Seven-in-one membrane electrode packaging clamp and proton exchange membrane fuel cell

A membrane electrode and clamping technology, which is applied in the direction of fuel cells, circuits, electrical components, etc., can solve problems such as position deviation, achieve strong positioning and fixing capabilities, prevent wear, and overcome uneven force effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

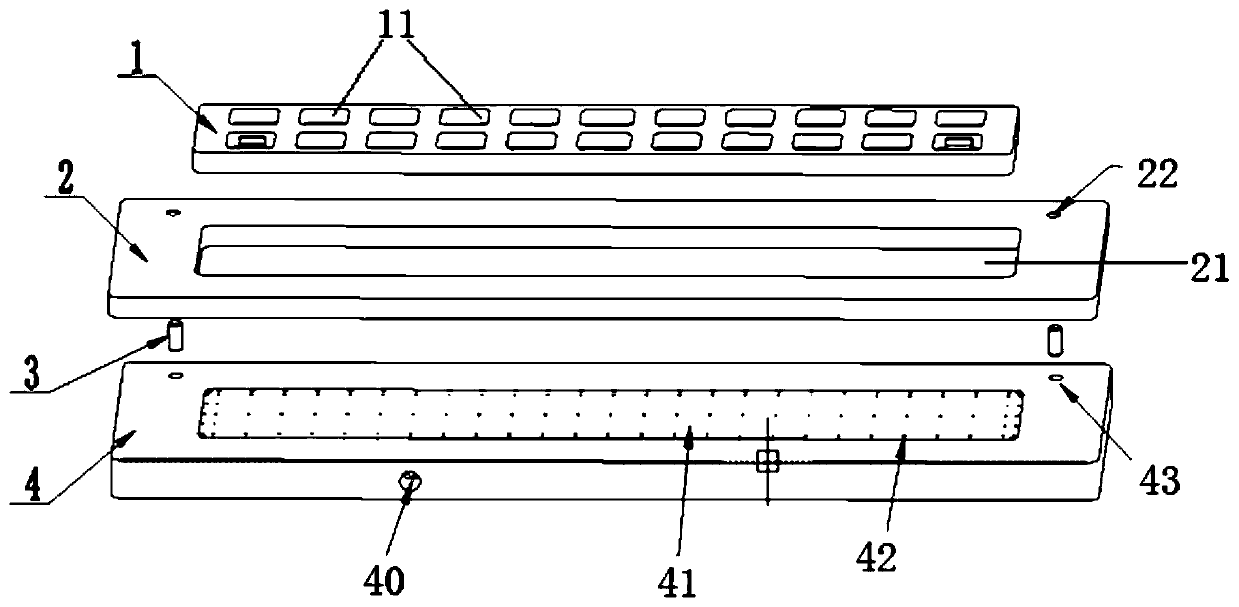

Embodiment 1

[0046] Example 1: Preparation of seven-in-one membrane electrode with a clamp without gas flow channel. The bottom plate is fixed in the dispenser, and the dispenser is programmed according to the fixed position. After the program is set, place the gas diffusion layer in the groove of the lower bottom plate and use a dispenser to dispense. After dispensing, spread the five-in-one membrane electrode on the gas diffusion layer along the location of the positioning hole, and lightly press the dispensing position before performing the dispensing operation. After dispensing, press the positioning frame along the positioning hole on the membrane electrode. Then spread another gas diffusion layer on the membrane electrode along the inner edge of the positioning frame, and finally press the upper cover plate flat on the gas diffusion layer. Put the whole set of clamps on the press and press for a certain time under a certain pressure, and then take out the sample to obtain the seven-...

Embodiment 2

[0047] Example 2: Using the fixture of the present invention to prepare a seven-in-one membrane electrode, the bottom plate is fixed in the dispenser, and the dispenser is programmed according to the fixed position. After the program is set, place the gas diffusion layer in the groove of the lower bottom plate and open the vacuum adsorption device, and then use the dispenser to dispense. After the dispensing is completed, the five-in-one membrane electrode is laid flat on the gas diffusion layer along the positioning hole and the dispensing operation is performed. After dispensing, press the positioning frame along the positioning hole on the membrane electrode. Then spread another gas diffusion layer on the membrane electrode along the inner edge of the positioning frame, and finally press the upper cover plate flat on the gas diffusion layer to close the vacuum adsorption device. Put the whole set of clamps on the press and press for a certain time under a certain pressure, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com