GNSS product automatic test method based on function test

A technology for automated testing and functional testing, which is applied to measurement devices, radio wave measurement systems, satellite radio beacon positioning systems, etc., and can solve the problems of unimplemented automated debugging and testing methods, low efficiency of manual visual inspection, and incomplete exposure. Achieve the effect of improving test efficiency and accuracy, reducing inspection costs, and reducing manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

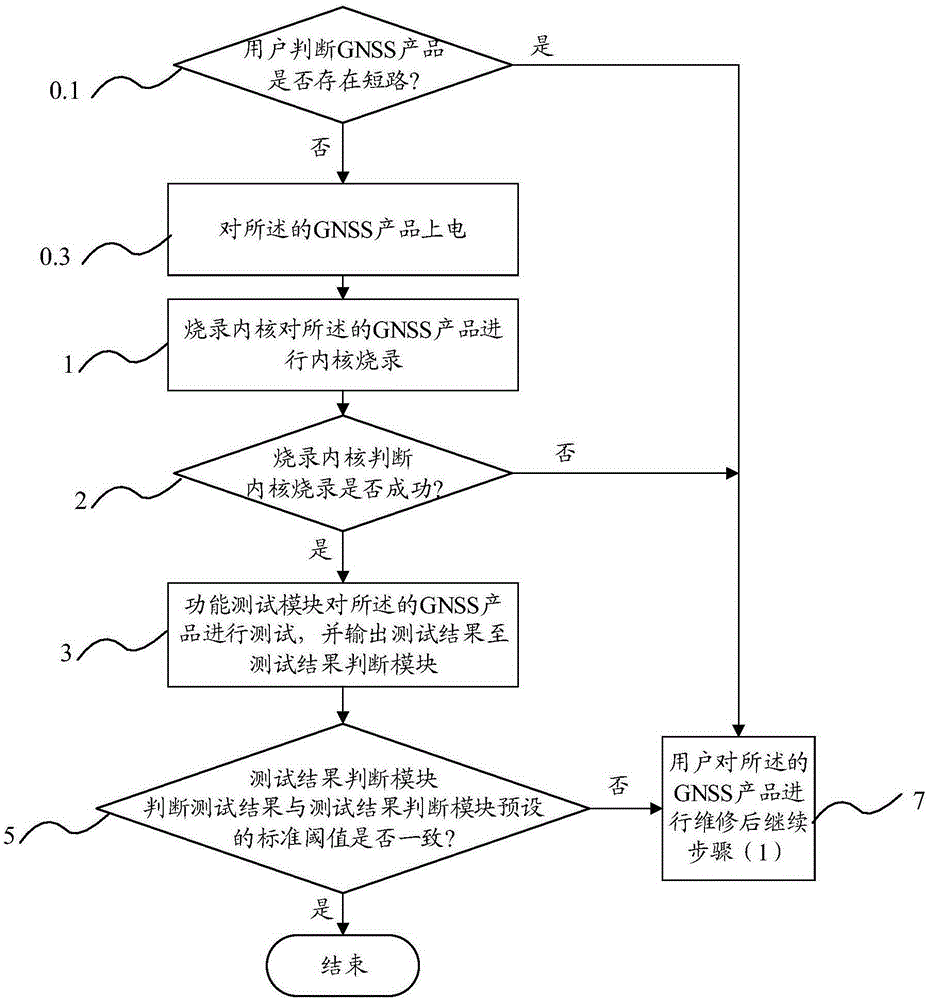

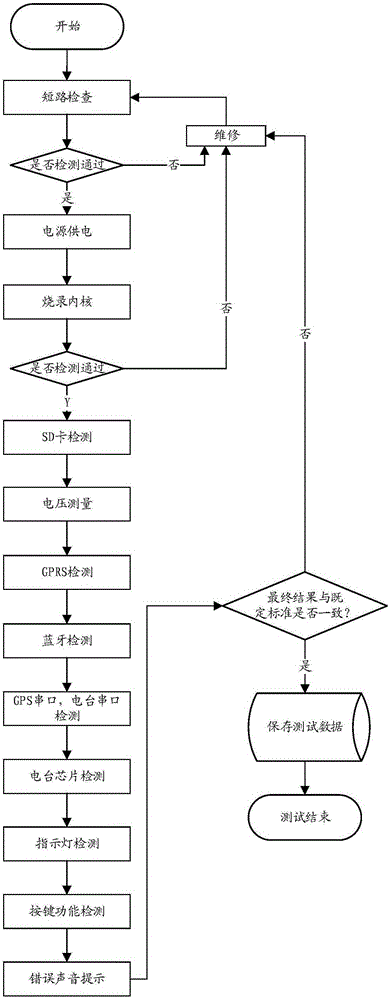

[0071] see Figure 1 to Figure 4 As shown, the method for realizing the automated testing of GNSS products based on functional testing comprises the following steps:

[0072] (1) Burn the kernel to burn the kernel of the GNSS product mentioned above; the GNSS product mentioned here mainly refers to the PCBA main board of the GNSS product. The kernel programming described here mainly refers to downloading the program of the function to be realized by the GNSS product to the PCBA main board, so that the subsequent function test module can perform functional test on the GNSS product.

[0073] (2) burning kernel judges whether described kernel burning is successful;

[0074] (3) If the kernel burning success described, then function test module tests described GNSS product, and output test result to test resu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com