Non-contact clutch position sensor

A clutch position, non-contact technology, applied in the direction of using electric/magnetic devices to transmit sensing components, etc., can solve problems such as poor contact and poor work reliability, achieve accurate and more stable output signals, prolong working life, and improve reliability and safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

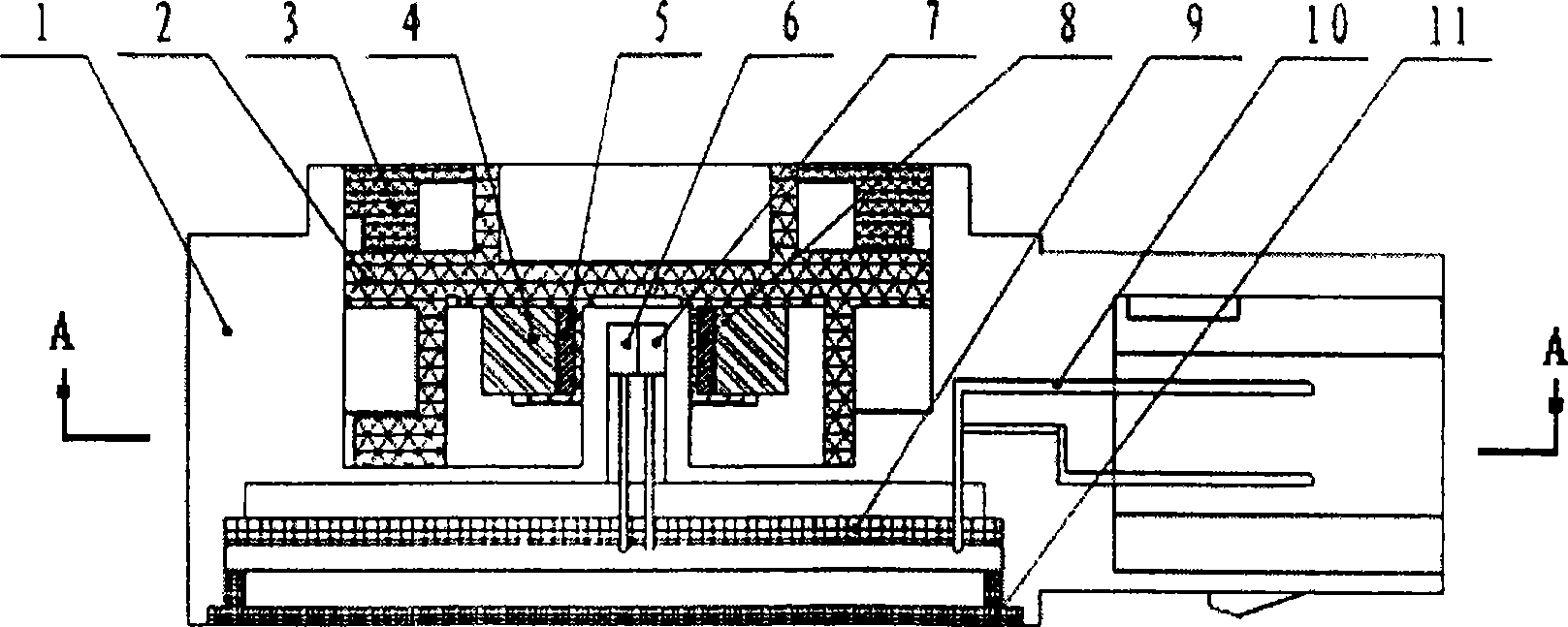

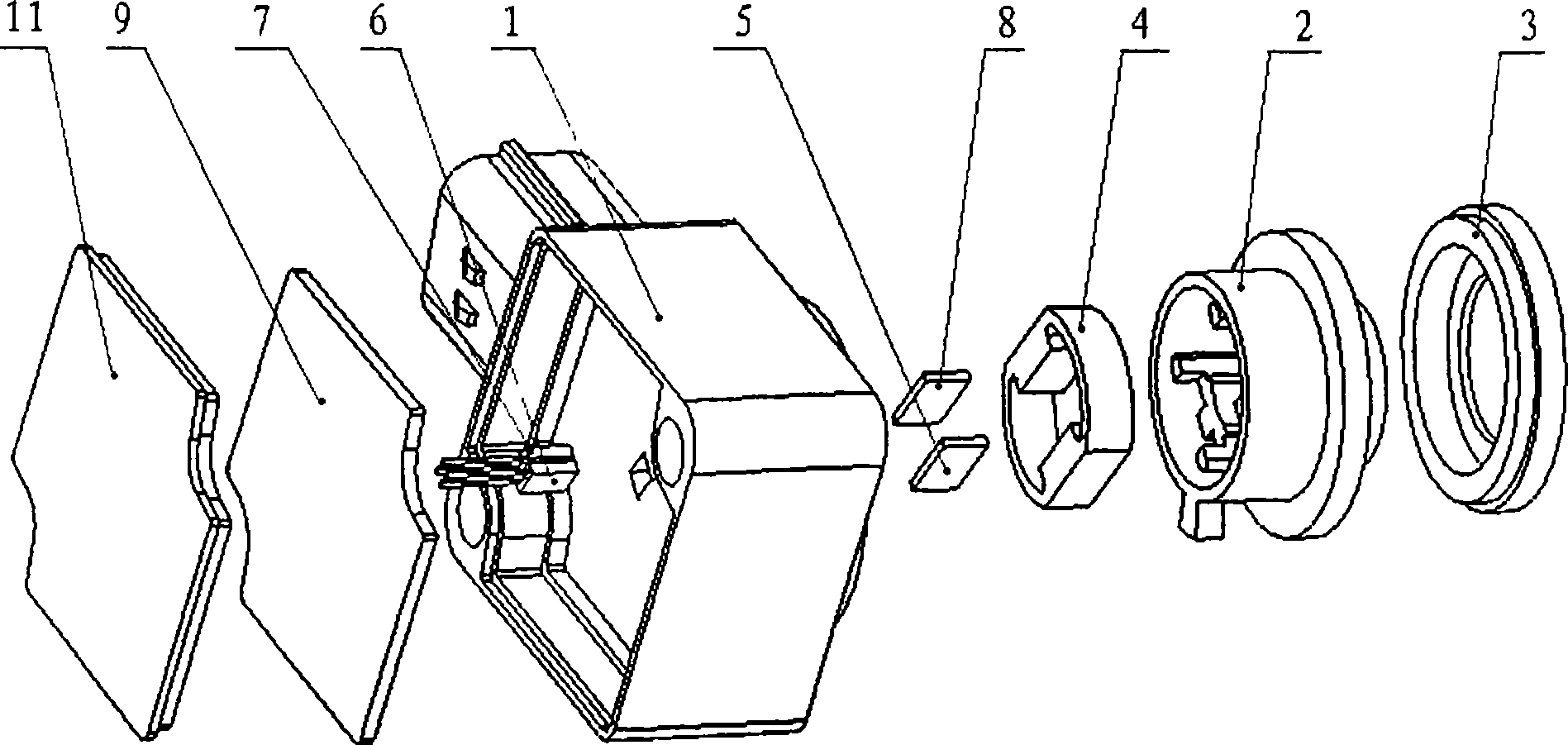

[0018] see figure 1 , figure 2 , the non-contact clutch position sensor includes a housing 1, an upper cover 3 and a rear cover 11, a rotor 2 and a circuit board 9 are installed in the housing 1, and the circuit board 9 corresponds to the inner side of the rear cover 11 and is connected to the circuit The terminal 10 connected to the board 9 extends out of the housing;

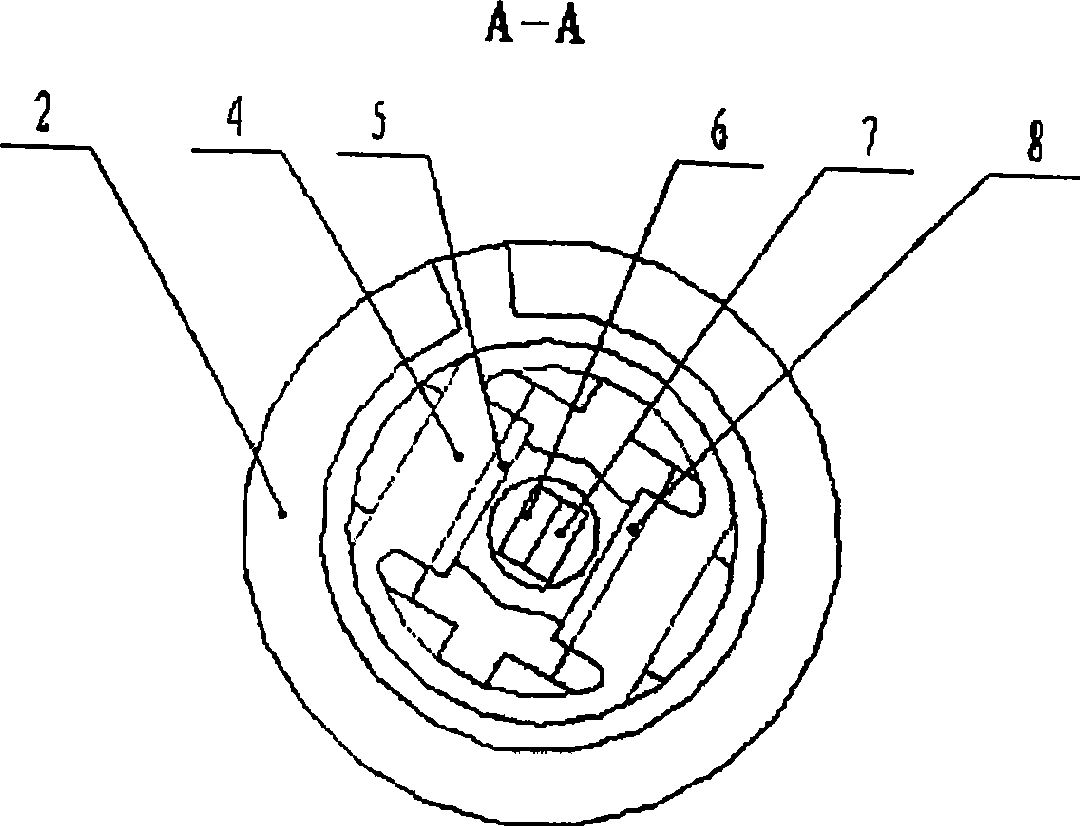

[0019] The rotor 2 is a cylindrical body with one end closed in the axial direction. A magnetic steel ring 4 is installed inside the rotor 2. The inner walls of the magnetic steel ring 4 are respectively symmetrically installed with A permanent magnet block 5 and B permanent magnet block 8, and A permanent magnet block 5 and B permanent magnet block. A cavity is formed between the permanent magnet blocks 8; the middle part of the circuit board 9 is respectively connected to the A Hall chip 6 and the B Hall chip 7 through two conductor rods, and the A Hall chip 6 and the B Hall chip 7 are located on the A per...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com