Preparation process for high-strength PVC power pipe

A preparation process and power pipe technology, which is applied in the field of preparation technology of high-strength PVC power pipe, can solve the problems of large addition amount, general light stability, large loss, etc., and achieves increasing van der Waals force, improving light stability, and absorption The effect of increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

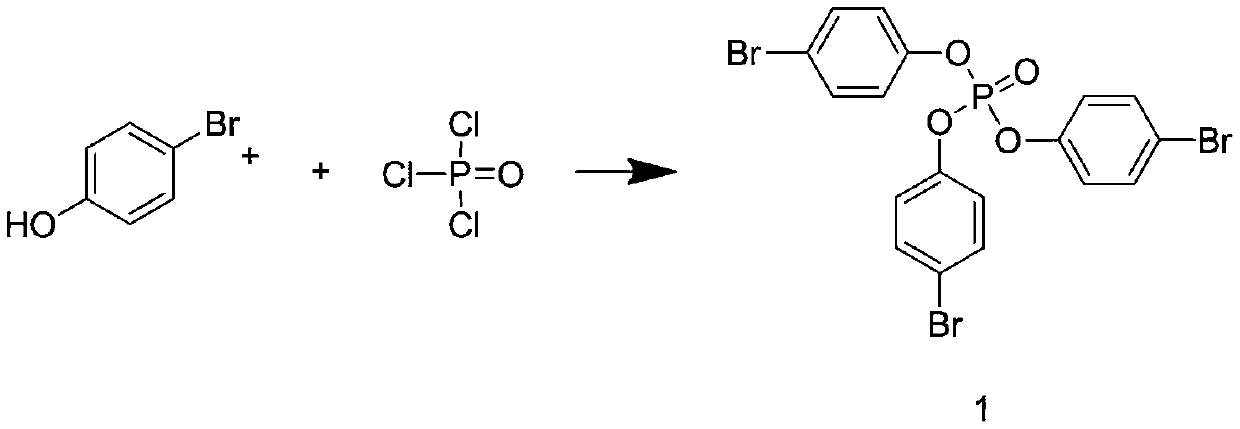

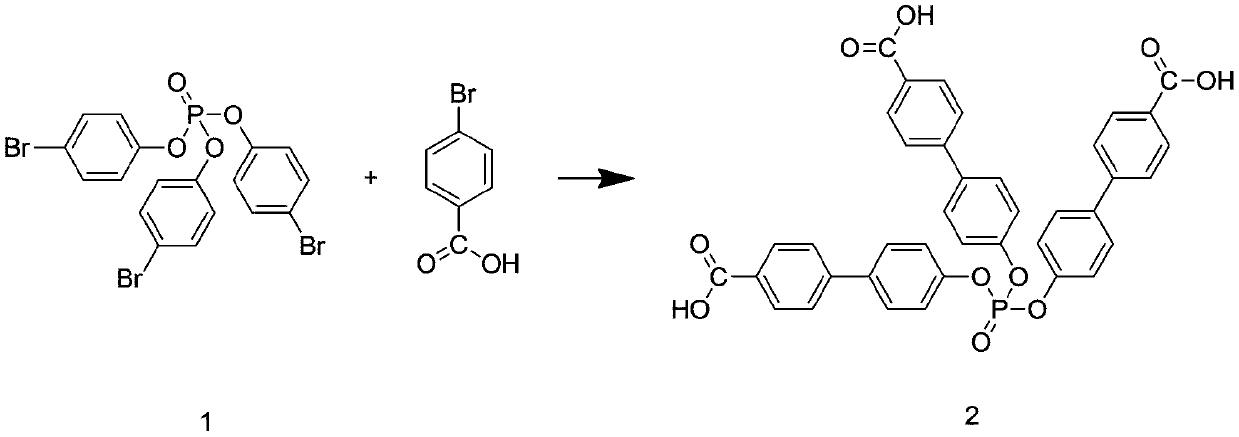

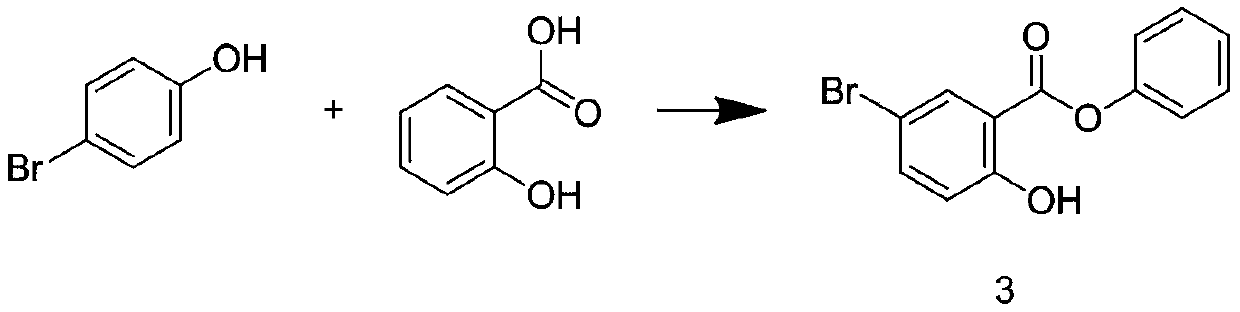

Method used

Image

Examples

Embodiment 1

[0046] A preparation process of high-strength PVC power pipe, which is made of the following parts by weight of raw materials: 20 parts by weight of polyvinyl chloride resin, 8 parts of modified tricresyl phosphate flame retardant, and modified o-hydroxybenzoic acid 8 parts of phenyl ester light stabilizer, 8 parts of impact modifier, 5.5 parts of lubricant, 3.5 parts of heat stabilizer, 6.5 parts of plasticizer;

[0047] The high-strength PVC power pipe is prepared by the following method:

[0048] Step S1: The polyvinyl chloride resin is added to the reaction kettle, and under the conditions of a temperature of 175°C and a rotation speed of 200r / min, it is melted for 1 hour until the polyvinyl chloride resin turns into a viscous state, and the modified tricresyl phosphate flame retardant , The modified phenyl phthalate light stabilizer, impact modifier, and heat stabilizer are added to the reaction kettle, and stirred for 2 hours at a temperature of 170°C and a speed of 200r / min ...

Embodiment 2

[0063] A preparation process of high-strength PVC power pipe, which is made of the following parts by weight of raw materials: 25 parts by weight of polyvinyl chloride resin, 10 parts of modified tricresyl phosphate flame retardant, and modified phenyl o-hydroxybenzoate 10 parts of light stabilizer, 10 parts of impact modifier, 7 parts of lubricant, 5 parts of heat stabilizer, 8 parts of plasticizer;

[0064] The PVC power pipe is prepared by the following method:

[0065] Step S1: The polyvinyl chloride resin is added to the reaction kettle, and the modified tricresyl phosphate flame retardant is melted for 1 hour until the polyvinyl chloride resin turns into a viscous state under the conditions of a temperature of 180°C and a rotation speed of 200r / min. , The modified phenyl phthalate light stabilizer, impact modifier, and heat stabilizer are added to the reaction kettle, and stirred for 2.5 hours under the conditions of a temperature of 175°C and a speed of 200r / min. A mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com