Light emitting diode (LED) lamp bulb

A technology of LED light bulbs and LED light boards, which is applied to lighting devices, cooling/heating devices of lighting devices, light sources, etc., can solve the problems of the lack of a diversion and heat dissipation structure of the light bulbs, the overheating of the LED light bulbs, and the failure of the LEDs, so as to improve the heat dissipation efficiency. , The effect of improving the coverage angle and reducing the resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

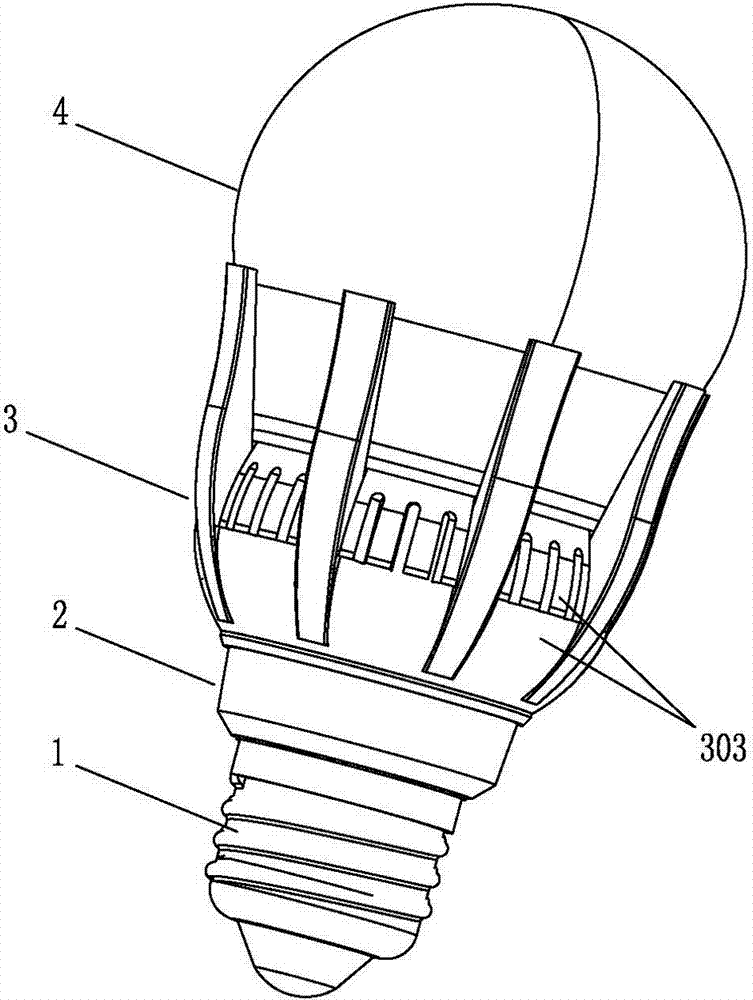

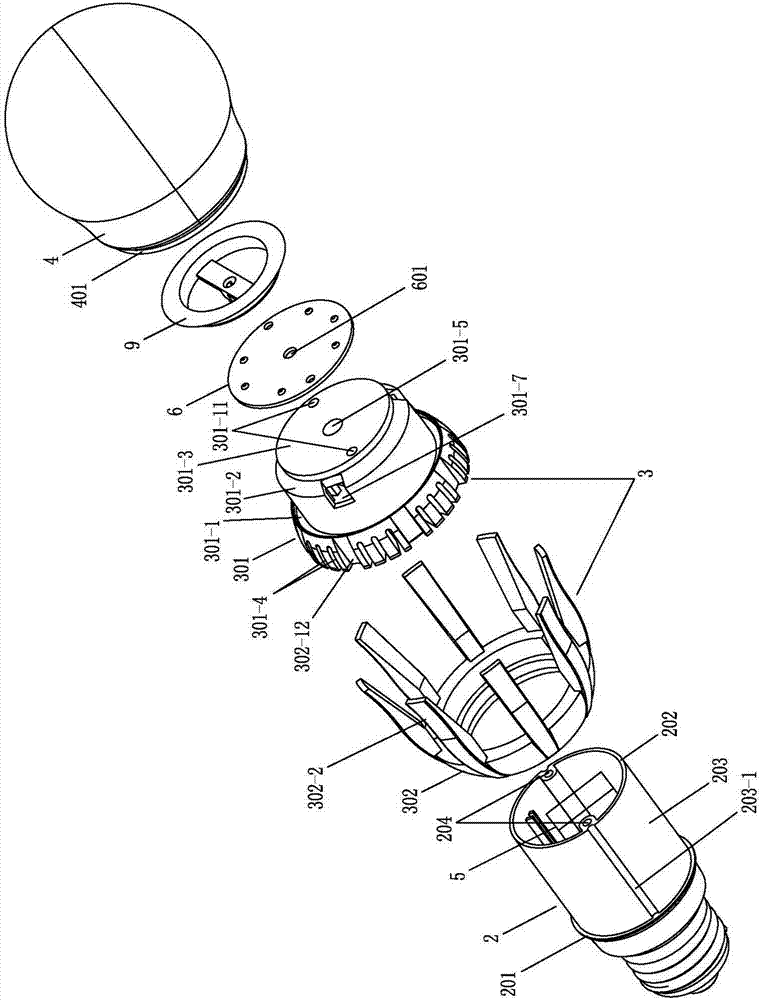

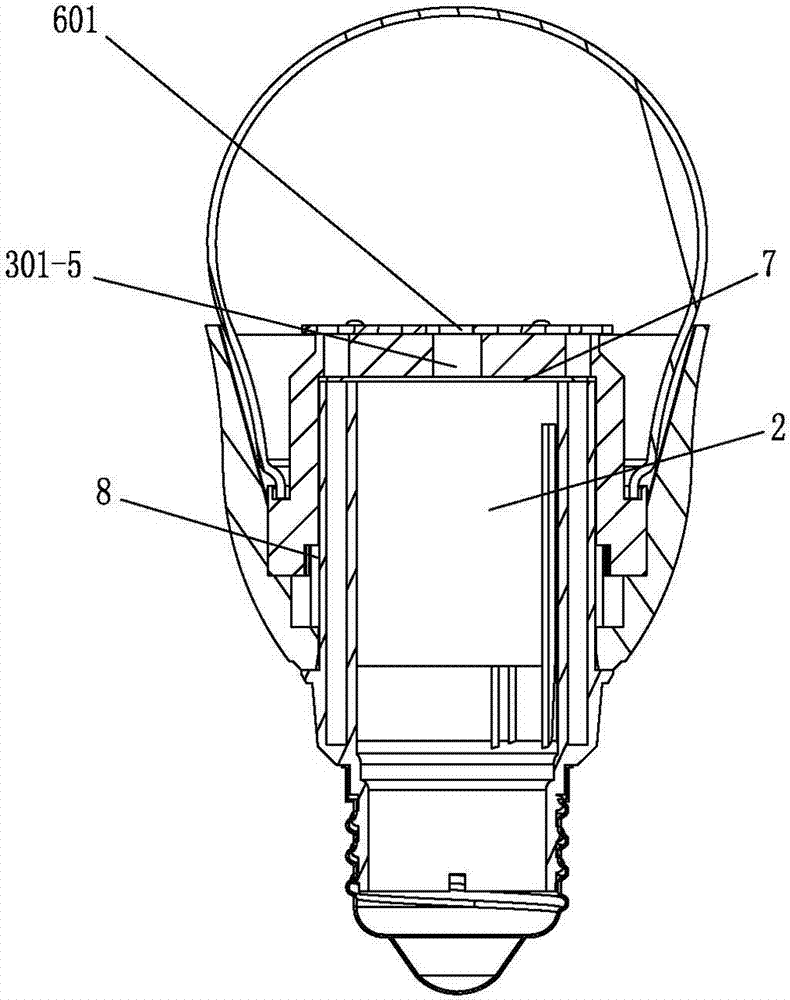

[0029] The first embodiment: as Figure 1 to Figure 3 As shown, an LED light bulb includes a metal connector 1, an insulating sleeve 2, a radiator 3 and a glass cover 4. The metal connector 4 is connected to the bottom end of the insulating sleeve 2, and an electronic component drive is installed in the insulating sleeve 2. The module 5, the radiator 3 is sleeved on the insulating sleeve 2, and the LED lamp board 6 is fixed on its top surface, and the characteristics are as follows;

[0030] The radiator 3 is a hollow spherical shape composed of an upper radiator 301 and a lower radiator 302 spliced above and below. The outer wall of the insulating sleeve 2 near the bottom is provided with a supporting ring 201, which is sleeved on the insulating sleeve 2. The bottom surface of the lower radiator 302 is in contact with the supporting ring 201, and the top surface 301-1 of the upper radiator 301 is extended with a heat dissipation sleeve 301-2. The heat dissipation sleeve 301...

no. 2 example

[0042] The second embodiment: as Figure 4 As shown, its structure is similar to that of the first embodiment, the difference is that the side wall of the lower radiator 302 is provided with a plurality of lower cooling holes 302-1 corresponding to the upper cooling holes 301-4 in the circumferential direction; The hole 301-4 and the lower heat dissipation hole 302-1 form a heat dissipation ventilation slot, which increases the flow of cold and hot air in and out, and improves the heat dissipation effect.

no. 3 example

[0043] The third embodiment: as Figure 5 As shown, other structures are similar to the first embodiment and / or the first embodiment as an improvement to the range of illumination angle of the light source, except that the top surface of the heat dissipation sleeve 301-2 is extended with lamp board protrusions 301-8, the side walls of the lamp board protrusions 301-8 are composed of three sides 301-9 arranged in a circle, and each side 301-9 is respectively equipped with an LED lamp board 6, and the lamp board protrusions 301- 8 is provided with an upper cooling channel communicating with the upper center through hole, and the top plate of the cooling sleeve adjacent to each LED lamp board is provided with a top surface through hole 301-10 communicating with the upper cooling hole 301-5, There is also a convex post channel 301-13 communicating with the upper cooling hole 301-5 on the convex post of the lamp board, and the opening 301-14 of the convex post channel 301-13 is ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com