Polyester adhesive

A technology of adhesives and polyesters, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., to achieve long storage time, reduce glue waste, and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

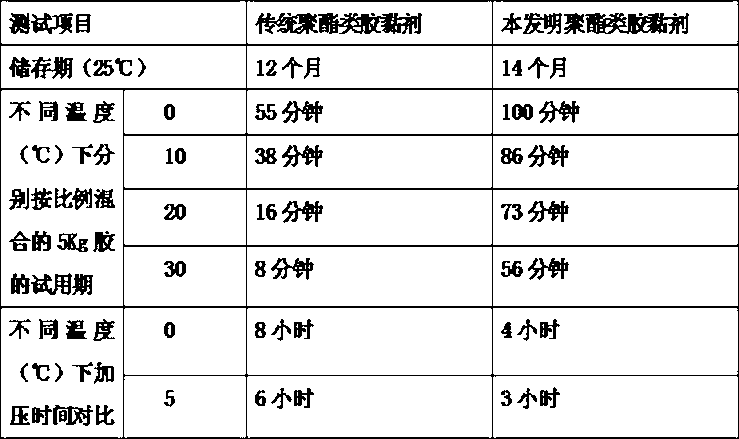

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A polyester adhesive, which is composed of two components, A and B:

[0018] The first component is composed of the following raw materials in parts by weight: n-butanol 8, 307 unsaturated polyester 60, talcum powder 2, aluminum powder 4, calcium carbonate 20, triethylenetetramine 1, chlorobenzene 35;

[0019] Add the above-mentioned raw materials in parts by weight into a stirred tank, and stir under vacuum for 1 hour at a temperature of 120°C to obtain component A;

[0020] The B component is composed of the following raw materials in parts by weight: propylene glycol 80, toluene diisocyanate 15, dibutyltin dilaurate 0.2, phenyl salicylate 0.5, modified nano clay 1.2;

[0021] Add the raw materials in the above parts by weight into the stirring and dispersing kettle, and stir at high speed for 18 minutes to obtain component B;

[0022] The preparation method of the modified nano-clay is as follows: mix the clay with 3% dicumyl peroxide by mass, heat to 60°C and stir ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com