A complete line of chassis packaging detection line

A detection line and chassis technology, which is applied in the field of chassis packaging detection line, can solve the problems of mechanical arm position deviation and easy misalignment, and achieve the effect of reducing accuracy requirements, avoiding misalignment, and improving comprehensiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

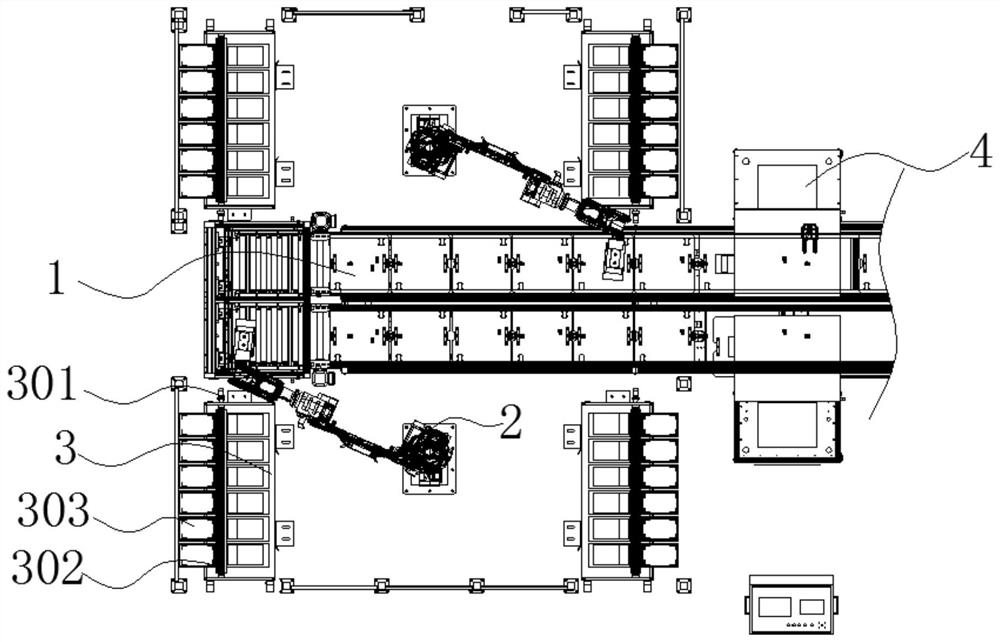

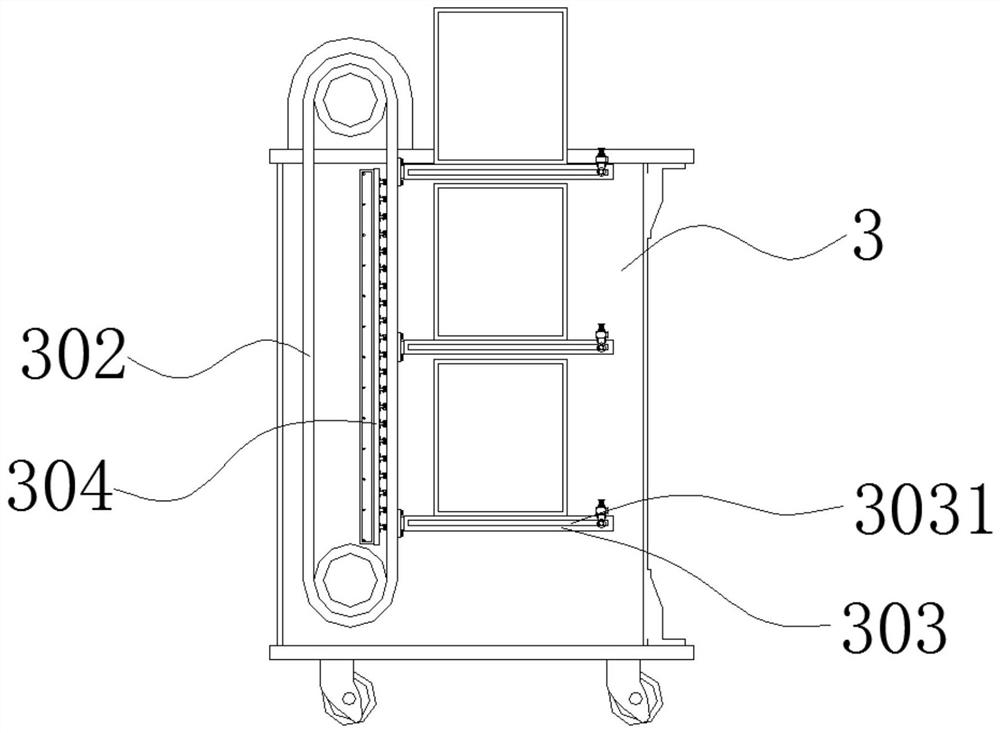

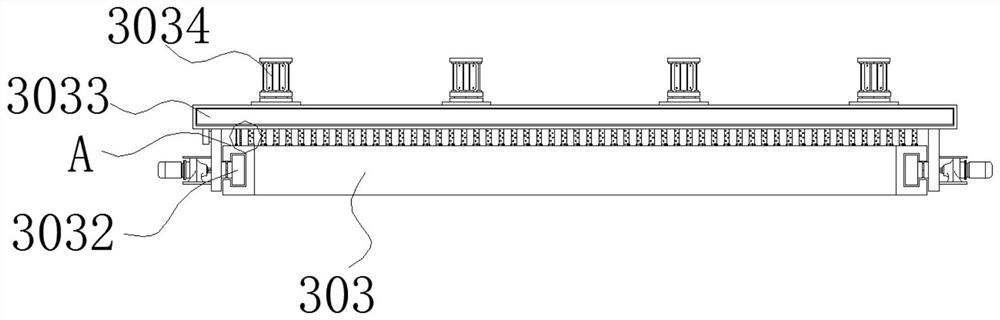

[0059] like Figure 1-4 As shown, a complete line of chassis packaging inspection line includes: a first transmission line 1 for transmitting a mobile chassis; a robotic arm 2, which is arranged on both sides of the first transmission line 1; a test vehicle 3, which is arranged in the The outer side of the robotic arm 2; the chassis to be tested and transmitted are arranged in layers in the test car 3. The test car 3 includes: a servo motor 301, which provides power for the lifting of the chassis; a lifting belt 302, which is connected to the servo motor 301. The outer wall of the output shaft; the chassis placing plate 303, the chassis placing plate 303 is fixed on the surface of the lifting belt 302, and the chassis placing plate 303 and the lifting belt 302 are vertically distributed, stabilizing the movable shaft 304, and the stabilizing movable shaft 304 is fixed on the test vehicle 3, and the stabilizing movable shaft 304 is evenly distributed on the inner side of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com