Alnico piston-type magneto-rheological damper with single piston rod

A magnetorheological damper, piston-type technology, applied in vibration suppression adjustment, non-rotational vibration suppression, etc., can solve the problems of small damping force, enhancement or weakening, and large power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

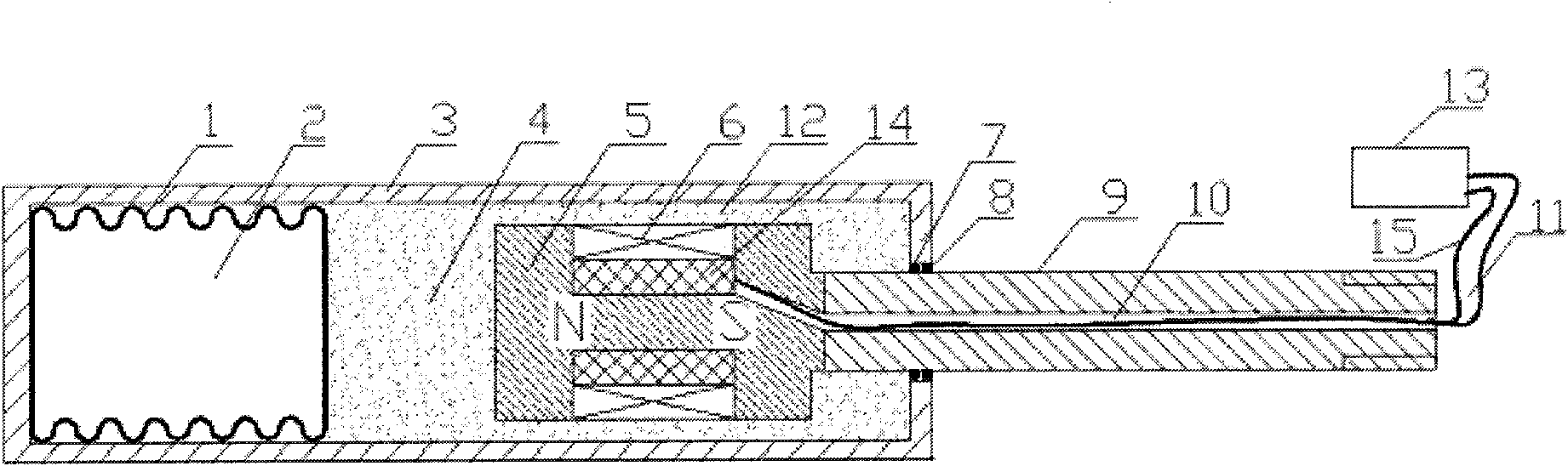

[0011] The structure of the present invention is described in detail below in conjunction with accompanying drawing:

[0012] see figure 1 , which is a specific structure of the present invention, which includes a working cylinder 3, a piston 5, a piston rod 9 and a compensation air bag 1; the piston 5 is made of magnetic steel, and an excitation coil 6 and a charging and demagnetizing coil are wound in the middle of the magnetic steel piston 5 14. The control line 11 and control line 15 of the exciting coil 6 and the charging and demagnetizing coil 14 are led out from the central through hole 10 of the piston rod 9 and then connected to the control power supply 13. The magnetic steel piston 5 is installed in the working cylinder 3, and the magnetic steel piston 5 The outer diameter of the cylinder 3 is smaller than the inner diameter of the working cylinder 3 and there is a flow gap 12 of the magnetorheological fluid 4. One end of the piston rod 9 made of non-magnetic materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com