Waterfroof agent for cement mortar and its preparation method

A cement mortar and waterproofing agent technology, applied in the field of building materials, can solve problems such as low compressive performance, increase construction procedures, and prolong construction period, so as to increase hydration products, reduce investment in production equipment, and increase hydration speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

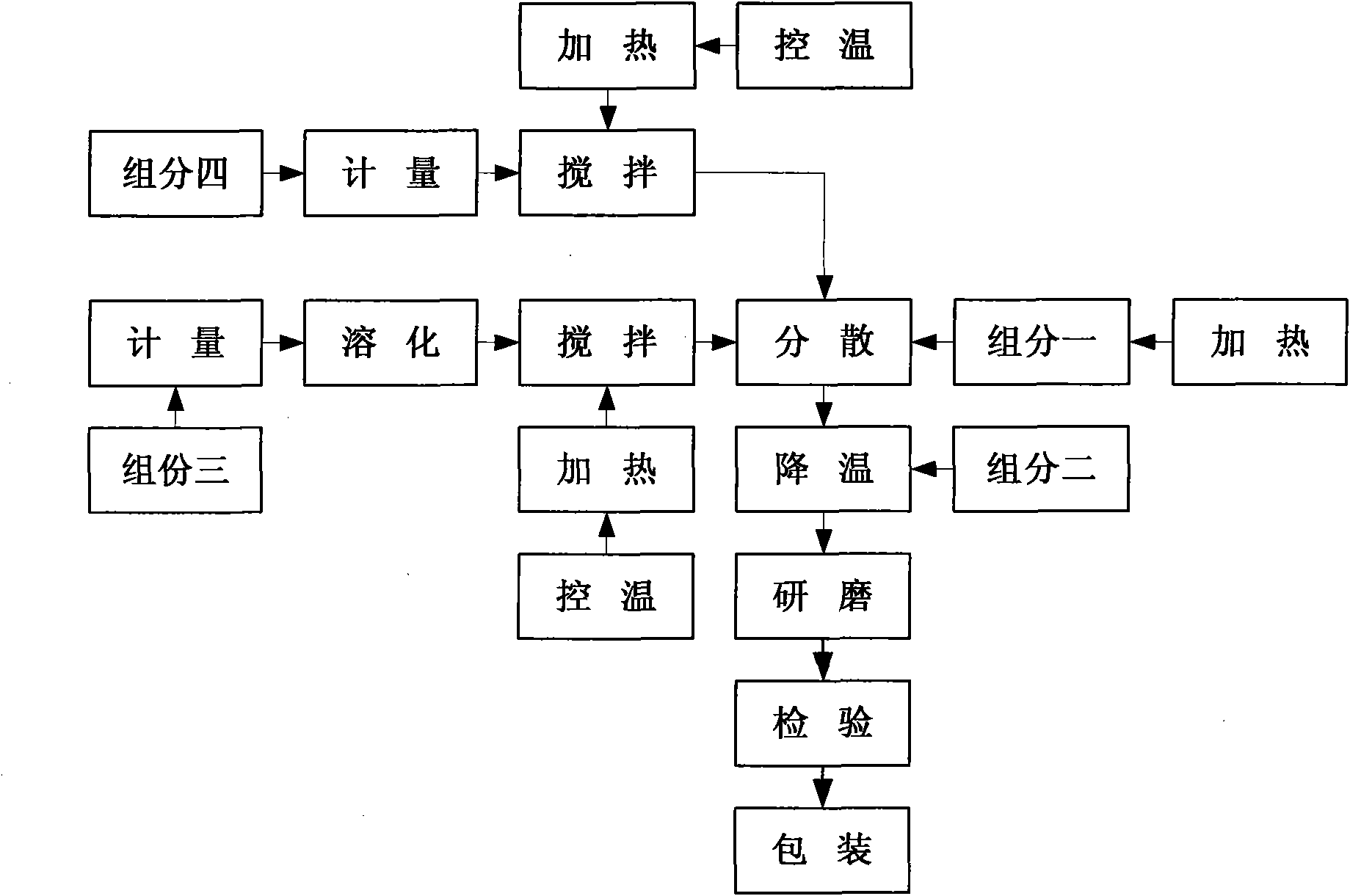

[0063] according to figure 1 The production process shown is to prepare a waterproofing agent used in cement mortar of the present invention. The specific method is as follows:

[0064] 1. Raw material composition

[0065] Component one is: 15.0 parts by weight of deionized water;

[0066] The second component is: 45.0 parts by weight of deionized water;

[0067] The third component is: 15.0 parts by weight of deionized water and 0.6 parts by weight of potassium hydroxide;

[0068] The fourth component is: 5.0 parts by weight of paraffin wax, 3.0 parts by weight of silicone oil, 0.8 parts by weight of fatty acids and 1.0 part by weight of triethanolamine.

[0069] 2. Preparation of waterproofing agent

[0070] The preparation method is carried out as follows:

[0071] 1) Weigh 15.0 parts by weight of component 1 and 45.0 parts by weight of deionized water of component 2 in the raw material composition, and put them into two containers for use;

[0072] 2) Weigh 15.0 parts by weight of the ...

Embodiment 2

[0078] according to figure 1 The production process shown is to prepare a waterproofing agent used in cement mortar of the present invention. The specific method is as follows:

[0079] 1. Raw material composition

[0080] Component one is: 12.0 parts by weight of deionized water;

[0081] The second component is: 50.0 parts by weight of deionized water;

[0082] The third component is: 17.0 parts by weight of deionized water and 0.5 parts by weight of sodium hydroxide;

[0083] The fourth component is: 8.0 parts by weight of paraffin wax, 3.5 parts by weight of silicone oil, 1.0 part by weight of fatty acid and 1.5 parts by weight of triethanolamine.

[0084] 2. Preparation of waterproofing agent

[0085] The preparation method is carried out as follows:

[0086] 1) Weigh 12.0 parts by weight of component 1 and 50.0 parts by weight of deionized water of component 2 in the raw material composition, and put them into two containers for use;

[0087] 2) Weigh 17.0 parts by weight of deionize...

Embodiment 3

[0093] according to figure 1 The production process shown is to prepare a waterproofing agent used in cement mortar of the present invention. The specific method is as follows:

[0094] 1. Raw material composition

[0095] Component one is: 20.0 parts by weight of deionized water;

[0096] The second component is: 40.0 parts by weight of deionized water;

[0097] The third component is: 18.0 parts by weight of deionized water and 1.0 parts by weight of OP-10;

[0098] The fourth component is: 10.0 parts by weight of paraffin wax, 4.0 parts by weight of silicone oil, 1.5 parts by weight of fatty acids, and 2.0 parts by weight of triethanolamine.

[0099] 2. Preparation of waterproofing agent

[0100] The preparation method is carried out as follows:

[0101] 1) Weigh 20.0 parts by weight of component 1 and 40.0 parts by weight of deionized water of component 2 in the raw material composition, and put them into two containers for use;

[0102] 2) Weigh 18.0 parts by weight of the deionized w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com