Water discharging device with cleaning function

A water outlet device and functional technology, applied in the field of water outlet devices, can solve the problems of complex structure and large space occupation, and achieve the effects of high deformation sensitivity, small space occupation, stable and reliable deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

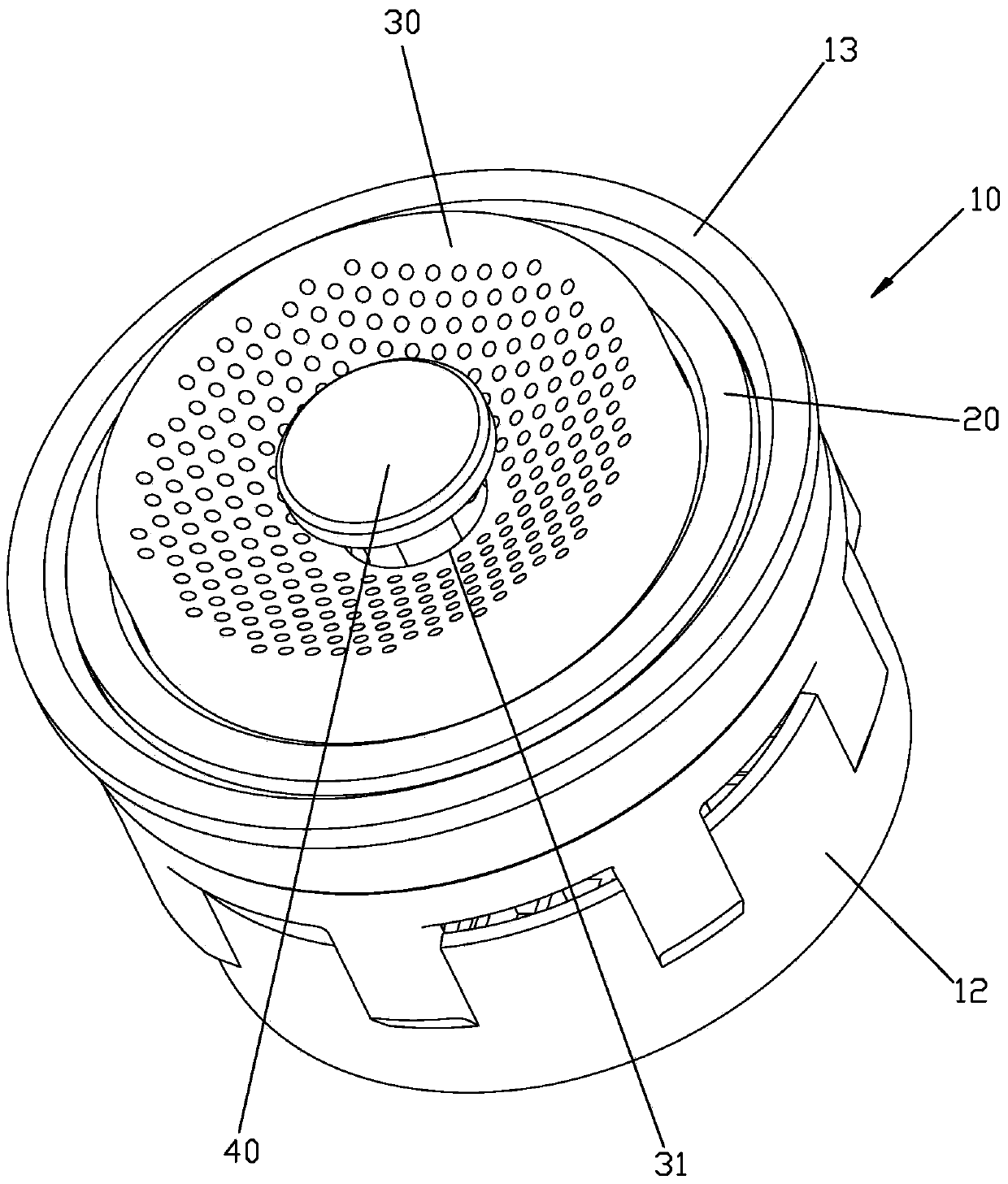

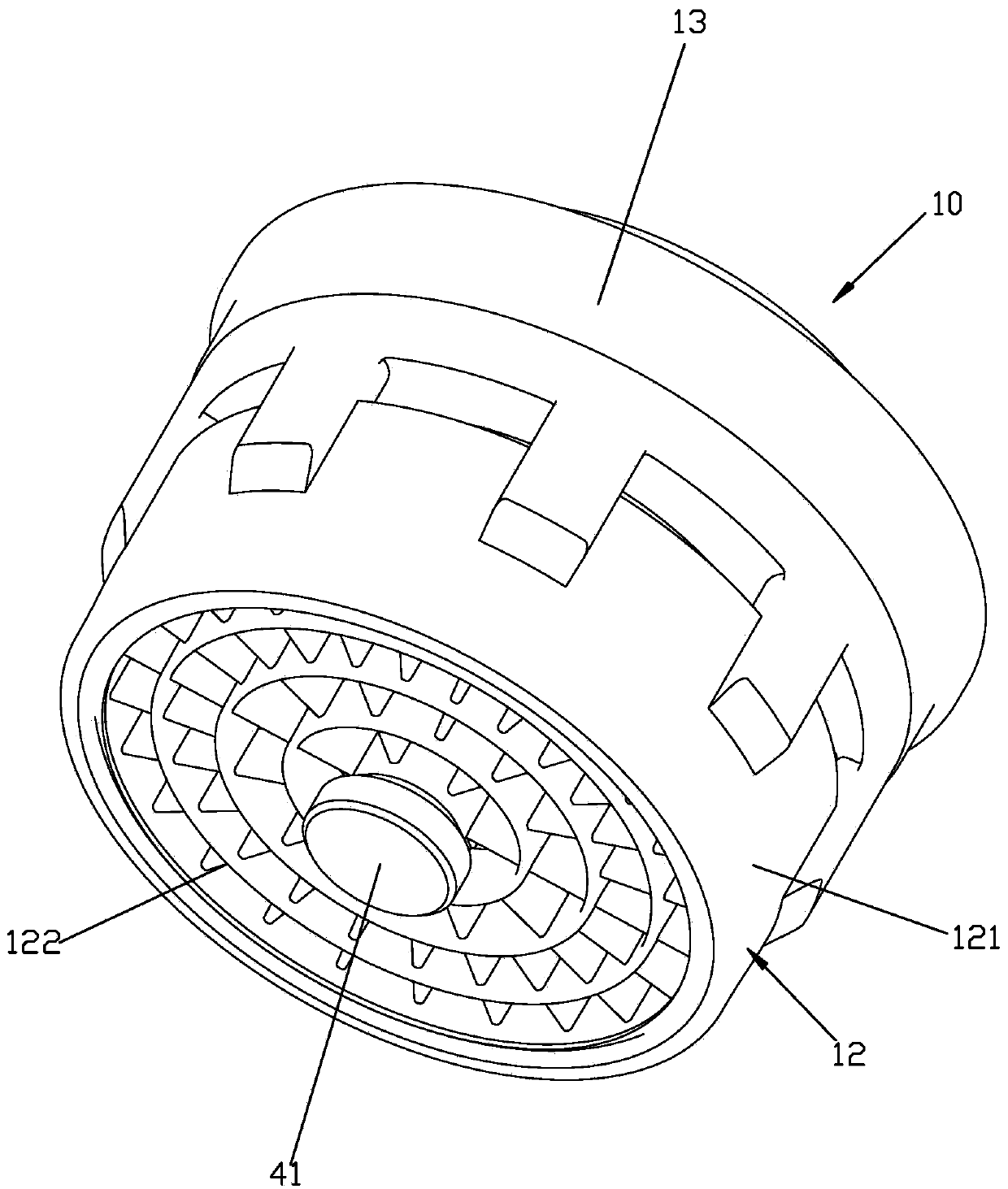

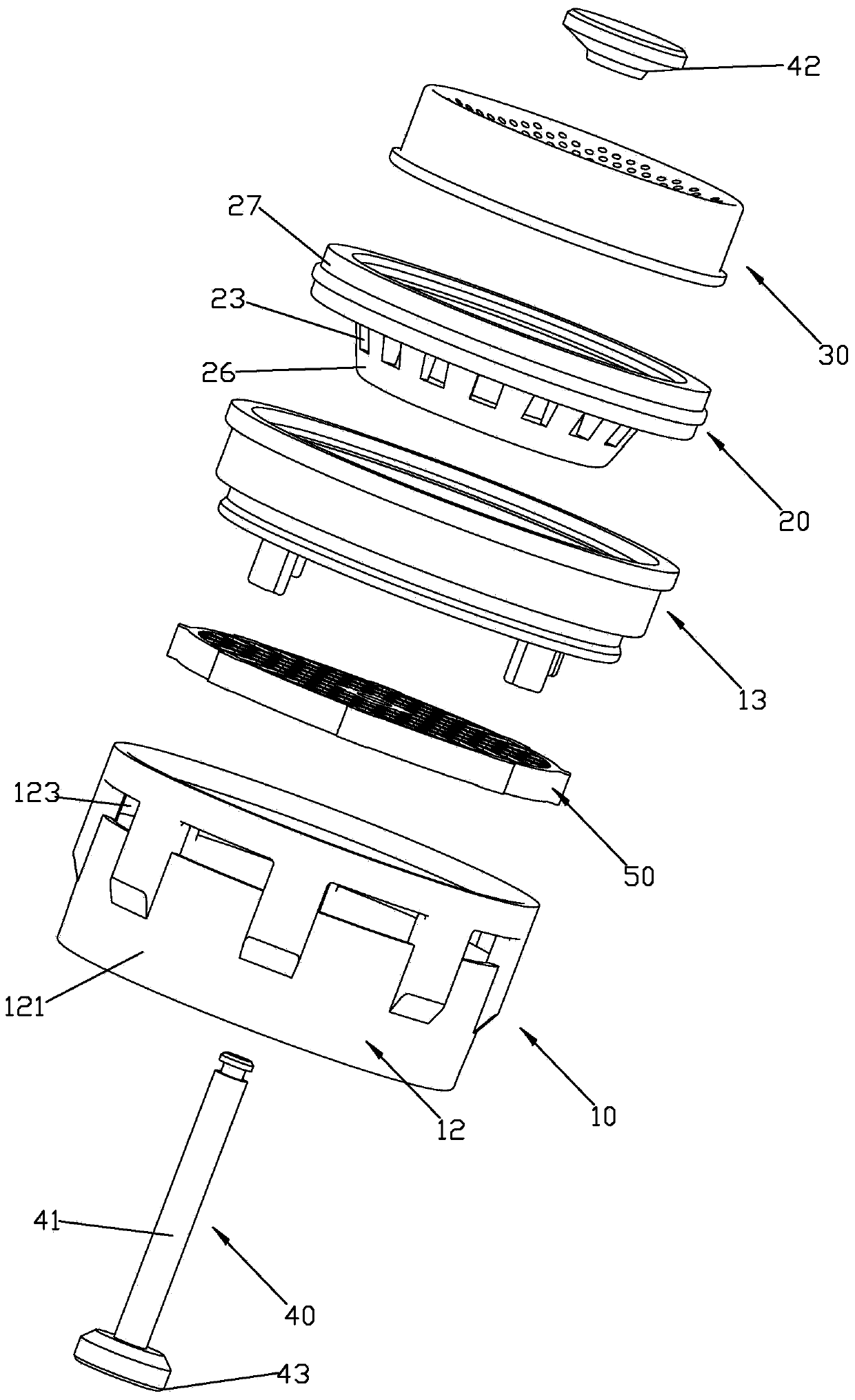

[0055] Please check Figure 1 to Figure 6 , a water outlet device with a cleaning function, including a body part 10 , a diverter 20 , a filter 30 , a rectifier 50 and a sewage channel 80 .

[0056] The body part 10 is provided with a mounting through hole 11 . In this embodiment, the body part 10 includes a body 12 and a fixing ring 13 . The body 12 includes a sleeve body 121 and a grid seat 122 fixed in the sleeve body 121. The fixing ring 13 and the sleeve body 121 are connected together by clamping so that the fixing ring 13 is fixedly mounted on the body. within 12. The specific attachment structure of the fixed ring 13 and the sleeve body 121 is, for example: the outer rotating surface of the fixed ring 13 is set as a stepped rotating surface and has a downward annular surface, and the outer rotating surface of the fixed ring 13 and the sleeve body 121 The inner walls are connected together by buckles. The buckles include a ring groove on the inner wall of the sleeve ...

Embodiment 2

[0065] Please check Figure 7 , It differs from Embodiment 1 in that: the sealing member 42 is adapted to the inner wall of the sewage through hole 31, and an impurity particle storage tank 70 is formed between the sealing member and the sewage through hole 31 in the sealed state.

Embodiment 3

[0067] Please check Figure 8 , it differs from Embodiment 1 in that: the sealing portion 40 includes a solid rod 46 fixed to the center of the bottom wall of the diverter 20 and a sealing valve plate 47 capable of sealing the sewage through hole 31, the sealing valve plate 47 Fixed on the top of the solid rod 46, the sealing valve plate 47 can be deformed by water pressure, and the sealing part 40 is controlled to be in a clean state or a sealed state through the deformation of the sealing valve plate 47.

[0068] When the water pressure is high, the sealing valve plate 47 deforms greatly, and the peripheral edge of the sealing valve plate 47 is sealed against the outside of the sewage discharge through hole. Filter on the filter net and store on the filter net; when the water pressure is small, the deformation of the sealing valve plate 47 is small, there is a gap between the periphery of the sealing valve plate 47 and the sewage through hole, the sewage through hole is open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com