Flame-retardant high-property PC/ABS alloy and preparation method thereof

A high-performance, alloy technology, applied in the field of alloy materials, can solve the problems of undiscovered patent publications, unsatisfactory flame retardant effect, inability to dust flame retardant, etc., and achieves improved processing performance, reduced internal stress, and good flame retardant effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

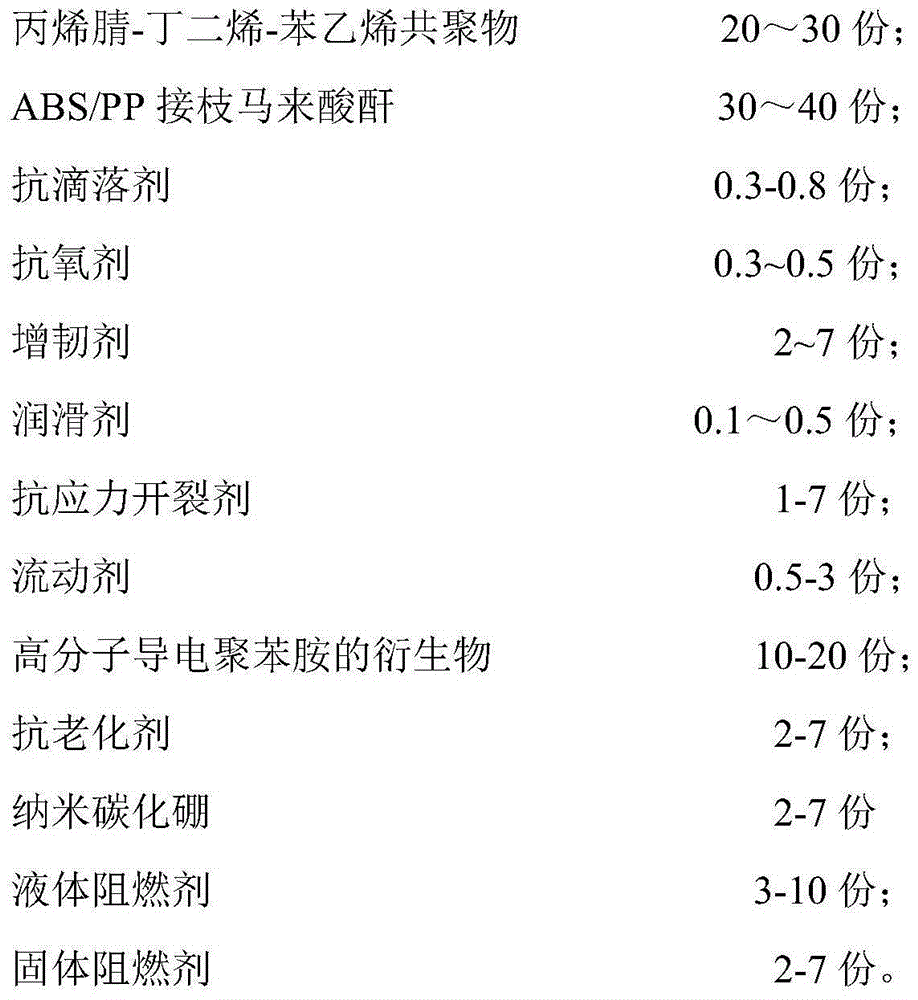

[0033] A flame-retardant high-performance PC / ABS alloy, the composition and mass parts of the alloy are as follows:

[0034]

[0035] The liquid flame retardant is diphenyl phosphate;

[0036] The solid flame retardant is a mixture of antimony trioxide and triphenyl phosphate, and the mass ratio of the two is 1:0.5;

[0037] The preparation method of described ABS / PP grafted maleic anhydride is as follows:

[0038] After uniformly mixing ABS, PP, maleic anhydride, initiator and stearic acid, put it into a high-speed mixer for preheating and stirring at a stirring speed of 800-1000 rpm, 90-100°C, stirring for 5 minutes, and then Send it into the twin-screw extruder, and the processing technology is as follows: from the feed port to the die head, the temperature in the first zone is 175-180°C, the temperature in the second zone is 175-180°C, the temperature in the third zone is 176-190°C, and the temperature in the fourth zone is 176-190°C , the temperature in the fifth zon...

Embodiment 2

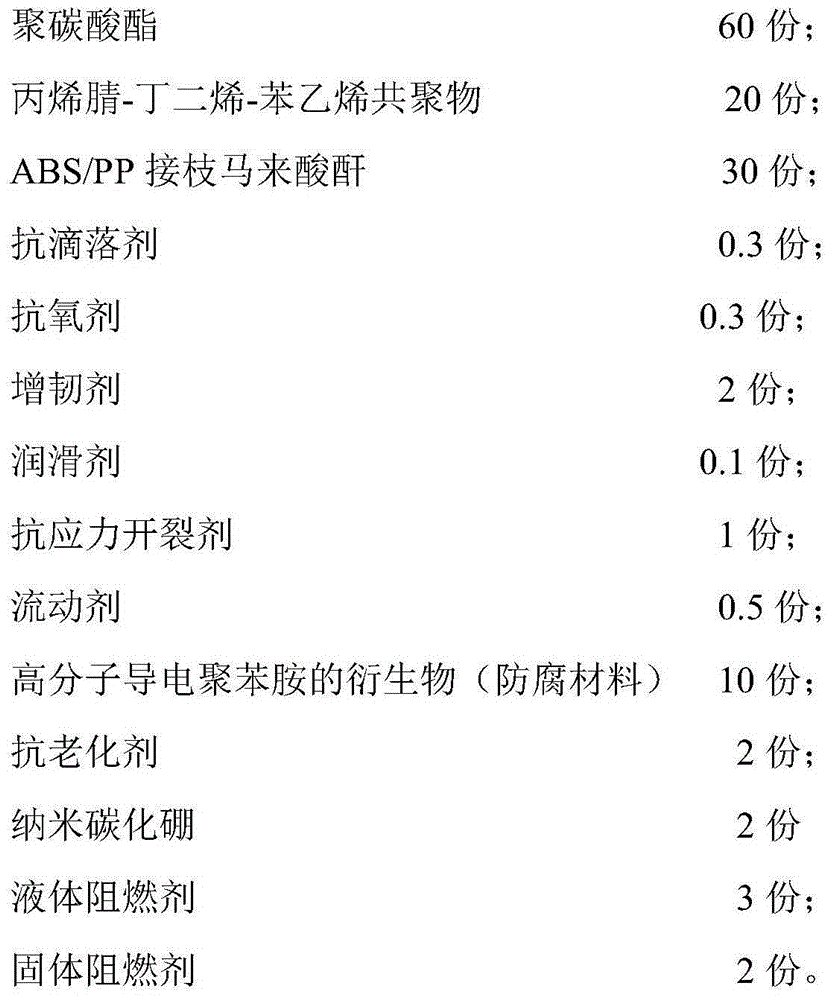

[0048] A flame-retardant high-performance PC / ABS alloy, the composition and mass parts of the alloy are as follows:

[0049]

[0050] Wherein, the acrylonitrile-butadiene-styrene copolymer is composed of granular acrylonitrile-butadiene-styrene copolymer and powdered acrylonitrile-butadiene-styrene copolymer, the two The mass ratio is 4:1.

[0051] The liquid flame retardant is diphenyl phosphate;

[0052] The solid flame retardant is antimony trioxide;

[0053] The antioxidant is [β-(3,5-di-tert-butyl 4-hydroxyphenyl) propionate] pentaerythritol ester or tri(2,4-di-tert-butylphenol) phosphite;

[0054] The anti-dripping agent is polytetrafluoroethylene;

[0055] The flow agent is a mixture of ethylene bisstearamide and PE wax, and the mass ratio of the two is 1:0.5-0.9.

[0056] The preparation method of the flame-retardant high-performance PC / ABS alloy described above has the same steps as in Example 1.

Embodiment 3

[0058] A flame-retardant high-performance PC / ABS alloy, the composition and mass parts of the alloy are as follows:

[0059]

[0060] Wherein, the acrylonitrile-butadiene-styrene copolymer is composed of granular acrylonitrile-butadiene-styrene copolymer and powdered acrylonitrile-butadiene-styrene copolymer, the two The mass ratio is 1:1.

[0061] The solid flame retardant is a mixture of triphenyl phosphate and MAC, and the mass ratio of the two is 3:2-3;

[0062] The preparation method of described ABS / PP grafted maleic anhydride is as follows:

[0063] After uniformly mixing ABS, PP, maleic anhydride, initiator and stearic acid, put it into a high-speed mixer for preheating and stirring at a stirring speed of 800-1000 rpm, 90-100°C, stirring for 5 minutes, and then Send it into the twin-screw extruder, and the processing technology is as follows: from the feed port to the die head, the temperature in the first zone is 175-180°C, the temperature in the second zone is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com