Heat-resistance and saline-alkaline-resistance type elastomer modified bitumen waterproof coil material

A technology of bitumen waterproofing membrane and modified bitumen, which is used in building thermal insulation materials, building components, buildings, etc., can solve the problems of poor viscosity, weak self-healing ability, and no self-adhesion, so as to improve waterproof performance and improve adhesion. performance, and the effect of preventing water seepage and channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

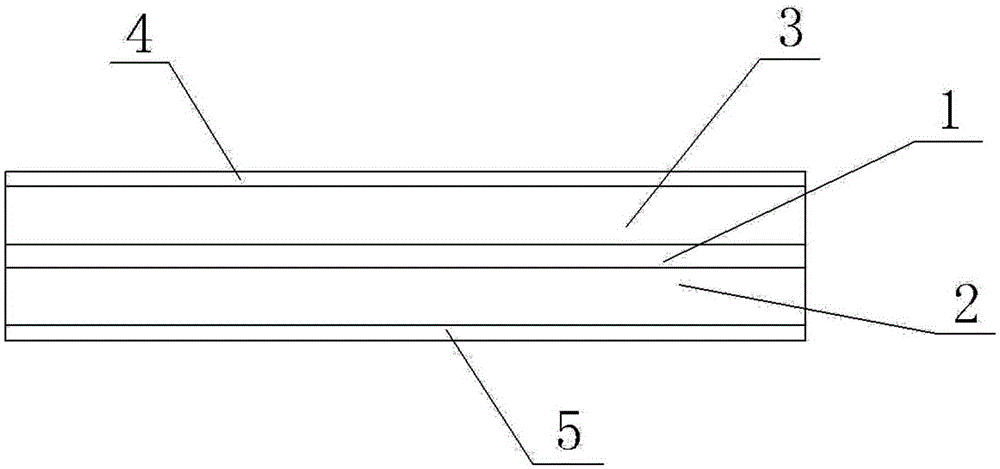

[0026] refer to figure 1 , the present invention proposes a heat-resistant, salt-alkali-resistant elastomer-modified asphalt waterproofing membrane, comprising a base 1, the upper and lower surfaces of the base 1 are respectively provided with a first asphalt layer 2 and a second asphalt layer 3, the first asphalt The side of the layer 2 away from the base 1 is provided with a first protective film 5, and the side of the second asphalt layer 3 away from the base 1 is provided with a second protective film 4; both the first asphalt layer 2 and the second asphalt layer 3 use Made from modified asphalt.

[0027] Substrate 1 is a mixture of polyester tire, glass fiber tire and glass fiber reinforced polyester felt at a weight ratio of 3.5:2:5.5. The first protective film 5 is a PET protective film. The second protective film 4 is a PE protective film.

[0028] The raw materials of modified asphalt include by weight: 1300 parts of 90# asphalt, 1100 parts of 10# asphalt, 500 part...

Embodiment 2

[0038] refer to figure 1 , the present invention proposes a heat-resistant, salt-alkali-resistant elastomer-modified asphalt waterproofing membrane, comprising a base 1, the upper and lower surfaces of the base 1 are respectively provided with a first asphalt layer 2 and a second asphalt layer 3, the first asphalt The side of the layer 2 away from the base 1 is provided with a first protective film 5, and the side of the second asphalt layer 3 away from the base 1 is provided with a second protective film 4; both the first asphalt layer 2 and the second asphalt layer 3 use Made from modified asphalt.

[0039] Substrate 1 is a mixture of polyester tire, glass fiber tire and glass fiber reinforced polyester felt in a weight ratio of 2:3:3. The first protective film 5 is a PE protective film. The second protective film 4 is a PE protective film.

[0040] The raw materials of modified asphalt include by weight: 1200 parts of 90# asphalt, 1200 parts of 10# asphalt, 400 parts of ...

Embodiment 3

[0049] refer to figure 1 , the present invention proposes a heat-resistant, salt-alkali-resistant elastomer-modified asphalt waterproofing membrane, comprising a base 1, the upper and lower surfaces of the base 1 are respectively provided with a first asphalt layer 2 and a second asphalt layer 3, the first asphalt The side of the layer 2 away from the base 1 is provided with a first protective film 5, and the side of the second asphalt layer 3 away from the base 1 is provided with a second protective film 4; both the first asphalt layer 2 and the second asphalt layer 3 use Made from modified asphalt.

[0050] Substrate 1 is a mixture of polyester tire, glass fiber tire and glass fiber reinforced polyester felt at a weight ratio of 5:1:8. The first protective film 5 is coated sand. The second protective film 4 is a PE protective film.

[0051] The raw materials of modified asphalt include by weight: 1400 parts of 90# asphalt, 1000 parts of 10# asphalt, 600 parts of 250# heav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com