Online multi-object crude oil blending optimization method

A multi-objective, crude oil technology, applied in the direction of control/regulation systems, instruments, adaptive control, etc., can solve problems such as inability to control attributes such as density, limit production levels, and inability to achieve trade-offs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

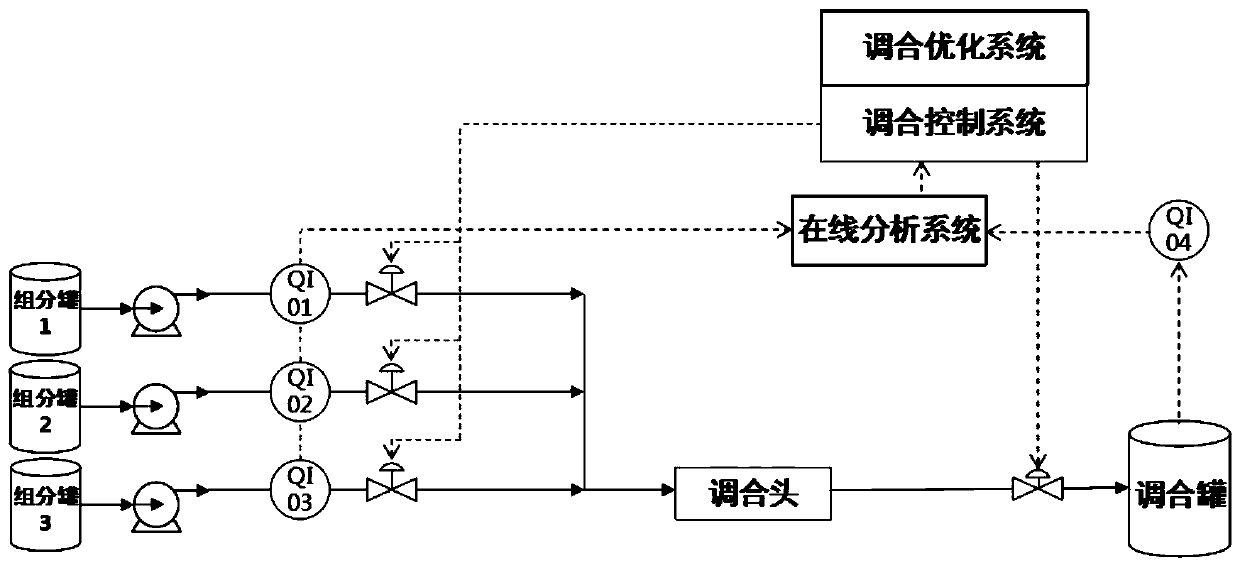

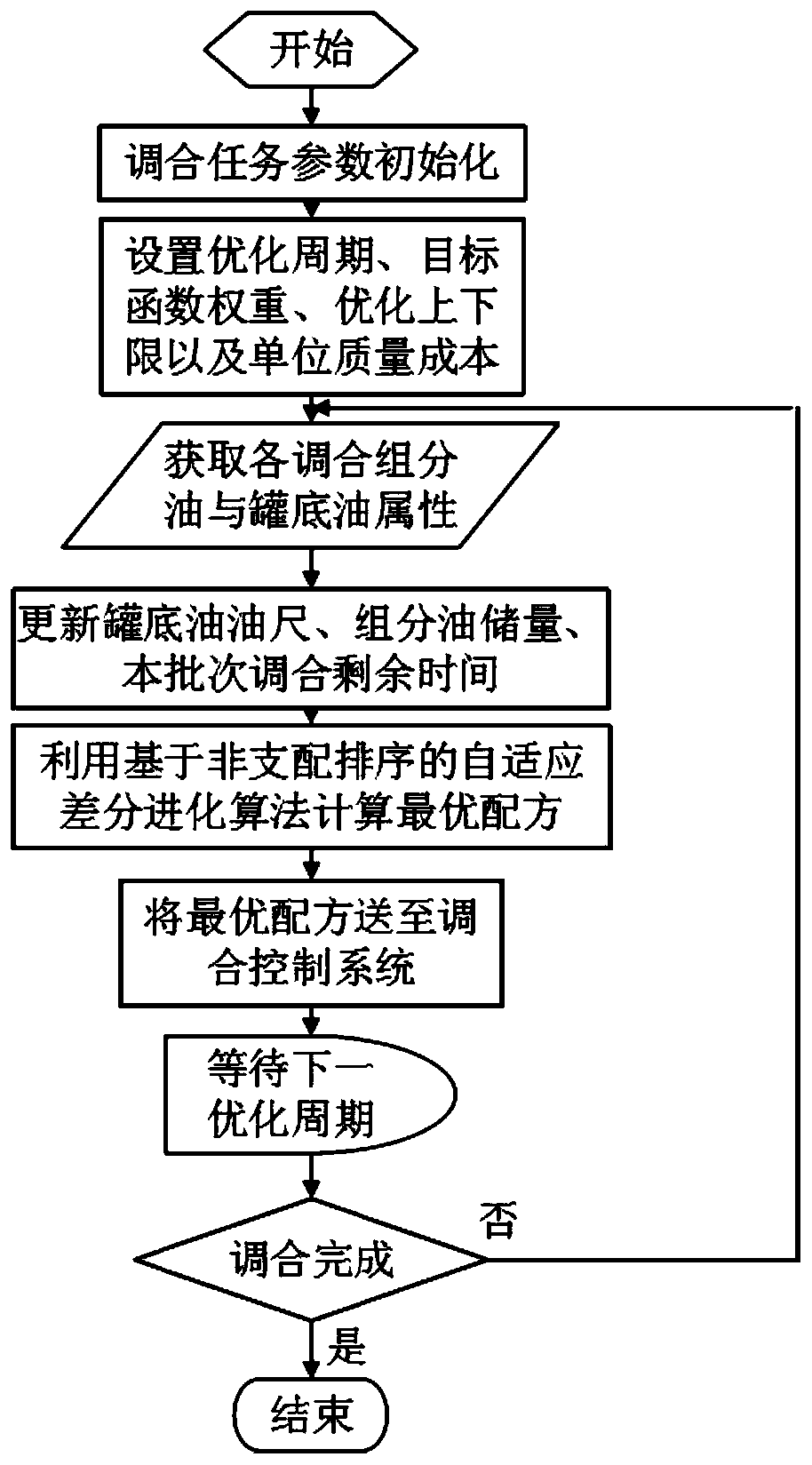

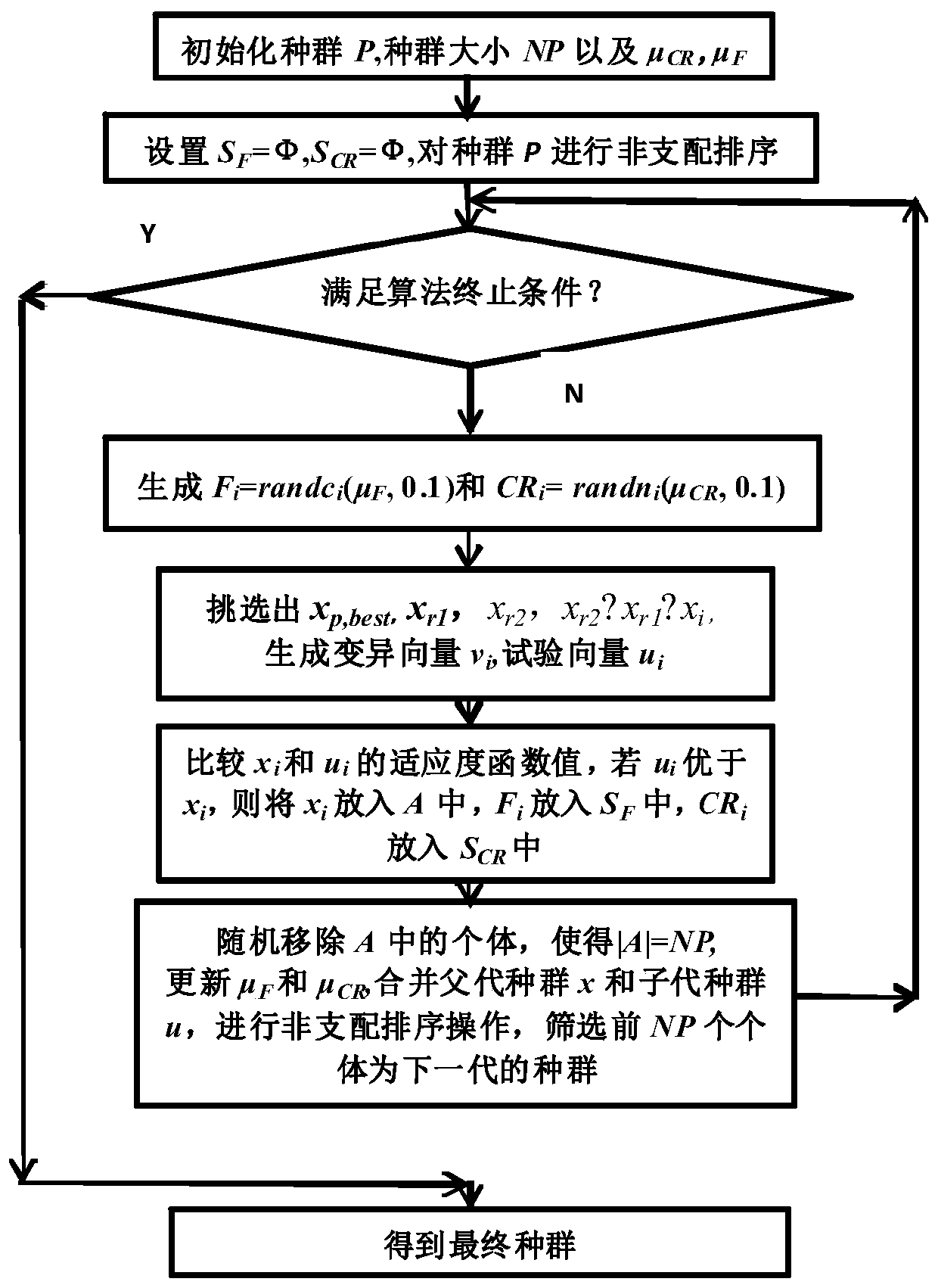

[0075] After extensive and in-depth research, the inventor proposed a multi-objective optimization method for crude oil blending in oil refining enterprises, aiming at the problem that the traditional algorithm can only perform single-objective optimization due to the capacity limitation of the traditional algorithm, and cannot fully balance each optimization goal. The objective online optimization method, and the adaptive differential evolution optimization method based on non-dominated sorting is used to optimize the solution.

[0076] For example, the inventor considered the lowest blending cost, the smallest deviation between the density of the blended crude oil and the target density, and at the same time considered the constraints of various crude oil quality indicators (sulfur content, acid value, naphtha yield, nitrogen content, etc.), various The stock limit of component oil, the formulation limit and flow limit of each component oil, etc. Under the condition of satis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com