Special close type spiral gear structure

A helical gear and compact technology, which is applied in the direction of belts/chains/gears, components with teeth, portable lifting devices, etc., can solve problems that affect the normal use of helical gears, cracks, and large forces, and achieve tightness Good, high position strength, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

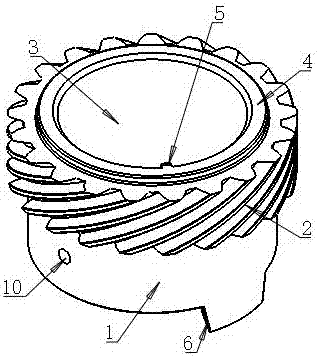

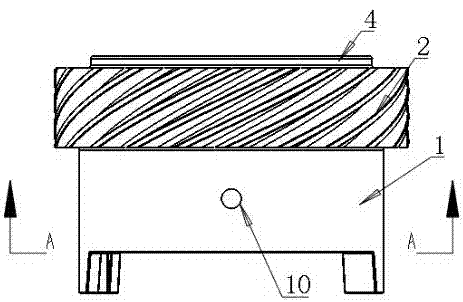

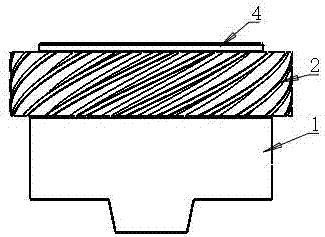

[0018] Such as Figure 1 to Figure 7 As shown, a special compact helical gear structure can better cooperate with the assembly mechanism during installation, and the connection is tighter. The structural strength is better during use and the service life is longer. It is more convenient in the process of assembling, and the installation efficiency is higher. It includes the cylindrical body structure 1, which is the main structure of the whole part. The upper cylindrical surface of the main structure 1 is provided with a helical tooth structure 2, which is used in conjunction with other helical tooth structures. The central position of the main structure 1 is provided with a cylindrical central assembly hole 3 that runs through the entire part, and is assembled and connected with the assembly shaft. The center of the upper end surface of the helical tooth structure 2 is provided with a cylindrical protective boss 4, which can effectively prevent the helical tooth from collid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com