Construction method for hoisting double rows of tank top beams synchronously

A construction method and cabinet top technology, applied in the processing of building materials, construction, building structure, etc., can solve problems such as affecting construction efficiency, time-consuming and labor-intensive, and poor overall project quality, saving manpower and construction costs. , The effect of shortening the construction period and overcoming the difficulty of installation personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the present invention more clearly understood, the technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

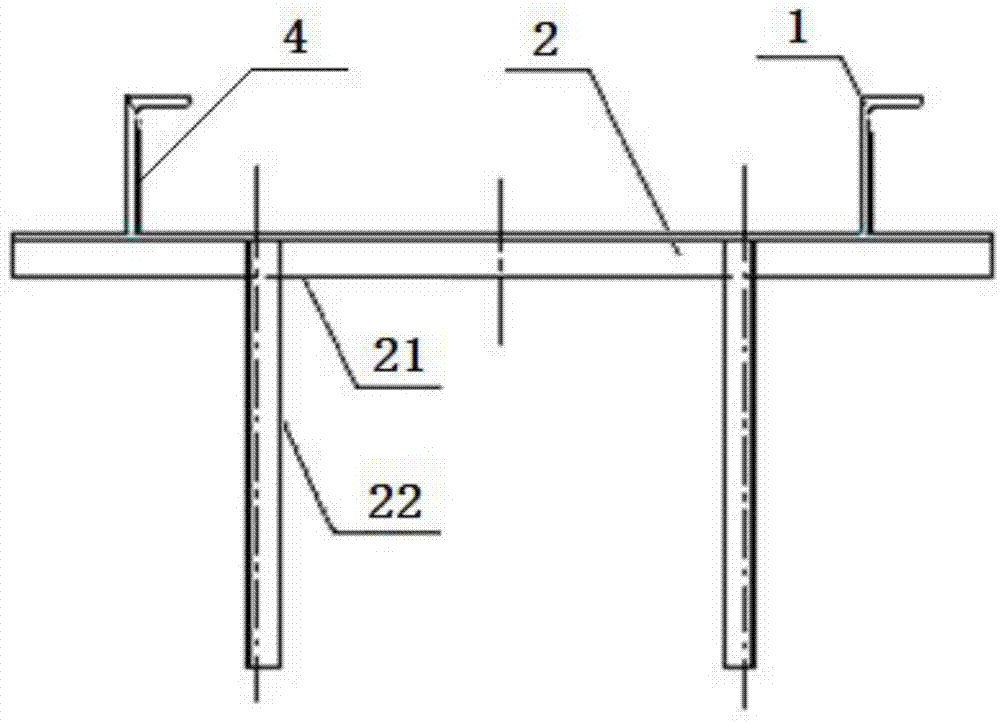

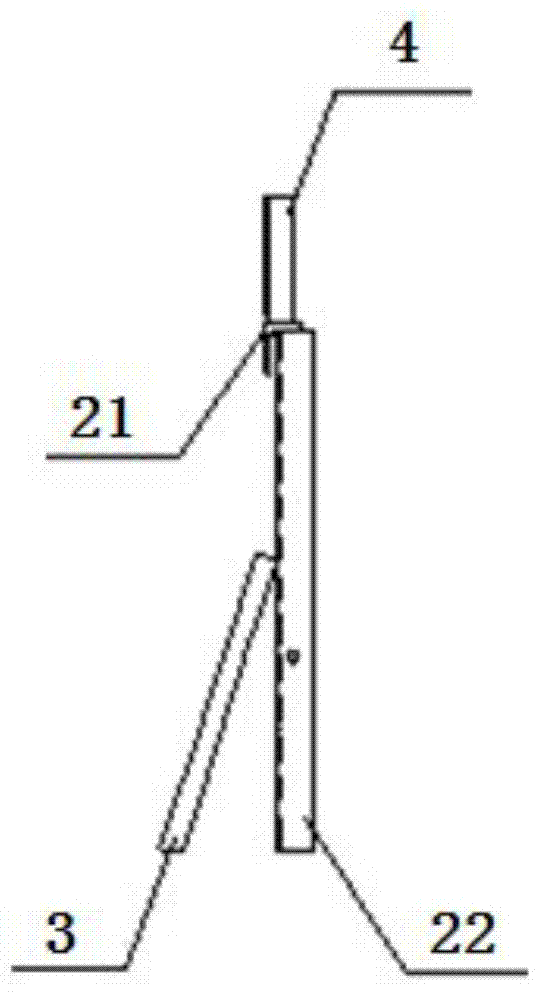

[0033] refer to figure 1 , figure 2 , image 3 , Figure 4 , the construction method of the simultaneous hoisting of the double cabinet top beam of the present invention comprises the following steps:

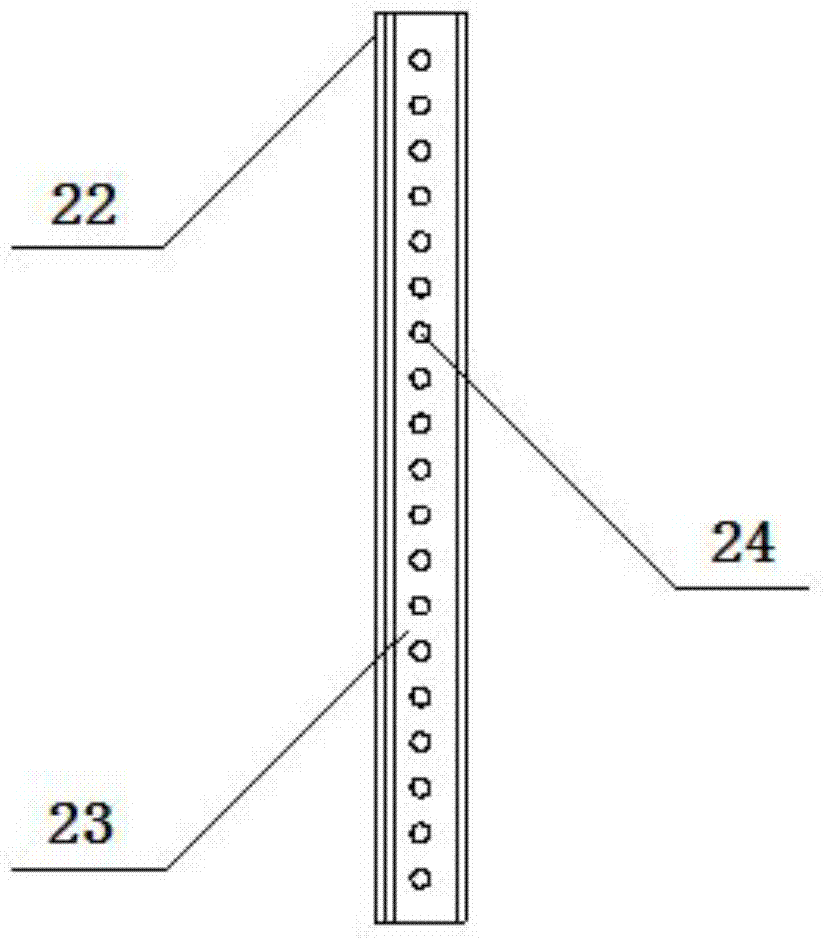

[0034] (1) First, according to the distance between the two cabinet top beams 1 on the gas cabinet, the cabinet top platform 2 is set up on the gas cabinet piston plate, and the cabinet top platform 2 is welded by the angle steel of model L50*6. The components include a crossbeam 21 and two support legs 22 arranged at the bottom of the crossbeam 21, and the bottom of the support legs 22 is a model L30*3 angle steel as a diagonal brace 3 (see figure 1 , figure 2 ), the other end of the diagonal brace 3 is fixed with the gas tank piston plate by spot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com