Magnetron tube core for microwave heating

A technology of microwave heating and magnetron, which is applied to the introduction and arrangement of magnetron and transit time electron tube, etc. It can solve the problems of complex sealing structure and welding process, affecting sealing performance and service life, and large difference in expansion coefficient. Problems, to achieve the effect of simplifying the sealing structure and sealing process, simple sealing structure and welding process, and improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

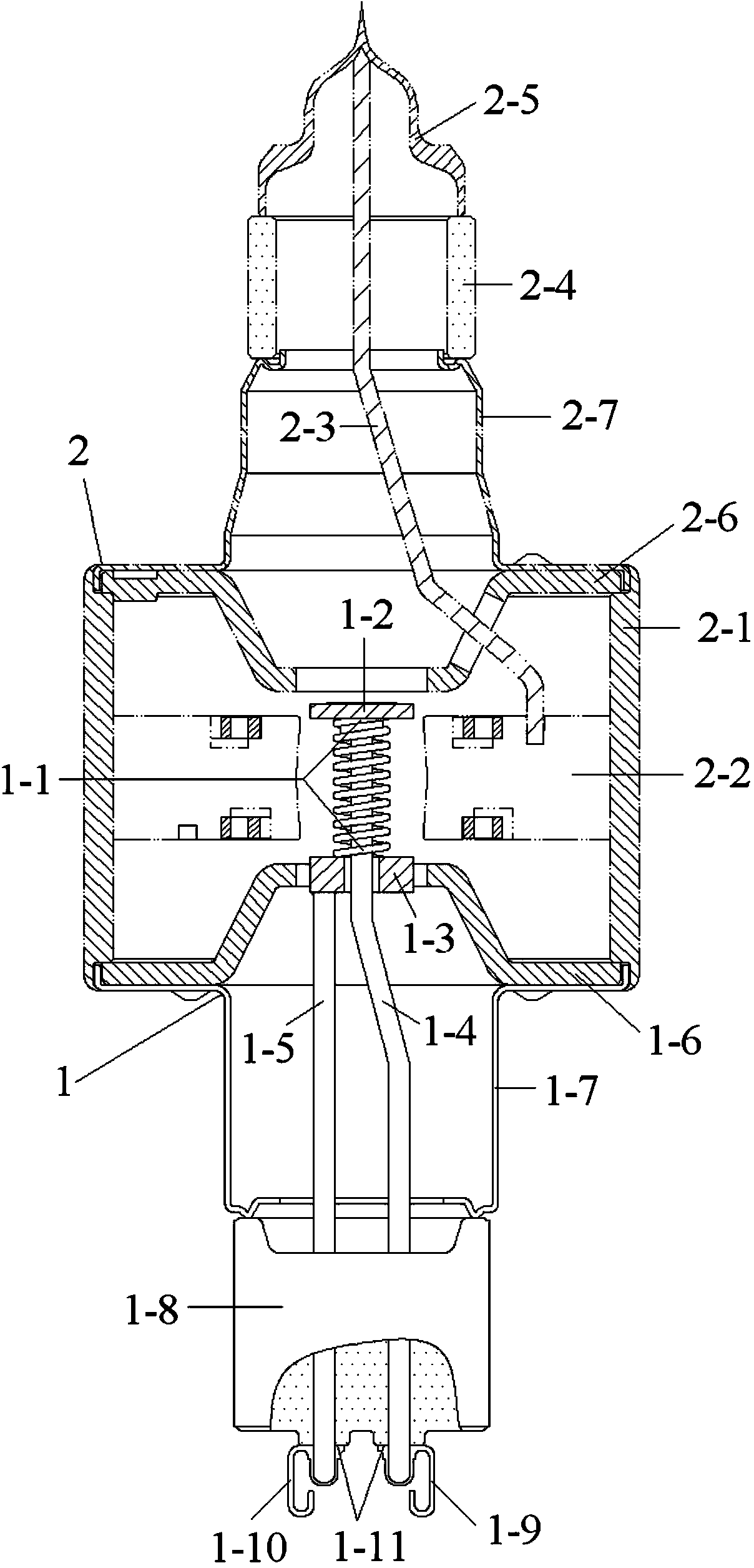

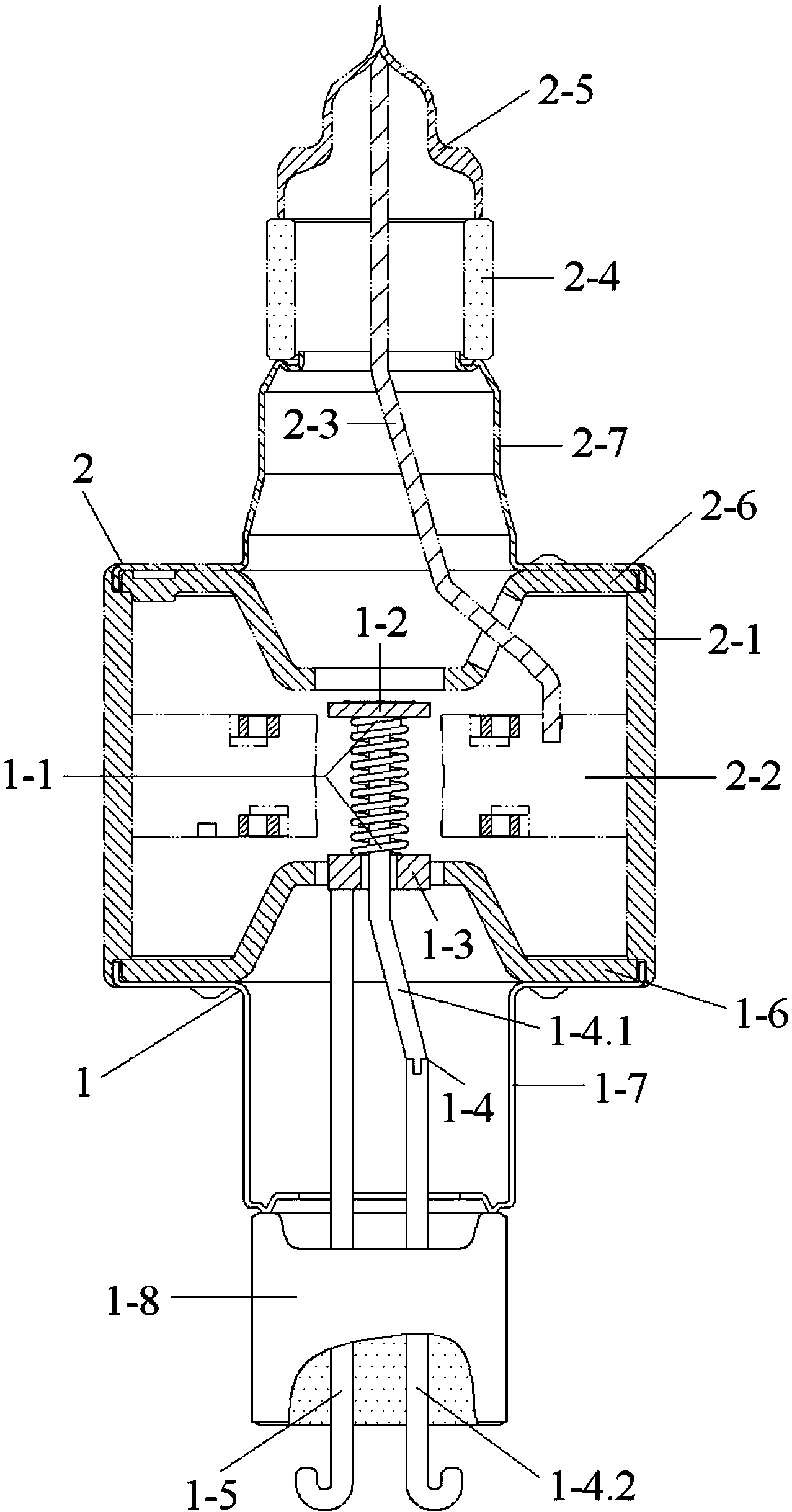

[0012] This embodiment takes a microwave heating magnetron with an operating voltage of 4.2kV and an output power of 900W-1200W as an example, in which: hot cathode emitter 1-1 (voltage 3.3V, current 10A), upper shielding cap 1-2 (φ7 .2mm, thickness 1.0mm), lower shielding cap 1-3 (outer diameter φ 7.2mm, inner diameter φ2.5mm, thickness 2.5mm), and lower magnetic pole 1-6, lower shell (ie die shell) 1 -7; anode cylinder 2-1, blade 2-2, antenna 2-3, output end ceramic cylinder 2-4, exhaust pipe head 2-5, upper magnetic pole 2-6, upper tube shell 2-7 its structure and The dimensions are the same as those of the same model (specification) microwave heating magnetron in the background technology; the materials of the high-voltage ceramics 1-8 in this embodiment (still containing Al 2 o 3 95% of 95 porcelain), the outer diameter and height are also the same as the background technology, but the outer end surface is not metallized and nickel-plated, only connected to the side supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com