Magnetron and microwave oven and high-frequency heating equipment equiped with the same magnetron

A magnetron and high-frequency technology, applied in the field of microwave ovens and high-frequency heating equipment, can solve the problems of increasing the weight and manufacturing cost of the magnetron, reducing the oscillation efficiency of the magnetron, and achieving the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

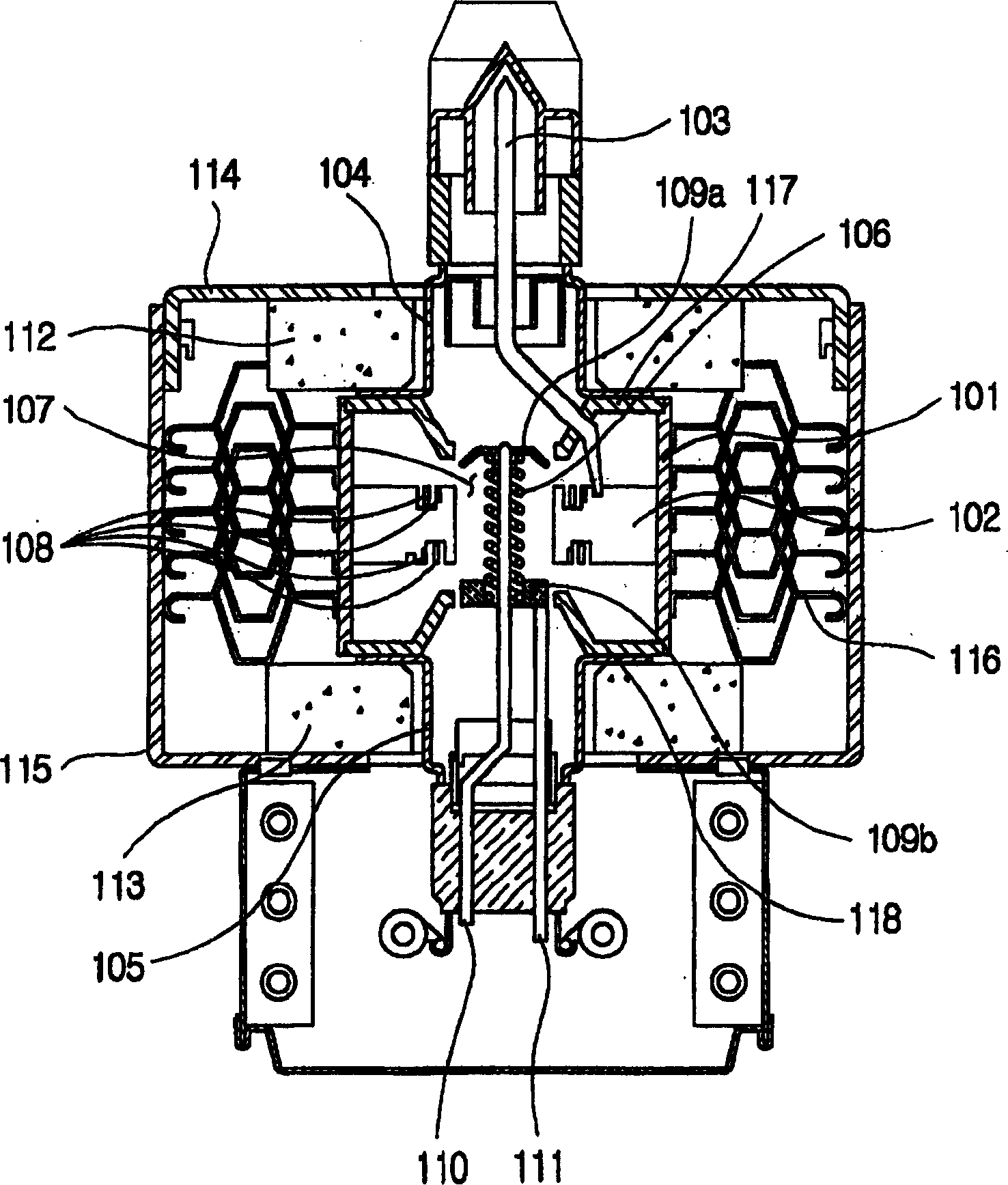

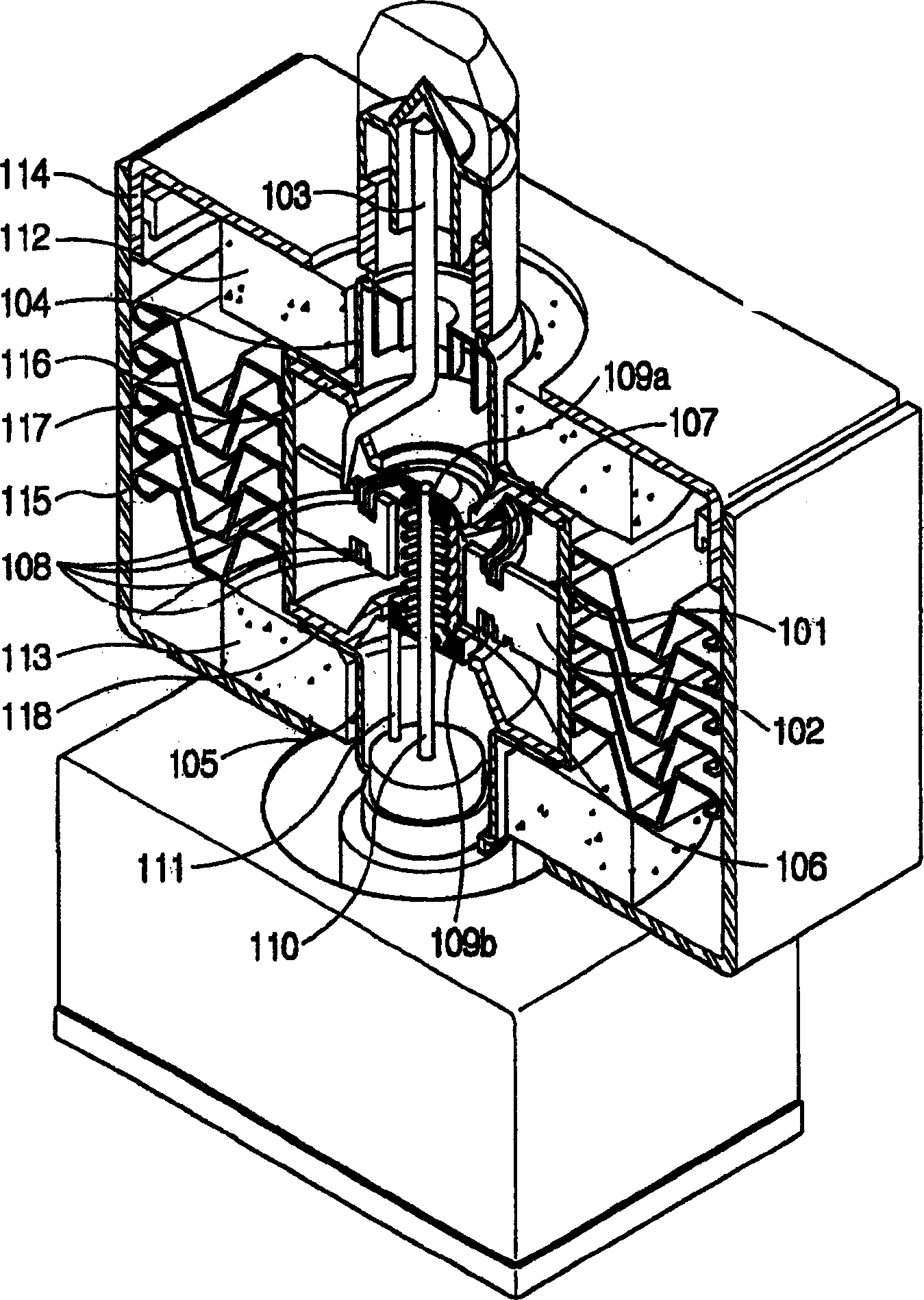

[0042] Specific embodiments of the present invention will now be described in detail, specific examples of which are shown in accompanying drawings, wherein like numerals indicate like parts. The embodiments will be described below in order to explain the invention by referring to the figures. Not only that, but for simplicity of illustration, the direction of rotation of the magnetic flux due to the polarization of the North and South poles is ignored.

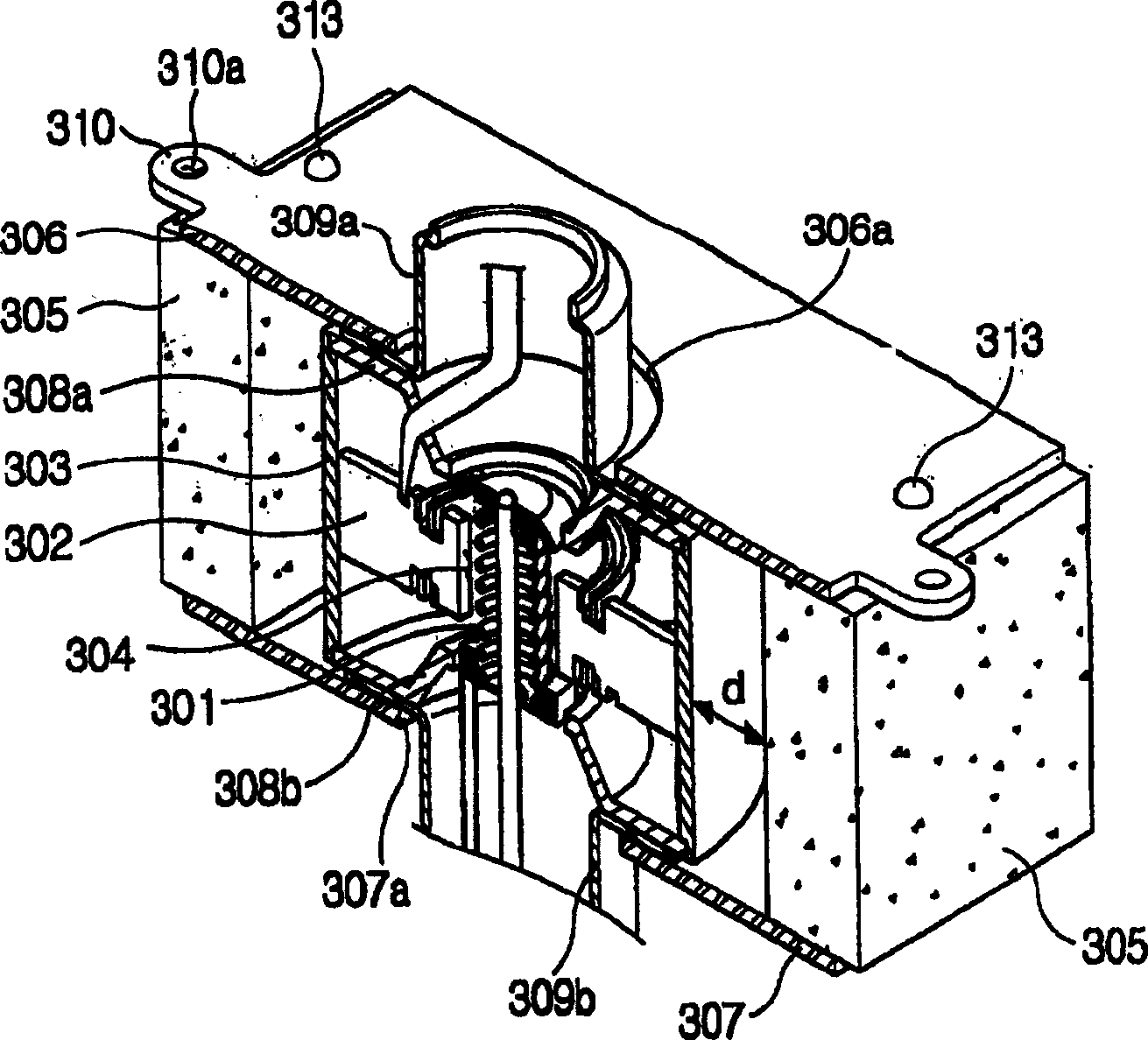

[0043] image 3 is the longitudinal section of the main part of the magnetron according to the embodiment of the present invention. exist image 3 Among them, the ring-shaped anode includes many blades forming a resonant circuit and the anode cylinder 303, the cathode including the filament 301 that releases thermions at high temperature is located in the center of the axis of the anode, and the thermion group moves in it under the influence of the electric and magnetic fields An active / predetermined space is formed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com