Wall paint with radiation protection and corrosion resistance

A corrosion-resistant and radiation-resistant technology, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of high coating cost, limited radiation protection effect, poor corrosion resistance, etc., to improve oxidation resistance and corrosion resistance Performance, improve radiation protection performance, improve the effect of waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

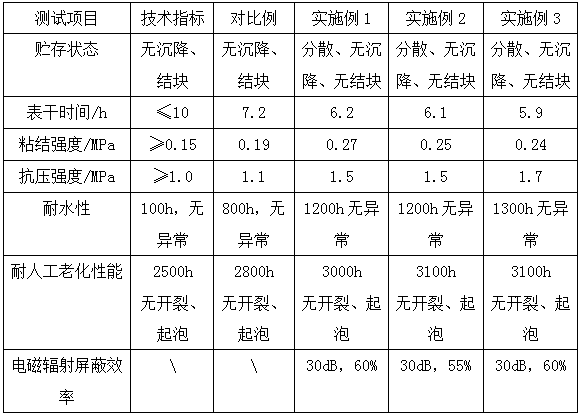

Embodiment 1

[0029] A wall paint with anti-radiation and corrosion-resistant properties. According to the mass parts, the wall paint includes the following components: 40 parts of water-based polyurethane-acrylate emulsion, 6 parts of silicone resin, 7 parts of titanium dioxide, coated metal 12 parts of fine powder, 1 part of graphene, 4 parts of pigment, 1 part of wetting and dispersing agent, 1 part of silane coupling agent, 15 parts of isocyanate curing agent, 2 parts of dimethylthiotoluenediamine, 0.3 part of defoamer, and the composition 0.5 part of film aid, 0.5 part of ultraviolet absorber.

[0030] In the present embodiment, the preparation method of the coated metal micropowder comprises the following steps: adding melamine and 35wt% formaldehyde solution into the reaction kettle according to the molar ratio of 1:3, and then adding ethyl alcohol which accounts for 0.5 times the volume of the mixture into the reaction kettle. Glycol solvent, after mixing and stirring evenly, adjust...

Embodiment 2

[0040] A wall paint with anti-radiation and corrosion-resistant properties, according to the mass parts, the wall paint includes the following components: 45 parts of water-based polyurethane-acrylate emulsion, 9 parts of silicone resin, 10 parts of titanium dioxide, coated metal 17 parts of fine powder, 3 parts of graphene, 7 parts of pigment, 2 parts of wetting and dispersing agent, 3 parts of silane coupling agent, 20 parts of isocyanate curing agent, 4 parts of dimethylthiotoluenediamine, 0.6 part of defoamer, and the composition 1.4 parts of film aid, 2.3 parts of ultraviolet absorber.

[0041] In the present embodiment, the preparation method of the coated metal micropowder comprises the following steps: adding melamine and 35wt% formaldehyde solution into the reaction kettle according to the molar ratio of 1:3, and then adding ethyl alcohol which accounts for 0.5 times the volume of the mixture into the reaction kettle. Glycol solvent, after mixing and stirring evenly, ...

Embodiment 3

[0051] A wall paint with anti-radiation and corrosion-resistant properties, according to the mass parts, the wall paint includes the following components: 43 parts of water-based polyurethane-acrylate emulsion, 8 parts of silicone resin, 9 parts of titanium dioxide, coated metal 15 parts of fine powder, 2 parts of graphene, 6 parts of pigment, 1.5 parts of wetting and dispersing agent, 2 parts of silane coupling agent, 18 parts of isocyanate curing agent, 3 parts of dimethylthiotoluenediamine, 0.5 part of defoamer, and the composition 0.9 parts of film aid, 1.5 parts of ultraviolet absorber.

[0052] In the present embodiment, the preparation method of the coated metal micropowder comprises the following steps: adding melamine and 35wt% formaldehyde solution into the reaction kettle according to the molar ratio of 1:3, and then adding ethyl alcohol which accounts for 0.5 times the volume of the mixture into the reaction kettle. Diol solvent, after mixing and stirring evenly, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com