Miniature collector lead wire sealing method and seal structure

A collector and lead technology, which is applied in the field of miniaturized collector ceramic and metal lead sealing, can solve the problems of difficulty in ensuring accuracy, unreliable vacuum air tightness, and difficulty in matching ceramic and metal leads. Tightness and reliability, requirements for reduced accuracy and metallization quality, avoidance of effects of sealing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

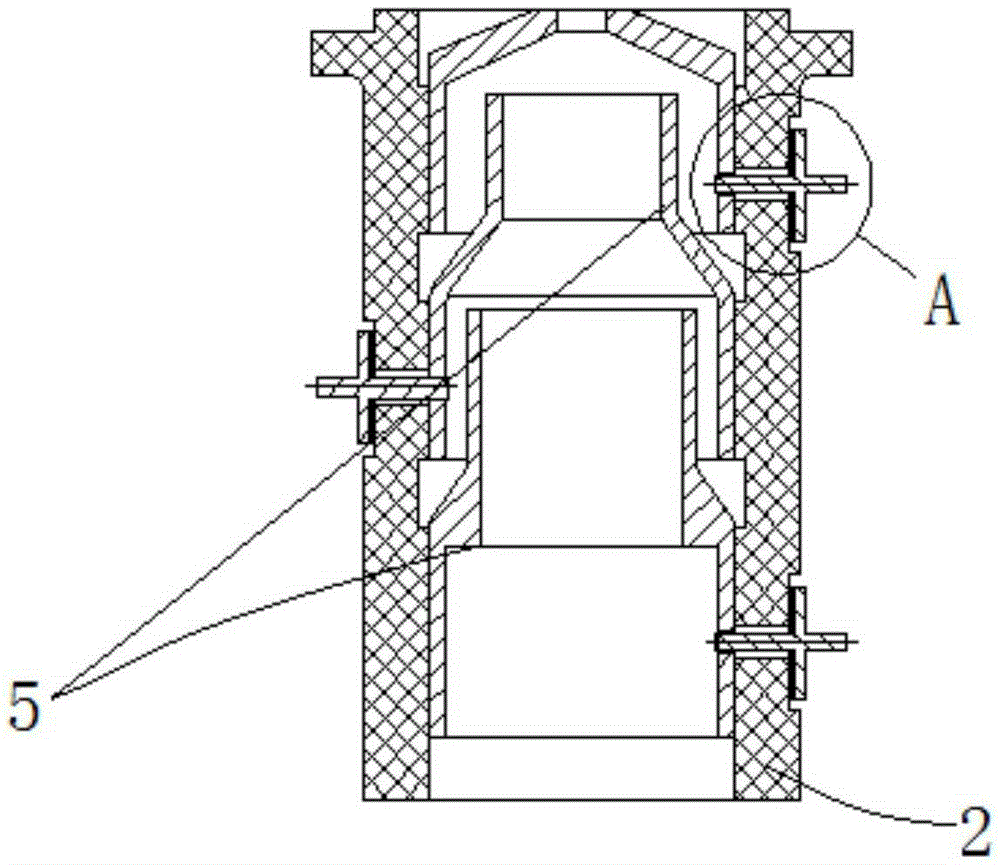

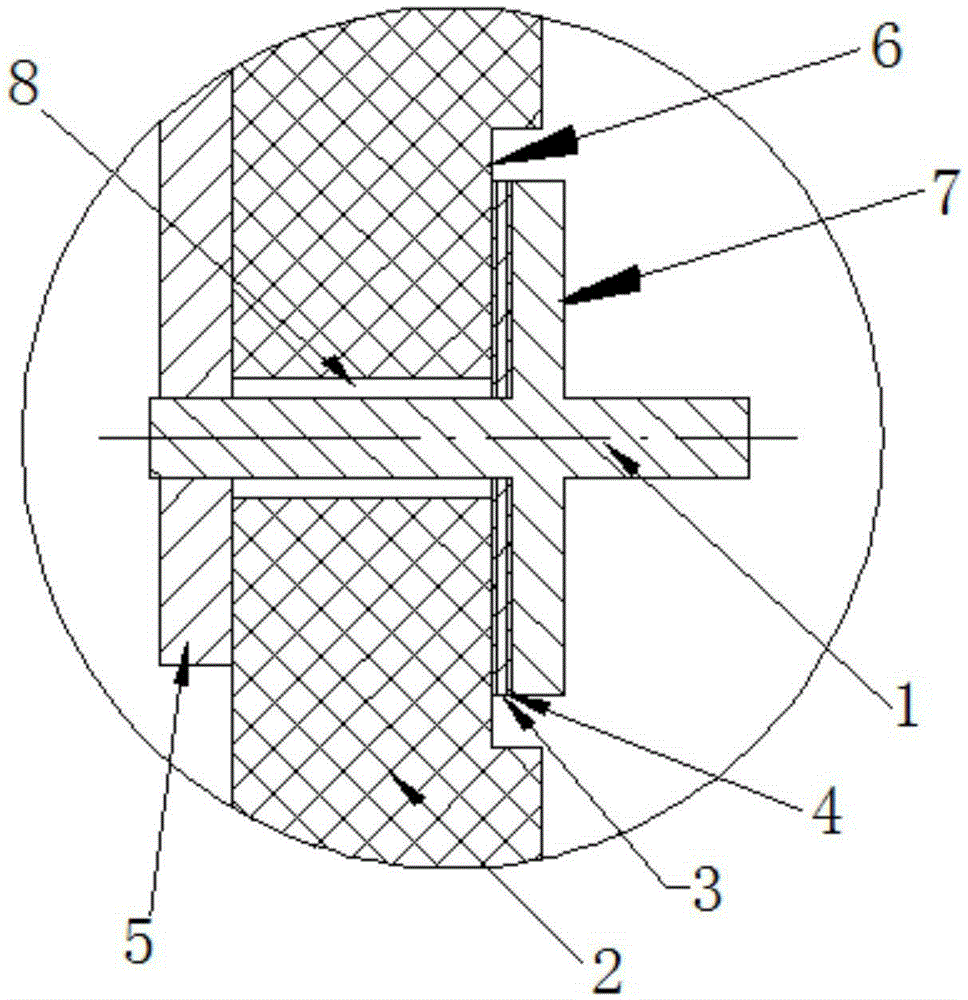

[0026] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and through the description of the preferred embodiments.

[0027] refer to figure 1 and figure 2 , the lead sealing method of the miniaturized collector, specifically:

[0028] On the outer surface of the collector ceramic 2, a platform 6 with an equal number of leads 1 of the collector is processed, and the surface of the platform 6 is metallized; the lead through hole 8 passing through the platform 6 is processed on the collector ceramic 2, and the hole diameter of the lead through hole 8 is larger than Lead 1; Process and install step 7 on lead 1;

[0029] The collector electrode 5 is loaded into the collector ceramic 2;

[0030] Select the metal ring 3, place a solder piece 4 on both sides of the metal ring 3 and place them on the platform 6 of the collector ceramic 2 together;

[0031] One end of the lead 1 is inserted into t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com