Production method of natural latex mattress

A technology of natural latex and a production method, which is applied in the field of production of natural latex mattresses, can solve the problems of high price, easily damaged surface, poor wear resistance, etc., and achieves the effects of low production cost, improved wear resistance and improved comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

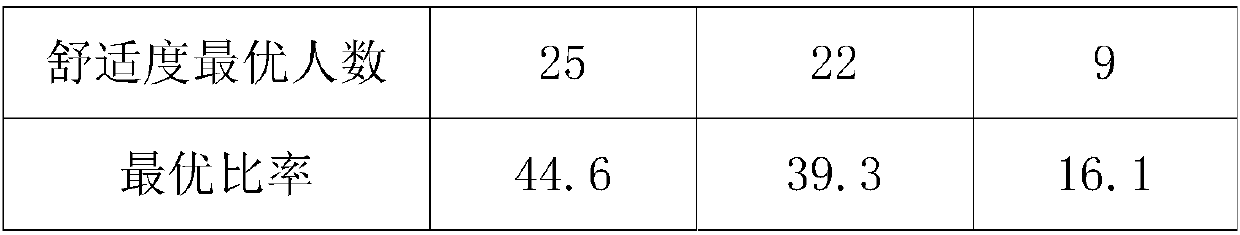

Examples

Embodiment 1

[0022] A kind of manufacture method of natural latex mattress that the present invention proposes, comprises the following steps:

[0023] S1, prepare the raw material of natural latex mattress, the raw material of described natural latex mattress comprises: natural latex, polyurethane elastomer, epoxy resin, liquid silica gel, far-infrared ceramic powder, sericite powder, Chinese medicine extract, benzotri Azole, phenyl o-hydroxybenzoate, vulcanizing agent, anti-yellowing agent, heat stabilizer, thickener, foaming agent and alcohol;

[0024] S2. Add the benzotriazole, phenyl o-hydroxybenzoate, far-infrared ceramic powder and sericite powder prepared in step S1 into ethanol, and disperse evenly by ultrasonic, then add the Chinese medicine extract prepared in step S1, and mix evenly to obtain mixture A;

[0025] S3, heat the natural latex prepared in step S1 and add polyurethane elastomer, epoxy resin and liquid silica gel, mix well and then add vulcanizing agent, anti-yellowi...

Embodiment 2

[0030] A kind of manufacture method of natural latex mattress that the present invention proposes, comprises the following steps:

[0031] S1, prepare the raw material of natural latex mattress, the raw material of described natural latex mattress comprises: natural latex, polyurethane elastomer, epoxy resin, liquid silica gel, far-infrared ceramic powder, sericite powder, Chinese medicine extract, benzotri Azole, phenyl o-hydroxybenzoate, vulcanizing agent, anti-yellowing agent, heat stabilizer, thickener, foaming agent and alcohol;

[0032] S2. Add the benzotriazole, phenyl o-hydroxybenzoate, far-infrared ceramic powder and sericite powder prepared in step S1 into ethanol, and disperse evenly by ultrasonic, then add the Chinese medicine extract prepared in step S1, and mix evenly to obtain mixture A;

[0033] S3, heat the natural latex prepared in step S1 and add polyurethane elastomer, epoxy resin and liquid silica gel, mix well and then add vulcanizing agent, anti-yellowi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com