Miniaturized power gain balancer

A technology of power gain and equalizer, which is applied in the direction of the circuit components of the time-of-flight electronic tube and the introduction arrangement of the time-of-flight electronic tube. The effect of complexity, steep decay curve, and high Q value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

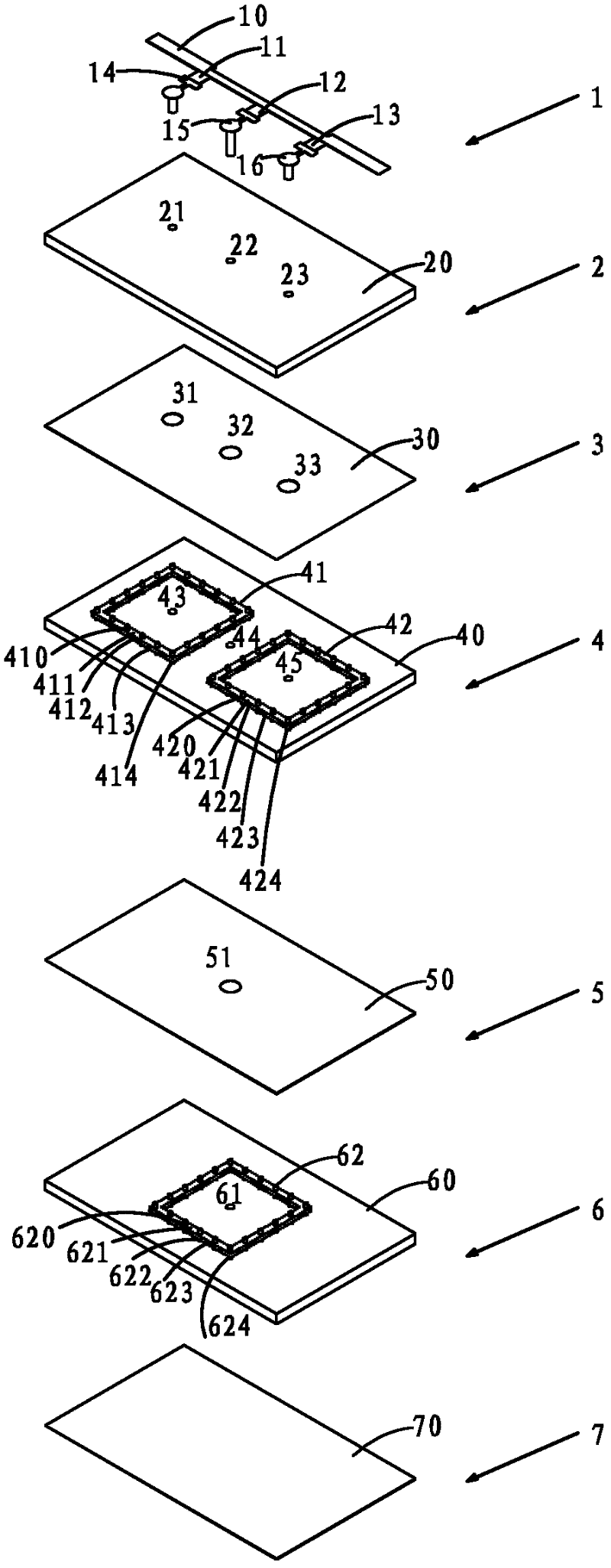

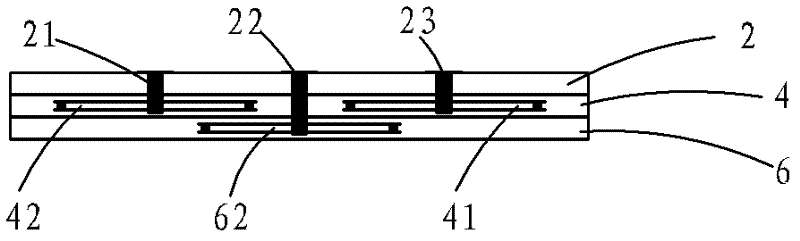

[0027] like figure 1 , figure 2 and image 3 As shown, a miniaturized power gain equalizer includes a microstrip layer 1, a first dielectric layer 2, a first metal layer 3, a second dielectric layer 4, a second metal layer 5, and The third dielectric layer 6 and the third metal layer 7;

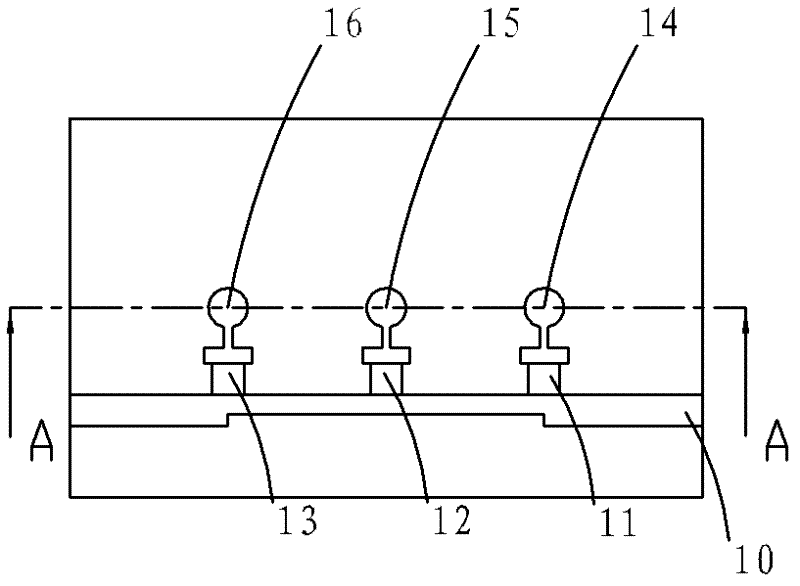

[0028] The microstrip layer 1 includes a transmission line main line 10, a first thin film resistor 11, a second thin film resistor 12, a third thin film resistor 13, a first metal connecting plate 14, a second metal connecting plate 15 and a third metal connecting plate 16, The first thin-film resistor 11, the second thin-film resistor 12, and the third thin-film resistor 13 are connected to the first metal connection plate 14, the second metal connection plate 15, and the third metal connection plate 16 respectively, and then arranged in sequence and connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com