A stamping die with in-mold quick adjustment and mold core assembly removal

A technology of mold core components and stamping dies, which is applied in the field of stamping dies with quick adjustment and replacement of core components in the mold, can solve problems such as abnormalities, improve production efficiency, improve operation accuracy, and facilitate mass production of products Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

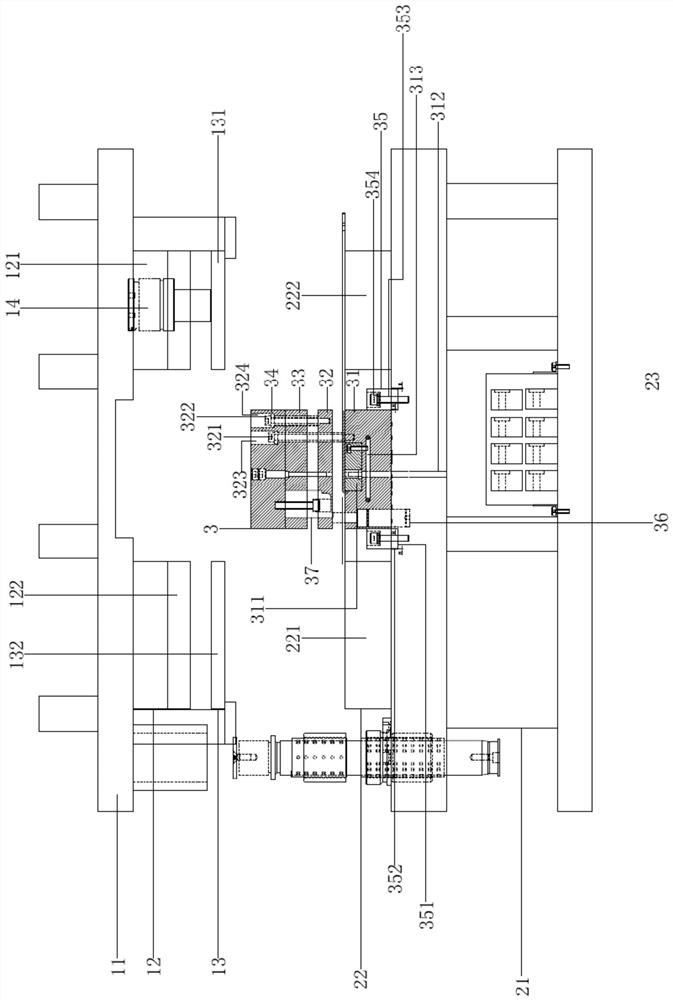

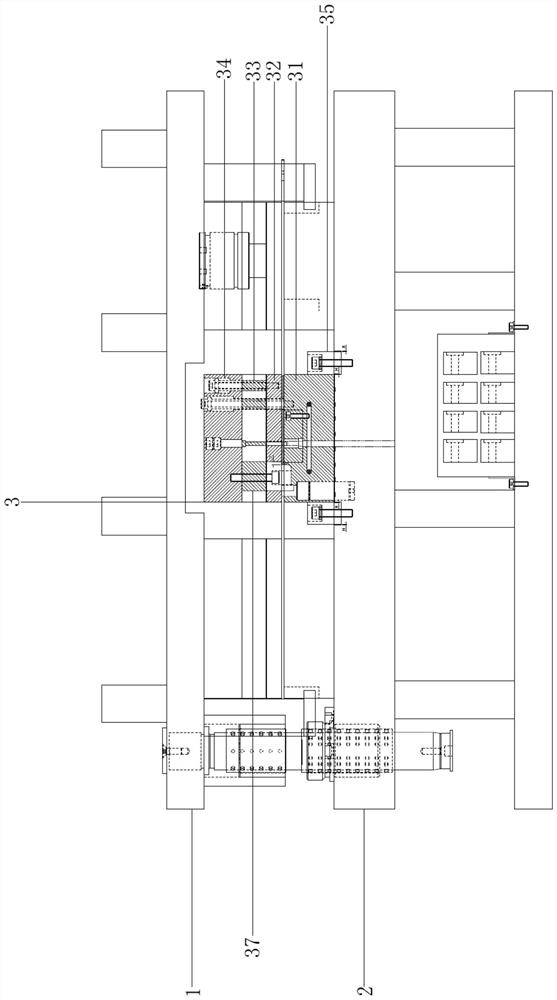

[0026] see Figure 1 to Figure 2 , the figure shows a stamping die provided by Embodiment 1 of the present invention with in-mold quick adjustment and replacement core assembly, which includes:

[0027] Upper mold mechanism 1, it comprises upper mold base 11, upper backing plate 12 and upper pressing plate 13, upper backing plate 12 is fixedly connected under upper mold base 11, upper backing plate 12 comprises the first upper backing plate unit 121 of symmetry and the second Two upper platen units 122, the upper platen 13 includes a symmetrical first upper platen unit 131 and a second upper platen unit 132, the first upper platen unit 131 is connected to the first upper platen unit 121 through the first nitrogen spring 14, The second upper platen unit 132 is elastically connected under the second upper backing plate unit 122;

[0028] Lower mold mechanism 2, it comprises lower mold base 21 and lower template 22, lower template 22 is fixedly connected on the lower mold base 2...

Embodiment 2

[0035] see Figure 1 to Figure 2, the figure shows a stamping die provided by Embodiment 2 of the present invention with in-mold quick adjustment and core assembly replacement. This embodiment further makes the following improvements on the basis of the above embodiment Technical solution: the lower mold base 21 is provided with an adjustment groove 351, the adjustment block 35 is installed in the adjustment groove 351, the width of the adjustment groove 351 is larger than the width of the adjustment block 35, and there is a gap between the groove wall of the adjustment groove 351 and the adjustment block 35 , an elastic pad 352 is installed in the gap, the thickness of the gap is 1-2 mm, and the elastic pad 352 has a compression amount between 0.8-1.4 mm, and the elastic pad 352 is made of rubber. Through the setting of the above structure, the depth position can be adjusted quickly; specifically, an adjustment groove is provided on the lower mold base, and the adjustment blo...

Embodiment 3

[0037] see Figure 1 to Figure 2 , the figure shows a stamping die provided by Embodiment 3 of the present invention with in-mold quick adjustment and core assembly replacement. This embodiment further makes the following improvements on the basis of the above embodiment Technical solution: the adjustment block 35 is connected in the adjustment groove 351 by a screw 353, the top of the adjustment block 35 has a screw penetration groove, the screw head of the screw 353 is located in the screw penetration groove, and the screw head and the screw penetration groove are at the bottom of the groove A toothed washer 354 is disposed therebetween, and the toothed washer 354 is sleeved on the screw body of the screw 353 .

[0038] Through the setting of the above structure, the position of the adjustment block can be tightened by the anti-loosening washer. Specifically, the adjustment block is connected in the adjustment groove through the stop screw. The top of the adjustment block ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com