Lubricating pump, pump body and pump cover thereof

A technology of oil pump and pump body, which is applied in the field of oil pumps, can solve problems such as the influence of oil pump flexibility, loss of diesel engine users, and limited positioning strength, and achieve the effects of convenient pump cover positioning, reliable assembly quality, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

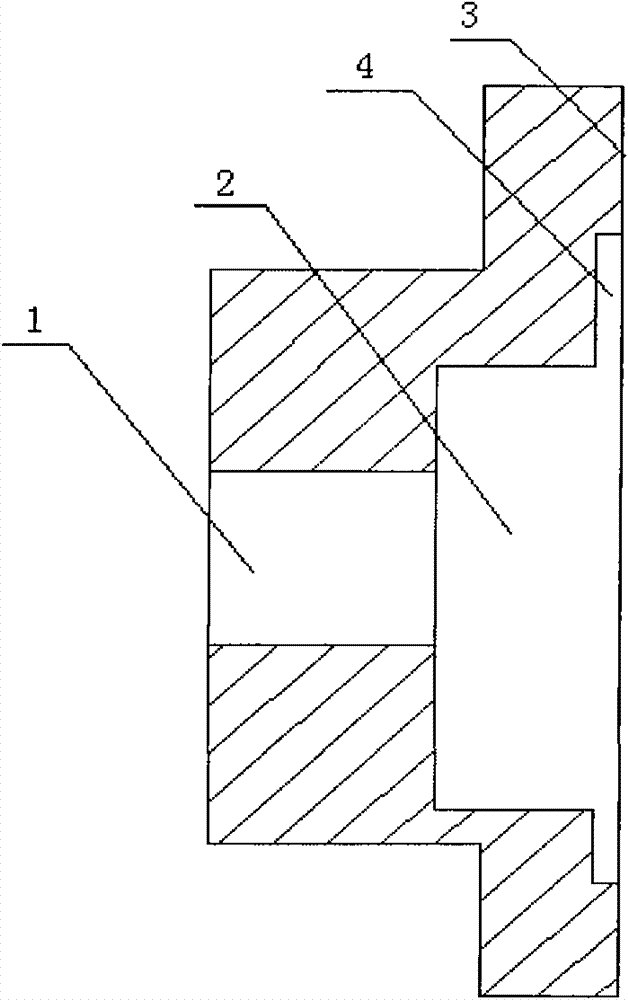

[0017] see figure 1 , an oil pump pump body, including a pump shaft support hole 1, a rotor cavity 2 and a large end surface 3 for installing a pump cover, and the large end surface 3 is recessed radially inward along the rotor cavity 2 to form a stepped hole 4. The specific size of the oil pump body of this machine can be determined according to the actual situation. In this embodiment, the diameter of the rotor chamber 2 is 41mm, the diameter of the step hole 4 is 60mm, and the diameter of the pump shaft support hole 1 is 16mm. When assembling the pump body of the oil pump, the outer edge of the pump cover matching the step hole 4 is embedded in the step hole, and the pump cover and the step hole 4 are transitionally fitted, so the original drilling, reaming, riveting and other processes are cancelled, and the assembly work It is more simple, the assembly speed is greatly improved, and the assembly quality is better. It not only improves the accuracy and positioning strength...

Embodiment 2

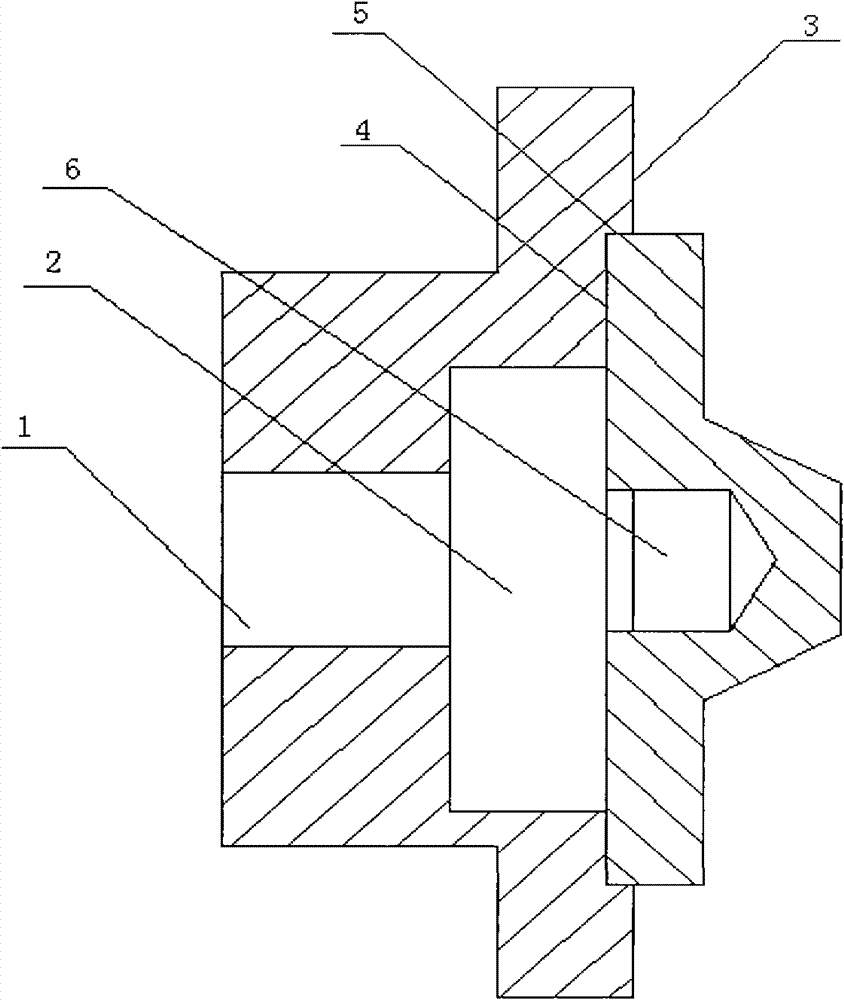

[0019] see figure 2 , an oil pump casing, including a pump body and a pump cover, the pump body is provided with a pump shaft support hole 1, a rotor chamber 2 and a large end face 3 for installing the pump cover, the large end face 3 extends along the diameter of the rotor chamber 2 Inwardly recessed to form a stepped hole 4, the outer edge 5 of the pump cover is embedded in the stepped hole 4 and transitionally fits with the stepped hole 4, the pump cover is provided with a pump shaft end support hole 6, and the pump shaft end support hole 6 , the central axis of the stepped hole 4 and the pump shaft support hole 1 coincide. The support hole 6 at the end of the pump shaft, the step hole 4 and the pump shaft support hole 1 are concentric holes, which further facilitates the positioning of the pump cover, and also makes the positioning of the pump cover more accurate, and the connection between the pump cover and the pump body is firmer; The pump cover is fixed on the pump b...

Embodiment 3

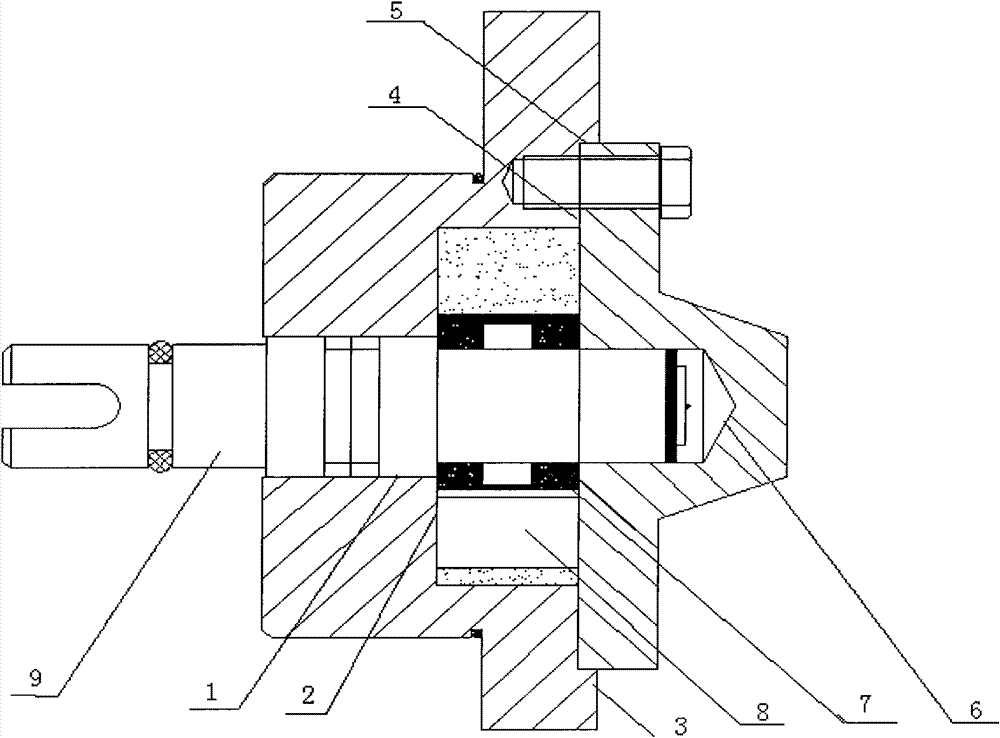

[0021] see image 3 , Figure 4 and Figure 5 , an oil pump, comprising a pump body, a pump cover, an inner rotor 7, an outer rotor 8 and a pump shaft 9, the pump body is provided with a pump shaft support hole 1, a rotor cavity 2 and a large end face 3 for installing the pump cover, The large end face 3 is recessed radially inward along the rotor chamber 2 to form a step hole 4, the pump cover is provided with a pump shaft end support hole 6, the inner rotor 7 and the outer rotor 8 are arranged in the rotor chamber 2, and the edge of the pump cover 5 and the stepped hole 4 transitionally fit and seal the rotor cavity 2, the pump shaft 9 passes through the pump shaft support hole 1 and the end of the pump shaft 9 extends into the pump shaft end support hole 6, and there is also an overflow in the pump shaft 9 The overflow return hole 10 extends axially from the end of the pump shaft 9 away from the pump cover along the pump shaft 9 , and the axial length of the overflow retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com