Ceramsite foam concrete and preparation process thereof

A foamed concrete and foamed concrete technology, which is applied to the field of ceramsite foamed concrete and its preparation technology, can solve the problems that the compressive strength of concrete needs to be improved, the amount of cement is large, etc., so as to improve the impermeability and waterproof performance, improve the compressive strength, The effect of high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-3

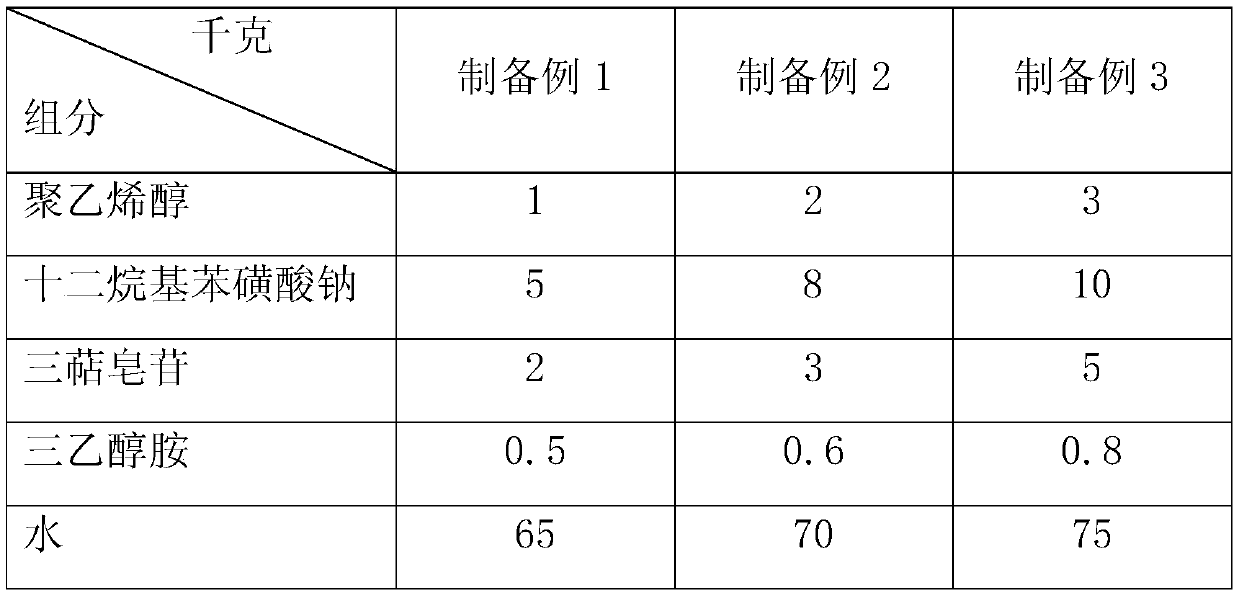

[0037] The raw material ratio of blowing agent in the preparation example 1-3 of table 1

[0038]

preparation example 1

[0039]Preparation Example 1: According to the proportioning in Table 1, add 65kg of water to the reactor at normal temperature, adjust the stirring paddle speed of the reactor to 150rpm, then add 1kg of polyvinyl alcohol, 5kg of dodecylbenzenesulfonic acid Add sodium, 2kg triterpene saponins, and 0.5kg triethanolamine into the reaction kettle, stir and mix continuously during the addition process, continue stirring for 5min until the solution is evenly mixed, add the mixed solution into the pressure foaming machine, start the pressure foaming machine to foam, and wait for the foam The foaming is uniform and the volume of the bubbles is uniform and stable, that is, the foaming agent solution is prepared.

preparation example 2

[0040] Preparation Example 2: According to the proportioning in Table 1, add 70kg of water to the reactor at normal temperature, adjust the stirring paddle speed of the reactor to 180rpm, then add 2kg of polyvinyl alcohol, 8kg of dodecylbenzenesulfonic acid Add sodium, 3kg triterpene saponins, and 0.6kg triethanolamine into the reaction kettle, stir and mix continuously during the addition process, continue stirring for 6 minutes until the solution is evenly mixed, add the mixed solution into the pressure foaming machine, start the pressure foaming machine to foam, and wait for the foam The foaming is uniform and the volume of the bubbles is uniform and stable, that is, the foaming agent solution is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com