Method for producing laminated shell fabric of full window blind

A technology of composite fabrics and production methods, which is applied in the field of preparation of blackout roller blinds and fabric art curtains, can solve the problems that roller blinds or fabric art curtains cannot be washed, dry cleaned and ironed, insufficient aging resistance, waste water pollution, etc., and achieve good results. The effect of UV resistance and anti-aging ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

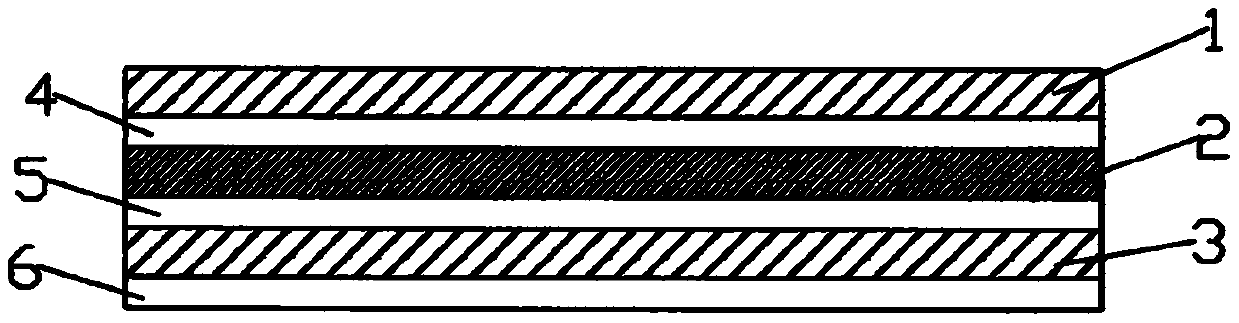

[0022] combine figure 1 The embodiment is described in detail. The production method of a full blackout curtain composite fabric involved in this embodiment includes the first base fabric layer 1, TPU black shading film 2 and the second base fabric layer. Cloth layer 3. The first base fabric layer 1 and the light-shielding film 2 are combined through the first adhesive layer 4 , and the second base fabric layer 3 and the TPU black light-shielding film 2 are combined through the second adhesive layer 5 . The surfaces of the first base cloth layer 1 and the second base cloth layer 2 both have patterns formed by embossing.

[0023] The composite fabric of full blackout curtain is produced according to the following steps: (1) treatment of base fabric, (2) preparation of TPU black shading film, (3) first step of hot pressing compounding, (4) second step of hot pressing compounding.

[0024] In step (1) in the treatment of the base cloth, the fabrics selected for the first base c...

Embodiment 2

[0034] combine figure 2 , to describe this embodiment in detail. A kind of production method of the composite fabric of full blackout curtain involved in this embodiment, (one) the treatment of base fabric, (two) the preparation of TPU black light-shielding film, (three) the first step hot pressing composite, (four) the second Step hot pressing compound.

[0035] The treatment of the first base cloth layer and the second base cloth layer is the same as that of Embodiment 1, and the treatments such as degreasing and desizing or desizing are carried out so that the base cloth does not have other oil stains or other impurities that affect hot-pressing composite, and then It will affect the composite with the black and white shading film, which will reduce the bonding strength between the base fabric and the black and white shading film, and affect the service life of the shading curtain.

[0036] In the preparation of step (two) TPU black shading film, be the polyurethane of 4...

Embodiment 3

[0043] The difference between the production method of a full blackout curtain composite fabric involved in this embodiment is that in step two, the prepared TPU black light-shielding film is made of 50 parts of polyurethane, 12 parts of low-density polyethylene Ethylene, 20 parts by mass of carbon black, 50 parts by mass of opalescent agent, 8 parts by mass of titanium dioxide, 0 part of nano-gelatin microbeads, and 8 parts of phenyl salicylate are uniformly mixed, and then extruded and blown. The obtained parts are parts by mass.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com