High-flow magnetorheogical fluid recycling device

A technology of magnetorheological fluid and recovery device, applied in metal processing equipment, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of restricting flow rate and rotational speed, and achieve the goal of increasing rotational speed, ensuring magnetic field strength, and increasing nozzle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

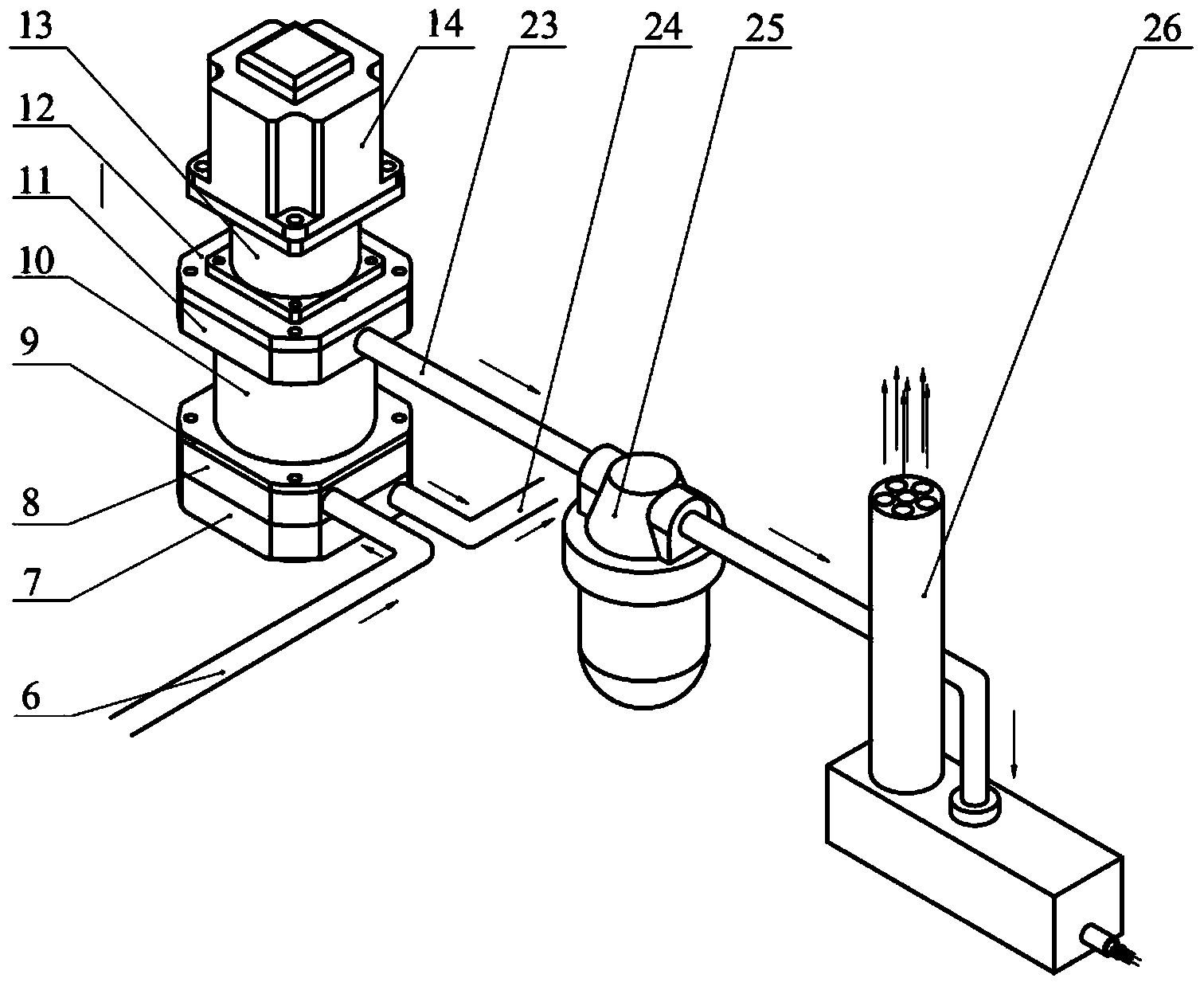

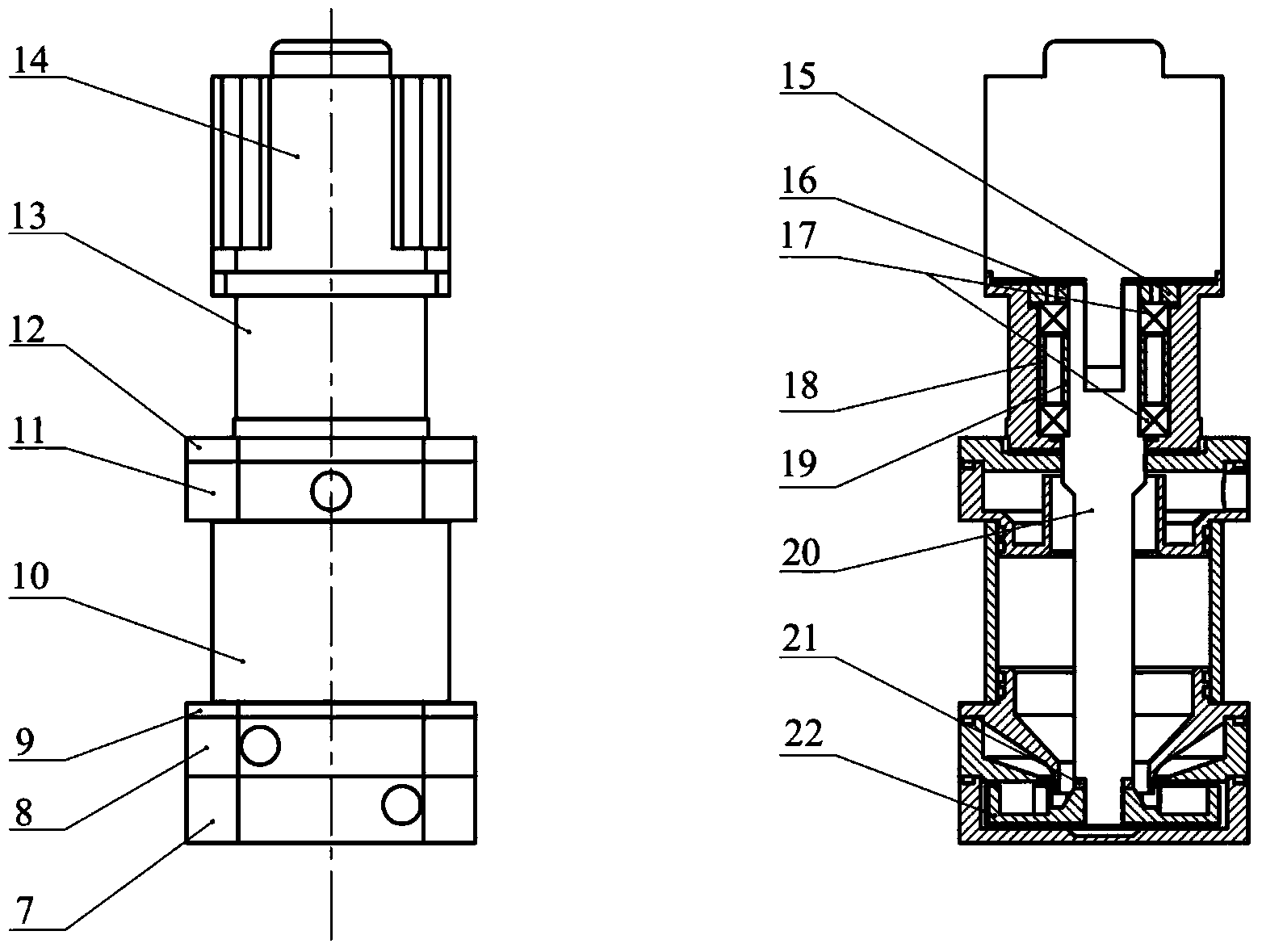

[0031] The inventive idea of the present invention is: the present invention provides a novel magnetorheological fluid recovery device, which can be retrofitted on the existing magnetorheological polishing machine tool without changing the original mechanical structure of the machine tool.

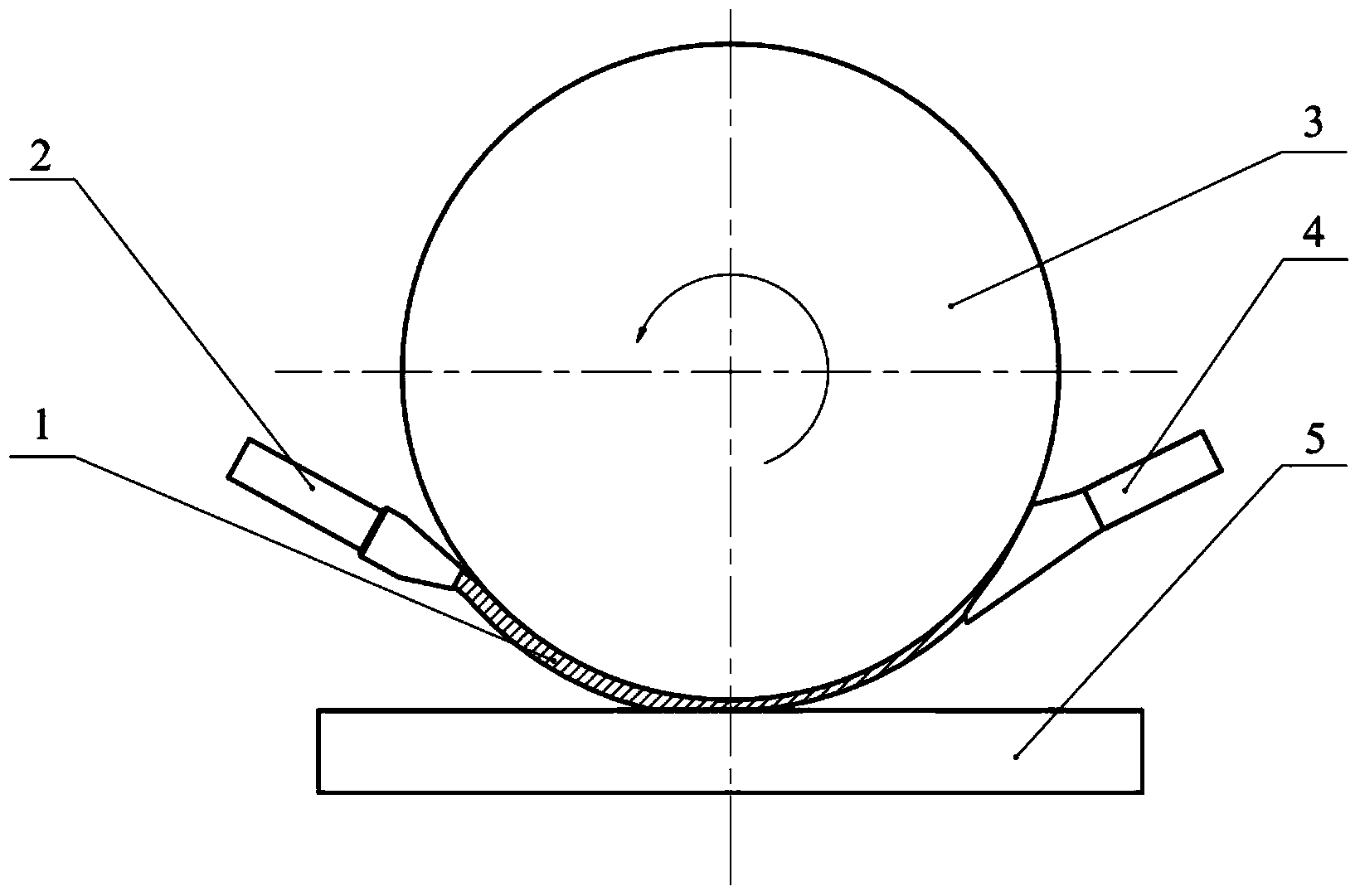

[0032] The device is composed of a gas-liquid separation device subsystem and a vacuum generation subsystem. The vacuum generation subsystem is the power device for recovery, and the gas-liquid separation device subsystem completes the gas-liquid separation and completes the cycle process. The recovery head is in flexible line contact with the polishing wheel, so that the magnetorheological fluid is separated from the polishing wheel.

[0033] The feature of the present invention is that the recovering head is installed near the area where the magnetorheological fluid has just left the polishing area. At this time, the magnetic field strength is attenuated compared with the polishing are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com