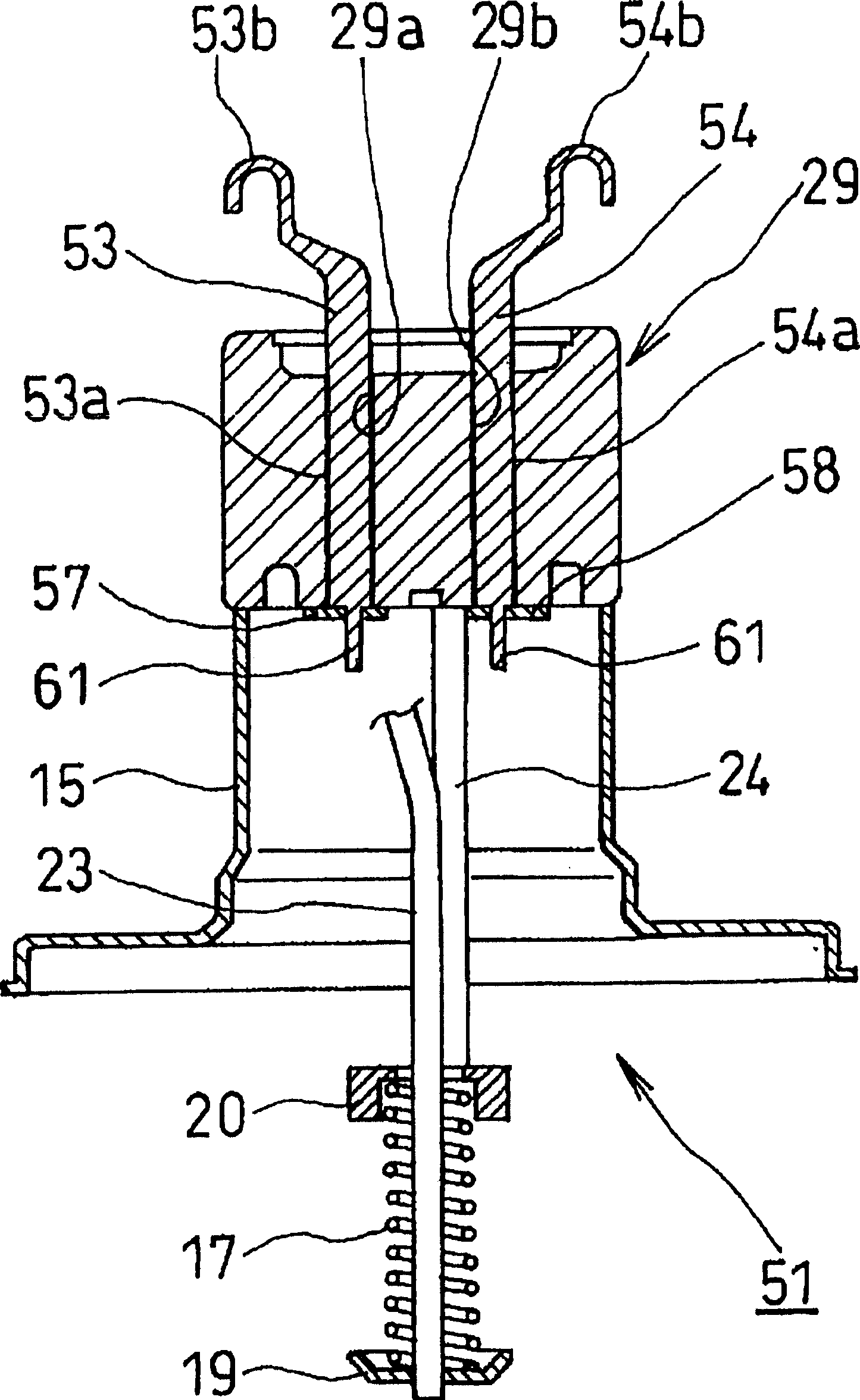

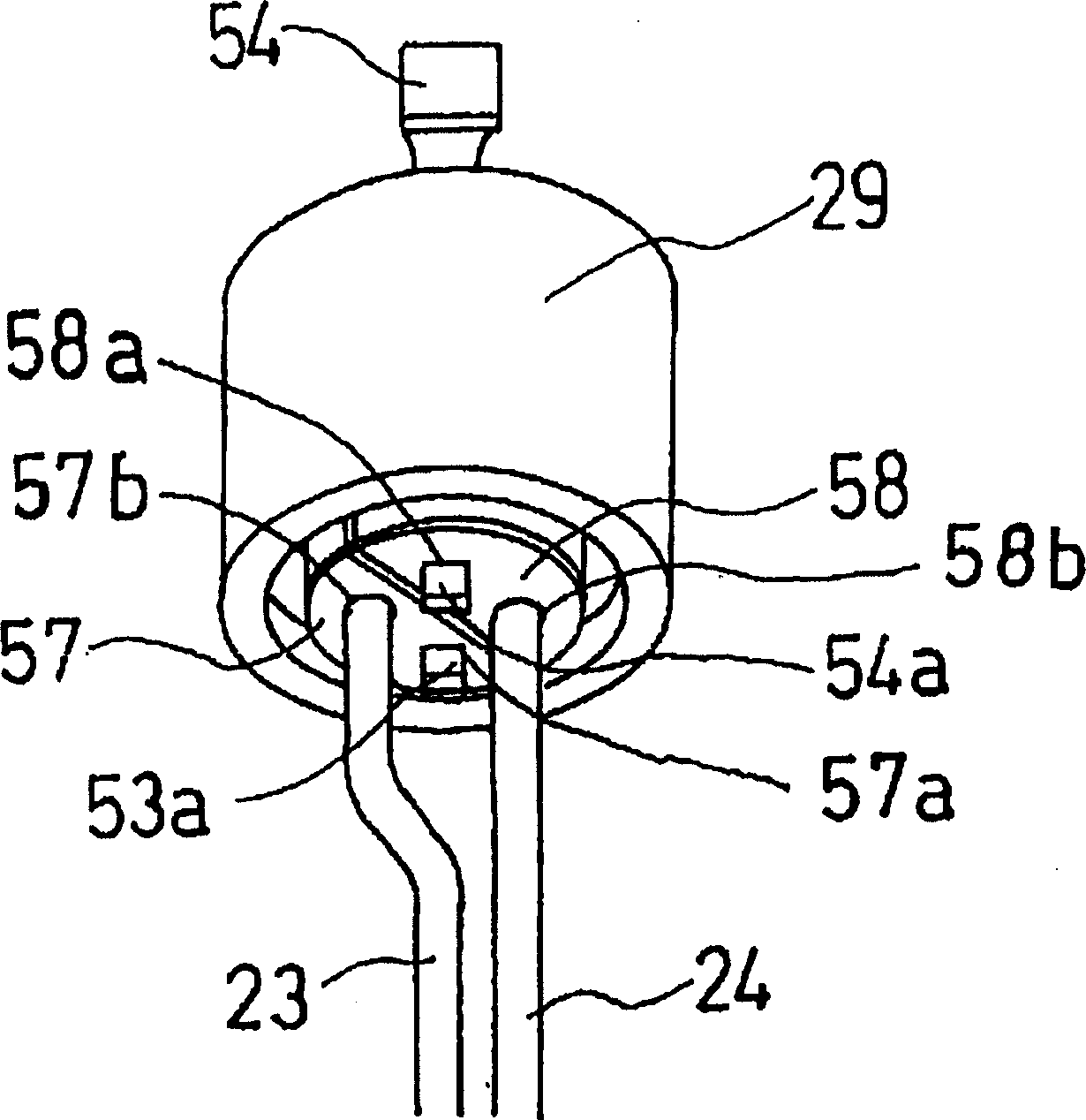

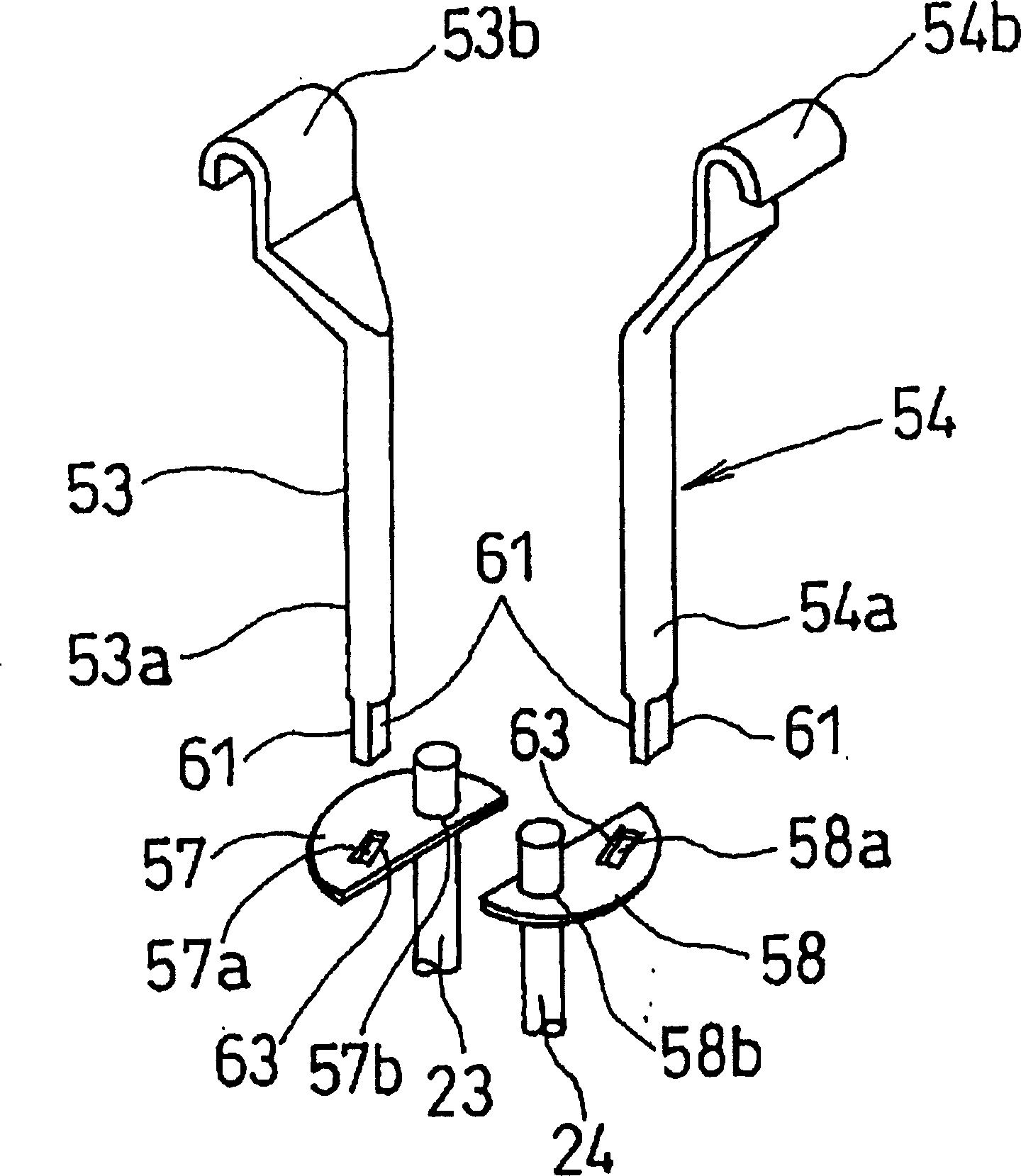

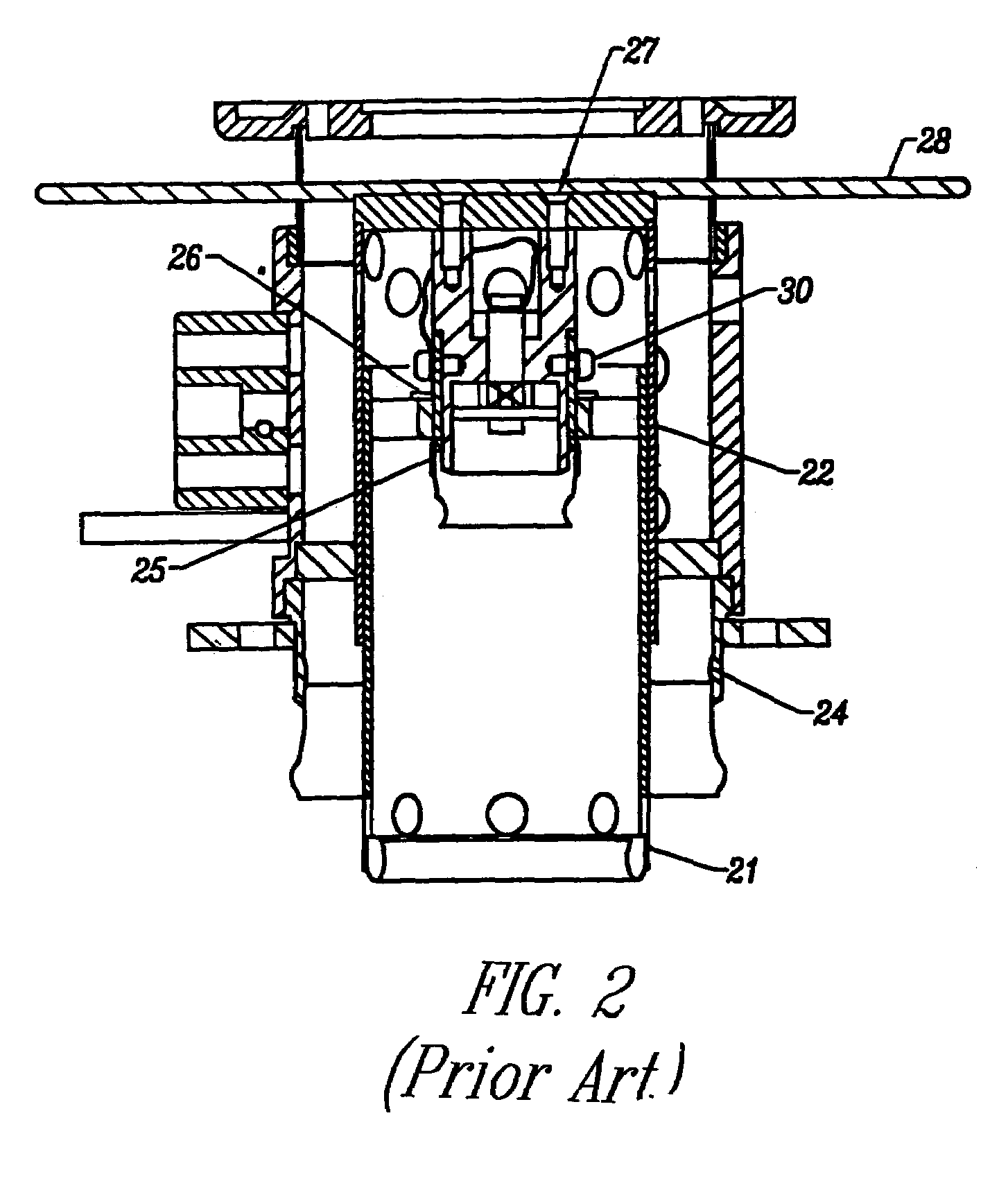

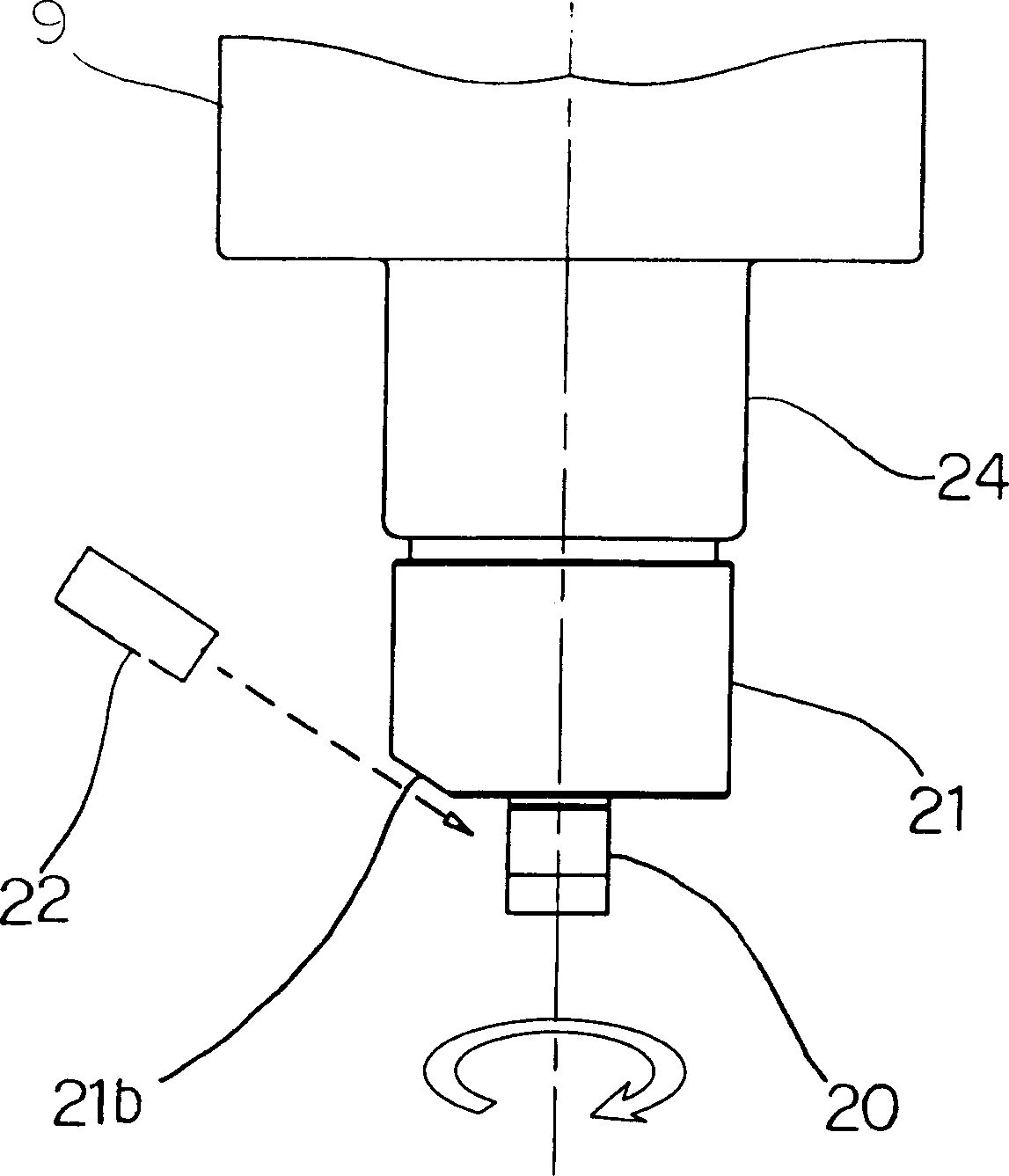

Magnetron cathode assembly

InactiveCN1599012AHigh positioning accuracyImprove connection strengthTransit-tube leading-in arrangementsTransit-tube cathodesMetalCathode

A magnetron cathode assembly which realizes stopping of turn of an external terminal inserted into a stem insulator without increasing a manufacturing cost. A leading end of a base end axial portion of an external terminal has a non-circular section by providing a flat surface in at least one position on its peripheral surface, and a straight stop edge that fits to the flat surface thereby to carry out stopping of turn of the external terminal is provided for a terminal fitting hole of a sealing metal plate into which the leading end of this external terminal is fitted.

Owner:PANASONIC CORP

Magnetron

InactiveCN1472767AReduced parts countReduce noise levelTransit-tube leading-in arrangementsMulti-cavity magnetronsMagnetic polesThird harmonic

Owner:PANASONIC CORP

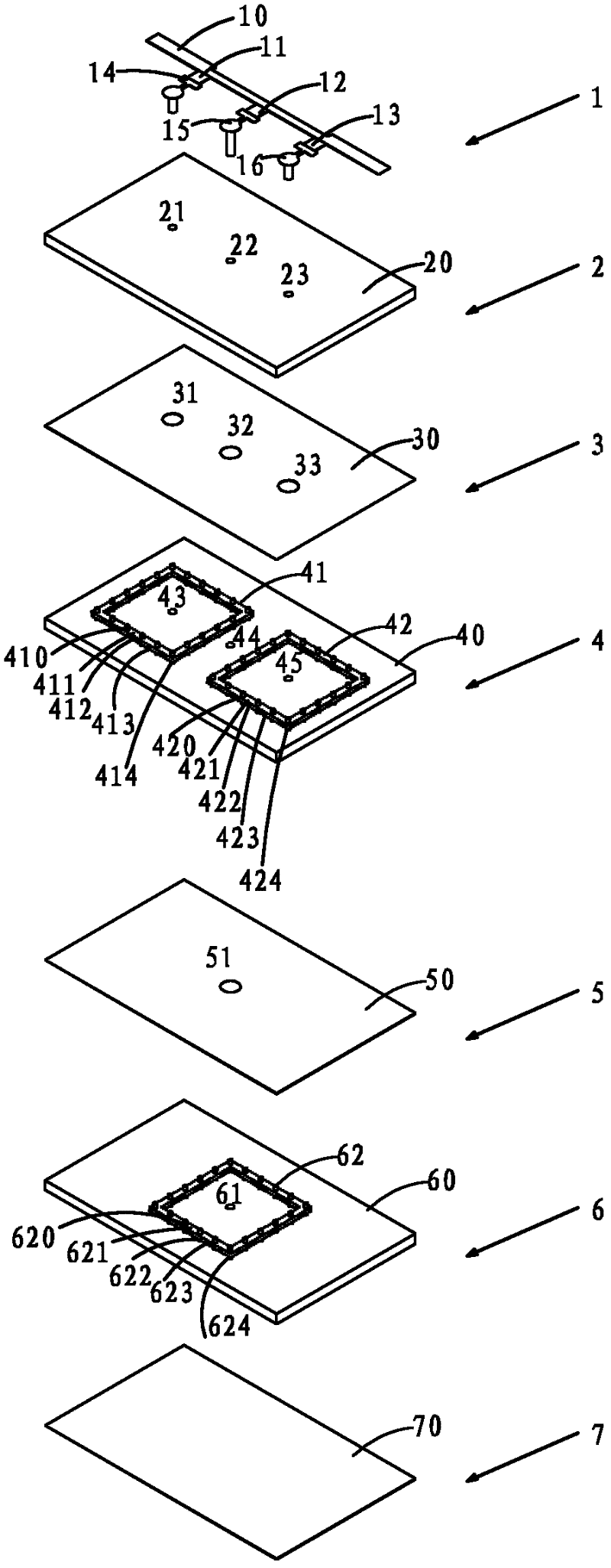

Miniaturized power gain balancer

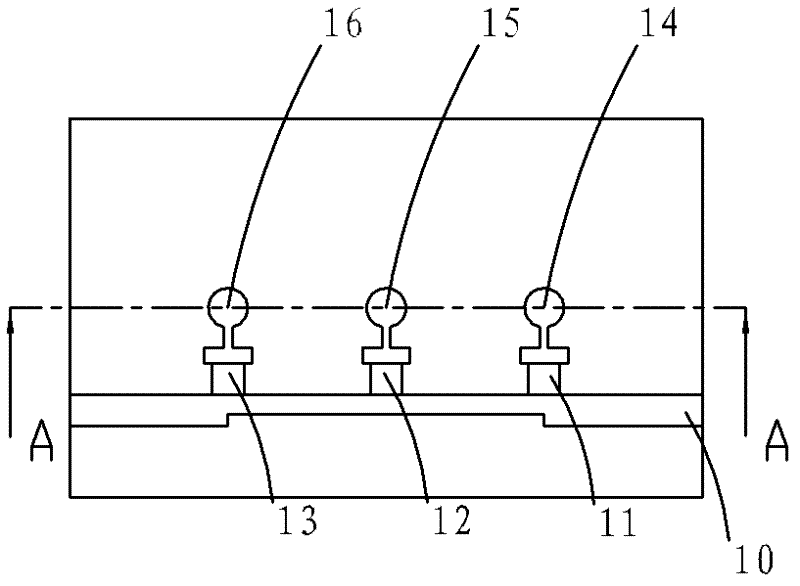

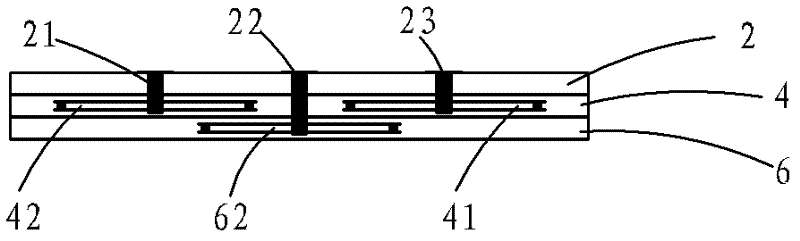

InactiveCN102646565AReduce mechanical structureEliminates the need for tunable mechanical structuresTransit-tube leading-in arrangementsTransit-tube circuit elementsResonant cavityMiniaturization

The invention relates to a miniaturized power gain balancer, which comprises a micro-strip layer, a first medium layer, a first metal layer, a second medium layer, a second metal layer, a third medium layer and a third metal layer sequentially stacked from top to bottom. A first metalized through hole penetrates through a first via hole to be connected with a first metalized counter bore to form a probe structure, and the top of the probe structure is connected with a first metal connecting plate. A third metalized through hole penetrates through a third via hole to be connected with a second metalized counter bore to form a probe structure, and the top of the probe structure is connected with a third metal connecting plate. A second metalized through hole penetrates through a first via hole to be connected with a metalized through hole and then penetrates through a via hole to be connected with a metalized counter bore to form a probe structure, and the top of the probe structure is connected with a first metal connecting plate. The miniaturized power gain balancer has the advantages that a resonant cavity is embedded in a multi-layer medium substrate by the low-temperature co-fired ceramic technique, occupied planar space is reduced by a stereo staggered layer arrangement way, and miniaturization is realized.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Magnetron, and microwave oven and high-frequency heating apparatus each equipped with the same

InactiveUS7026762B2Low costImprove oscillation efficiencyTransit-tube leading-in arrangementsDomestic stoves or rangesMicrowave ovenResonance

A magnetron includes a ring-shaped anode, a cathode, an activating space, at least one permanent magnet and a magnetic flux carrying unit. The ring-shaped anode forms a plurality of resonance circuits. The cathode is disposed at the axial center of the anode to emit thermions. The activating space is formed between the anode and the cathode. The at least one permanent magnet is provided beside the anode. The magnetic flux carrying unit carries magnetic flux generated by the at least one permanent magnet to the activating space. A microwave oven and / or high frequency heating apparatus may utilize the magnetron.

Owner:SAMSUNG ELECTRONICS CO LTD

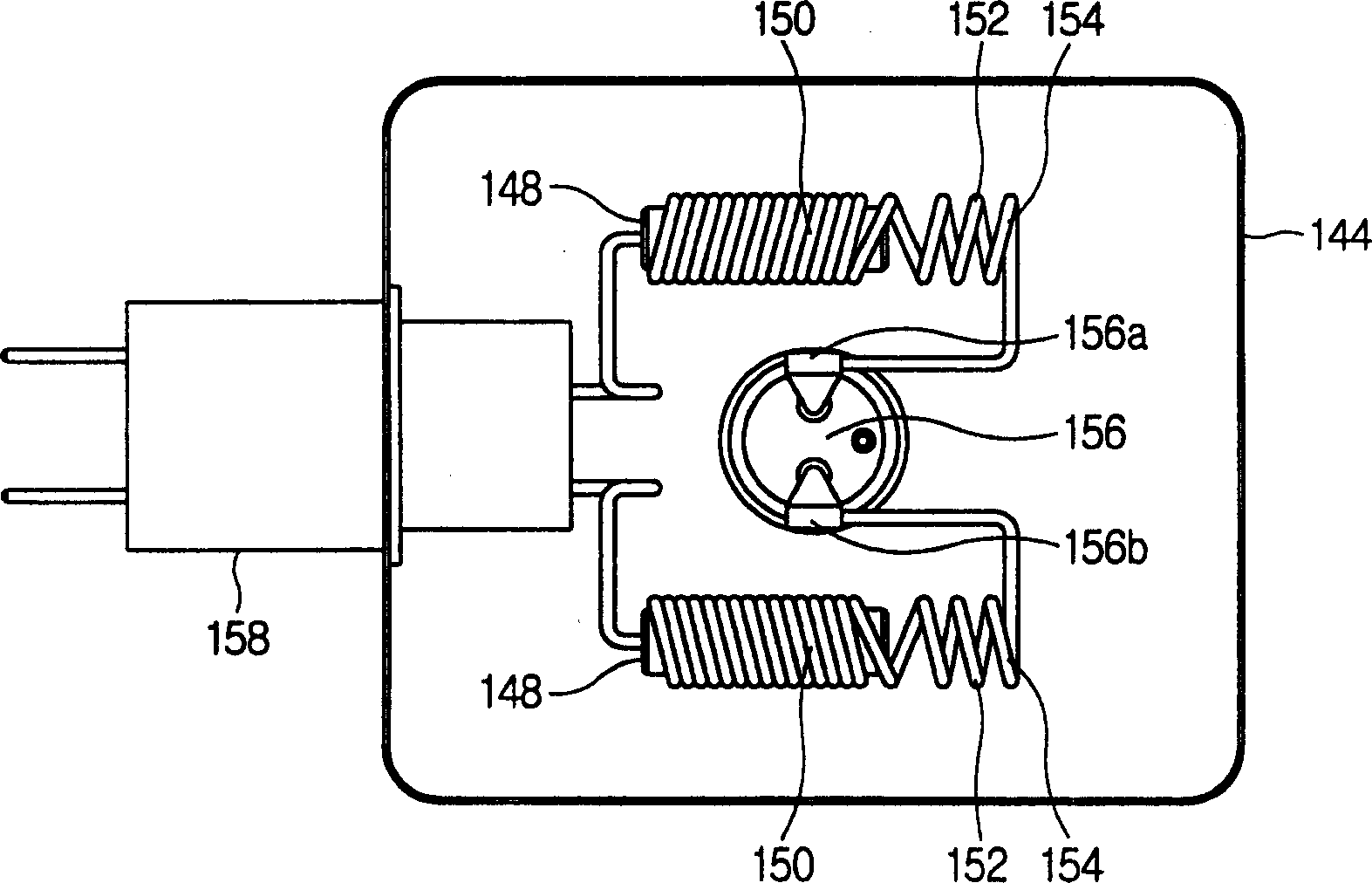

Filtering structure of magnetron

InactiveCN102237240APrevent proliferationAvoid lossTransit-tube leading-in arrangementsMagnetronsMicrowaveEngineering

The invention discloses a filtering structure of a magnetron. The structure is arranged on the lower part of the magnetron and comprises a filtering coil, a central guide rod, a side guide rod, a shielding box and a capacitor, wherein the central guide rod and the side guide rod are connected with filaments in the magnetron respectively; the shielding box encircles the filtering coil; a closed space is formed inside the shielding box; the lower end of a ceramic part of the magnetron passes through a through hole in the upper part of the shielding box and is fixed with the shielding box; the capacitor is arranged outside the shielding box and connected with the filtering coil; and a shielding layer which encircles the filtering coil is arranged in the space inside the shielding box. Microwaves which are guided from a cathode outgoing line can be diffused into a space which is formed by the shielding layer, and electromagnetic waves can be prevented from passing through mesh holes, which are less than one fourth of the wavelength of the microwaves, in the shielding layer, so the leaked microwaves have a loss in the shielding layer, high-frequency harmonic waves are avoided from being diffused from the cathode outgoing line to the outside, and a harmonic noise and a linearly-conducted noise which are generated during the operation of the magnetron can be well shielded.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

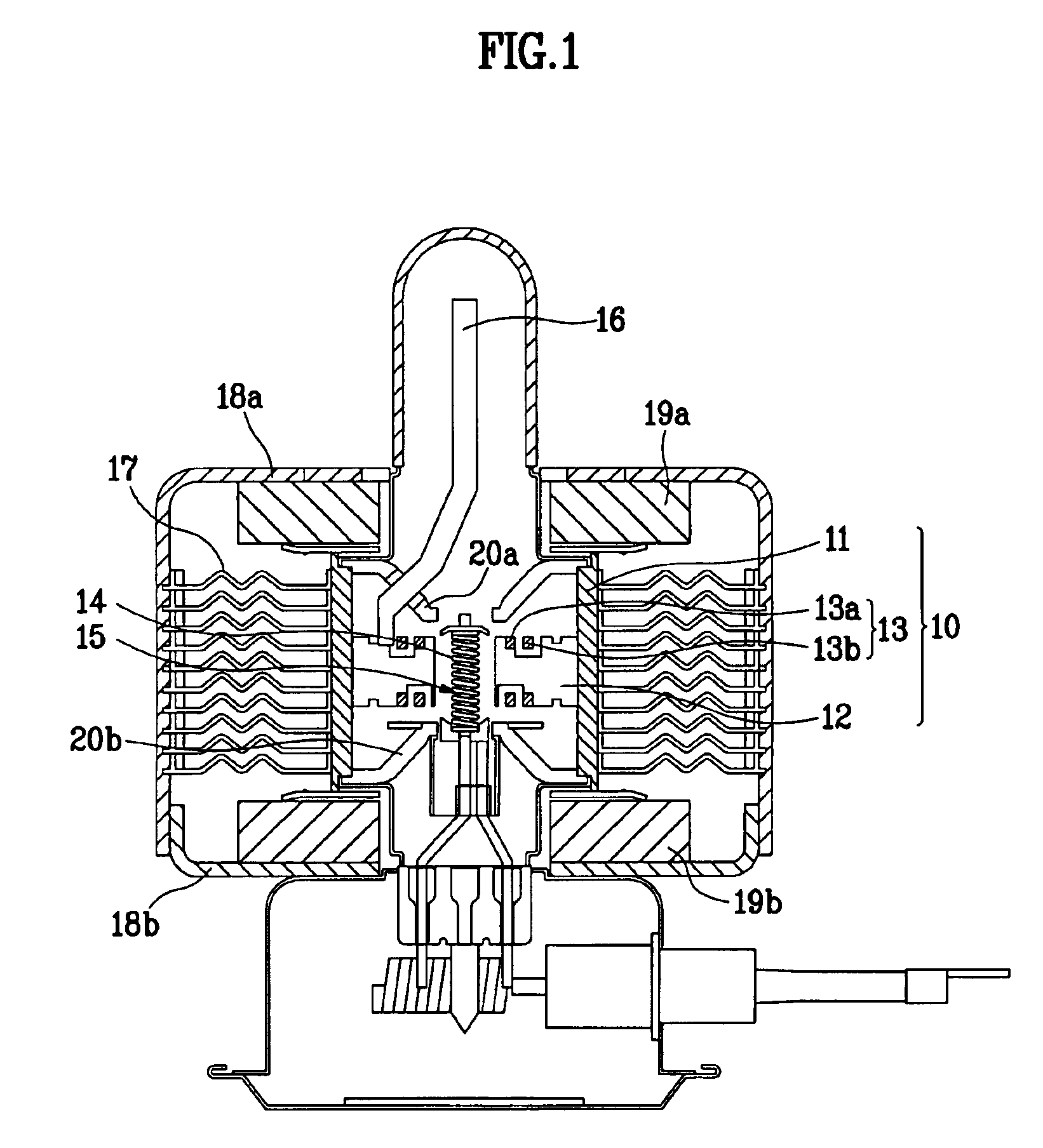

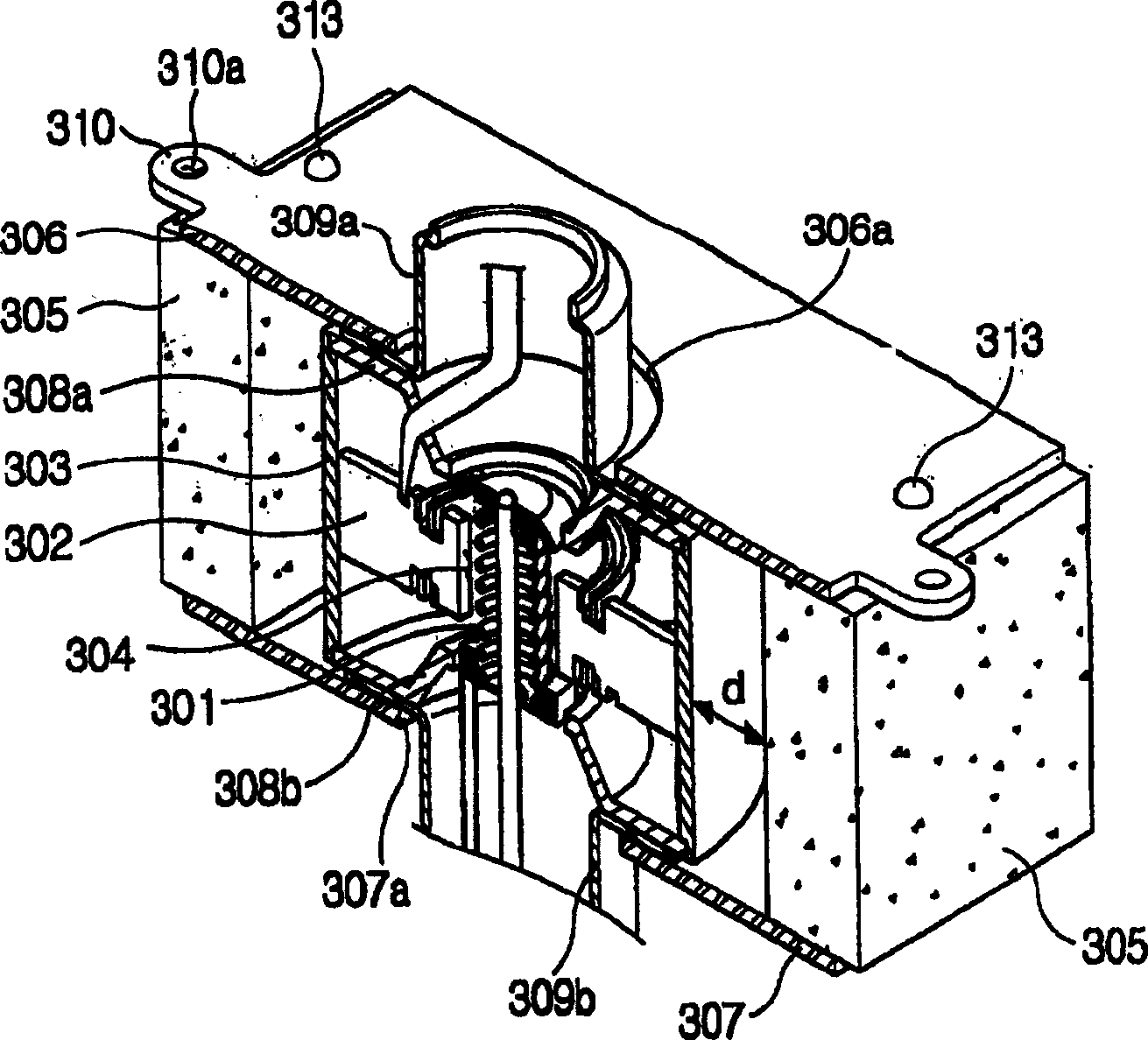

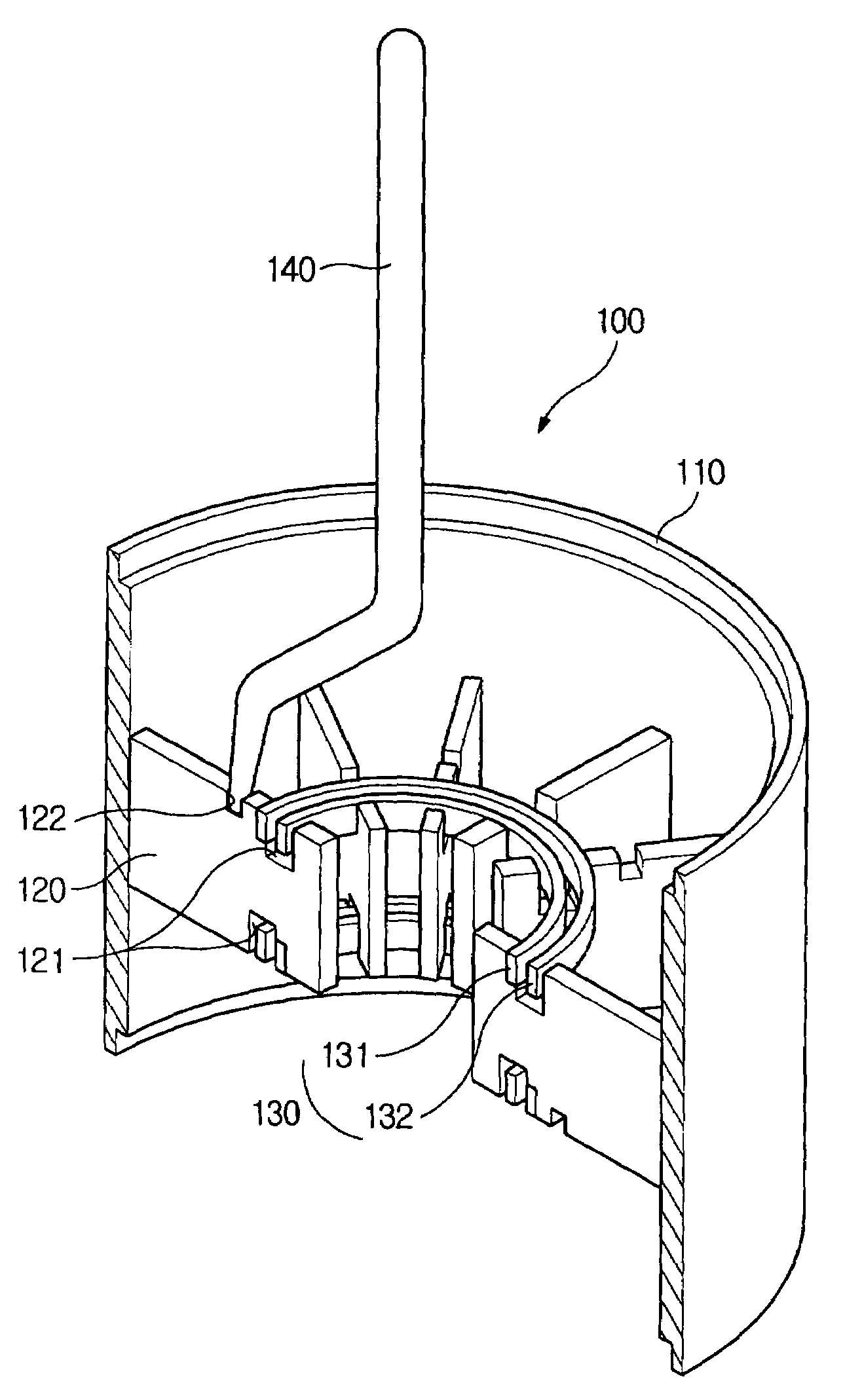

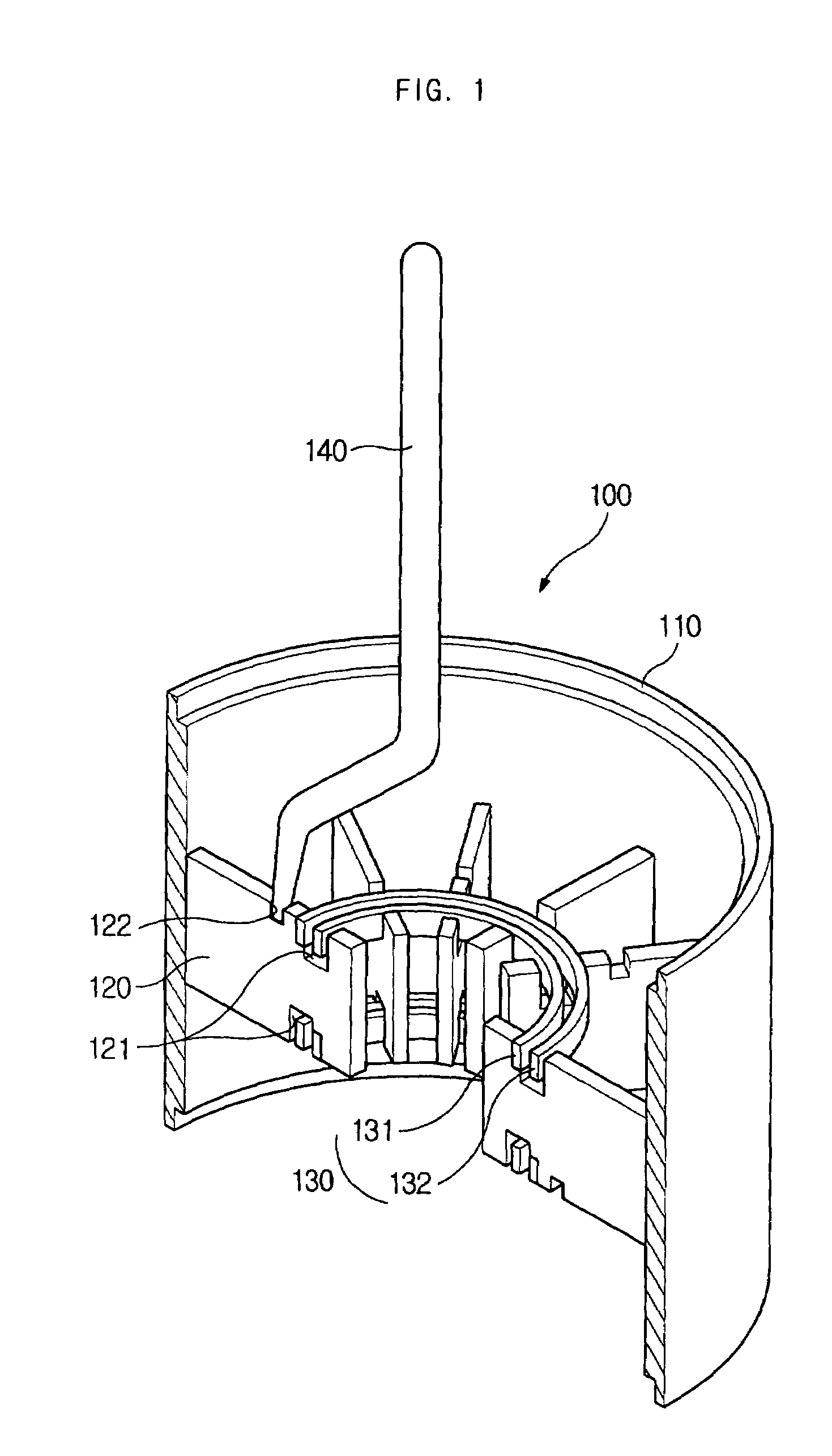

Magnetron for microwave oven

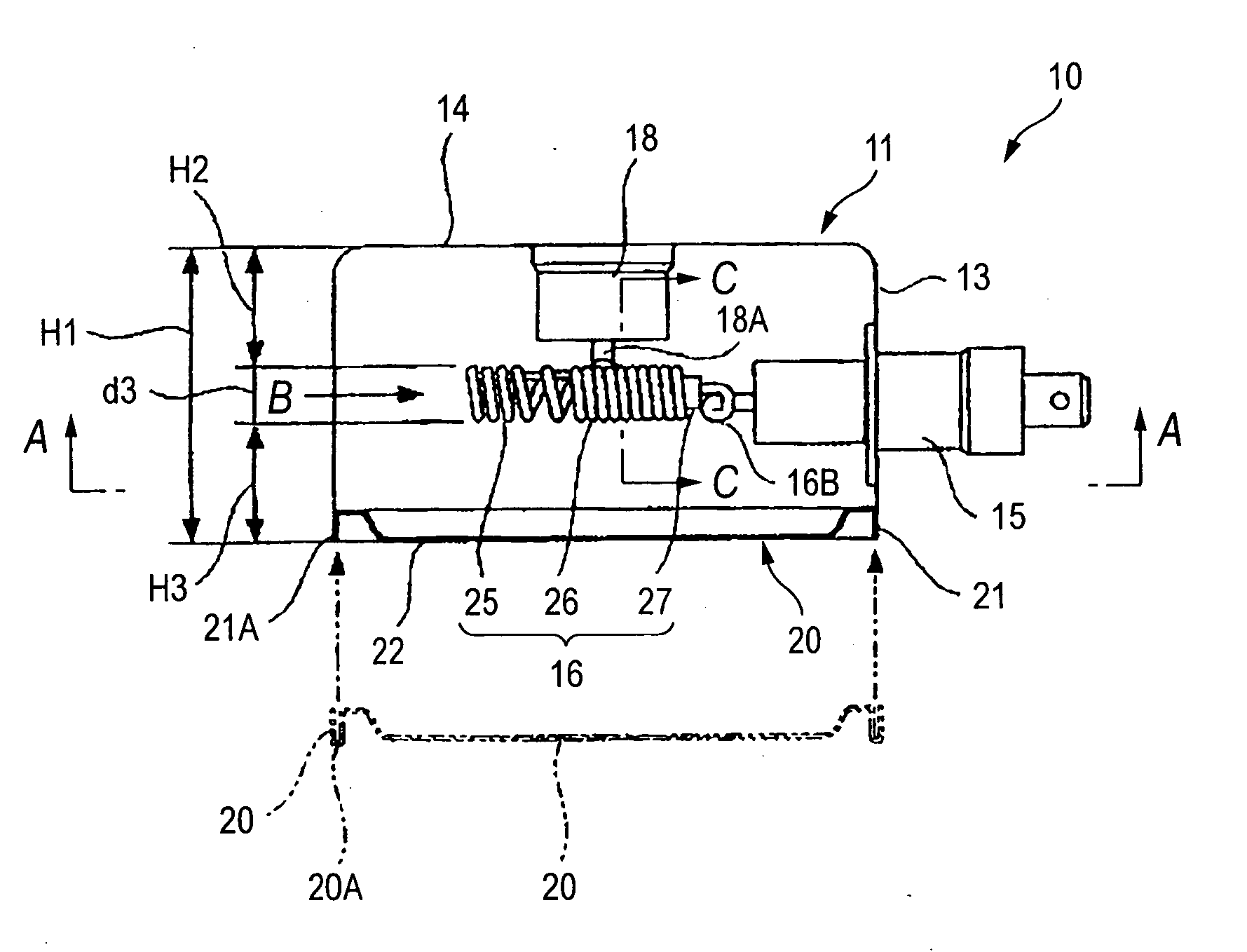

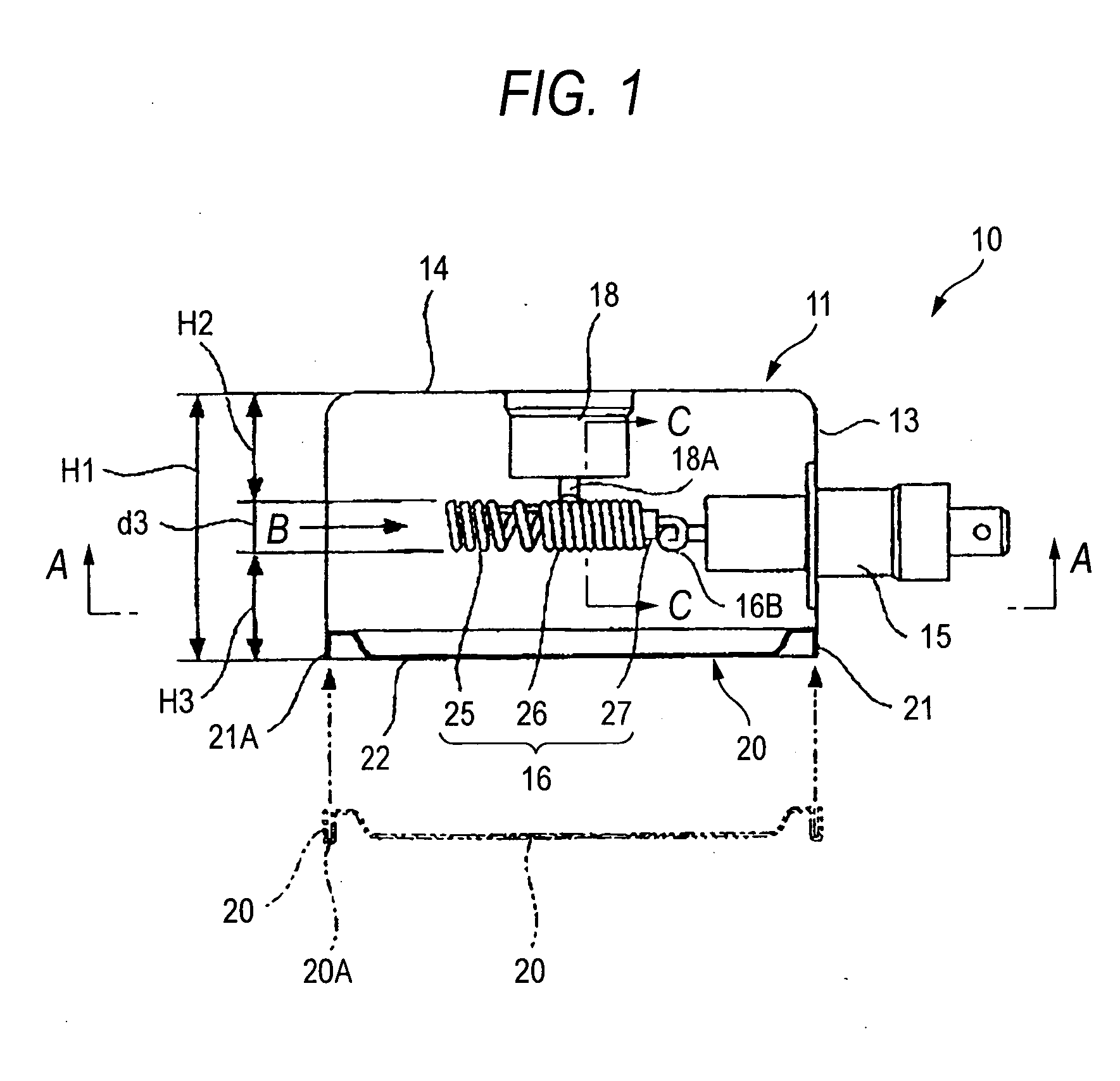

ActiveUS20060238129A1Reduce shapingSuppresses noise generationTransit-tube leading-in arrangementsMagnetronsMicrowave ovenEngineering

It is an object to provide a magnetron for a small-sized microwave oven which takes safety standards and a noise into consideration, in a magnetron 10 for a microwave oven, a pair of choke coils 16 and 17 are provided in a filter case 11, and a height H1 of the internal surface of the filter case 11 is set to be 35 to 45 mm, an outside diameter d3 of an air-core type inductance 25 is set to be 5.5 to 7.5 mm and a sectional area S of a high frequency absorbing member 27 is set to be 5 to 16 mm2. In the magnetron 10 for a microwave oven, an electrostatic capacity between capacitor terminals 15A and 15B and the filter case 11 is increased to be 500 to 700 pF.

Owner:PANASONIC CORP

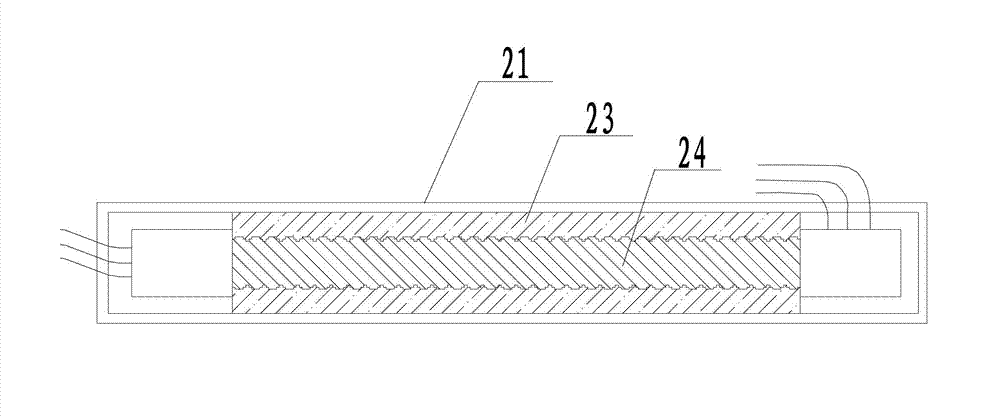

Encapsulating structure of electronic element

InactiveCN102891058AImprove plasticityIncrease contact areaTransit-tube leading-in arrangementsConductive materialsElectron

The invention discloses the encapsulating field of electronic elements, and specifically relates to an encapsulating structure of a high-power electronic element. The electronic element comprises a heat producing component and a shell. A composite thermal conductive material is encapsulated between the heat producing component and the shell, and the composite thermal conductive material is aluminum particles coated with resin. Compared with the existing heat-dissipating mode, the encapsulating structure of the electronic element disclosed by the invention has the characteristics of high heat conductivity, low encapsulating temperature, easy molding and the like.

Owner:CHENGDU GUOGUANG ELECTRIC

Magnetron

A magnetron is provided including a yoke having an inner space; a first magnet provided at one end of the inner space, a second magnet provided at a second end of the inner space, the second magnet being axially spaced from the first magnet. Further, there is an anode cylinder that generates a high frequency provided between the first magnet and the second magnet; a first pole piece and a second pole piece provided proximate first and second openings of the anode cylinder, respectively. Additionally, a seal that prevents outward leakage and has an inward protrusion extending axially toward the anode cylinder; and a choke filter, provided beneath a free end of the inwardly bent end of the seal to prevent outward leakage, may be provided.

Owner:LG ELECTRONICS INC

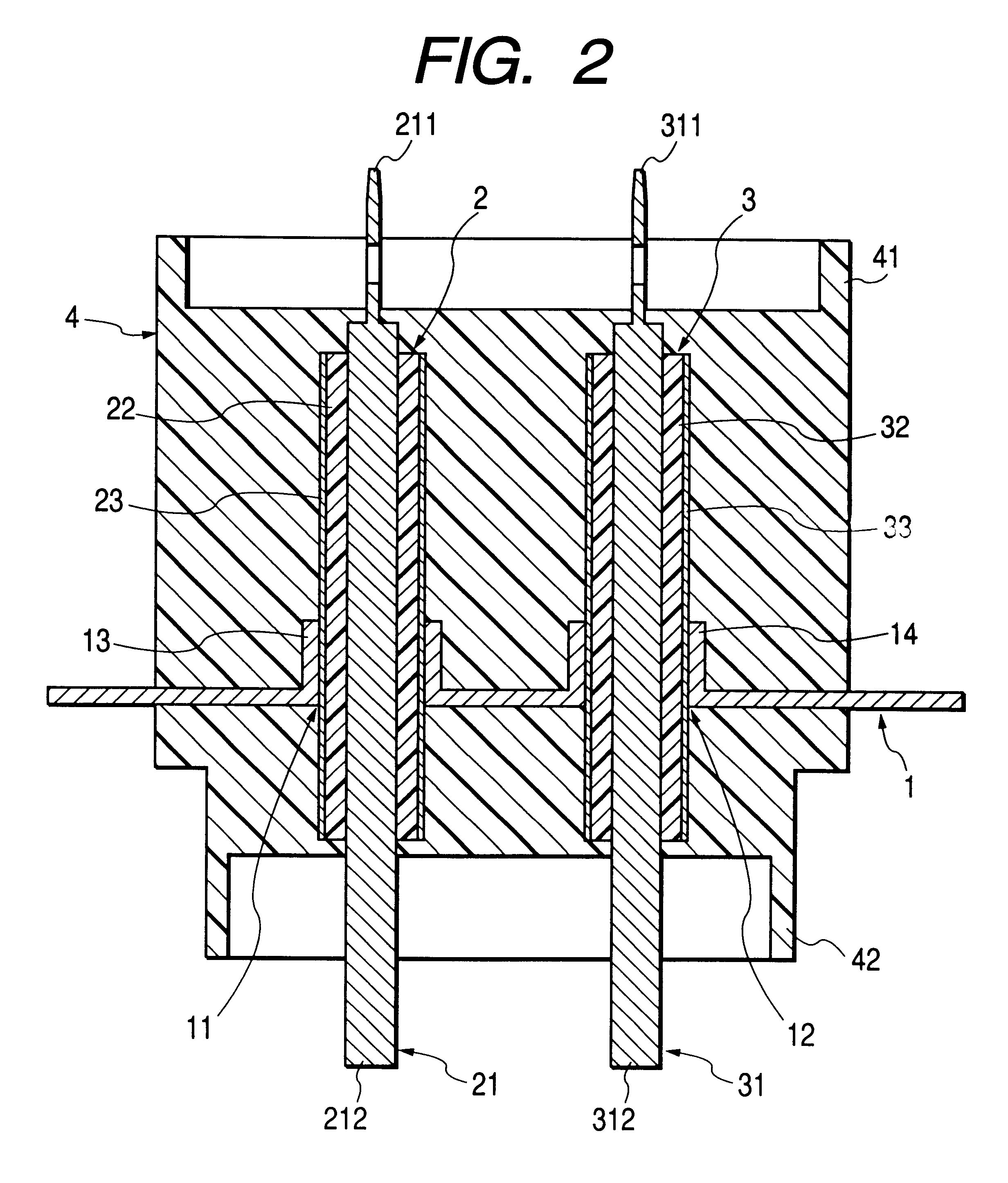

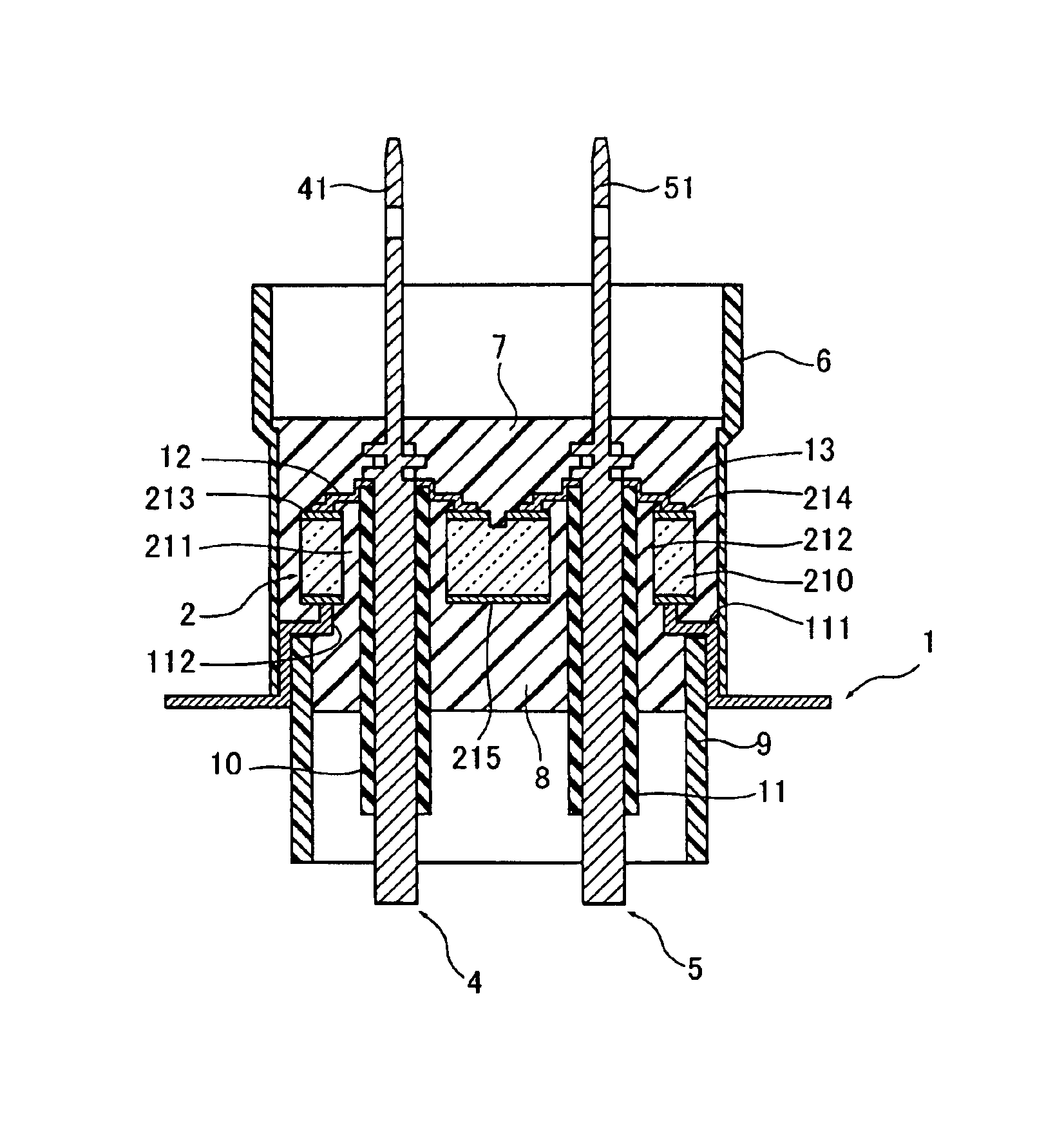

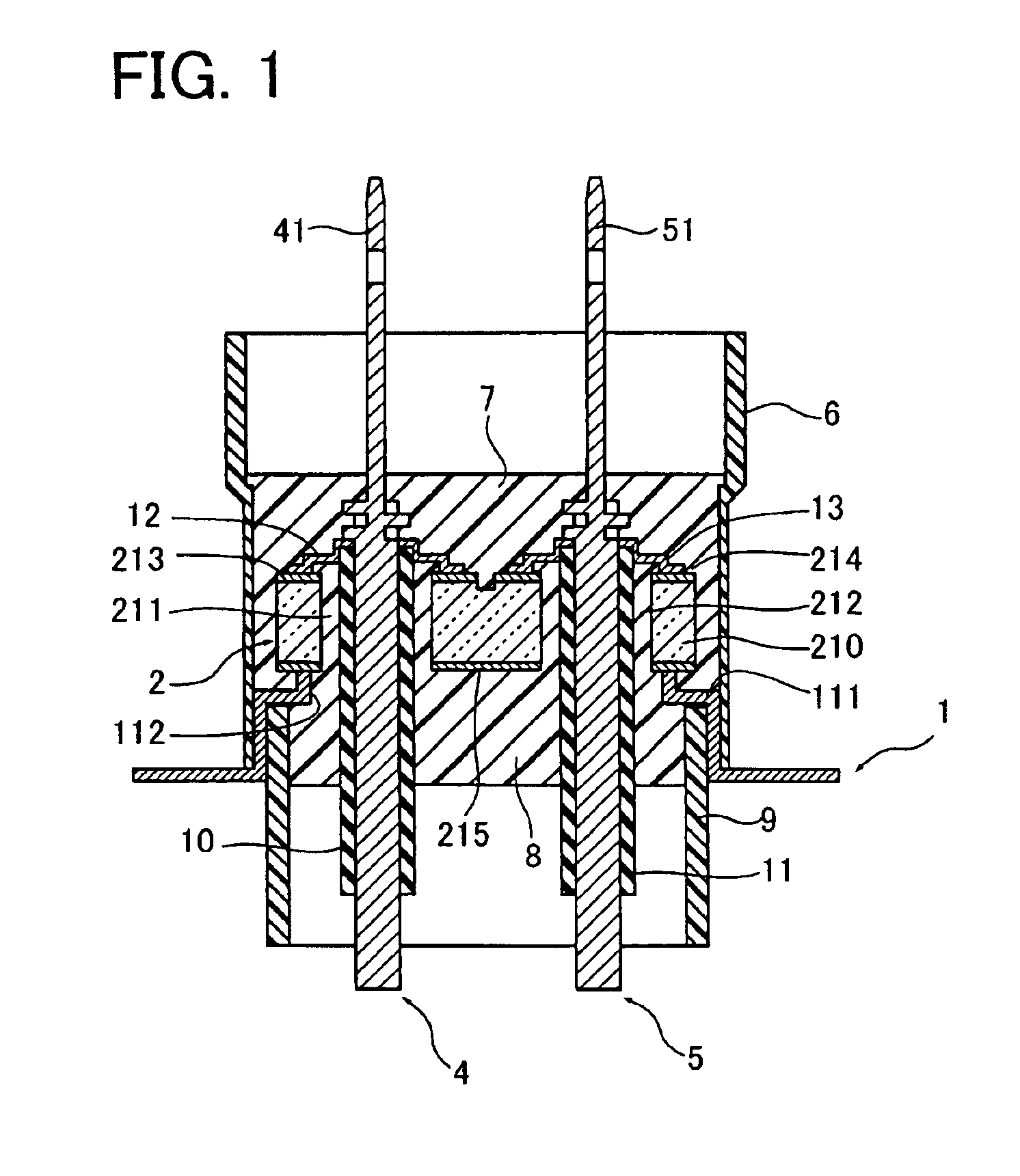

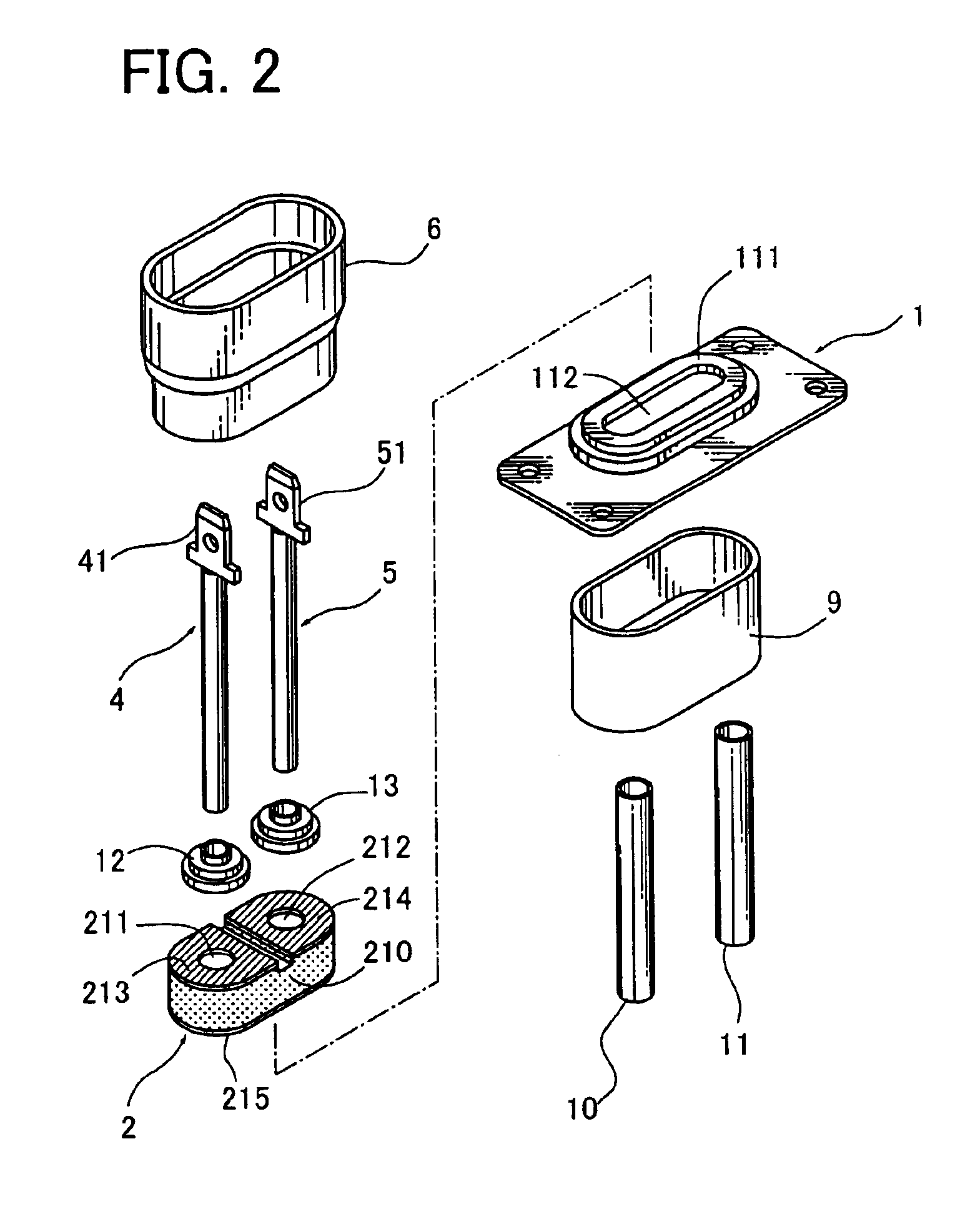

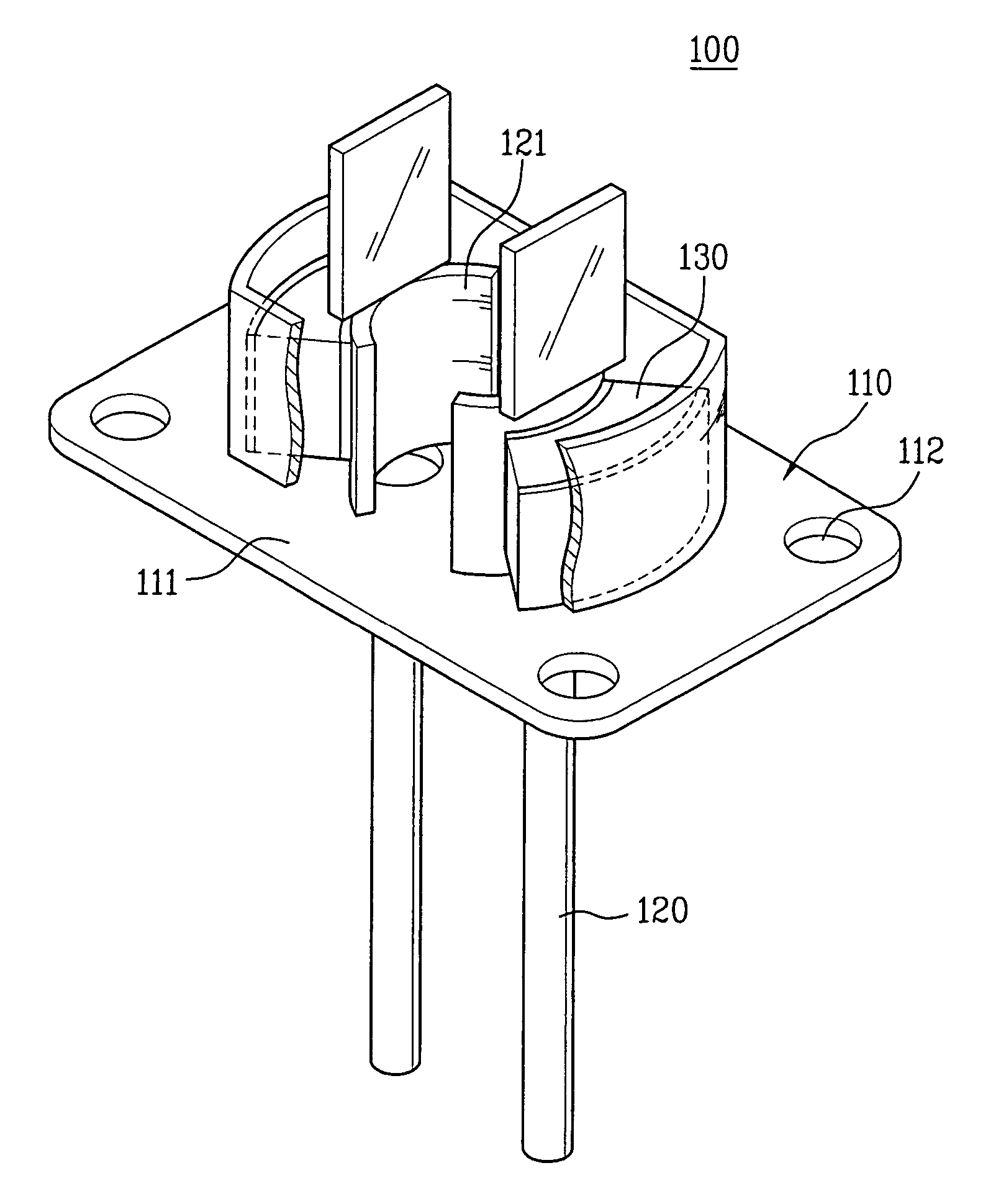

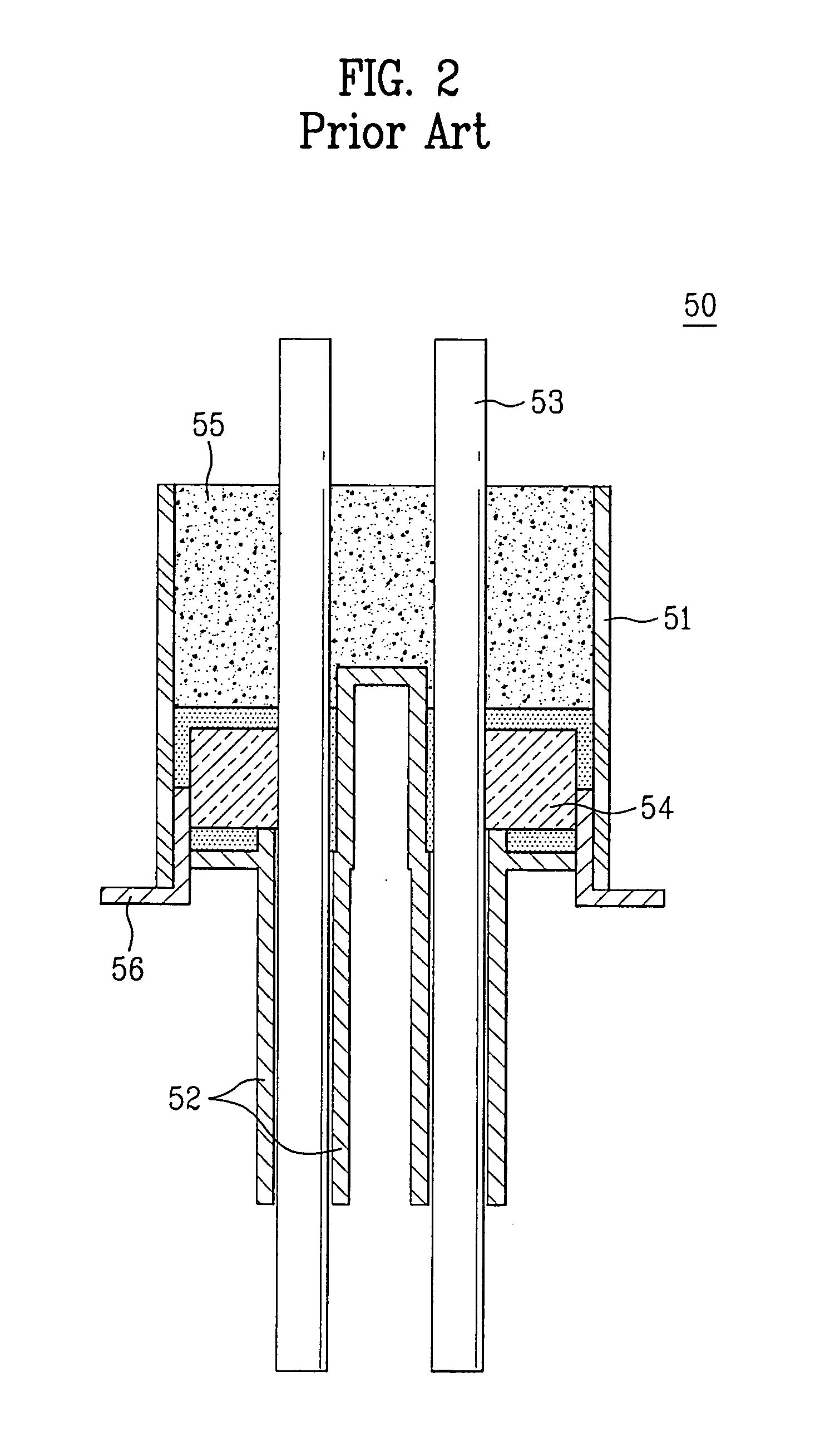

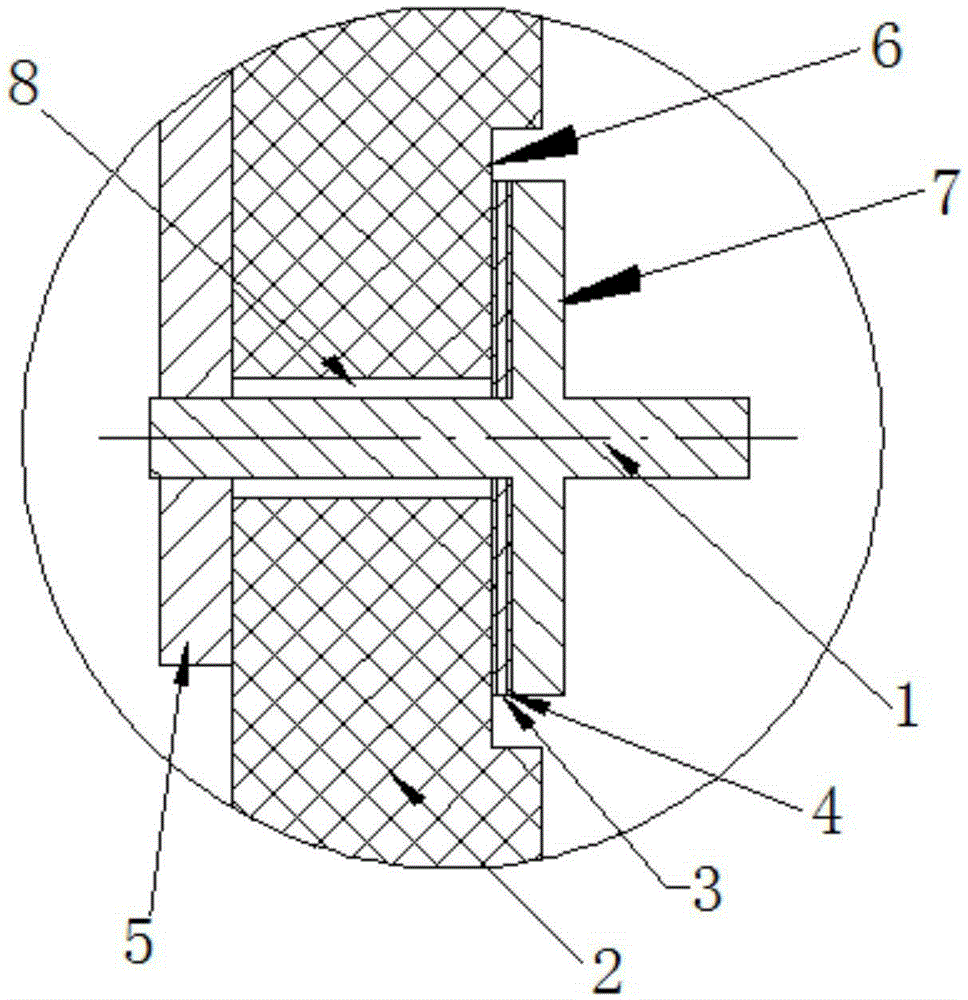

High voltage capacitor and magnetron

ActiveUS6909590B2Improve reliabilityCharacteristics shortAnti-noise capacitorsTransit-tube leading-in arrangementsInterior spaceElectrical conductor

A capacitor has electrodes at surfaces thereof, with one of the electrodes secured onto one surface of a grounding metal. Through conductors pass through the capacitor and the grounding metal and are connected to the other electrodes so as to achieve electrical continuity. An insulating case is provided at one surface of the grounding metal, with one end of the insulating case fitted around the external circumference of the raised portion of the grounding metal. Insulating resin fills a space inside the insulating case, the internal space of the grounding metal and a space around the capacitor. The insulating resin comprises an epoxy resin containing a brominated fire retardant, and the brominated fire retardant is a brominated aromatic glycidyl ether.

Owner:TDK CORPARATION

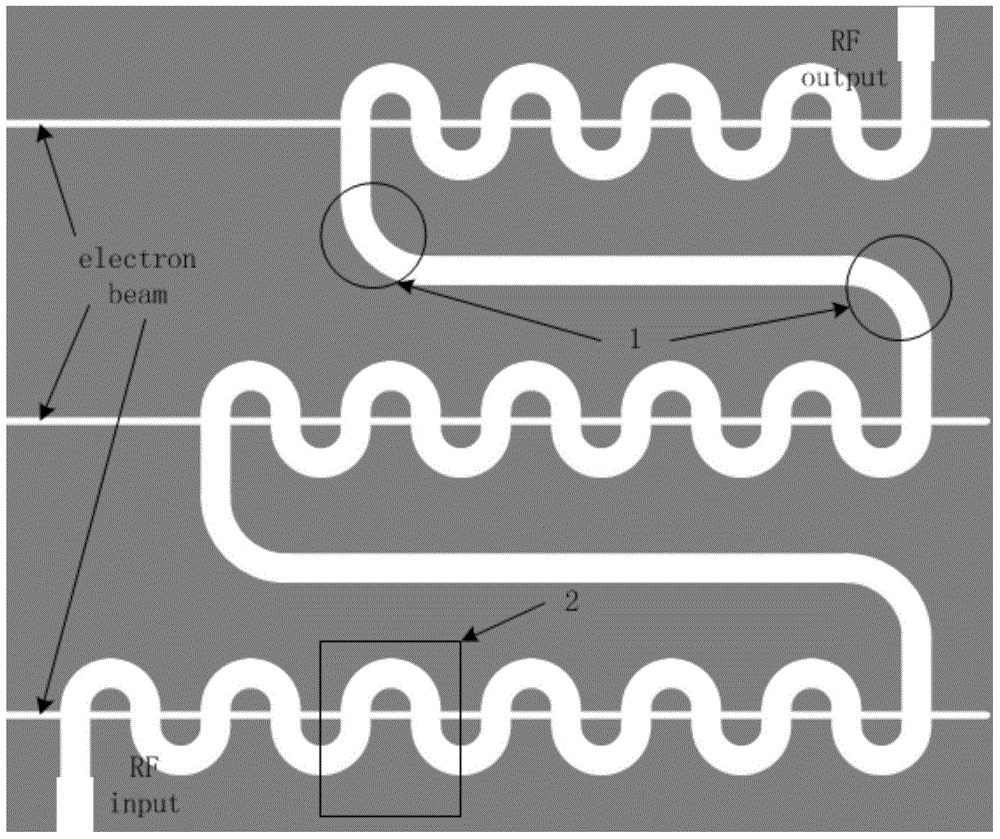

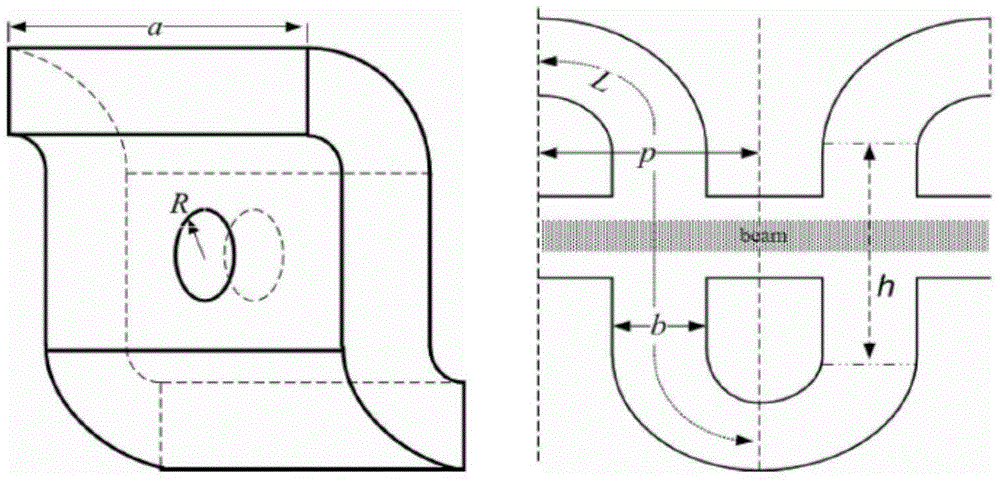

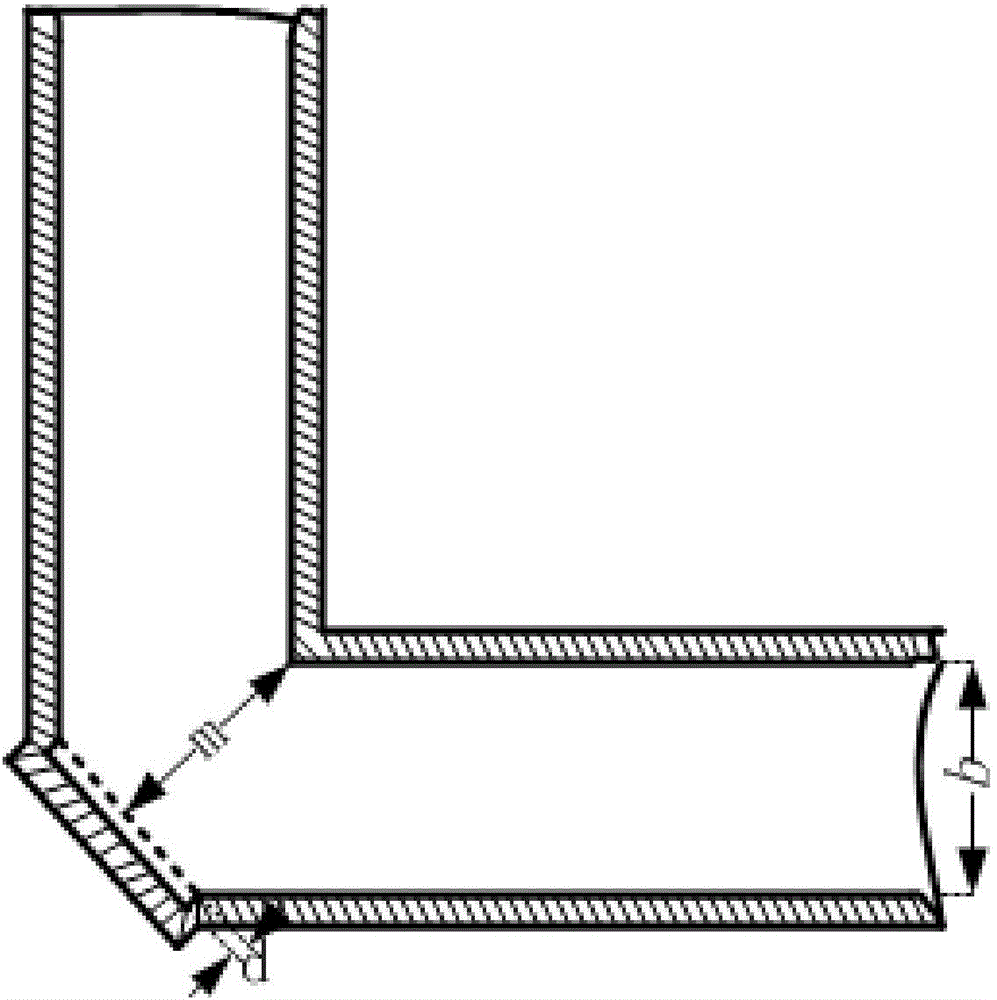

Connecting structure for cascading folded waveguide

ActiveCN104599925AOptimize spaceWeight optimizationTransit-tube leading-in arrangementsTravelling-wave tubesElectricityMicrowave

The invention discloses a connecting structure for cascading folded waveguide, and belongs to the field of microwave electron vacuum. The connecting structure is in a form of a bent rectangular waveguide and is characterized in that the bending angle of the bent rectangular waveguide is 90 degrees, and the outer folding angle of the bent part outwards extends to form a rectangular cavity; the connecting structure is a full-metal structure. The connecting structure has a good input / output feature; the connection size of the cascading folded waveguide travelling wave tubes at all levels is reduced to some extent, and therefore, the travelling wave tubes are compact in structure and light in weight, and as a result, the applicable scope of a plurality of folded waveguide travelling wave tube bundles is expanded.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

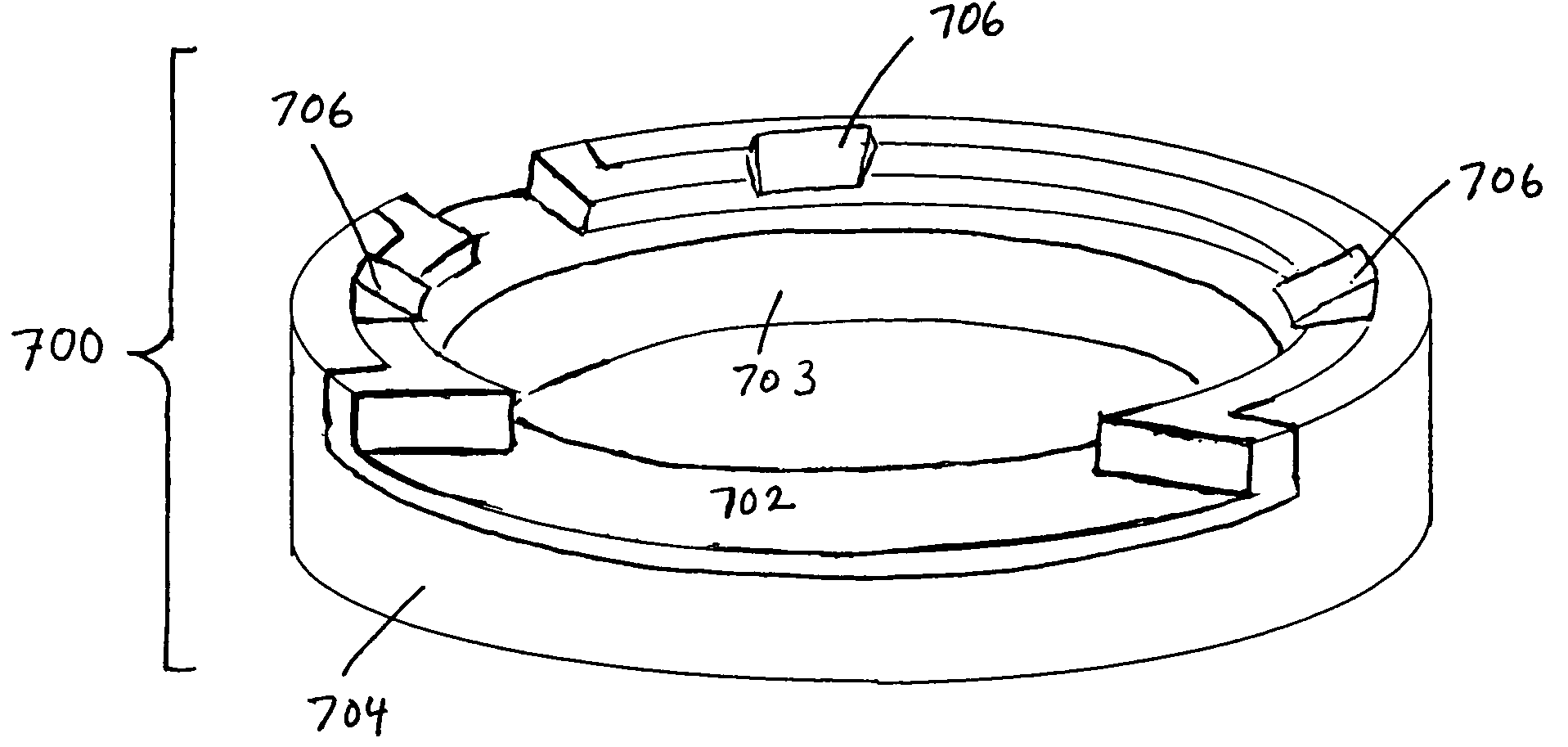

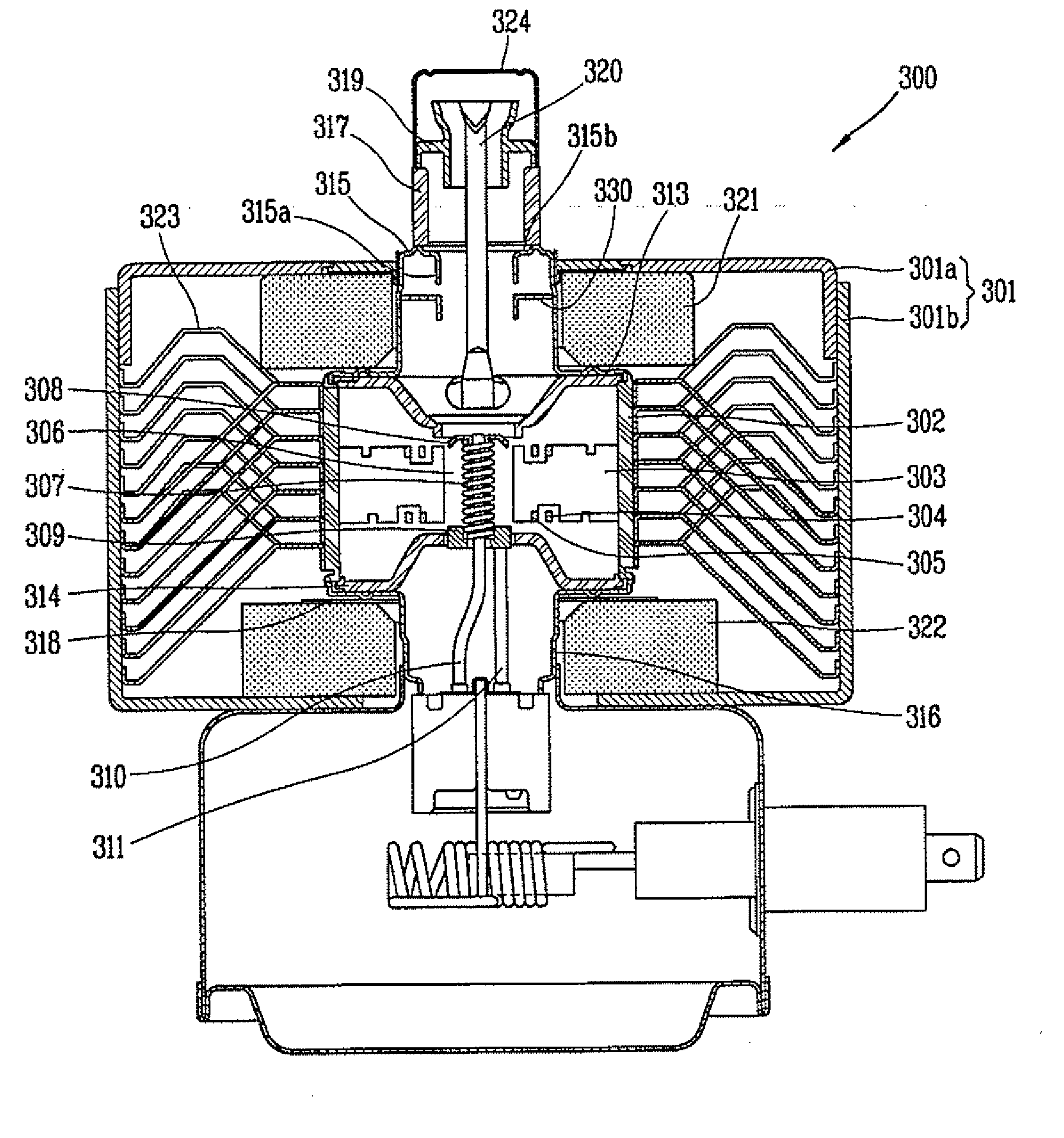

Magnetron having choke filter configured to intercept external leakage

InactiveUS7511251B2Transit-tube leading-in arrangementsMicrowave heatingRadio frequency energyEngineering

A magnetron is provided including a yoke having an internal space, a first magnet provided at one end of the internal space, a second magnet provided at a second end of the internal space, the second magnet being axially spaced from the first magnet. Further, an anode cylinder that generates radio frequency energy may be provided axially between the first and second magnets, a first pole piece and a second pole piece may be provided proximate first and second openings of the anode cylinder, respectively. Additionally, the magnetron may also include a seal that intercepts external leakage, the seal may have an inward protrusion extending axially towards the anode cylinder; and a choke filter that intercepts external leakage provided proximate the seal.

Owner:LG ELECTRONICS INC

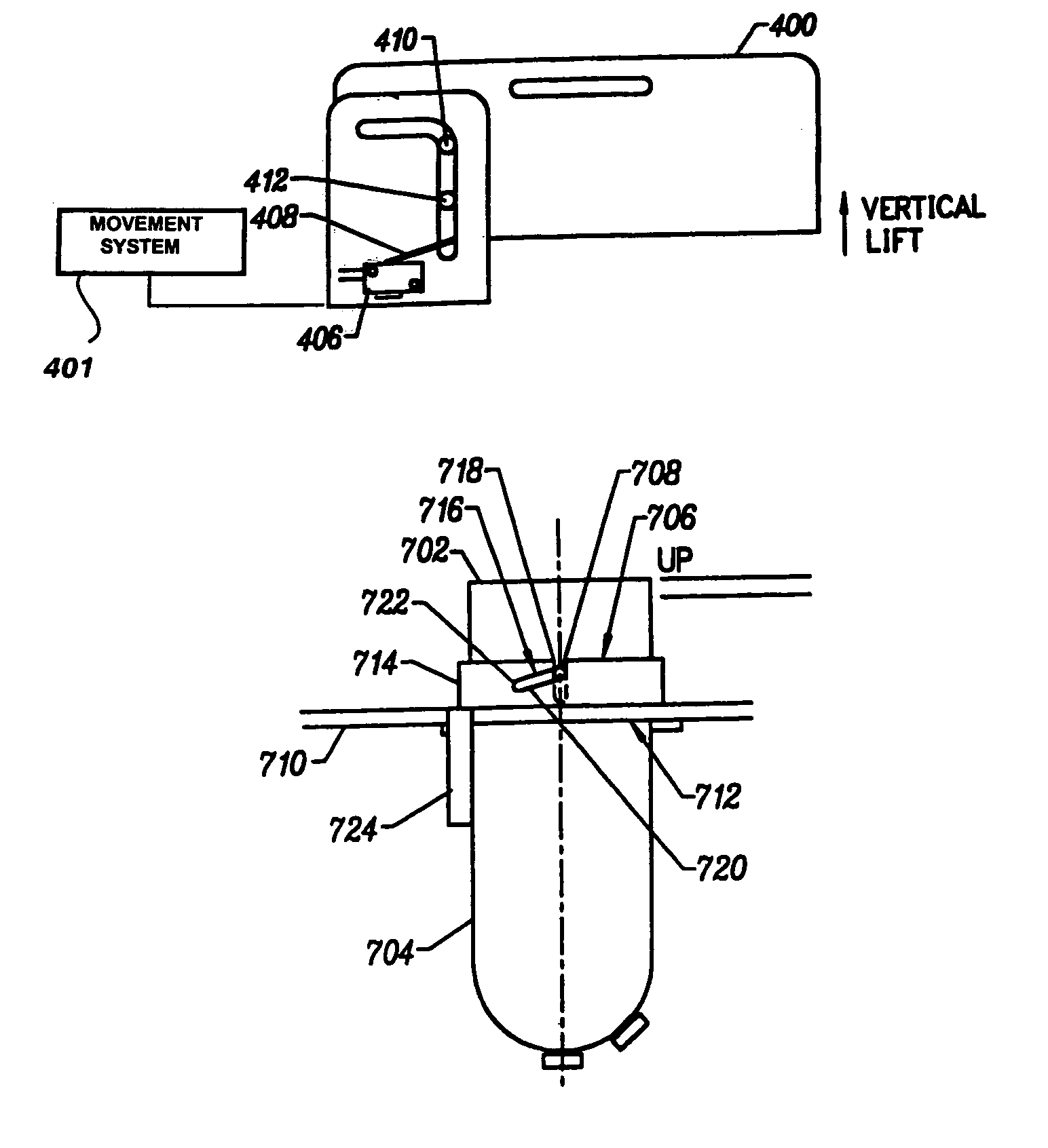

Cover assembly for vacuum electron device

InactiveUS7029296B1Good seat alignmentPrevent RF leakageTransit-tube vessels/containersTransit-tube leading-in arrangementsLocking mechanismEngineering

A self guiding cover assembly for a vacuum electron device (VED) enclosure has a cover, a pair of guide plates, and a pair of guide elements. The cover has a top, a sidewall, an inside and an outside, and at least one electrical connector disposed on the inside of the cover for mating with an electrical connector on a VED. The pair of guide plates is disposed on opposite sides of the outside of the sidewall of the cover. The guide plates each have a track. The guide elements are mounted on the enclosure on opposite sides of the cover. The pair of guide elements each mates with the track to guide the cover as it is lifted from the enclosure. The cover further comprises a breach lock mechanism for seating the VED into the VED enclosure having the cover and a base. The breach lock mechanism has guide elements mounted on the cover. A sleeve is mounted on the base and removably receives the cover with the VED. The sleeve rotates about the cover. The sleeve has tracks for mating with the guide elements. A rotation of the sleeve pulls the top into the base for seating the VED.

Owner:COMM & POWER IND

Magnetron and microwave oven and high-frequency heating equipment equiped with the same magnetron

InactiveCN1506999ALow costTransit-tube leading-in arrangementsDomestic stoves or rangesMicrowave ovenResonance

Owner:SAMSUNG ELECTRONICS CO LTD

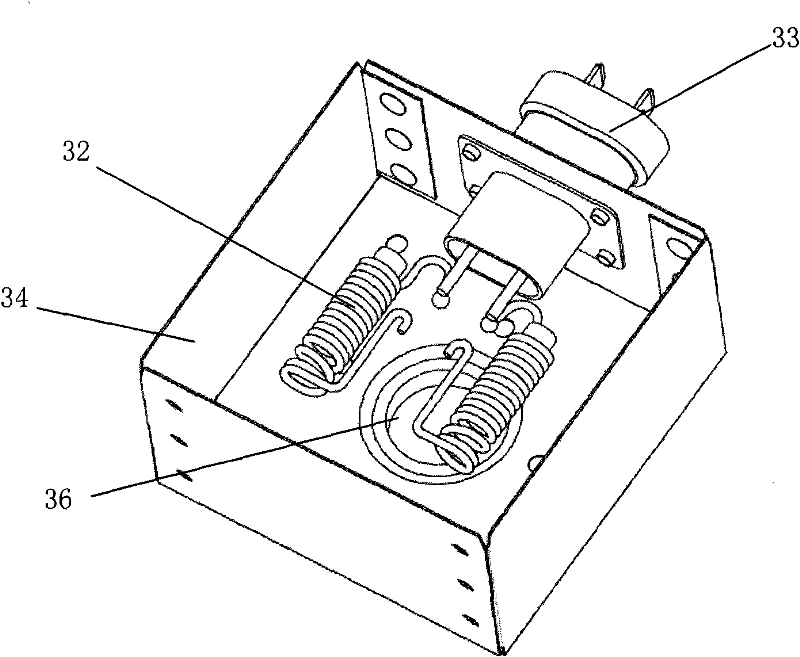

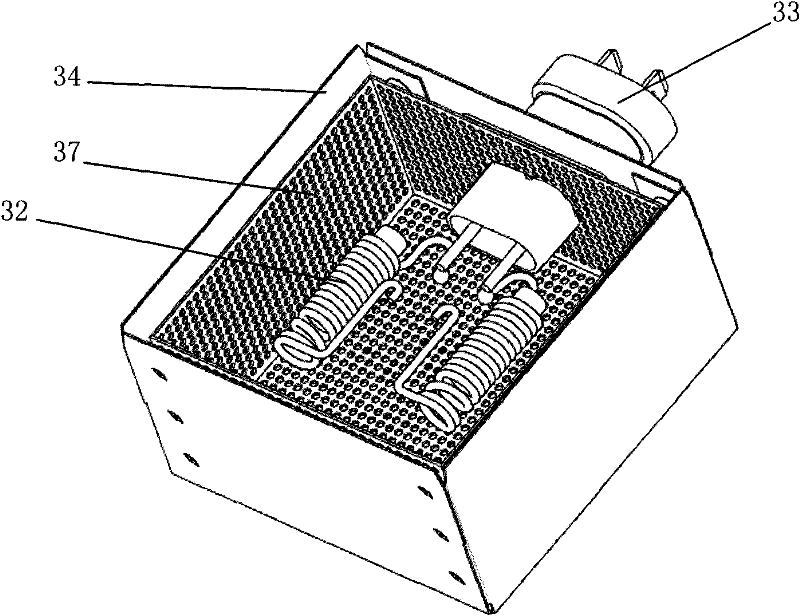

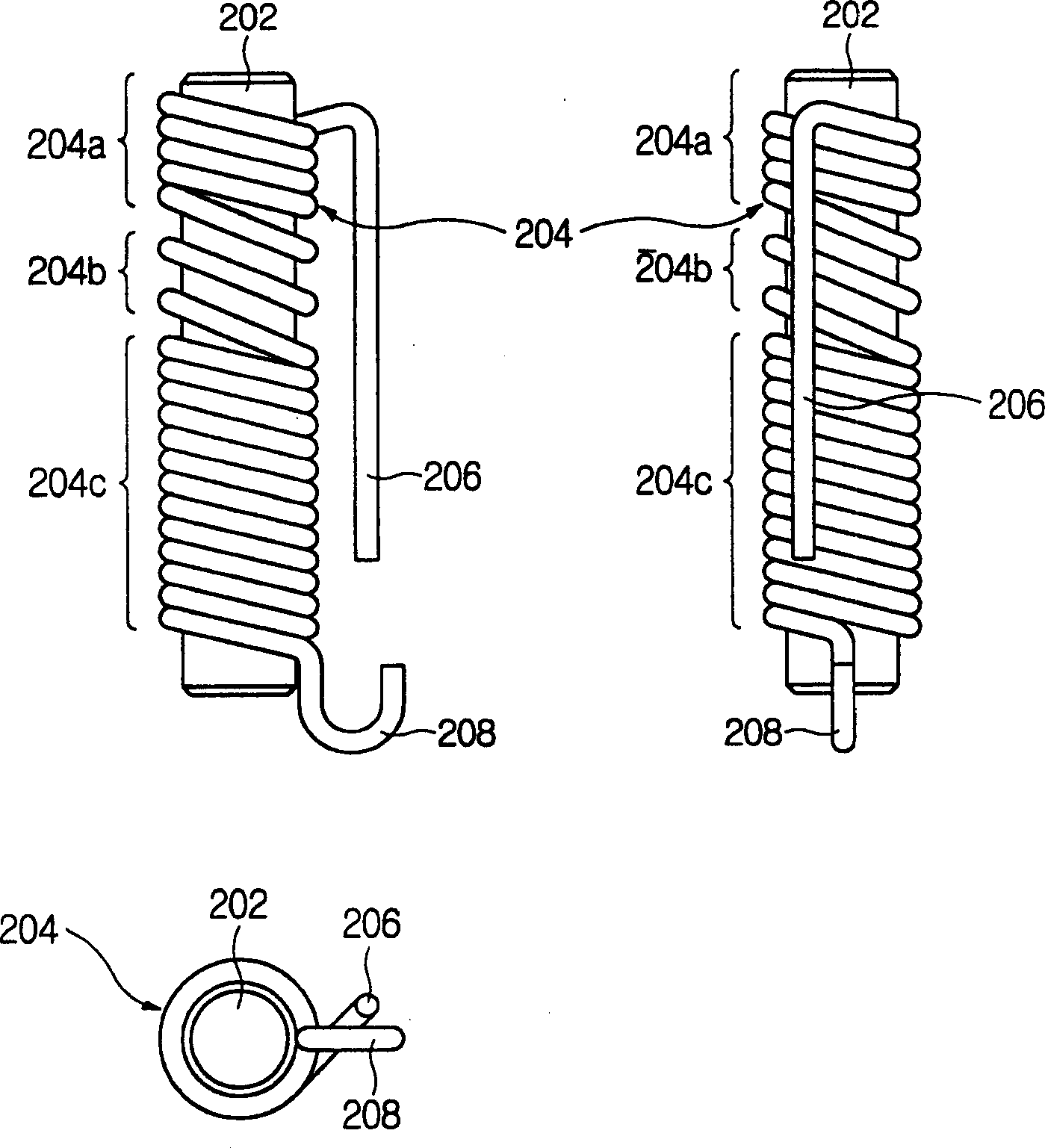

Noise filter for high-frequency generator

A noise filter for a high frequency generator maximizes a frequency band in which noise is attenuated by adjusting a spacing between winding turns of core inductors provided in the noise filter. The noise filter includes a choke coil having a first winding unit having a first spacing between turns thereof, a second winding unit having a second spacing between turns thereof and a third winding unit having a spacing the same as the first spacing between turns thereof. The first, second, and third winding units are connected in series to each other. The noise filter also includes a high-frequency energy absorbing member inserted into the choke coil. The high-frequency energy absorbing member is made of one of iron oxide, tin alloy and ferrite, and includes a sectional area to attenuate noise in a frequency band ranging from 30 MHZ to 1000MHz.

Owner:SAMSUNG ELECTRONICS CO LTD

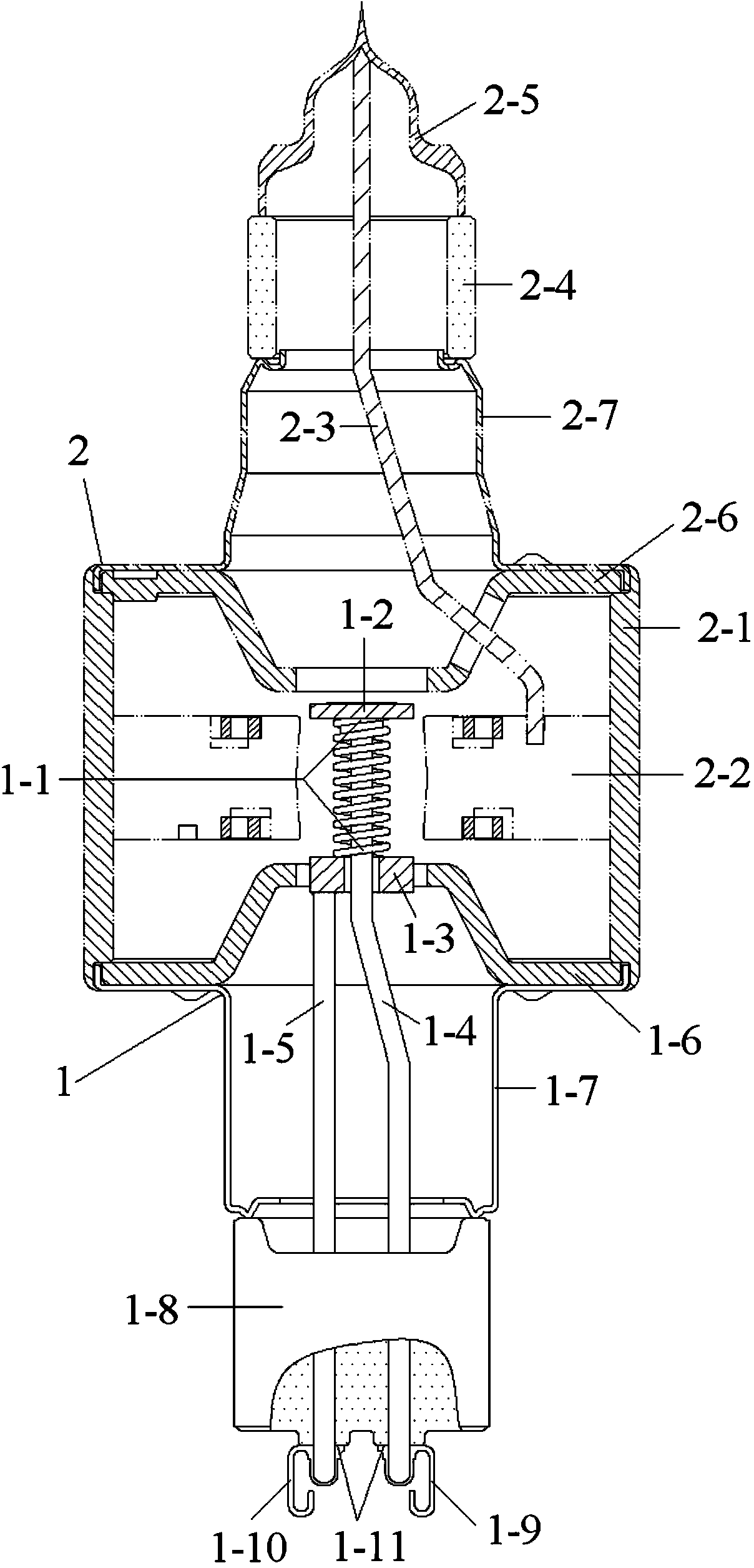

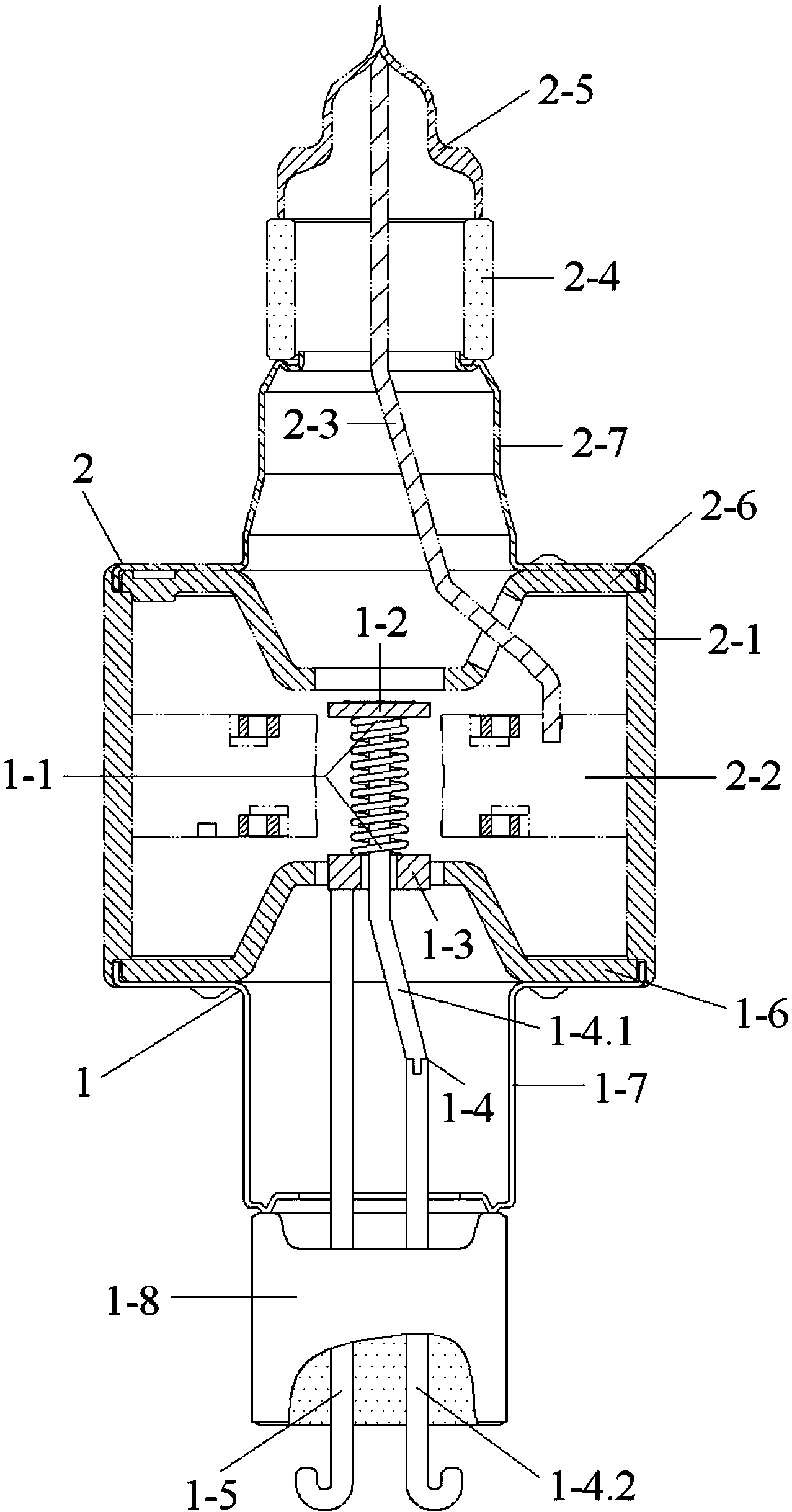

Magnetron tube core for microwave heating

InactiveCN103531419AImprove sealingSimple structure and processTransit-tube leading-in arrangementsMagnetronsMagnetic polesAlloy

The invention belongs to the field of magnetron design and production, and discloses a magnetron tube core for microwave heating. The magnetron tube core comprises a heated cathode emitter, an upper shielding cap, a lower shielding cap, a bimetal center support and upper electrode supply connecting rod, a side support and lower electrode supply connecting rod, a lower magnetic pole, a tube core casing and high-tension ceramic, wherein the upper shielding cap and the lower shielding cap are arranged on the heated cathode emitter; the bimetal center support and upper electrode supply connecting rod is welded by molybdenum as well as iron, nickel and cobalt constant-expansion ceramic sealing alloy; the side support and lower electrode supply connecting rod adopts iron, nickel and cobalt constant-expansion ceramic sealing alloy; and the high-tension ceramic is provided with sealing connection holes. According to the magnetron tube core for microwave heating, the iron, nickel and cobalt constant-expansion ceramic sealing alloy is adopted as lower half sections of the side support and lower electrode supply connecting rod and the center support and upper electrode supply connecting rod, a coefficient of linear expansion of the iron, nickel and cobalt constant-expansion ceramic sealing alloy is very similar to that of the high-tension ceramic, and the specific resistance of the iron, nickel and cobalt constant-expansion ceramic sealing alloy is far lower than that of molybdenum, so that the magnetron tube core has the characteristics of simple sealing structure and welding technology, good sealing performance, high reliability during working, long service life, high yield of production, lower cost and the like, and electrical performance of the cathode is improved to some extent.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

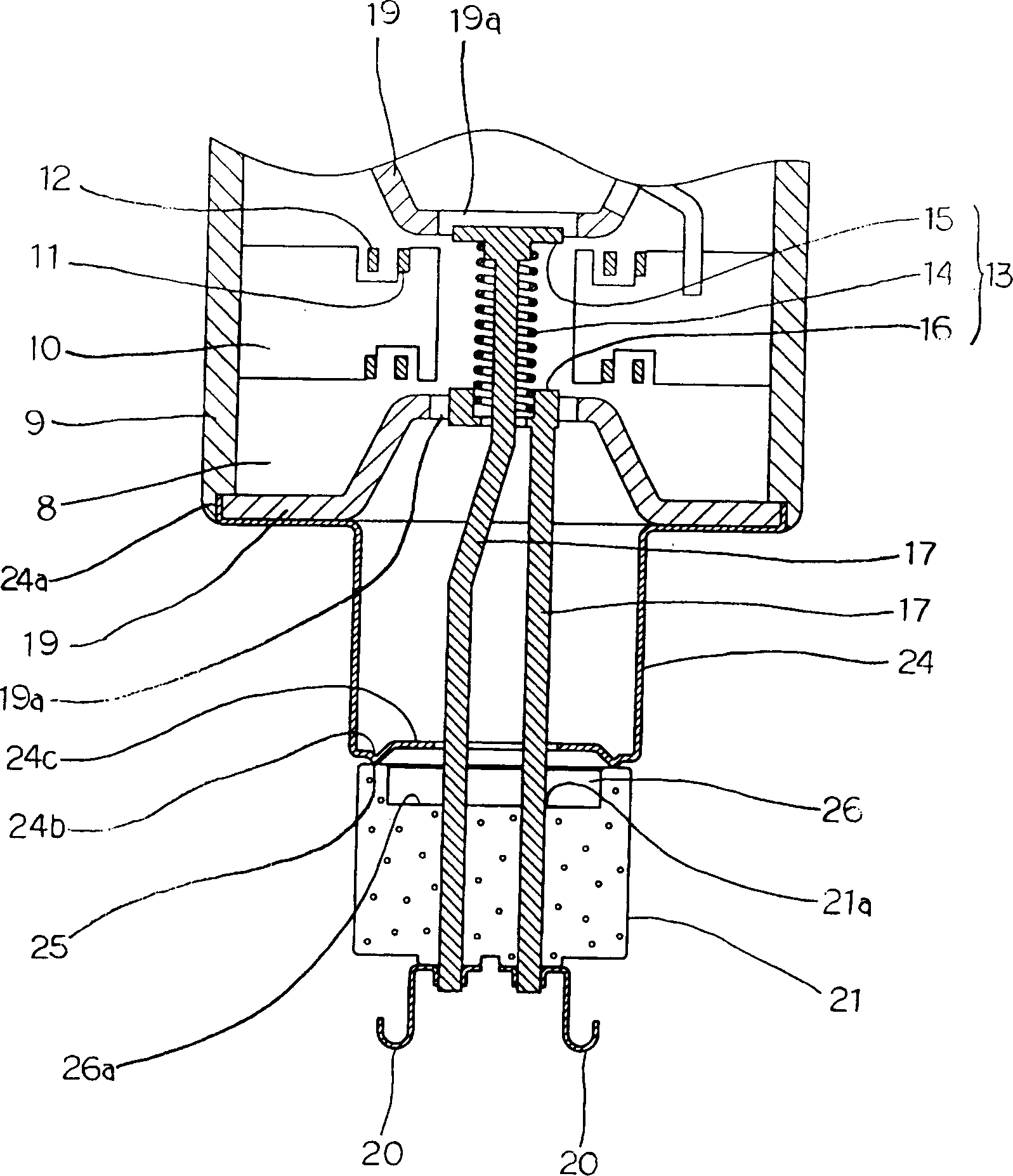

Magnetron

InactiveCN1404092AReduced insulation resistanceAvoid dischargeTransit-tube leading-in arrangementsMagnetronsMagnetic polesMetal

A cathode 13 with a filament 14 arranged at a center axis part of an anode 18 is supported by a pair of cathode leads 17, a pair of magnetic pole pieces 19 with a through-hole 19a formed at around the center are arranged at both ends of the anode 8, an opening 24b at one end of a cylindrical metal container 24 is joined airtightly with a junction face formed at a stem insulating body 21, a circular brim part 24c set in extension at the side of the cathode leads 17 is formed at the opening 24b, and a bottom face 26a of the stem insulating body 21 is to be covered with the brim part 24c. To surely prevent discharge generated between a junction part of a stem insulating body with a cylindrical metal container and cathode leads.

Owner:SANYO ELECTRIC CO LTD

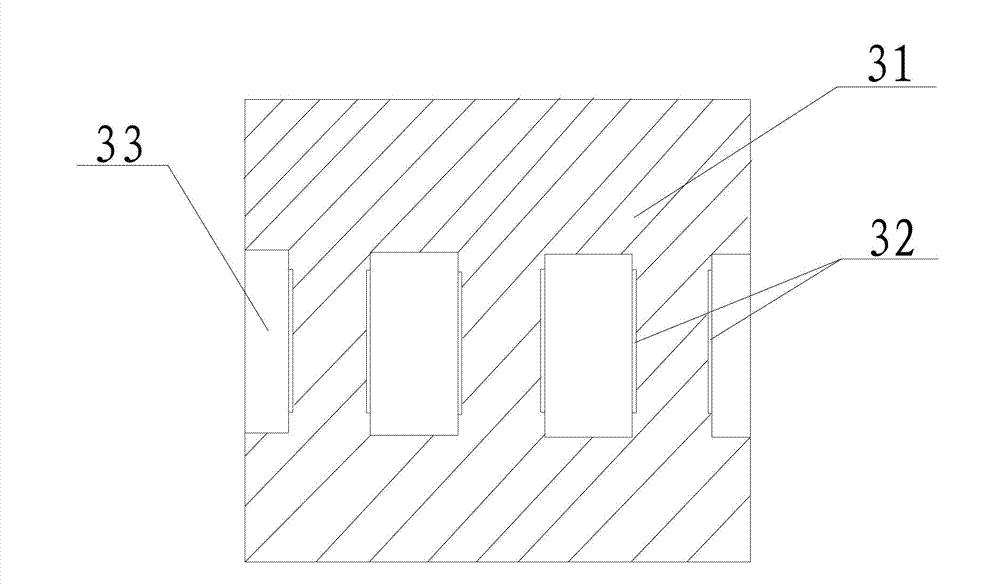

Capacitor of magnetron

ActiveUS7220949B2Increase capacitanceExcellent voltageAnti-noise capacitorsTransit-tube leading-in arrangementsCapacitanceDielectric

Disclosed herein is a capacitor for a magnetron. The capacitor has dielectric members, which have a converging angle of less than 180° defined between lines extending from both sides of each dielectric member formed between corresponding ends of inner and outer electrodes of the dielectric member. The capacitor is reduced in size while having enhanced capacitance, thereby reducing a manufacturing time. The capacitor also has central conductors having enlarged portions larger than the inner electrode, thereby further enhancing the capacitance.

Owner:LG ELECTRONICS INC

Magnetron for microwave ovens and method of forming same

InactiveUS7122773B2Improve performanceSimple manufacturing processTransit-tube leading-in arrangementsSoldering apparatusMicrowave ovenEngineering

A magnetron for microwave ovens includes an anode cylinder, a plurality of plate-shaped vanes radially arranged along an inside surface of the anode cylinder, one or more strap rings to electrically connect the plurality of plate-shaped vanes to each other, an antenna connected to one of the plurality of vanes to radiate microwaves generated from the plurality of vanes. Each of the vanes is plated with a brazing material to be brazed to one or more of the anode cylinder, the one or more strap rings and the antenna, and the brazing material has a plating depth of about 2.25 to 8 μm. The magnetron having the anode allows a manufacturing process of the anode to be simplified to reduce manufacturing time and equipment costs. Furthermore, the anode prevents brazing defects, and allows the magnetron to have an optimal performance.

Owner:SAMSUNG ELECTRONICS CO LTD

Miniature collector lead wire sealing method and seal structure

InactiveCN105355526AReduce precisionLower requirementTransit-tube leading-in arrangementsHydrogenWhole body

The invention discloses a miniature collector lead wire sealing method and seal structure. The sealing method is specifically characterized by carrying out processing on the outer surface of a collector ceramic to form platforms, the number of which is same with that of lead wires of a collector, and carrying out metallization processing on the surfaces of the platforms; carrying out processing on the collector ceramic to form lead wire through holes passing through the platforms, wherein the diameter of each lead wire through hole is larger than that of each lead wire; carrying out processing on the lead wires to form installation steps; putting collector electrodes into the collector ceramic; selecting metal rings, placing a solder piece to each of the two sides of each metal ring and then, putting the whole bodies onto the platforms of the collector ceramic; and enabling one end of each lead wire to pass through the lead wire through hole and insert into the collector electrode, and the installation steps on the other end of the lead wire to be placed on the metal ring and the solder piece at one side of the metal ring, and then, feeding the whole body into a hydrogen furnace for soldering, thereby realizing miniature collector lead wire sealing. The method can reduce the requirements for lead wire hole passing precision and metallization quality, and meanwhile, improves airtightness and reliability of seal between the collector ceramic and the metal lead wires.

Owner:HUADONG PHOTOELECTRIC TECHN INST OF ANHUI PROVINCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com